A ground truss pin shaft connection node structure

A technology for connecting nodes and trusses, applied in building components, building structures, buildings, etc., can solve the problems of inability to carry out structure, cushioning, and inability to increase support span, and achieve the effect of ensuring structural stability and increasing support span.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

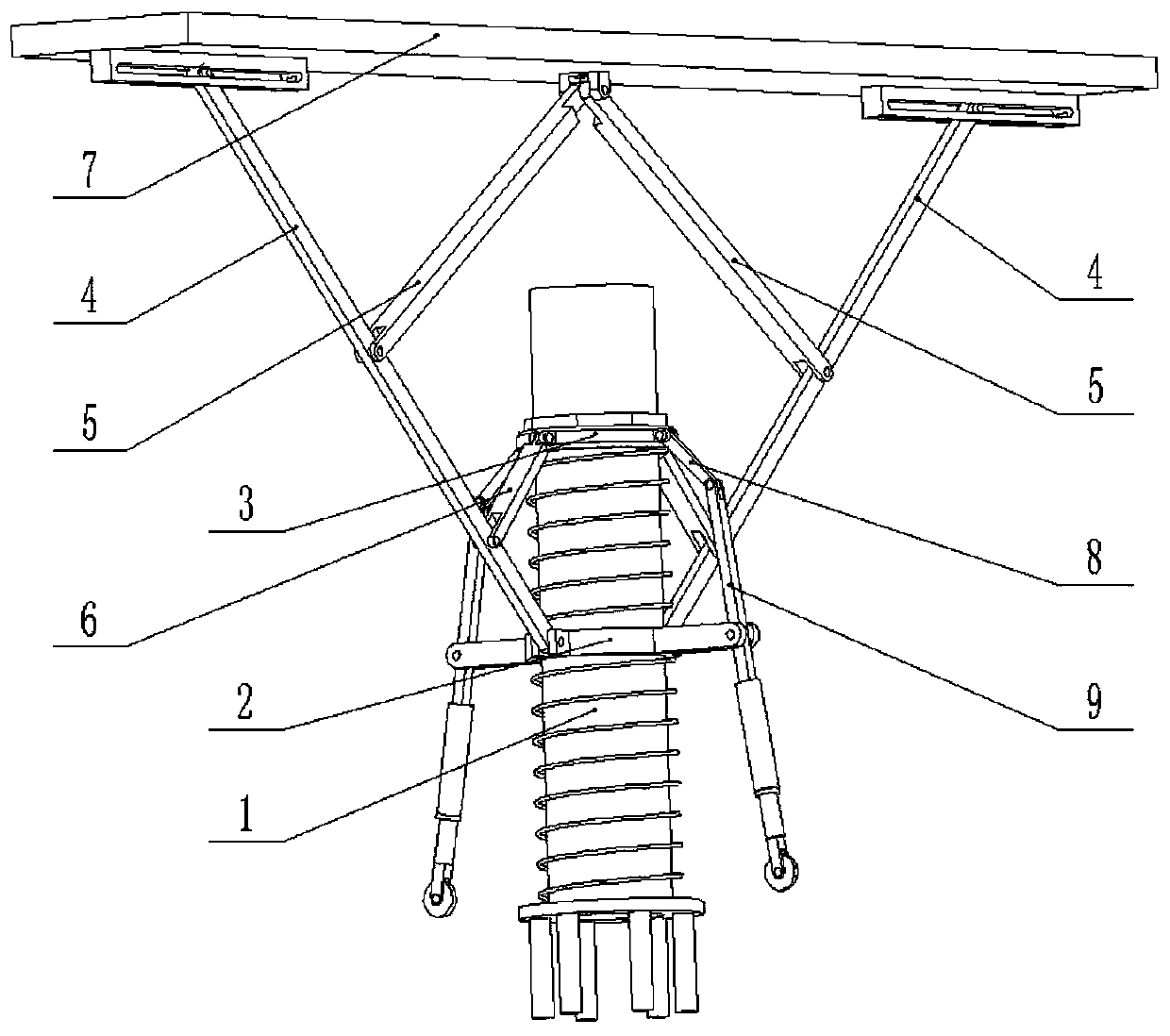

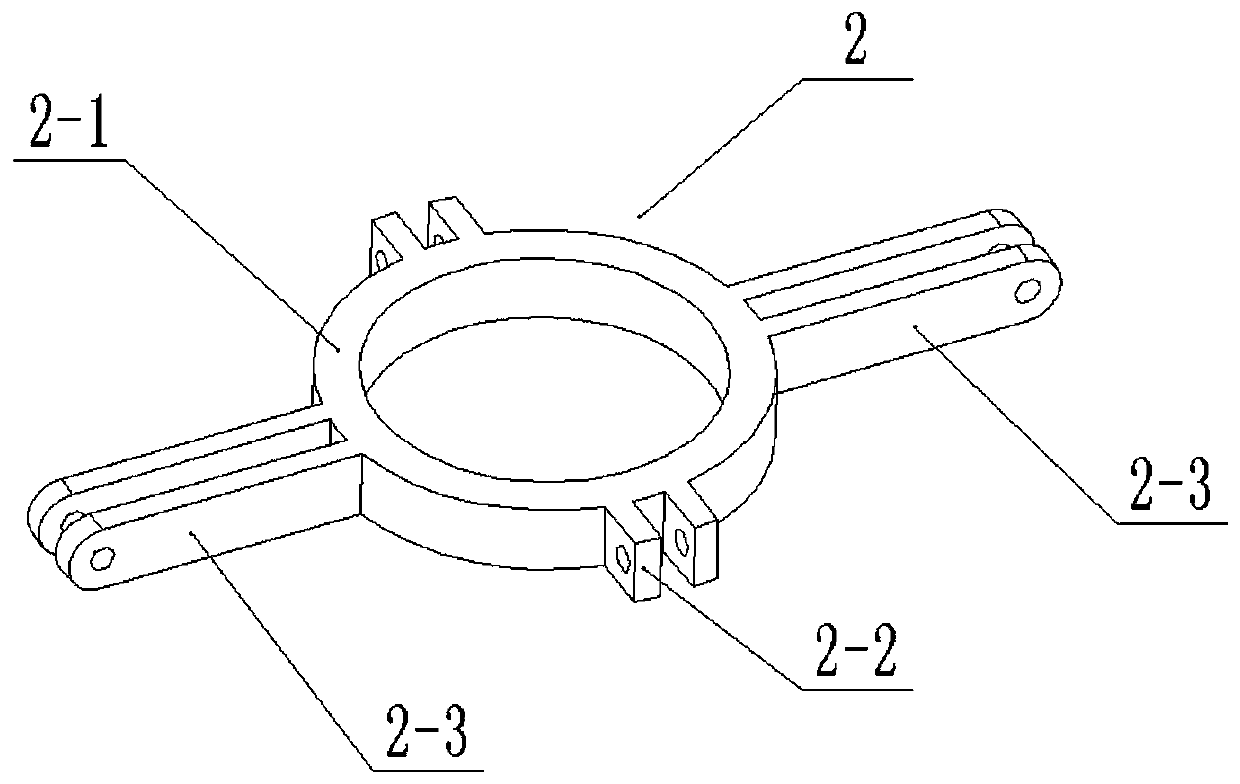

[0026] Combine below figure 1 , 2 , 3, 4, 5, 6, and 7 illustrate this embodiment, a floor truss pin shaft connection node structure, including a floor kingpin 1, a middle sliding sleeve 2, an adjusting screw sleeve 3, a truss side bar 4, a reinforcing bar 5, Adjust the support rod 6 and the top frame 7, the middle sliding sleeve 2 is slidably connected to the middle end of the landing kingpin 1, and the adjusting screw sleeve 3 is connected to the upper end of the landing kingpin 1 through thread fit, and the landing kingpin 1 Spring I and Spring II are sleeved on the top, and the spring I and spring II are respectively located at the upper and lower ends of the middle sliding sleeve 2, and the front and rear ends of the middle sliding sleeve 2 are respectively hingedly connected with the lower end of a truss side bar 4, The upper ends of the two truss side bars 4 are respectively slidably hinged to the left and right ends of the top frame 7, the middle end of the top frame 7...

specific Embodiment approach 2

[0028] Combine below figure 1 , 2 , 3, 4, 5, 6, and 7 illustrate this embodiment, and this embodiment will further explain Embodiment 1. The two reinforcing rods 5 are respectively parallel to the two adjusting struts 6, so as to ensure that the two reinforcing rods 5 force balance.

specific Embodiment approach 3

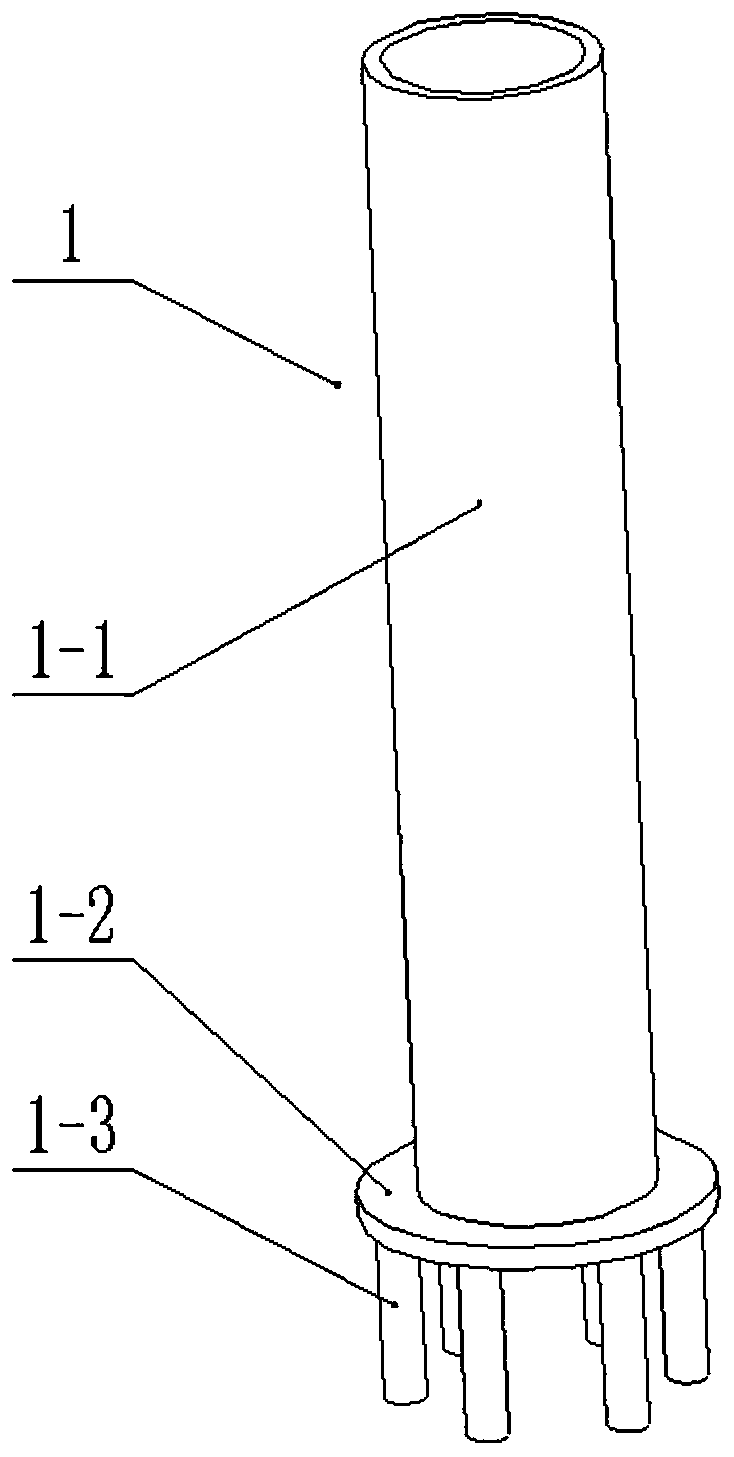

[0030] Combine below figure 1 , 2 , 3, 4, 5, 6, and 7 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The ground kingpin 1 includes a pin tube 1-1, a base 1-2 and a plurality of buried rods 1- 3. The base 1-2 is fixedly connected to the lower end of the pin tube 1-1, and the lower end of the base 1-2 is fixedly connected to a plurality of buried rods 1-3, and the spring II is located between the base 1-2 and the Between the sliding sleeves 2; by embedding a plurality of buried rods 1-3 into the ground, the landing kingpin 1 is fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com