Pressing device for ICT testing fixture

A technology of test fixtures and pressure plates, which is applied in the direction of measuring devices, measuring device shells, and parts of electrical measuring instruments, etc., can solve problems such as low test efficiency, troublesome picking and placing of PCB boards, and inability to meet the needs of use and testing. Simple structure, convenient installation and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

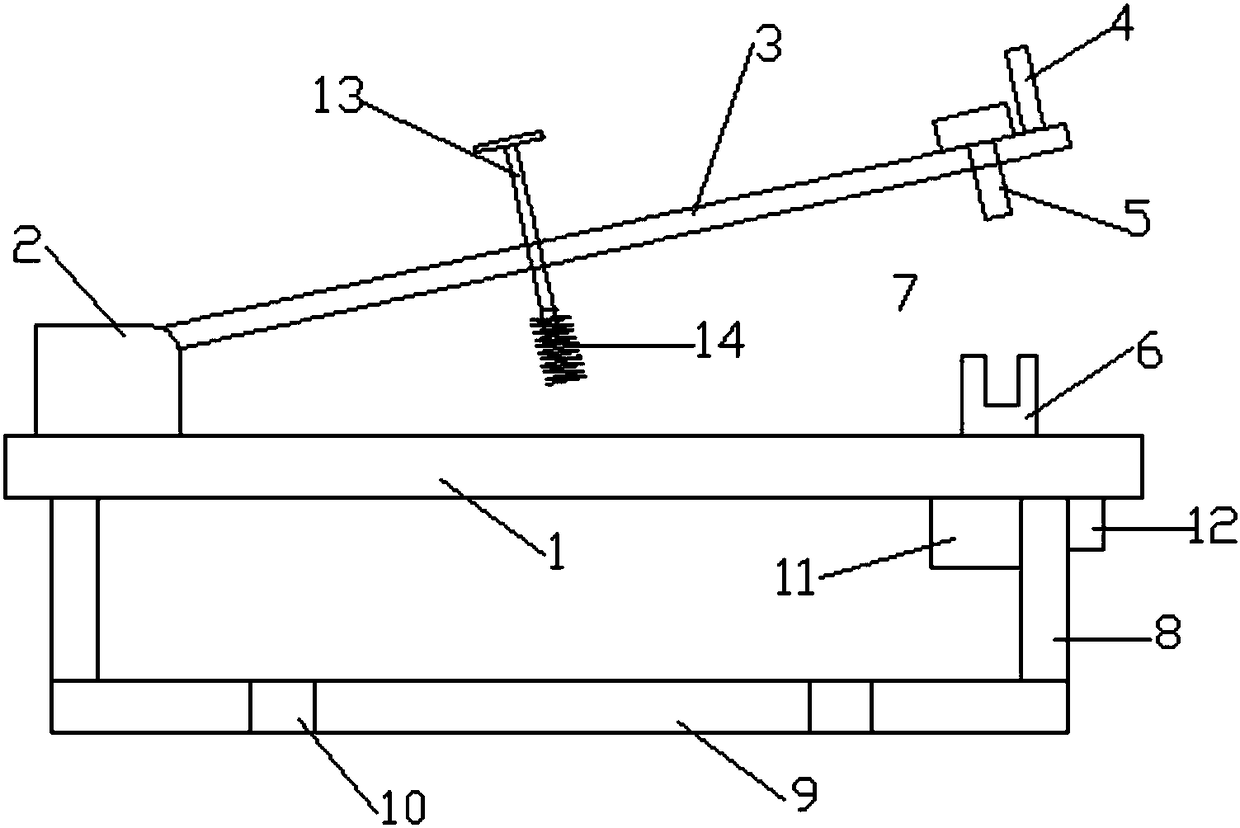

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0013] Please refer to the attached figure 1 , the embodiment of the present invention includes: support platform 1, hinge seat 2, pressure plate 3, push handle 4, iron block 5, electropermanent magnet 6, groove 7, pole 8, base 9, power supply element 11 and switch 12; A hinge seat 2 is provided on the left side of the upper end of the supporting platform 1; a pressing plate 3 is arranged on the right end of the hinge seat 2; a push handle 4 is arranged on the upper right side of the pressing plate 3; block 5, and the iron block 5 runs through the pressing plate 3, and the iron block 5 is T-shaped; the upper end right side of the support platform...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap