A stack simulation device for the development of high-power fuel cell thermal management system

A thermal management system and fuel cell technology, applied in vehicle power technology and application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

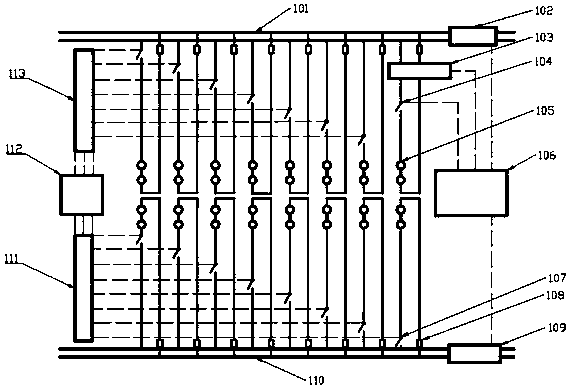

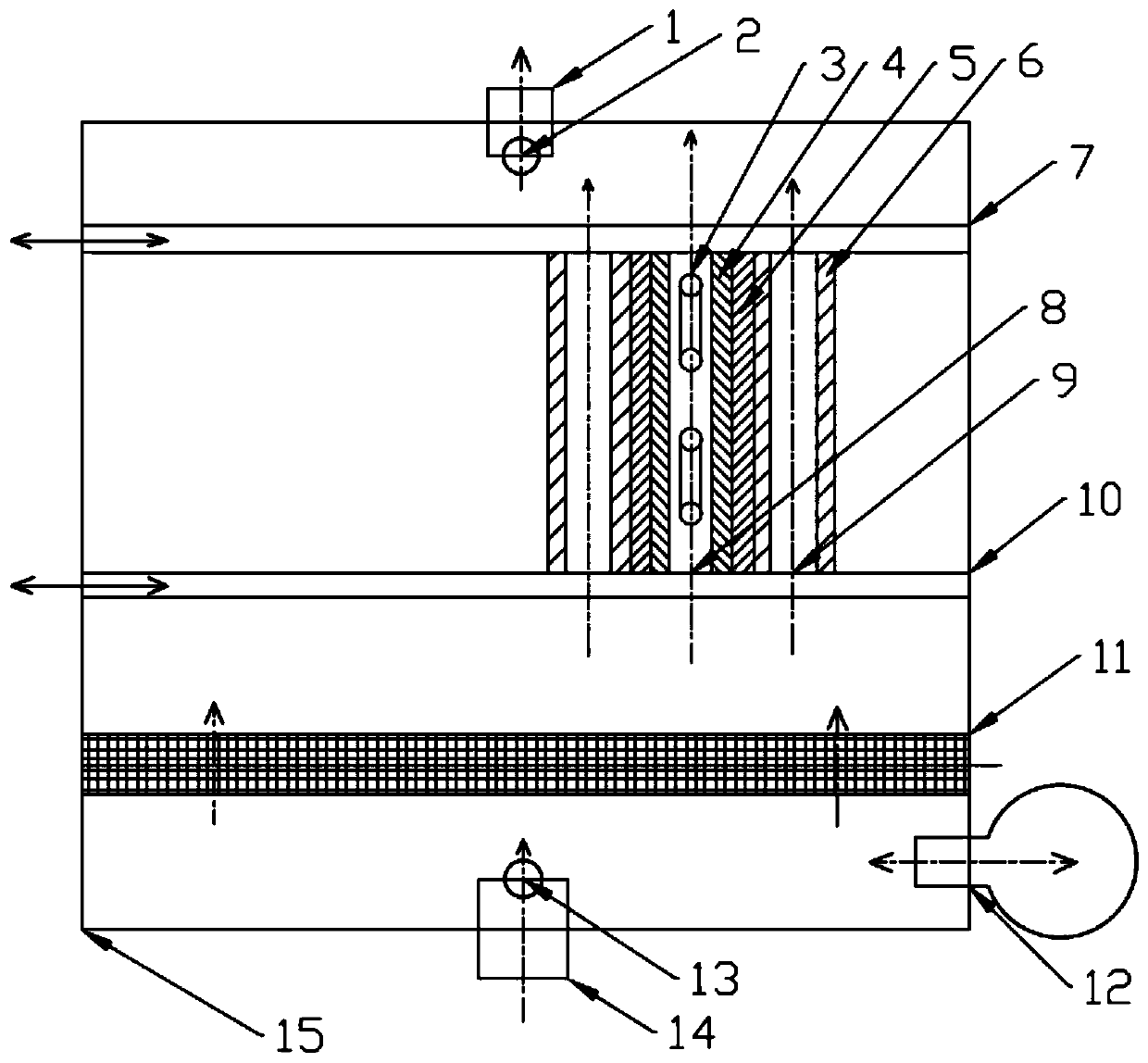

[0037] Such as figure 1 As shown, a stack simulation device used for the development of a high-power fuel cell thermal management system, the device is bounded by a device outer box 15 with good sealing and heat insulation characteristics, and can be connected with the periphery of the fuel cell thermal management subsystem Part of the connection, the interface is divided into coolant inlet and coolant outlet. This unit includes:

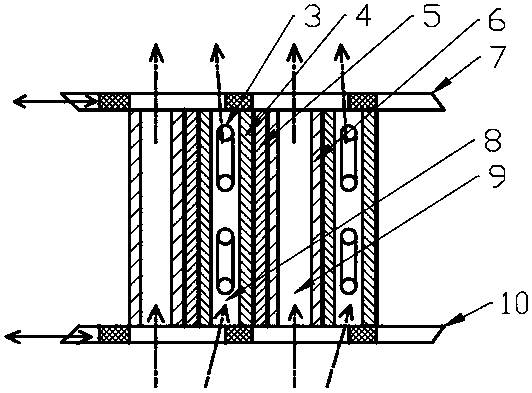

[0038] The heating simulation component includes heating plates 4 and cooling plates 6 alternately stacked. The heating plates 4 and the cooling plates 6 are respectively provided with a heating plate cavity 8 and a cooling plate cavity 9 for circulating cooling liquid. The heating plate cavity 8 is A heating device is provided to simulate the heating of a real electric pile. In this embodiment, the heating device includes an electric heating tube group; The front grid plate 10 and the rear grid plate 7 are used to adjust the coolant flow ratio fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com