Safety valve exhaust silencing device

A sound-absorbing device and safety valve technology, which is applied in the direction of valve devices, devices for absorbing fluid energy of valves, valve details, etc., can solve problems such as high air pressure, loud noise, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

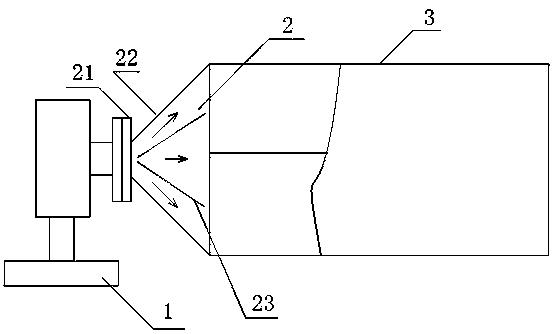

[0015] Such as figure 1 As shown, a safety valve exhaust silencing device, an expansion silencing unit is installed on the exhaust port of the safety valve 1, and the expansion silencing unit at least includes an expansion sub-body 2 and a ventilation muffler 3 connected with the expansion sub-fluid; The expansion split body 2 includes a flange 21 for connecting with the exhaust port, and a horn-shaped split body 22 connected with the flange, and a guide plate 23 along the airflow direction is arranged in the horn-shaped split body 22 .

[0016] The cross section of the ventilation muffler 3 is circular or square.

[0017] A sound-absorbing grille is arranged in the ventilation muffler 3 .

[0018] The length of the ventilation muffler 3 is 1.5 to 15 times the length of the expanding shunt body 2 .

[0019] The outer wall of the ventilation muffler 3 is a sound-absorbing and insulating structure, and the sound-absorbing and insulating structure is composed of an outer sound-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com