Liquid beverage stirring machine

A blender and beverage technology, which is applied to household appliances, applications, kitchen appliances, etc., can solve problems such as chocolate blocks or sugar blocks blocking the rotation of the blender, and achieve the effect of improving the user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

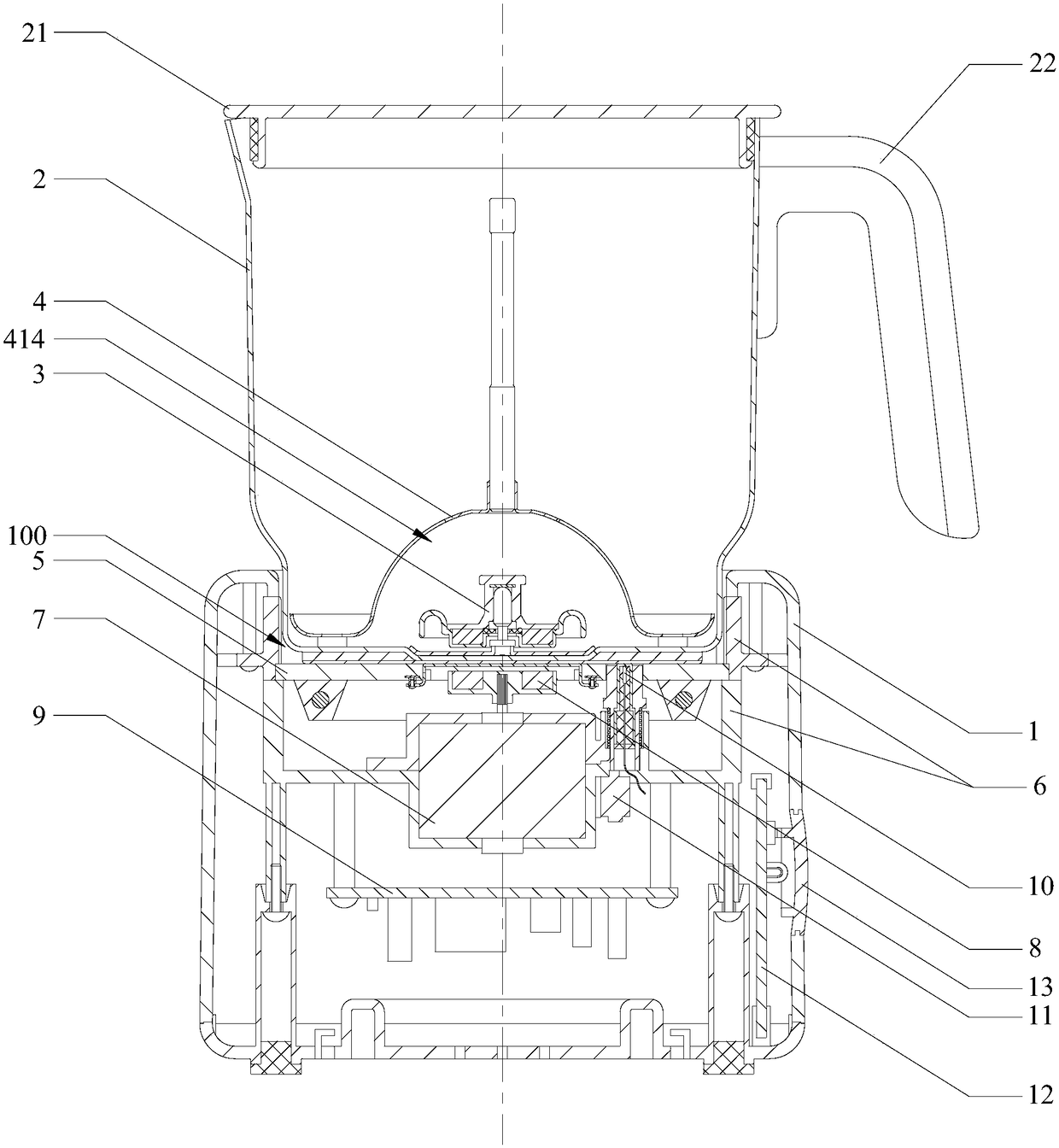

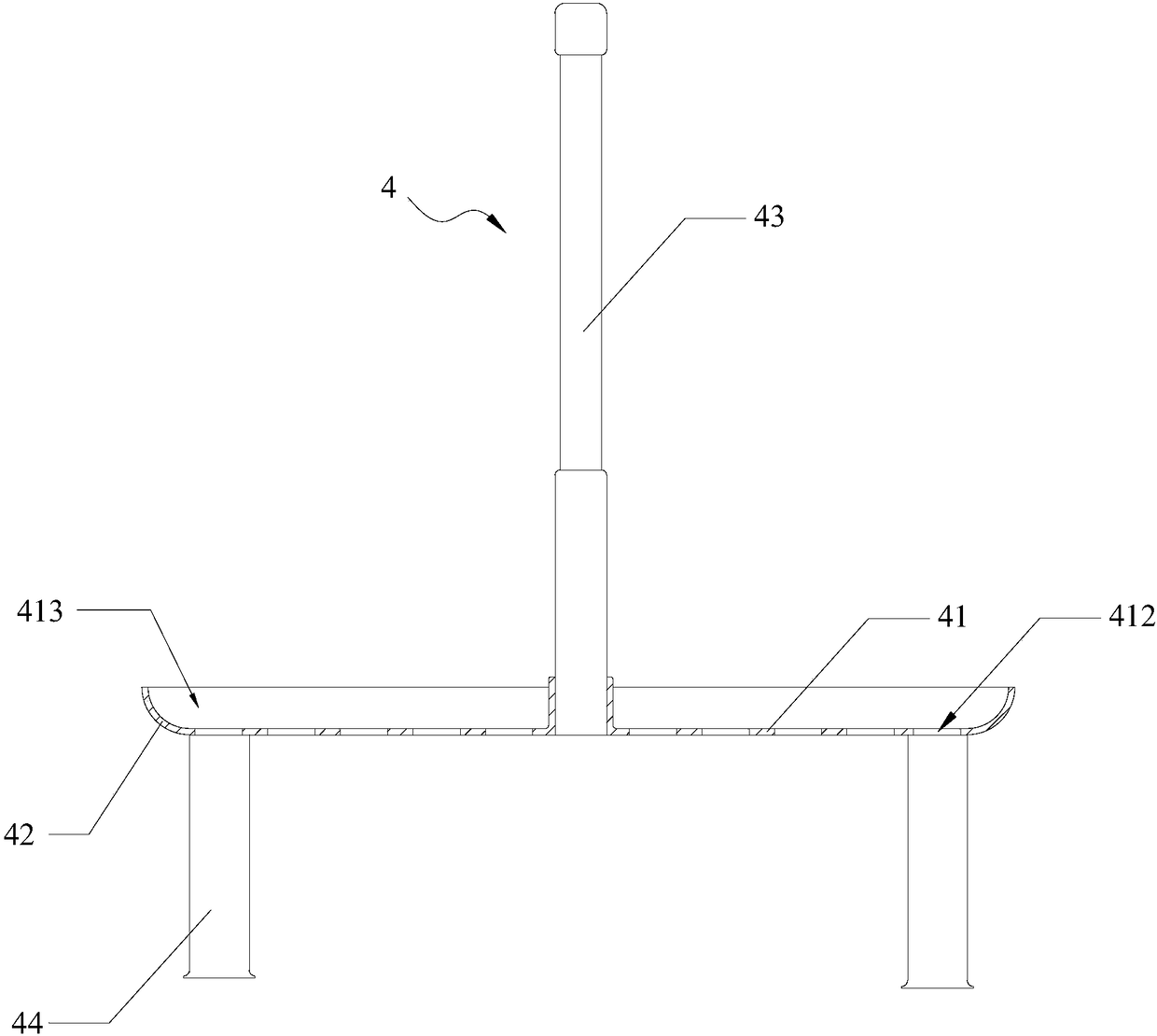

[0035] see figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 10, in the embodiment of the present invention, the liquid beverage mixer comprises a base 1, a container cup 2, an agitator assembly 3 and a feeding basket 4, wherein a heating plate 5, a driving motor 7, and a control circuit board 9 are arranged in the base 1 And the active magnet plate 8, the container cup 2 is detachably arranged on the heating plate 5, used to accommodate liquid beverages, such as: milk, and the center of the inner bottom surface of the container cup 2 is provided with a positioning groove 23, the heating plate 5 and The drive motor 7 is electrically connected with the control circuit board 9, the active magnet disk 8 is installed on the output shaft of the drive motor 7, the agitator assembly 3 is detachably arranged in the positioning groove 23, and the agitator assembly 3 is connected to the active magnet disk 8 Magnetic fit, specifically, th...

Embodiment 2

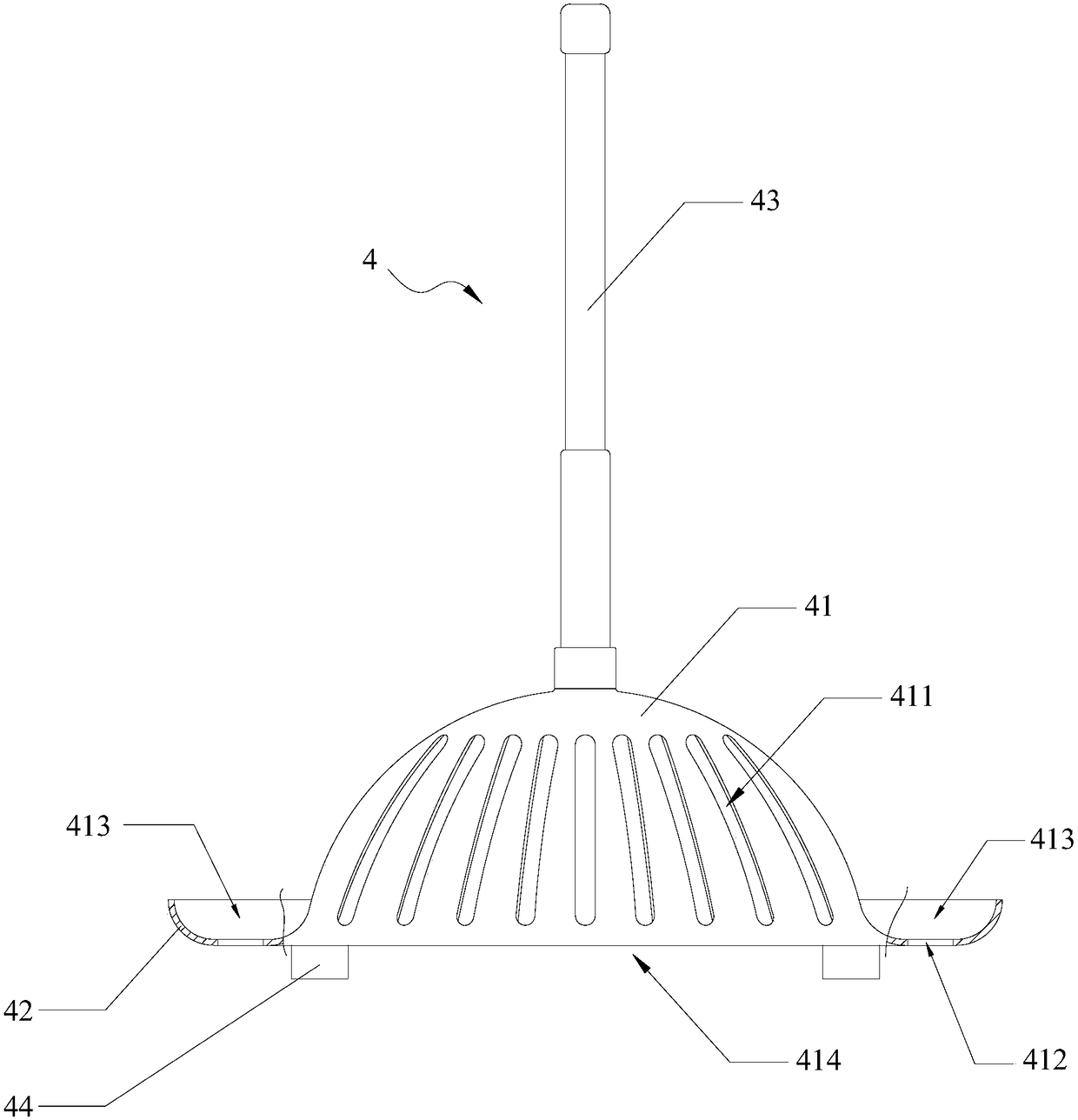

[0048] see figure 1 and image 3 , the embodiment of the present invention is basically the same as the liquid beverage mixer disclosed in Embodiment 1, the difference is that: the central depression of the basket body 41 is formed with an avoidance groove 414, and the avoidance groove 414 is used to avoid the above-mentioned agitator 31, here, The stirrer 31 can be accommodated in the avoidance groove 414 . Specifically, the escape groove 414 is in the shape of a spherical crown or a cone, so that the feeding basket 4 can cover the top and outside of the agitator 31, ensuring that there is a gap between the feeding basket 4 and the agitator 31, and the agitator 31 has sufficient room for rotation. , it is beneficial for the liquid beverage to flow in the container cup 2, and the stirring effect of the liquid beverage is improved. Of course, according to specific situations and needs, in other embodiments of the present invention, the avoidance groove 414 may also be in the ...

Embodiment 3

[0051] see Figure 9 , the embodiment of the present invention is basically the same as the liquid beverage mixer disclosed in the second embodiment, the difference is that the above-mentioned silicone ring 313 is replaced by an elastic buckle 314 . Specifically, the elastic buckle 314 is clamped in the above-mentioned avoidance hole 3113 by the above-mentioned upper positioning member 311 and the above-mentioned lower magnet box 312, the outer contour of the elastic buckle 314 is lip-shaped, and the inner diameter of the elastic buckle 314 is smaller than the above-mentioned positioning section The diameter of 3211 is greater than the diameter of the bottom of the above-mentioned avoidance groove 3212. When the positioning section 3211 passes through the inner hole of the elastic buckle 314, the inner hole of the elastic buckle 314 is elastically deformed, and the inner hole of the elastic buckle 314 is slightly supported. Large, so that the positioning section 3211 can pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com