Testing system and method used for simulating sunlight focusing

A test system and sunlight technology, applied in the field of test equipment, can solve the problems that the incident angle of sunlight cannot be adjusted accurately, the range of incident angle of sunlight is limited, and the equipment occupies a large area, so as to reduce the test distance and facilitate The effect of building and reducing the requirements of the test site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

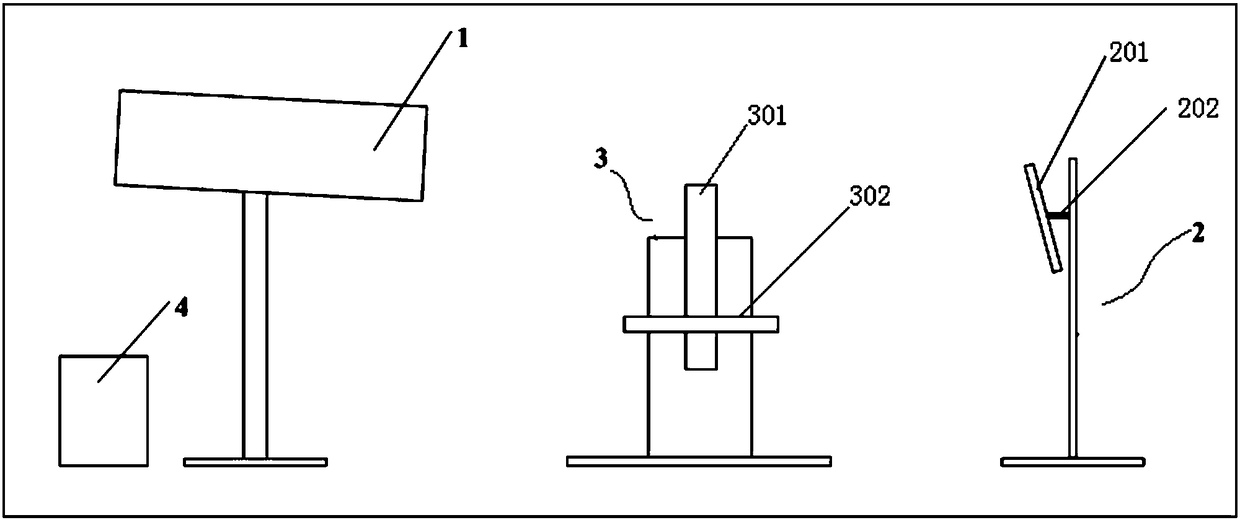

[0020] see figure 1 , a test system for simulating the focus of sunlight, comprising a sunlight simulation device 1, an angle adjustment device 3, and a reflector 2, the three are lined up with a certain distance between them; the angle adjustment device 3 has Rotating shaft 301, rotating shaft 301 is perpendicular to platform 302 and is fixedly connected; Rotating shaft 301 can rotate by itself under the drive of the first power mechanism, and can rotate in the facade under the drive of the second power mechanism, thereby driving platform 302 to rotate, and platform 302 is used for placing and fix the object to be detected; the reflector 2 has an emitting mirror surface 201, and a goniometer 202 is arranged on the reflecting mirror surface, and the reflecting mirror surface 201 receives the illumination of the sunlight simulation device 1 and reflects it onto the object to be detected, and the object to be detected Has a lens structure.

[0021] In this example, see figure ...

Embodiment 2

[0026] The difference from Embodiment 1 is that the rotating shaft 301 can rotate universally under the drive of the second power mechanism, so that the platform 7 and the object to be measured on it can be adjusted with a higher degree of freedom. All the other implementations are the same as in Example One.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com