plate tension rail

A technology of tensioning rail and printing plate, applied in the field of printing plate device, can solve the problems of inability to realize automatic operation and prolonging debugging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

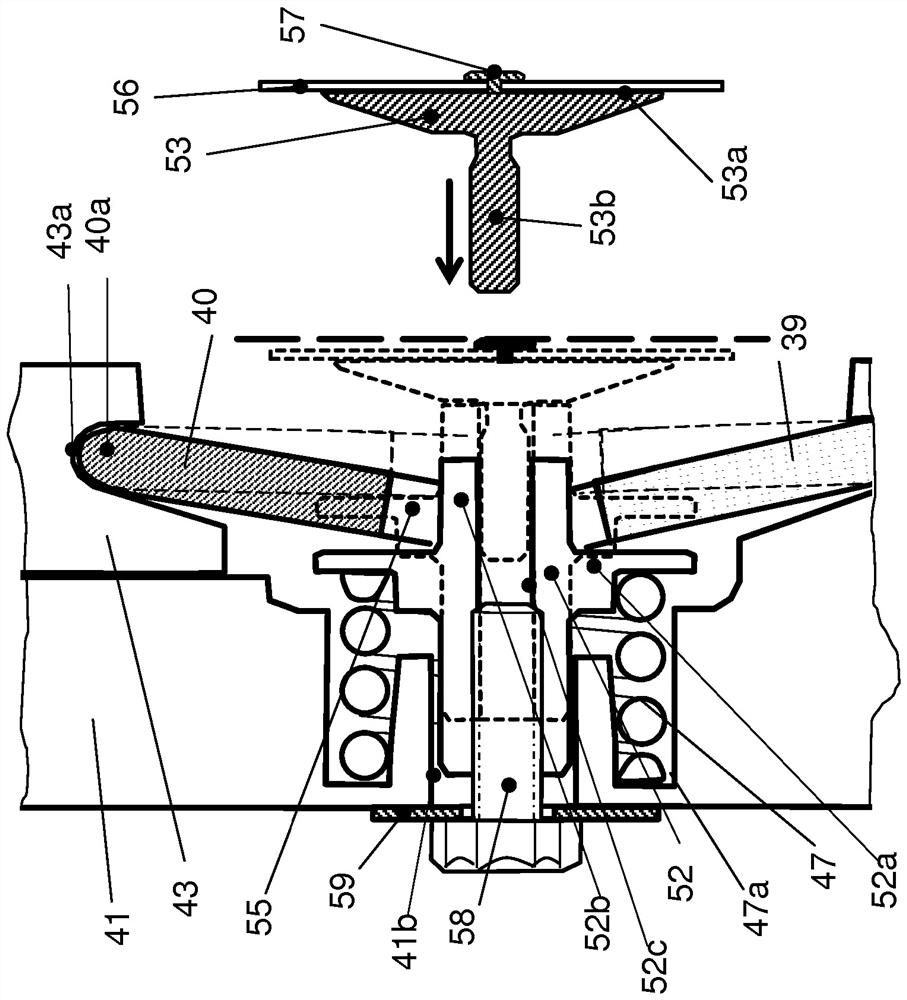

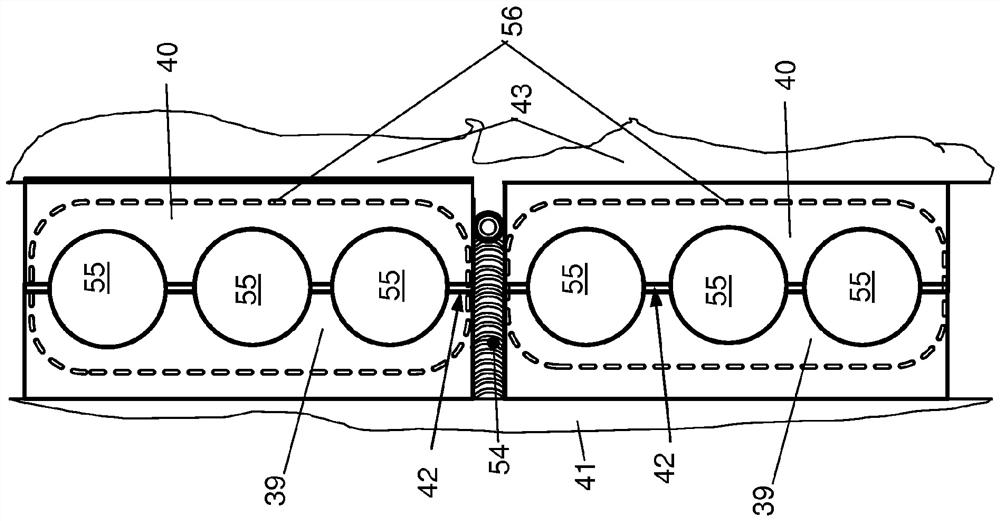

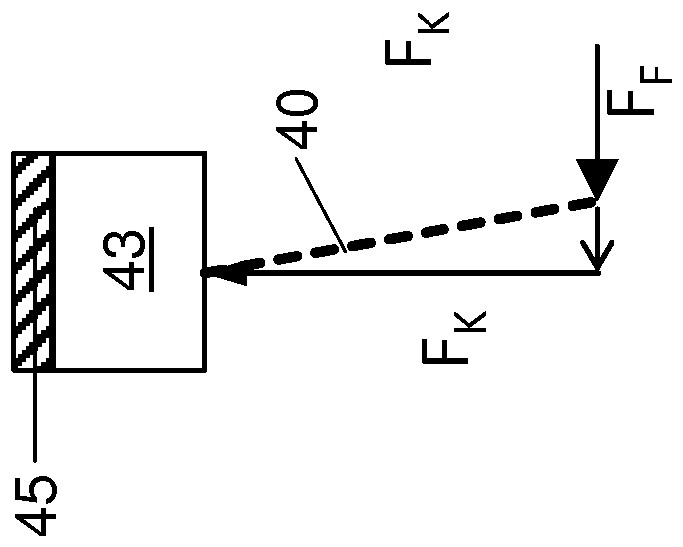

[0038] figure 1 A device according to the prior art is shown. The plate cylinder 1 is provided with a cylinder channel 2 for accommodating two plate tensioning rails 3 , only one of the two plate clamping rails being shown. The plate tensioning rail 3 is provided at the bottom 5 with a rail body 4 extending over the length of the plate cylinder 1 . The rail body 4 is displaceable in the drum channel 2 in the direction of the left and right lateral delimitations 6 , 7 . A plurality of fulcrums 8 for pivotably accommodating the respective lower end 11 of the lower rail link 9 of the toggle mechanism is arranged in an axis-parallel direction, the lower rail link of the toggle mechanism The upper end 12 of the upper track link 10 is then hingedly connected to the lower end 13 of the upper track link 10 , wherein the upper end 14 of the upper track link 10 is pivotably supported in a fulcrum 15 . The fulcrum 15 is arranged on an upper rail 16 which is pivotable relative to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com