Press Mechanism of Decorative Printing Paper Making System

A technology for printing paper and pressing machinery, applied in the direction of presses, fluid pressure actuating system components, jetting devices, etc., can solve the problems of unsatisfactory printing paper pressing thickness, imperfect production system, unsatisfactory printing paper pressing quality, etc. problems, to achieve the effect of protecting the pressing quality, high precision and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

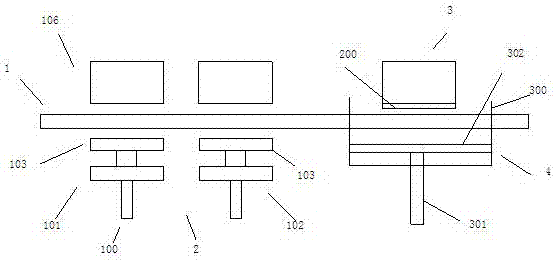

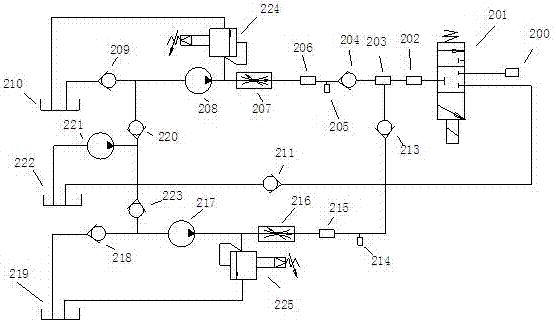

[0016] Embodiment: the pressing mechanism of decorative printing paper making system, as attached figure 1 As shown, it includes a conveyor belt 1, and the conveyor belt 1 is provided with a pressing mechanism 2, a spraying mechanism 3 and a sewage treatment mechanism 4;

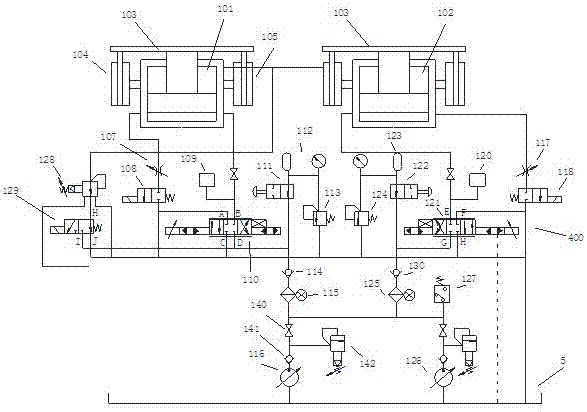

[0017] as attached figure 2As shown, the pressing mechanism 2 includes a pressing mechanical unit 100 and a pressing hydraulic unit 400, the pressing mechanical unit 100 is arranged on the first pressing cylinder 101 and the second pressing cylinder 102 on the conveyor belt 1, the first pressing cylinder 101 and the end of the extension rod of the second pressing cylinder 102 are provided with a briquetting block 103, both sides of the briquetting block 103 are provided with a front position sensor 104 and a rear position sensor 105, and a thickness gauge 106 is provided on the conveyor belt 1; The pressing hydraulic unit 400 described above includes a first throttle valve 107 connected to the rodless end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com