Open trench vibration isolation design method based on quantitative analysis

A quantitative analysis and design method technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as the inability to accurately determine the distance between vibration isolation ditch and the size of vibration isolation ditch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

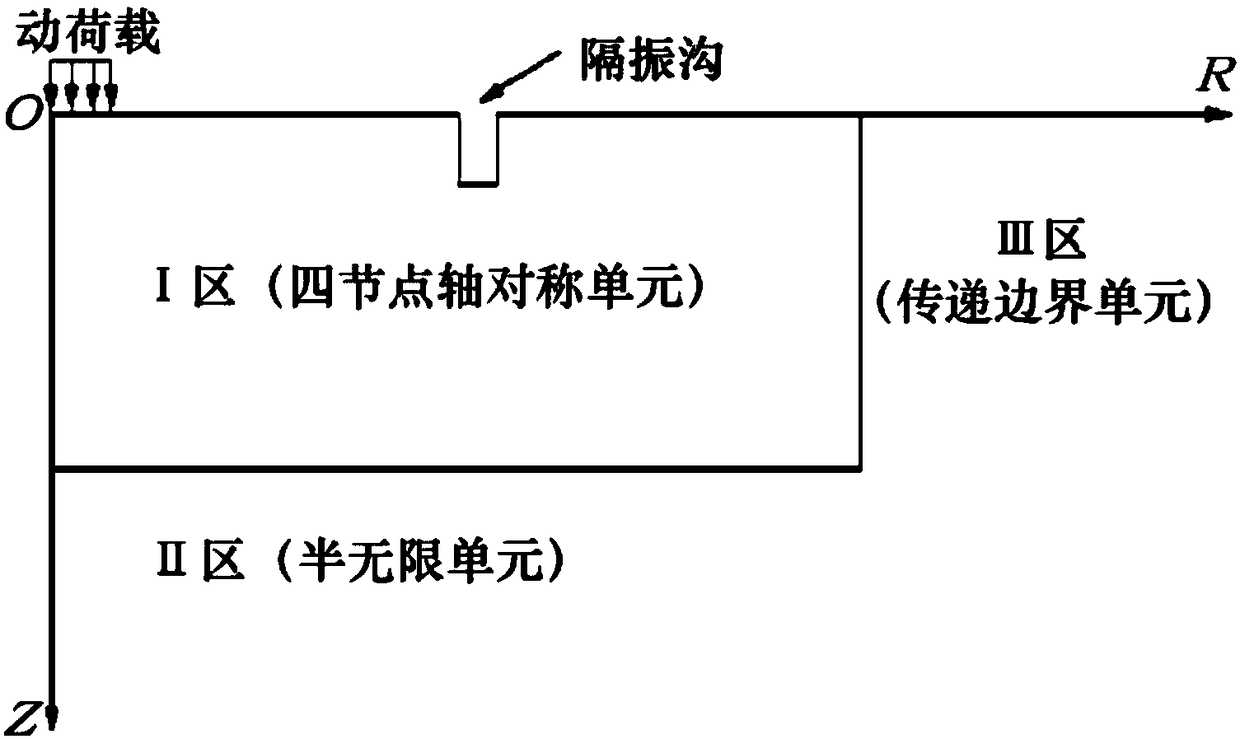

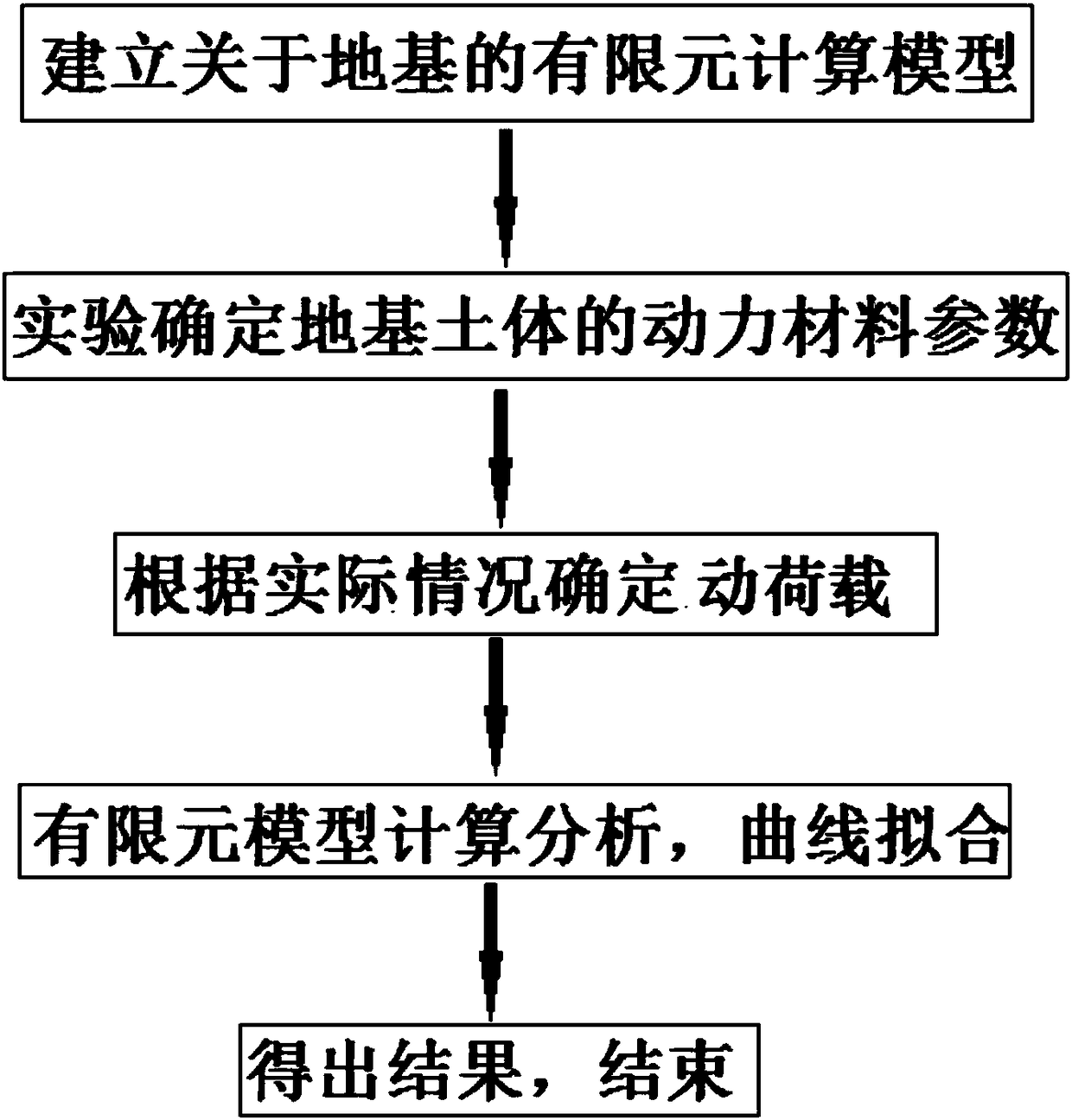

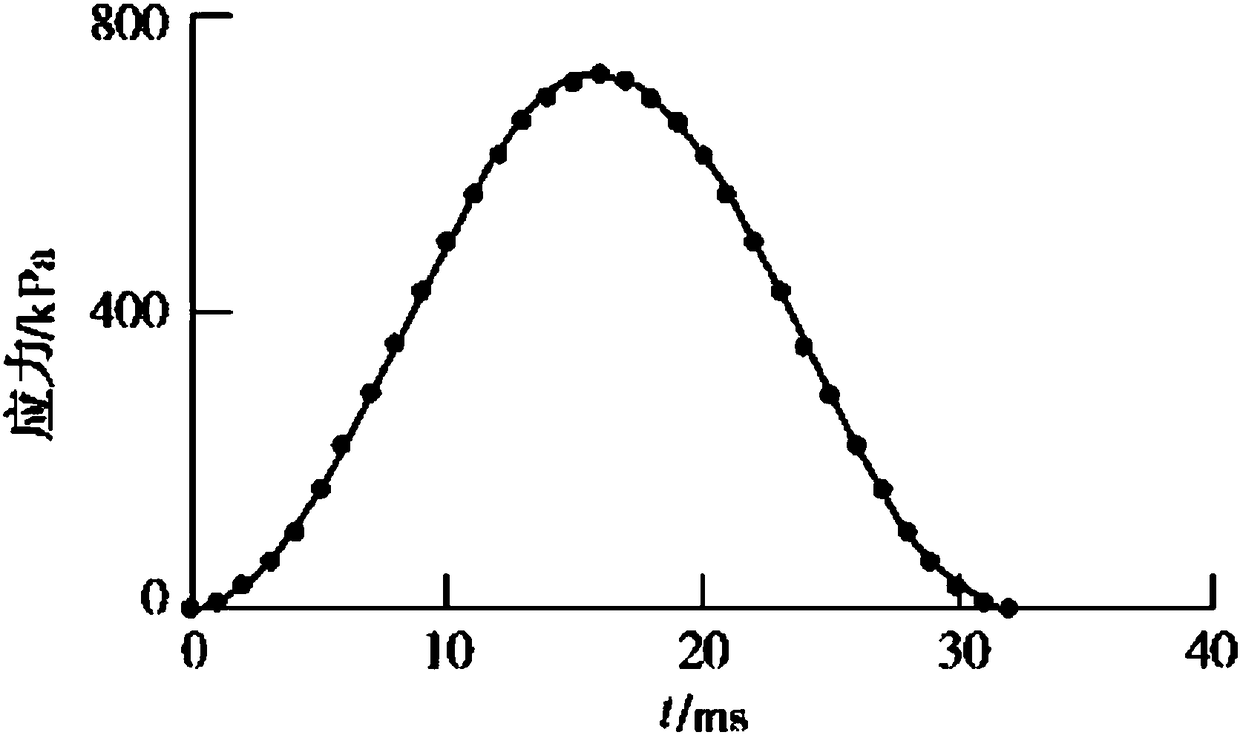

[0046] According to the design method of open ditch vibration isolation based on quantitative analysis of the present invention, carry out dynamic finite element analysis according to the loess foundation next to a certain highway in the Loess Plateau, select a calculation area of 120m * 60m in the actual analysis, the vibration isolation ditch width is 1m, depth They are respectively set to 0m, 1m, 2m and 3m. The front wall of the vibration isolation ditch is 19m away from the center of the vibration source, and the rear wall of the vibration isolation ditch is 20m away from the center of the vibration source. Relevant Mobility Guidelines. The FWD load is used to simulate the actual vehicle load, and the FWD load with a period of 32ms is as follows: image 3 shown. Finally, through dynamic finite element calculation and analysis and data fitting, the relationship between the maximum vibration velocity and distance of vibration isolation trenches at different depths is obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com