Coconut shell breaking machine capable of performing quick shell breaking

A coconut shelling machine, fast technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of cutting tools, waste of coconut milk, slipping, etc., and achieve the effect of improving the cutting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

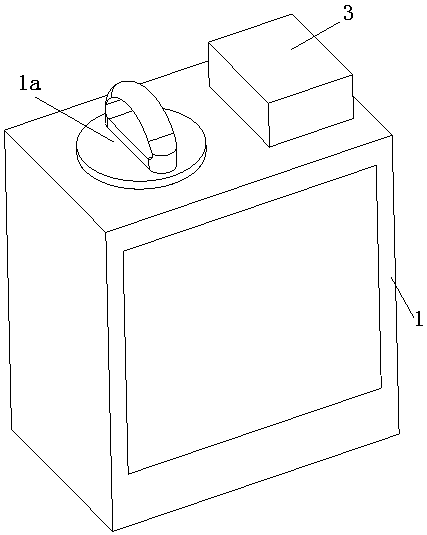

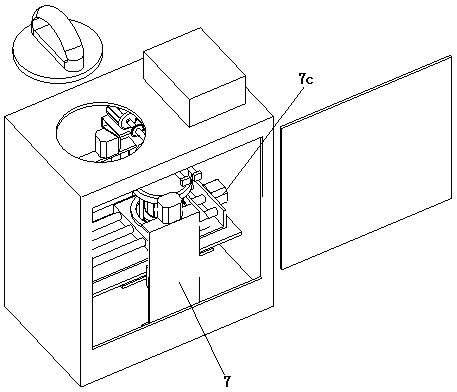

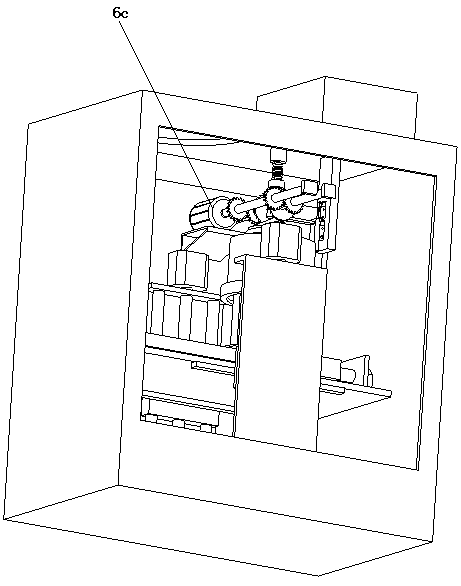

[0030] refer to Figure 1 to Figure 12 The shown coconut shell breaking machine capable of breaking shells quickly includes a machine box 1, a shell breaking assembly located in the machine box 1, and a reversing support assembly. The machine box 1 is a cuboid structure, and the shell breaking assembly includes symmetrical Two shell-breaking saw blades 2, the reversing support assembly includes a supporting bucket 8f and a reversing motor 8c for driving the supporting bucket 8f to rotate along its own axis, and the two shell-breaking saw blades 2 are vertically arranged On the top of the supporting barrel 8f, the machine box 1 is also provided with a displacement electric cylinder 7c for driving the supporting barrel 8f to slide along the length direction of the machine box 1. Inside, the top of machine box 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com