A liquid grinding aid for improving steel slag grinding efficiency

A grinding aid and steel slag powder technology, which is applied in the field of liquid grinding aids, can solve the problems of low solubility, limitation, and easy crystallization of sodium sulfate, and achieve the effects of improving steel slag grinding efficiency, sufficient supply, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

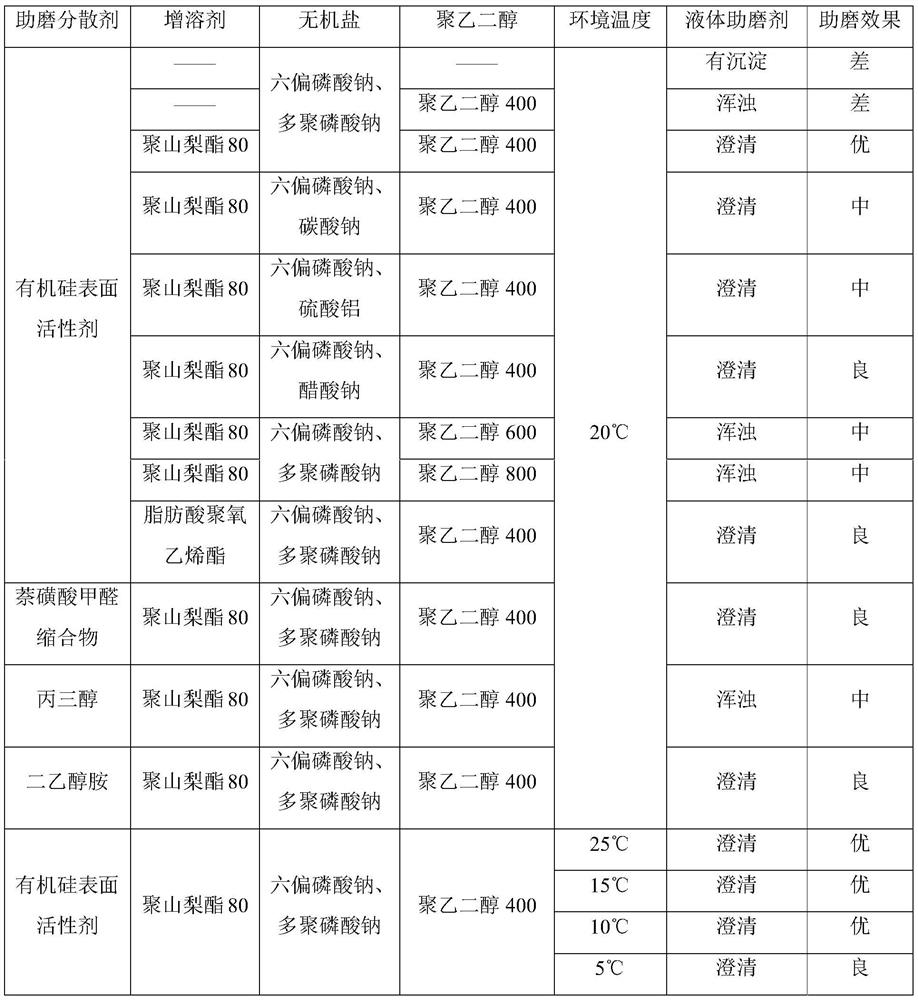

[0035] A liquid grinding aid for improving the grinding efficiency of steel slag, prepared from the following components in parts by weight: 15 parts of grinding aid dispersant, 4 parts of solubilizer, 25 parts of inorganic salt, 4 parts of polyethylene glycol, 32 parts of water. The determination of the optimal component is by comparing the quality and grinding aid effect of different components of liquid grinding aids, as shown in Table 1.

[0036] Table 1 The quality and grinding aid effect of different components of liquid grinding aid

[0037]

[0038]As can be seen from the data in Table 1, when the grinding aid dispersant is a silicone surfactant, the solubilizer is polysorbate 80, the inorganic salt is sodium hexametaphosphate and sodium polyphosphate, and polyethylene glycol is polyethylene glycol. When the diol is 400, the liquid grinding aid is clear without turbidity, and the grinding aid effect is excellent. The sodium polyphosphate described in table 1 is a ...

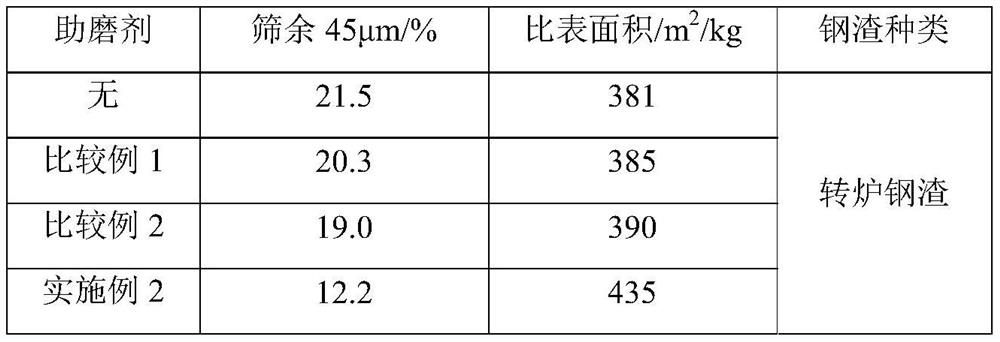

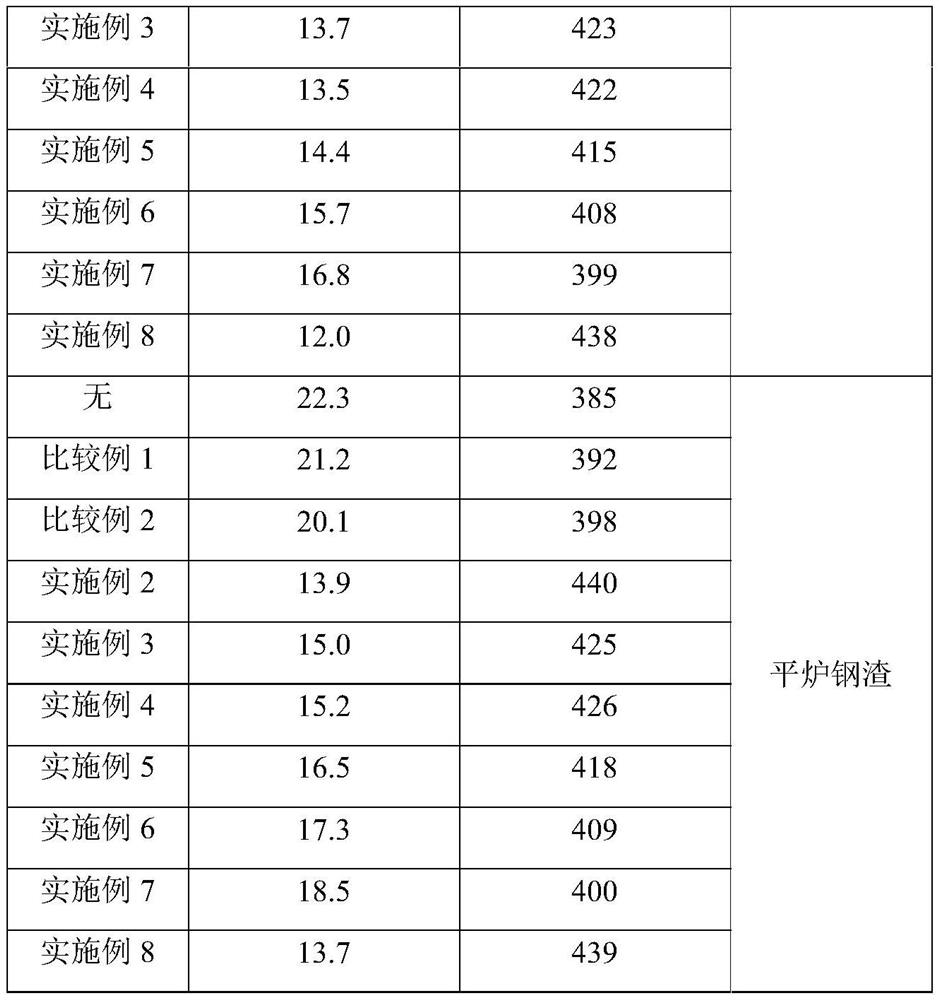

Embodiment 2

[0041] A liquid grinding aid for improving the grinding efficiency of steel slag, prepared from the following components in parts by weight: 15 parts of grinding aid dispersant, 4 parts of solubilizer, 25 parts of inorganic salt, 4 parts of polyethylene glycol, 32 parts of water; described grinding aid dispersant is organic silicon surfactant, and described solubilizer is polysorbate 80, and described inorganic salt is sodium hexametaphosphate and sodium tetrapolyphosphate, and its weight ratio is 0.7:1, The polyethylene glycol is polyethylene glycol 400.

[0042] The organosilicon surfactant described in this embodiment is polyoxyethylene ether trisiloxane, polyether modified silicone oil, polyether modified heptamethyltrisiloxane or polyether phosphate modified siloxane any kind.

[0043] For the purpose of mixing the liquid grinding aid in the steel slag, the amount of the liquid grinding aid in this embodiment is 0.48% of the mass of the steel slag.

Embodiment 3

[0045] A liquid grinding aid for improving the grinding efficiency of steel slag, prepared from the following components in parts by weight: 10 parts of grinding aid dispersant, 2 parts of solubilizer, 30 parts of inorganic salt, 6 parts of polyethylene glycol, 32 parts of water. Others are with embodiment 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap