Spraying Mechanism of Decorative Printing Paper Production System

A technology of spraying mechanism and printing paper, which is applied in the direction of spraying device, liquid spraying device, filtration and separation, etc., and can solve the problems of printing paper spraying effect and spraying efficiency not ideal, spraying mechanism is not perfect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

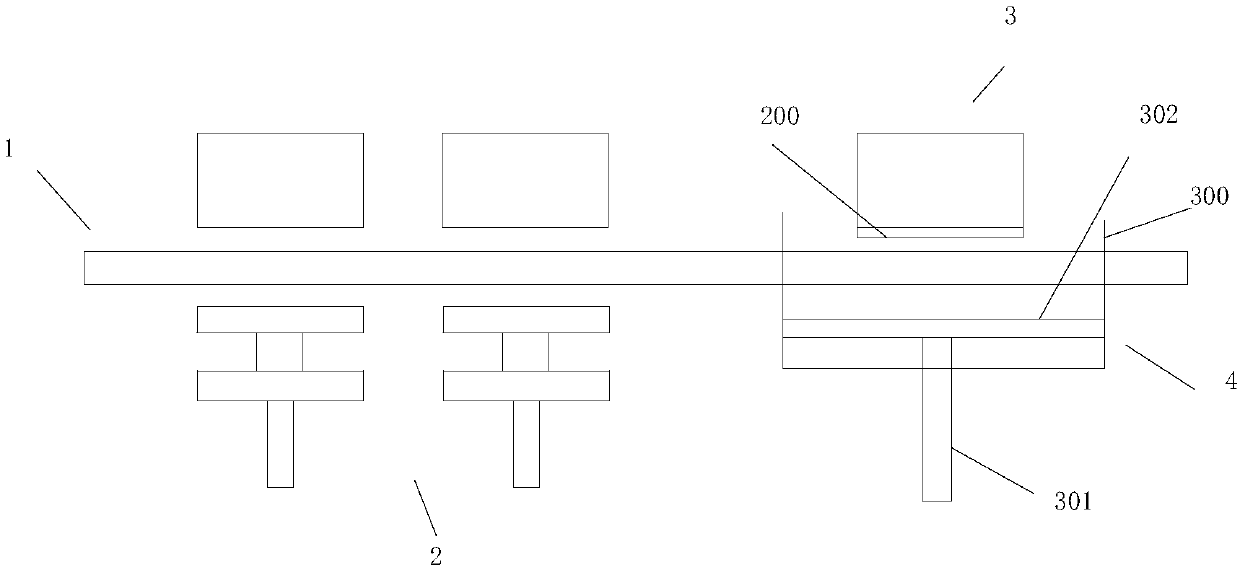

[0013] Embodiment: the spraying mechanism of decorative printing paper making system, as attached figure 1 As shown, it includes a conveyor belt 1, and the conveyor belt 1 is provided with a pressing mechanism 2, a spraying mechanism 3 and a sewage treatment mechanism 4;

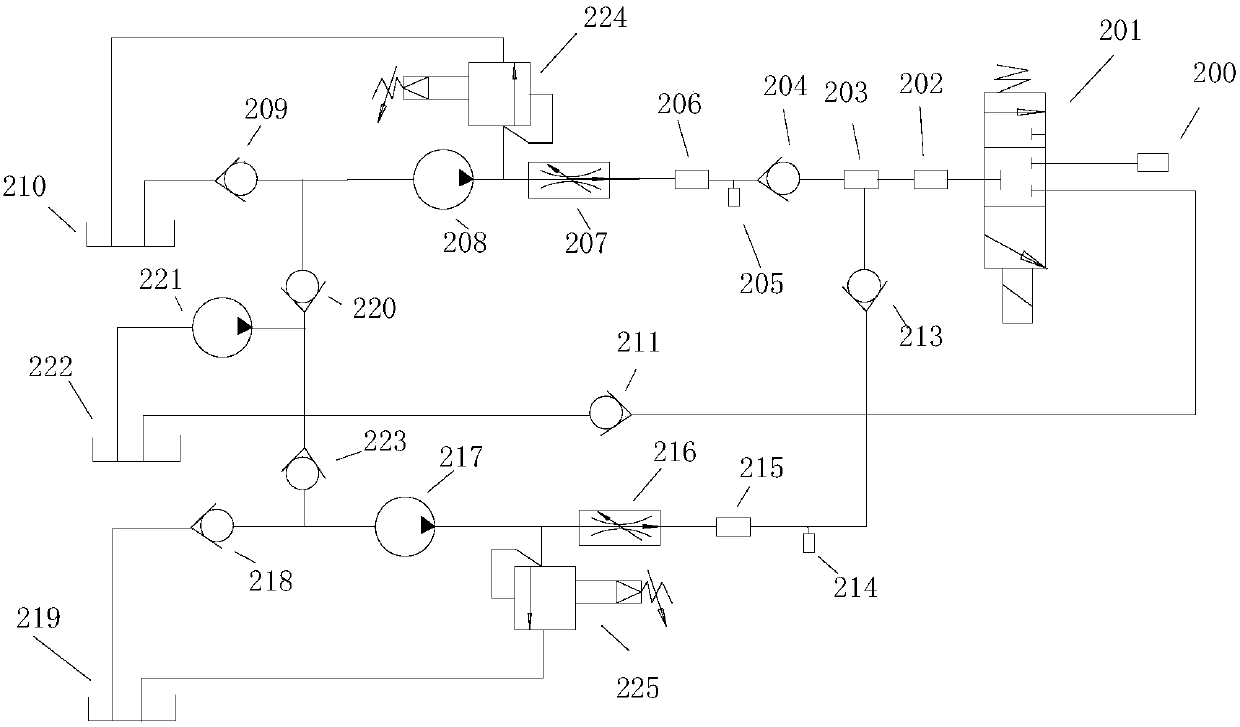

[0014] as attached figure 2As shown, the spraying mechanism 3 includes a post-stage mixing and spraying device 200 arranged above the conveyor belt 1. The post-stage mixing and spraying device 200 is connected to a three-way solenoid valve 201, and the three-way solenoid valve 201 is connected to a static mixer 202. The static mixer 202 is connected with a three-way mixer 203, the three-way mixer 203 is connected with a third one-way valve 204, the third one-way valve 204 is connected with a third pressure sensor 205, and the third pressure sensor 205 is connected with a first flow sensor 206, the first flow sensor 206 is connected to the first speed regulating valve 207, the first speed regulating valve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com