Automatic anti-overturn alarm system for safety carrying capacity of excavator

An alarm system and excavator technology, which is applied to alarms, earth movers/shovels, instruments, etc., can solve problems such as easy overturning of excavators, and achieve the effects of low cost, high work efficiency, and improved safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

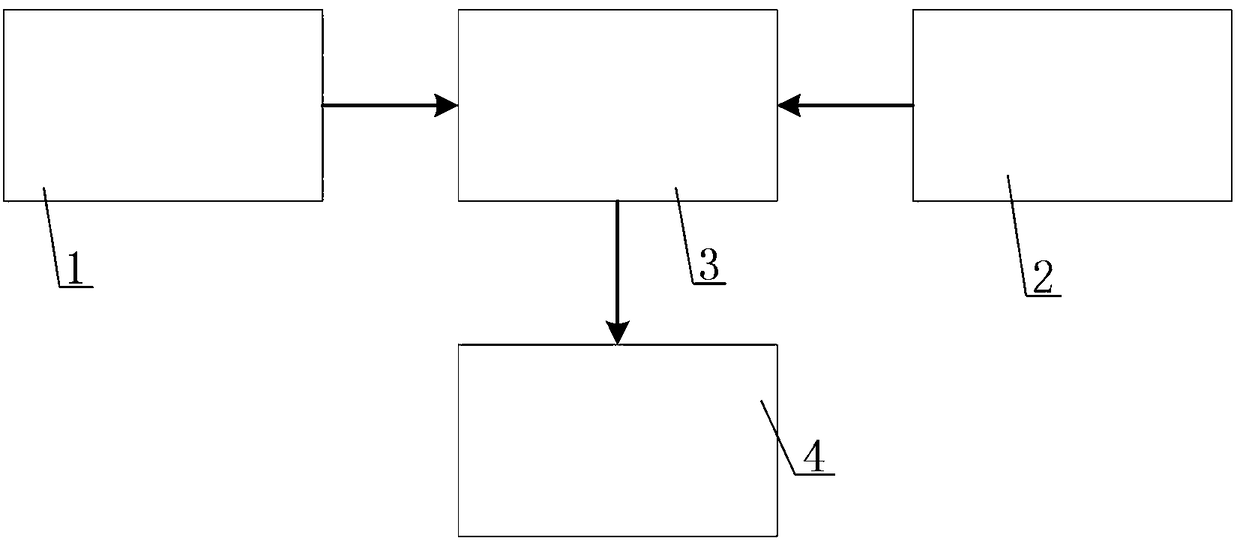

[0024] An automatic anti-overturning alarm system for the safe loading of an excavator, comprising a gravity sensor 1, a weighing device 2, a data processor 3 and a voice prompt alarm 4, the output end of the gravity sensor 1 and the output end of the weighing device 2 are respectively connected to the The input end of the data processor 3 is connected, and the output end of the data processor 3 is connected with the input end of the voice prompt alarm 4 .

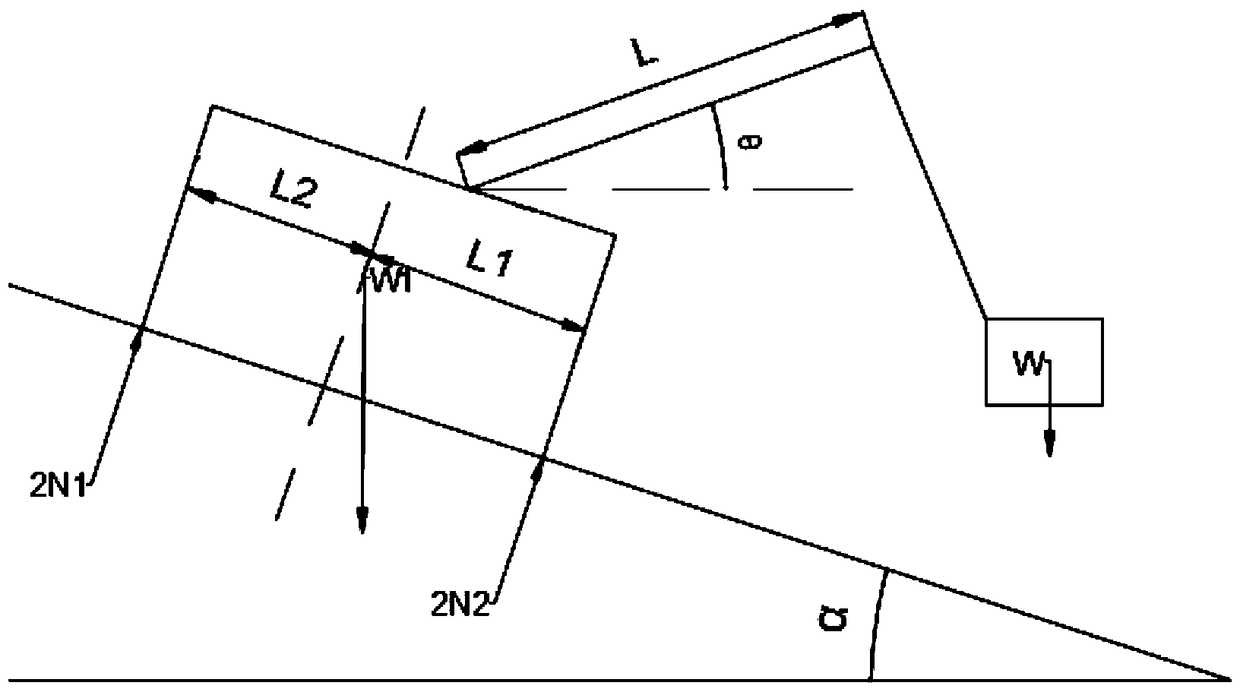

[0025] The gravity sensor 1 is installed on the bucket arm of the excavator, the turntable, the slewing bearing, and the turning mechanism.

[0026] The weighing device 2 is installed on the crawler belt of the excavator.

[0027] When using the above system, the following steps are involved:

[0028] 1) The inclination α of the excavator construction operation slope is measured by the gravity sensor 1;

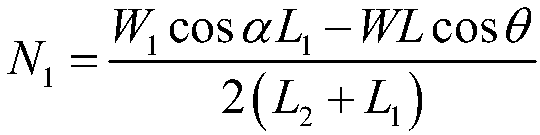

[0029] 2) The gravity G of the excavator and its load is measured by the weighing device 2, and the gravity W of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com