Spherical shield for bearing

A bearing and spherical technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of large vibration and noise, large friction coefficient, large radial clearance, etc., to achieve good sound quality, high-speed operation of heat generation, The effect of smooth ball rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the drawings:

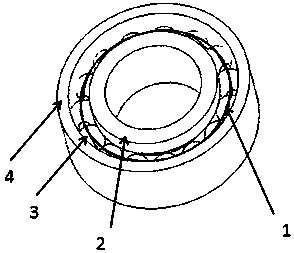

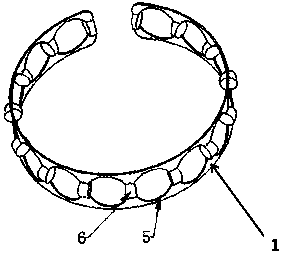

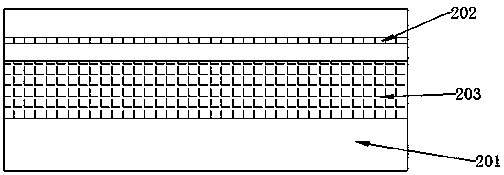

[0023] Such as Figure 1-Figure 5 As shown, a spherical bearing for a bearing includes an inner bushing 2 and a bearing jacket 4. A bearing holder 1 is provided between the inner bushing 2 and the bearing jacket 4, and the bearing holder 1 is provided with Steel ball 3, a positioning ring 5 is provided on the bearing holder 1, a lubricating device 6 is provided on the side of the positioning ring 5, and the inner bushing 2 is composed of an inner wall 201, a positioning groove 202 and a mounting nesting groove 203, so The positioning groove 202 and the mounting nesting groove 203 are arranged on the surface of the inner wall 201, the mounting nesting groove 203 is arranged below the positioning groove 202, and the lubricating device 6 consists of a tank 601, a lubricating oil The lubricating oil tank 602 is arranged inside the tank body 601, and the lubricating oil tank 602 passes th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap