Transmission system of hydraulic three-wheel slot milling machine

A technology of transmission system and slot milling machine, which is applied in the field of hydraulic three-wheel slot milling machine transmission system, can solve the problems of dependence on imported parts, equipment damage, high one-time investment cost of slot milling machine and supporting equipment, etc., and achieve the goal of making up for the technology Vacancies, the effect of improving reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

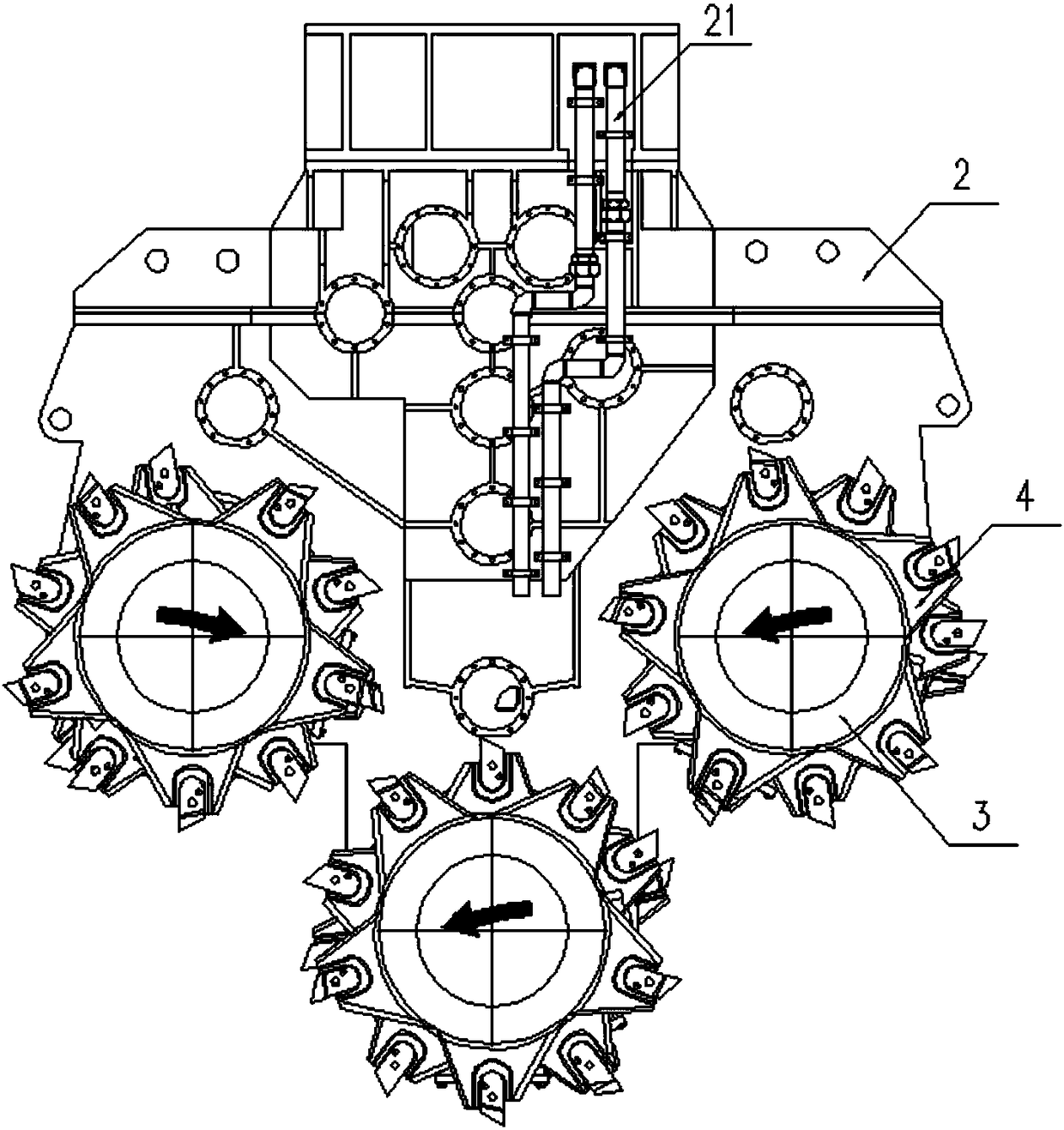

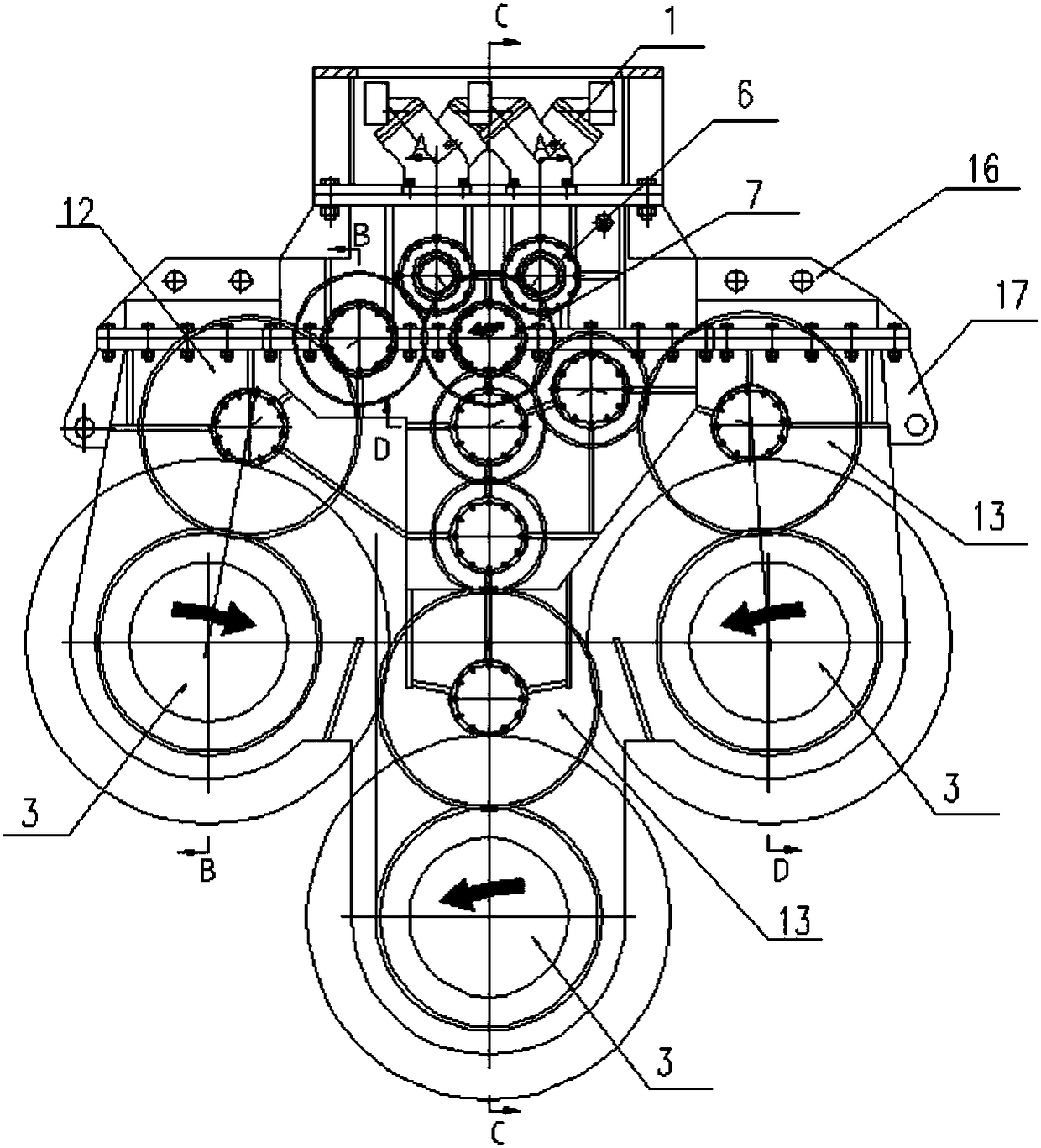

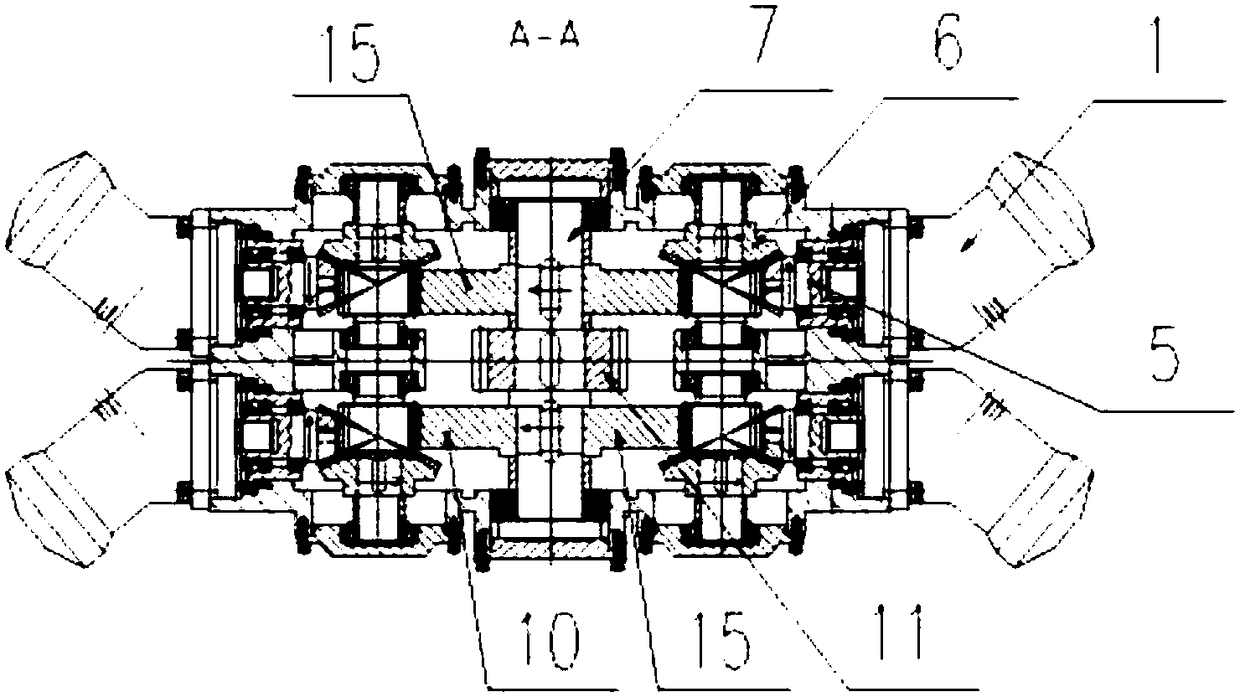

[0026] Such as figure 1 with figure 2 As shown, a hydraulic three-wheel groove milling machine transmission system of the present invention includes a hydraulic motor group 1, a gear box 2, a shell-turn reducer 3, and a milling wheel 4. The gear box 2 includes a box body and a gear box installed inside the box body. A grouting pipe 21 is fixed on the outer side of the gear box 2 for the transmission gear set and the intermediate gear set. The hydraulic motor group 1 is installed on the top of the gear box 2 and its output shaft 5 is meshed and transmitted with the transmission gear group on the first transmission shaft 7 in the gear box through multiple sets of bevel gears 6.

[0027] The shell-turn reducer 3 uses the GFT shell-turn reducer. The shell-turn reducer 3 includes three groups installed at the bottom of the box. The speed ratio of each group of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap