An Internal Gear Pump With Adjustable Volumetric Efficiency

An internal gear pump, volumetric efficiency technology, used in pumps, pump control, rotary piston pumps, etc., can solve the problem of slow wear of volumetric efficiency parts, failure of internal gear pumps, and inability to adjust volumetric efficiency of internal gear pumps, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

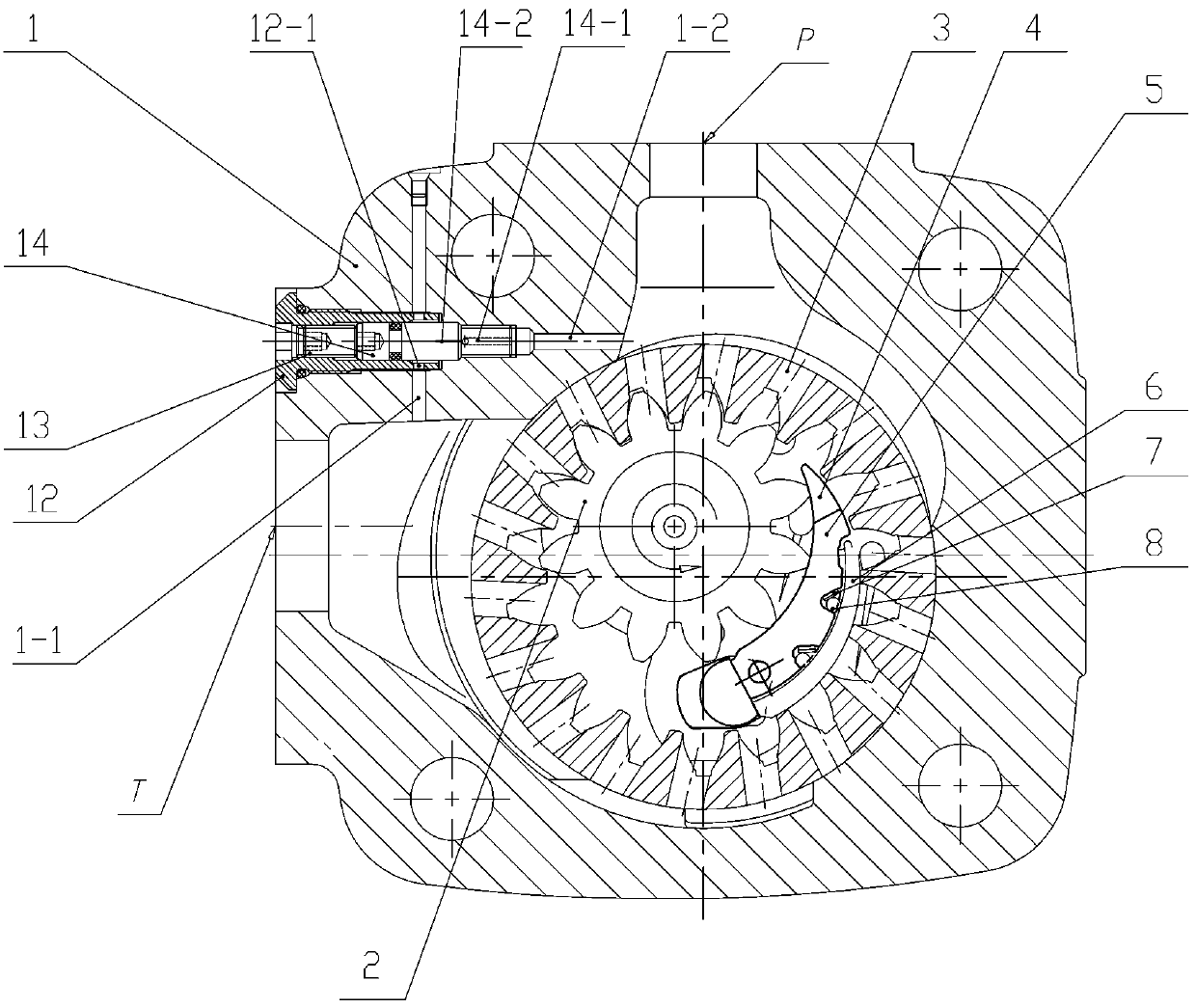

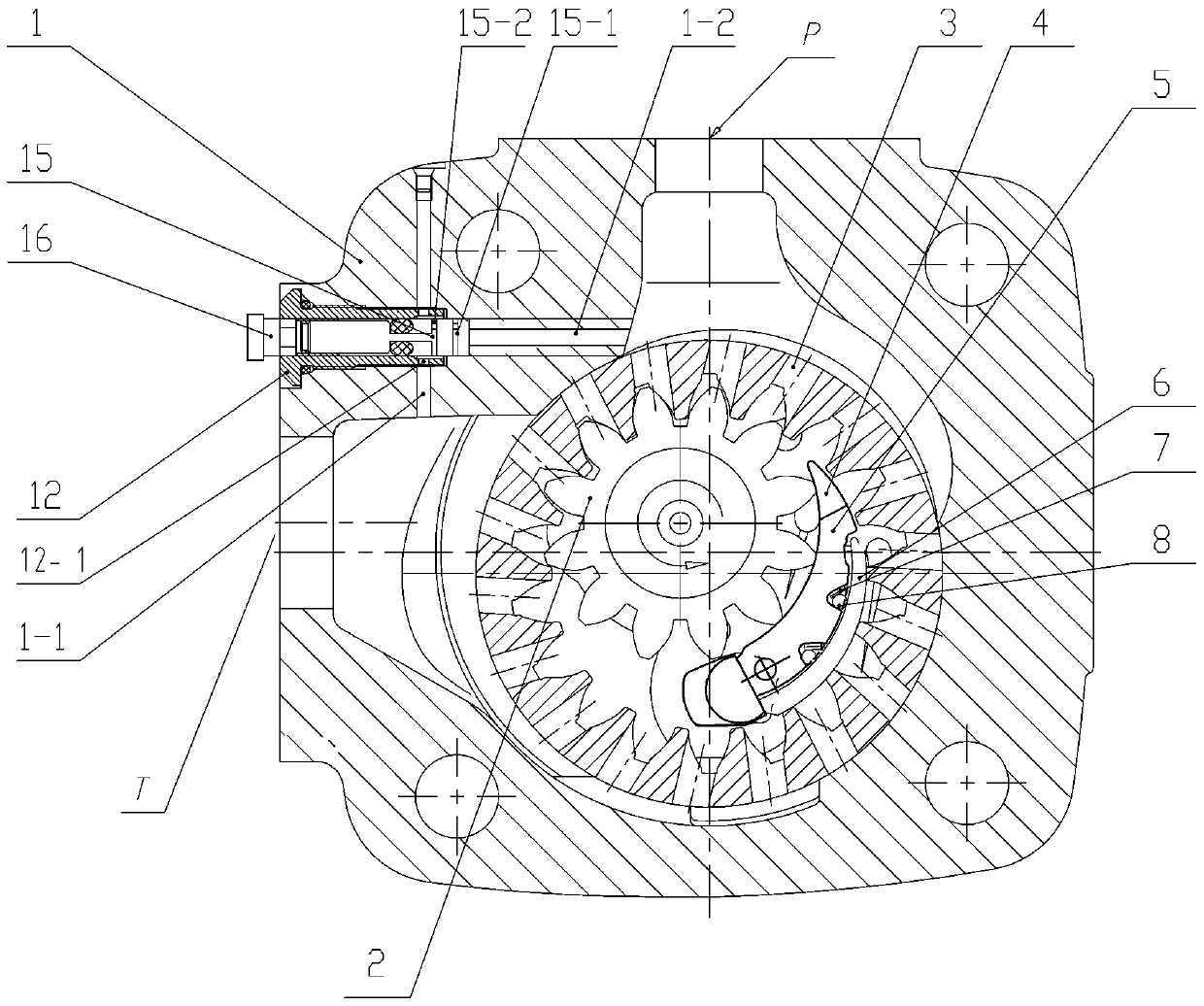

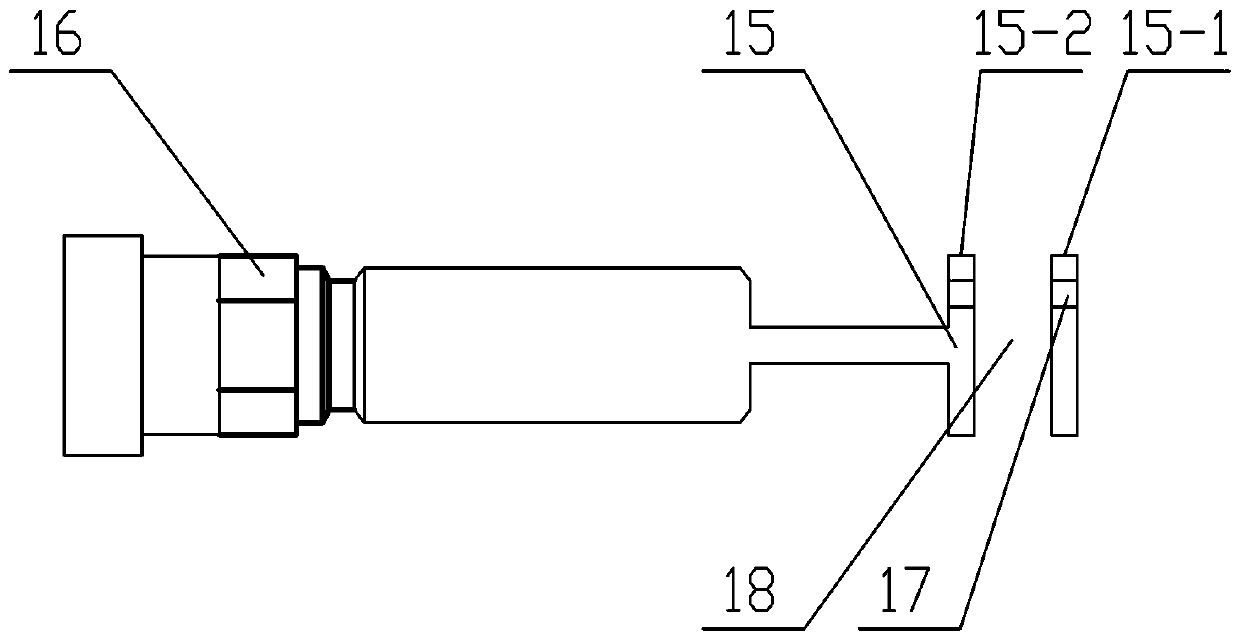

[0015] like figure 1 As shown, an internal meshing gear pump with adjustable volumetric efficiency provided by the present invention includes a pump body 1, a gear shaft 2, an inner ring gear 3, and a crescent plate 4, and the crescent plate 4 includes a crescent main plate 5 and a crescent sub-plate 6. There are two leaf springs 7 and two sealing rods 8 between the bonding surfaces of the crescent main board 5 and the crescent sub-plate 6, and the two leaf springs 7 are matched with the two sealing rods 8, and the crescent The bonding surface of the main board 5 and the crescent sub-board 6 is divided into three sections. The pump body 1 is provided with an oil suction chamber T and an oil pressure chamber P. The side wall of the pressure oil chamber P is provided with a high-pressure oil passage 1-2. The side wall of the oil suction chamber T is provided with an oil drain channel 1-1, and the pump body 1 is also provided with a valve sleeve 12, a locking screw 13 and a valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com