Patents

Literature

54results about How to "Clamping force adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

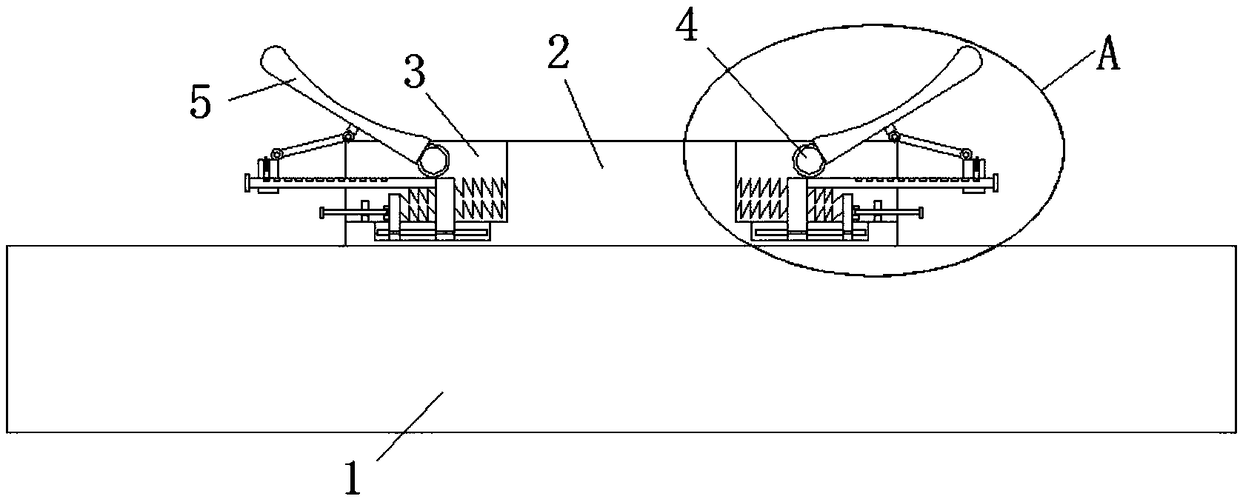

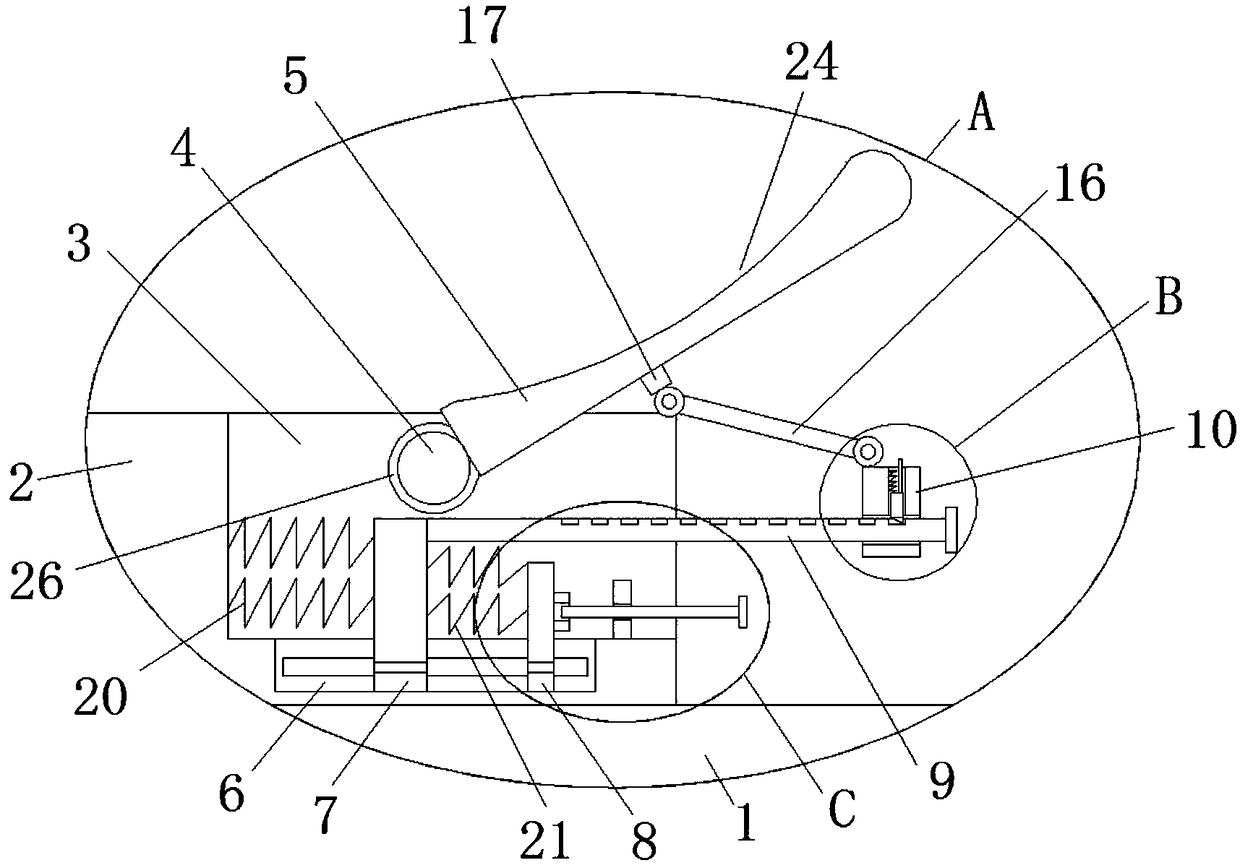

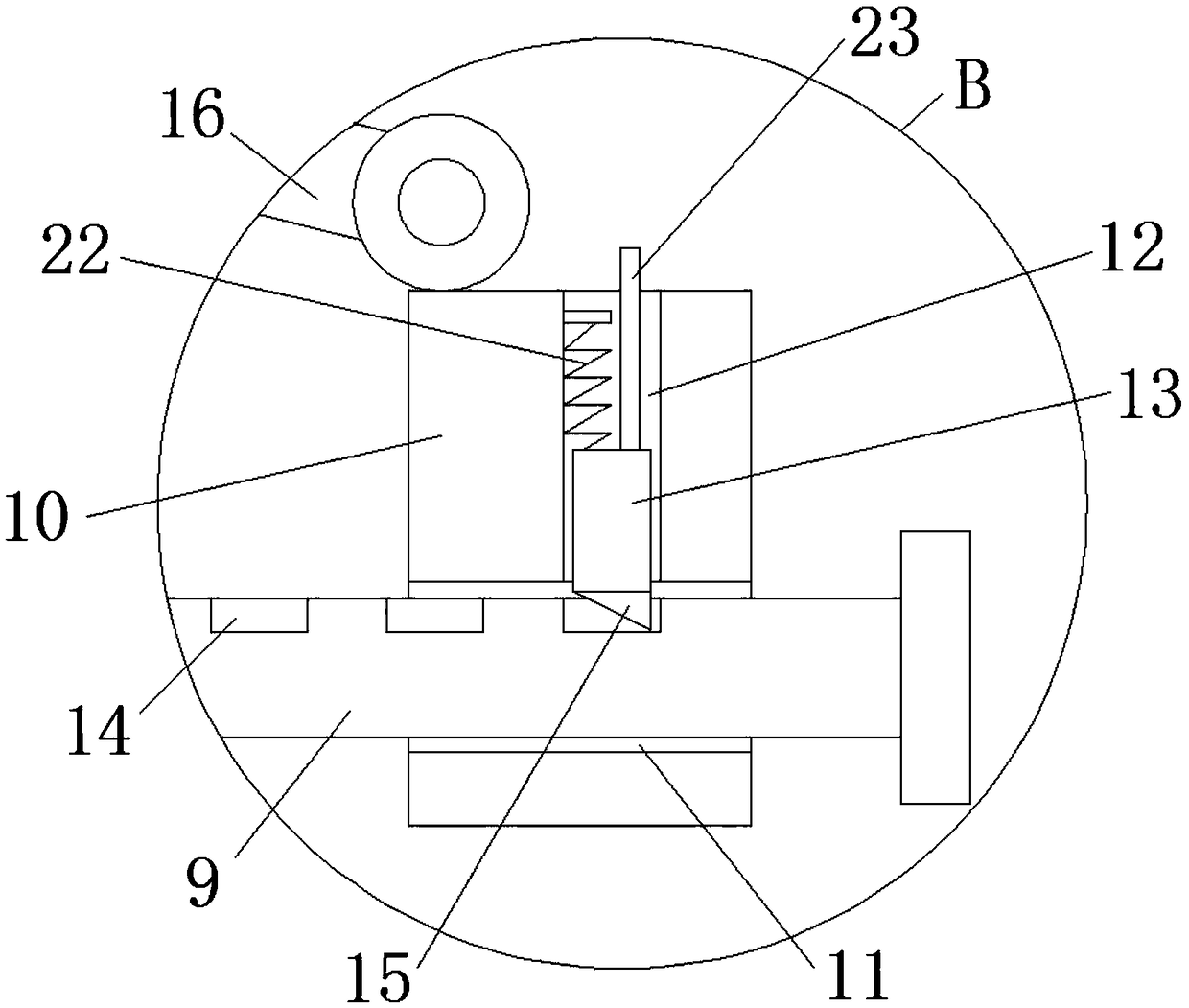

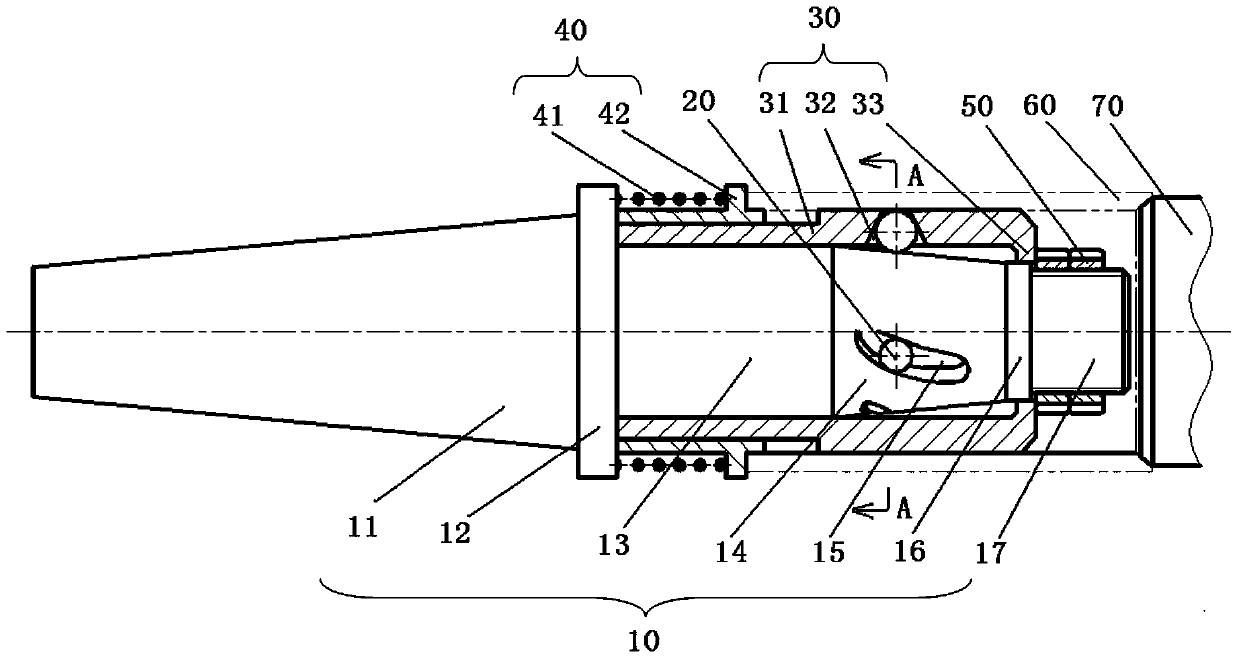

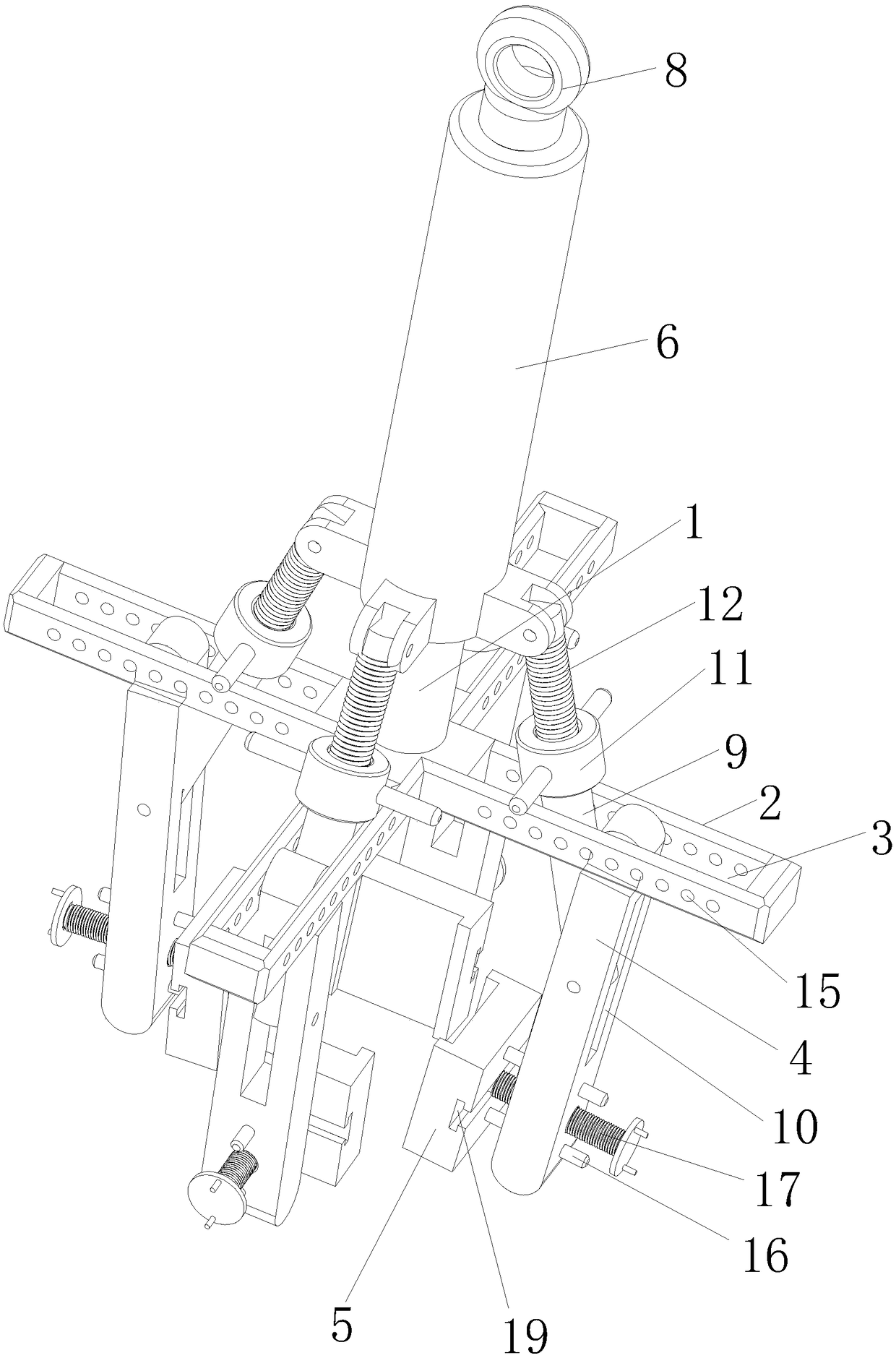

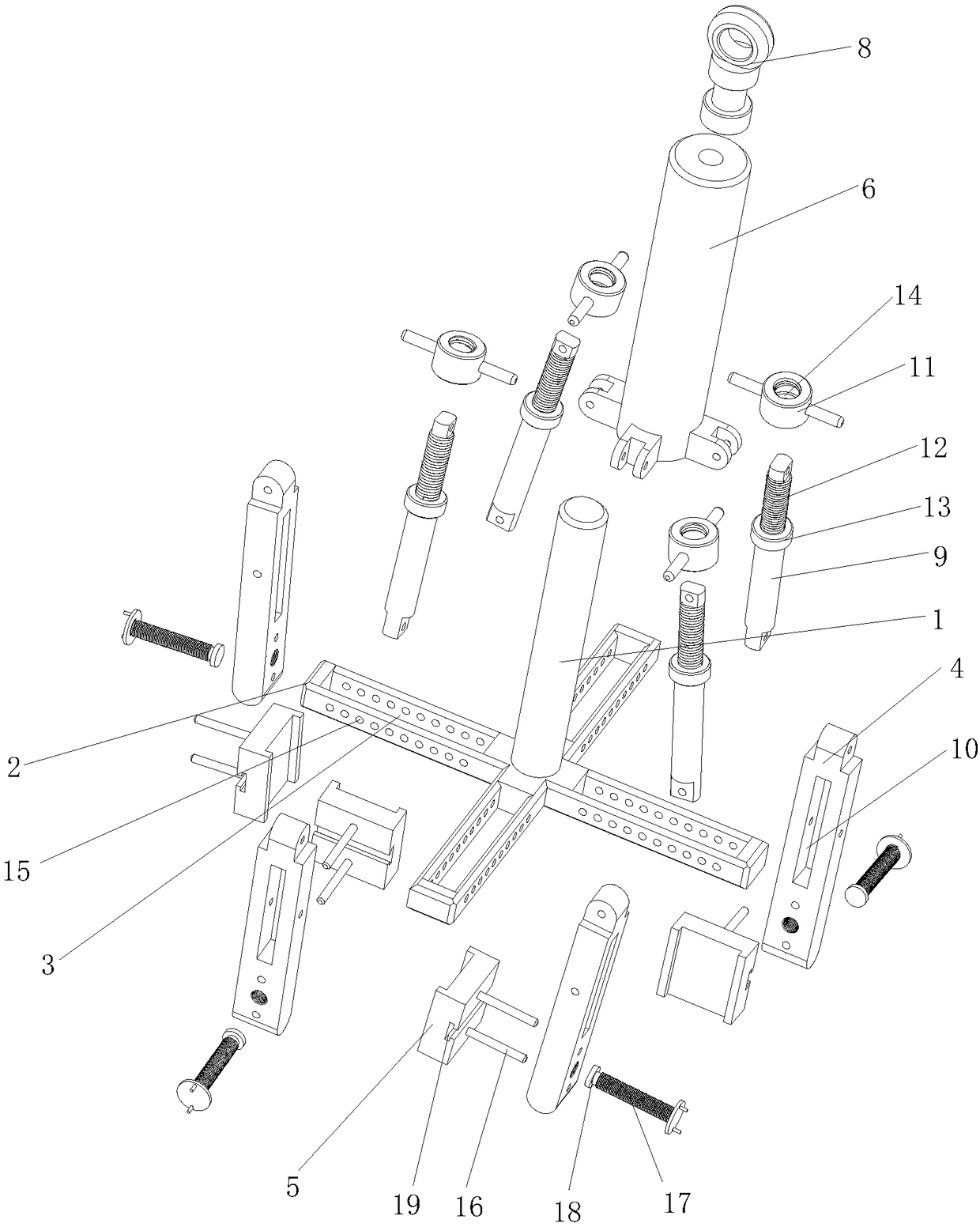

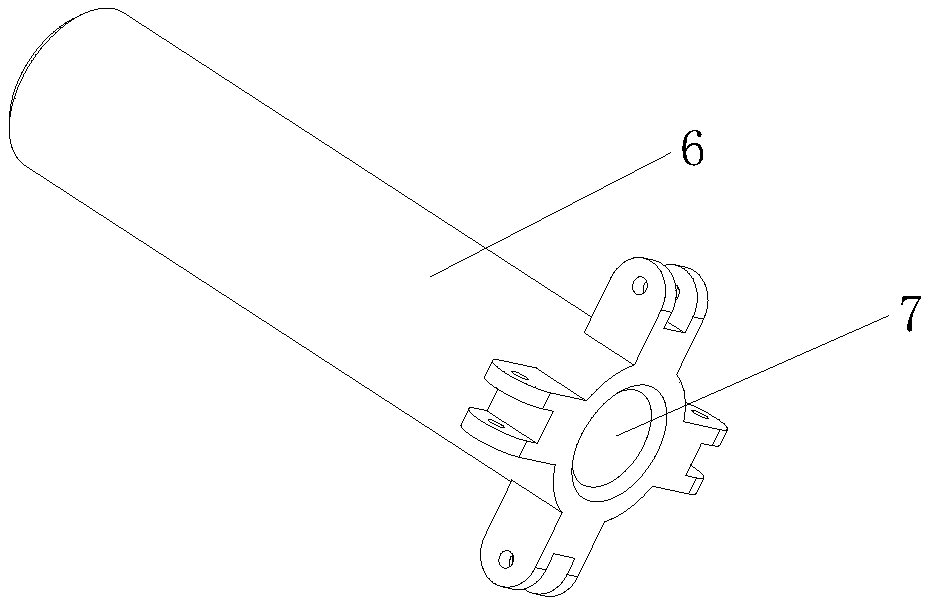

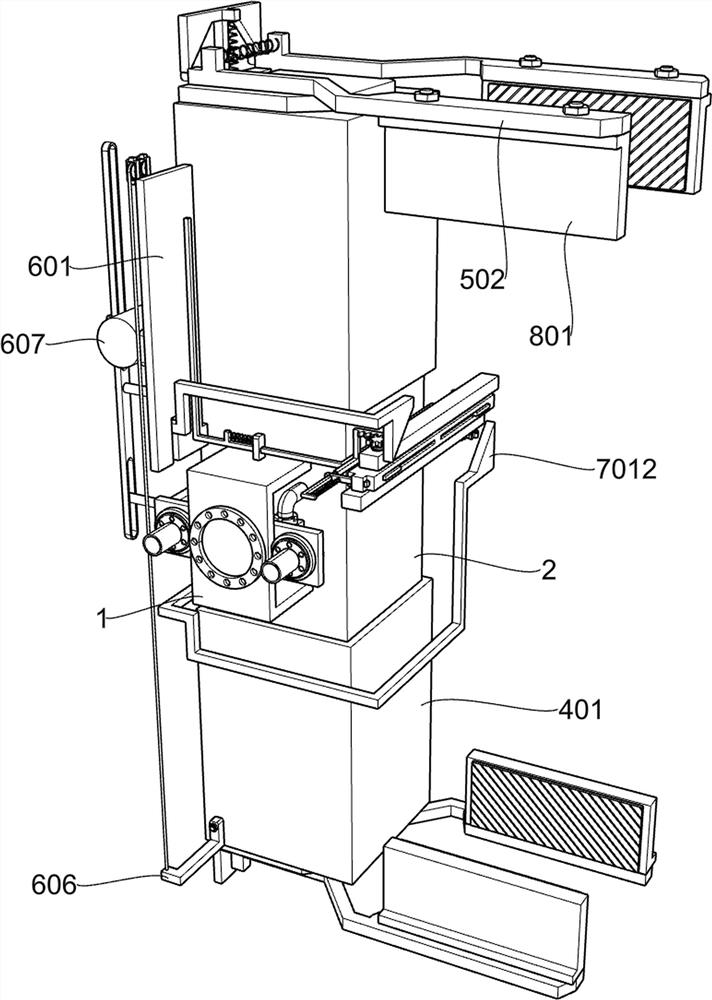

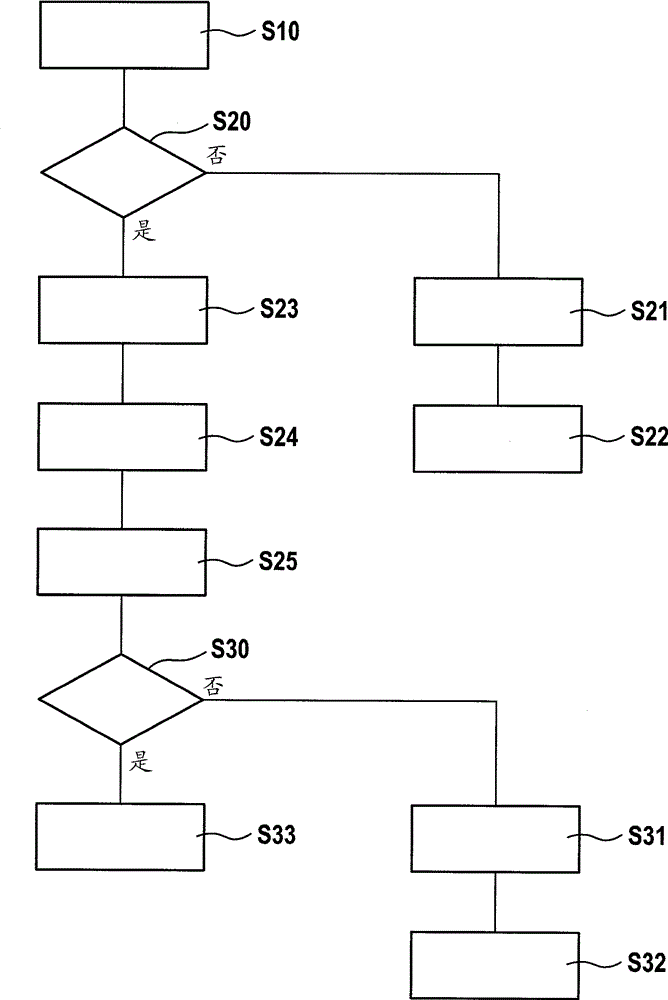

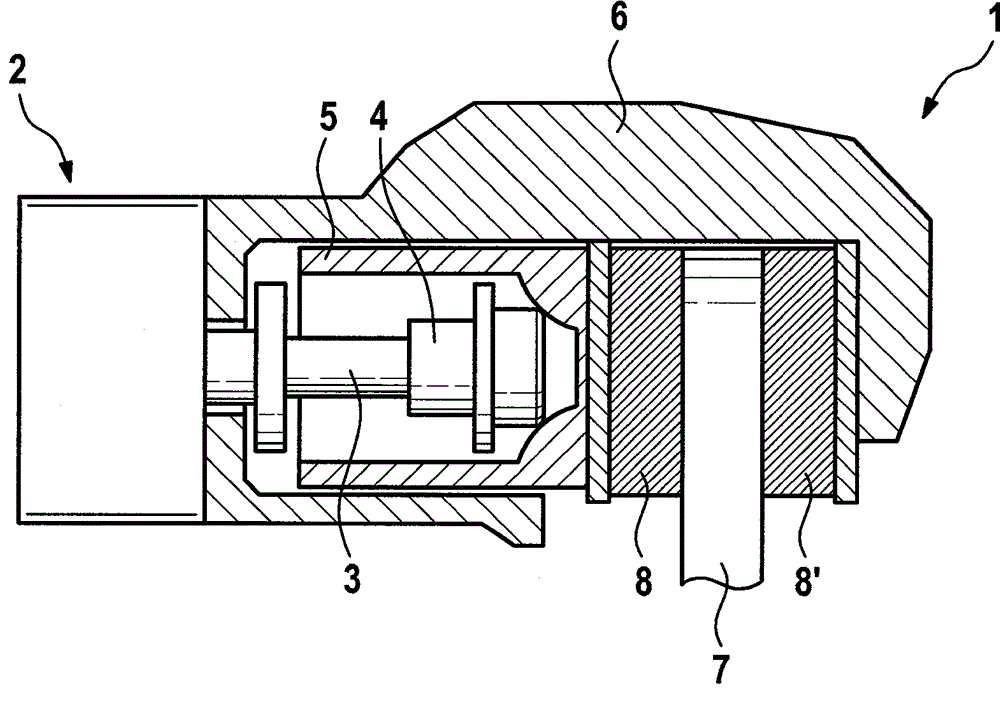

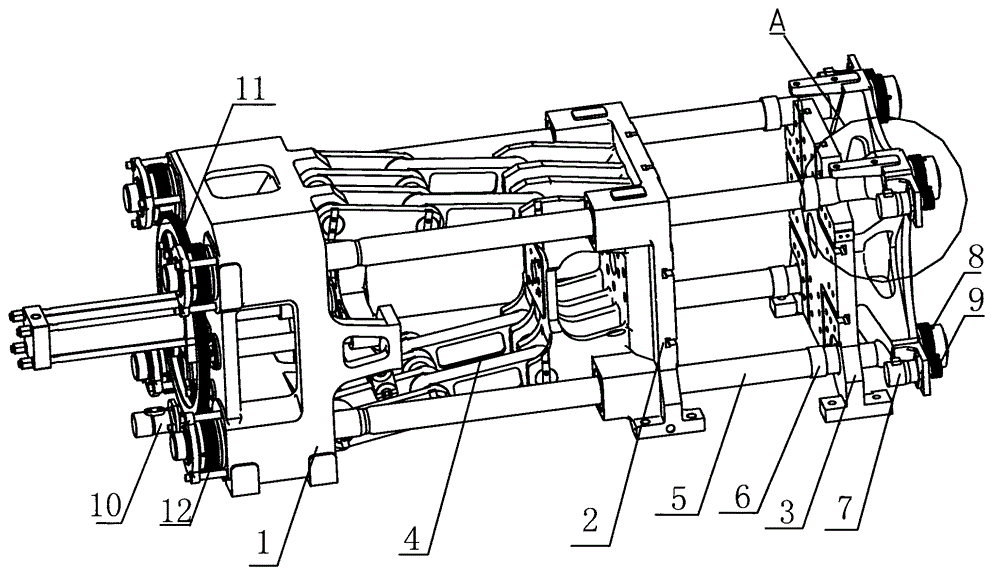

Mould-assembling mechanism for injection molding machine and balancing and adjusting method for mould-assembling force thereof

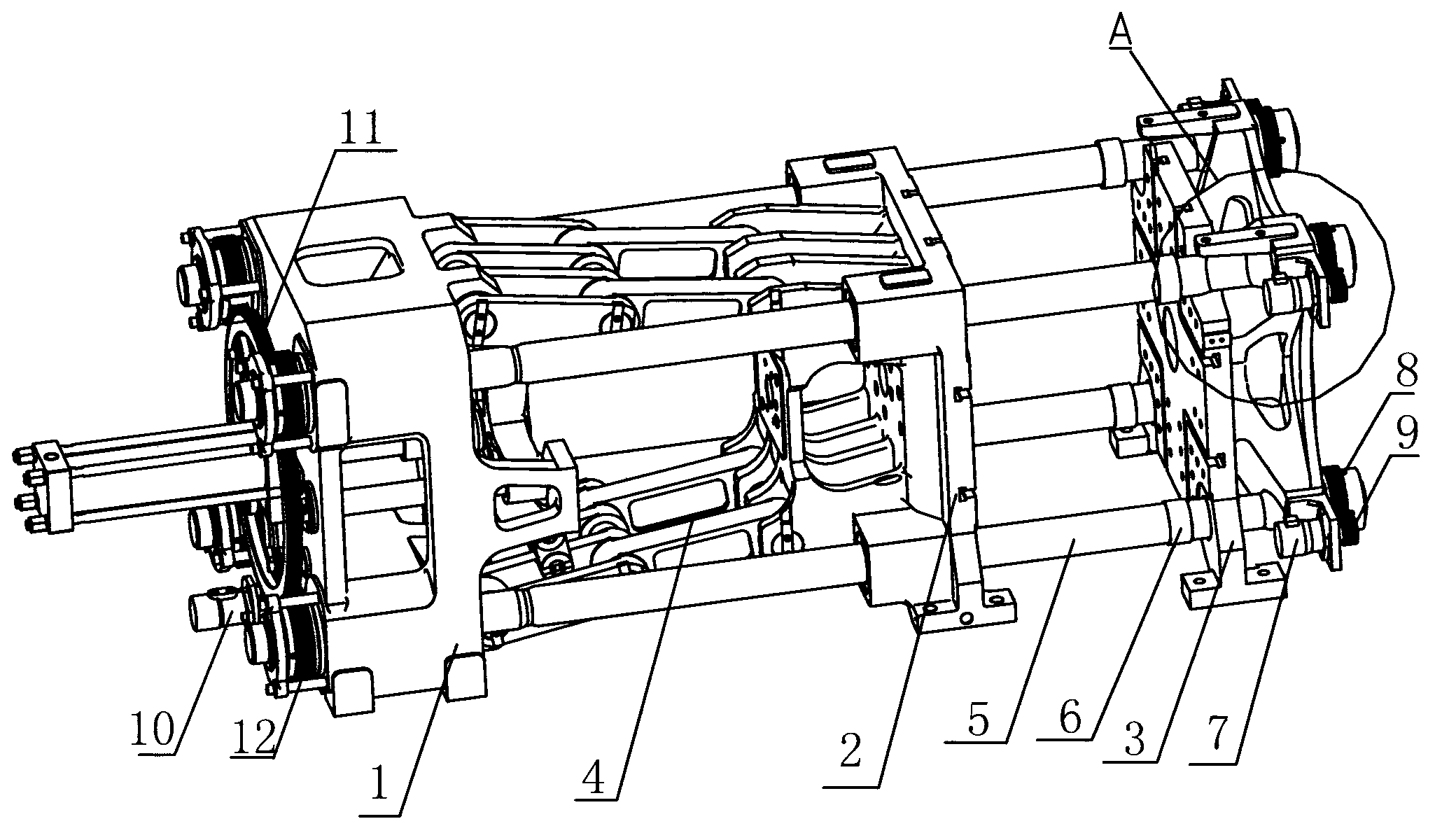

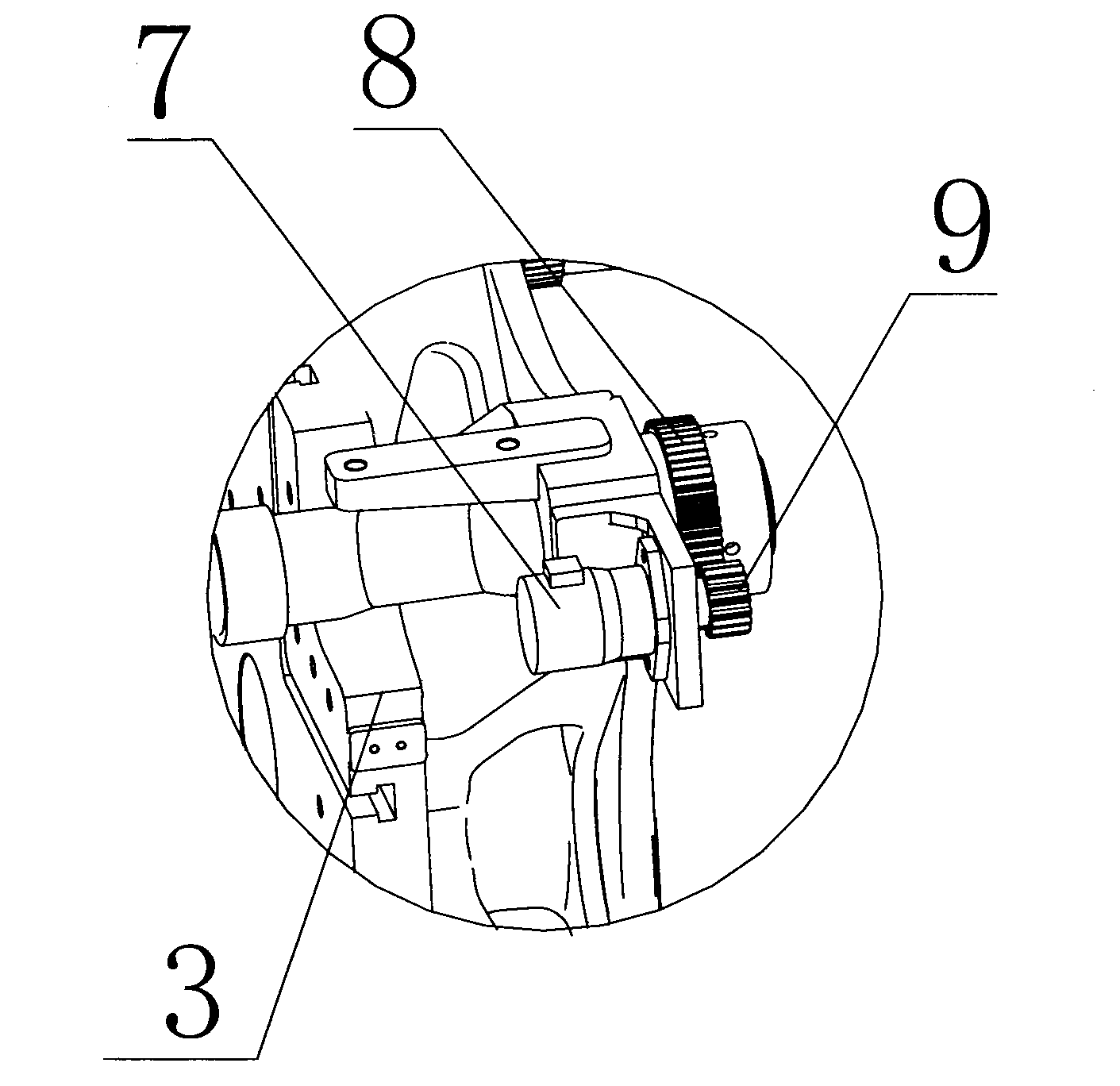

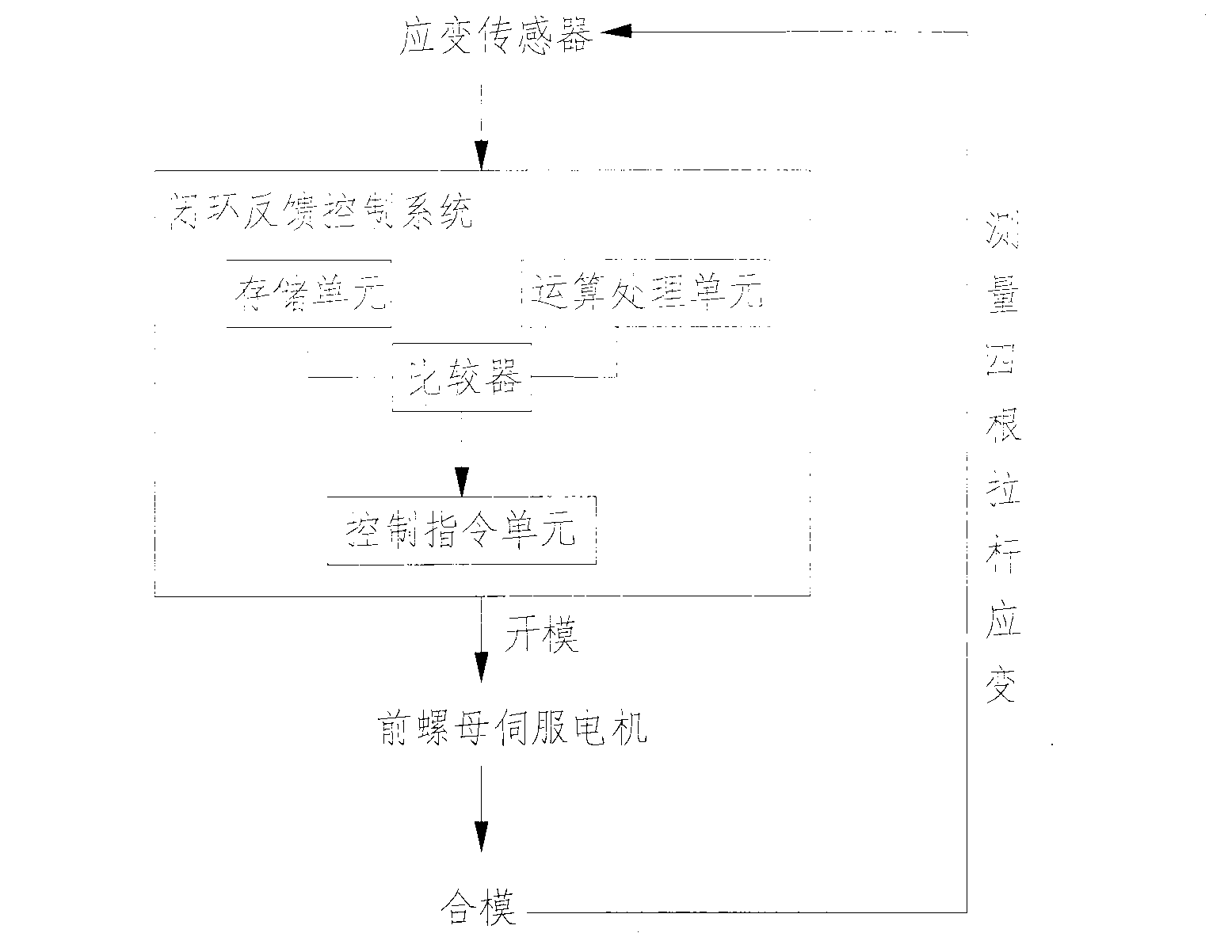

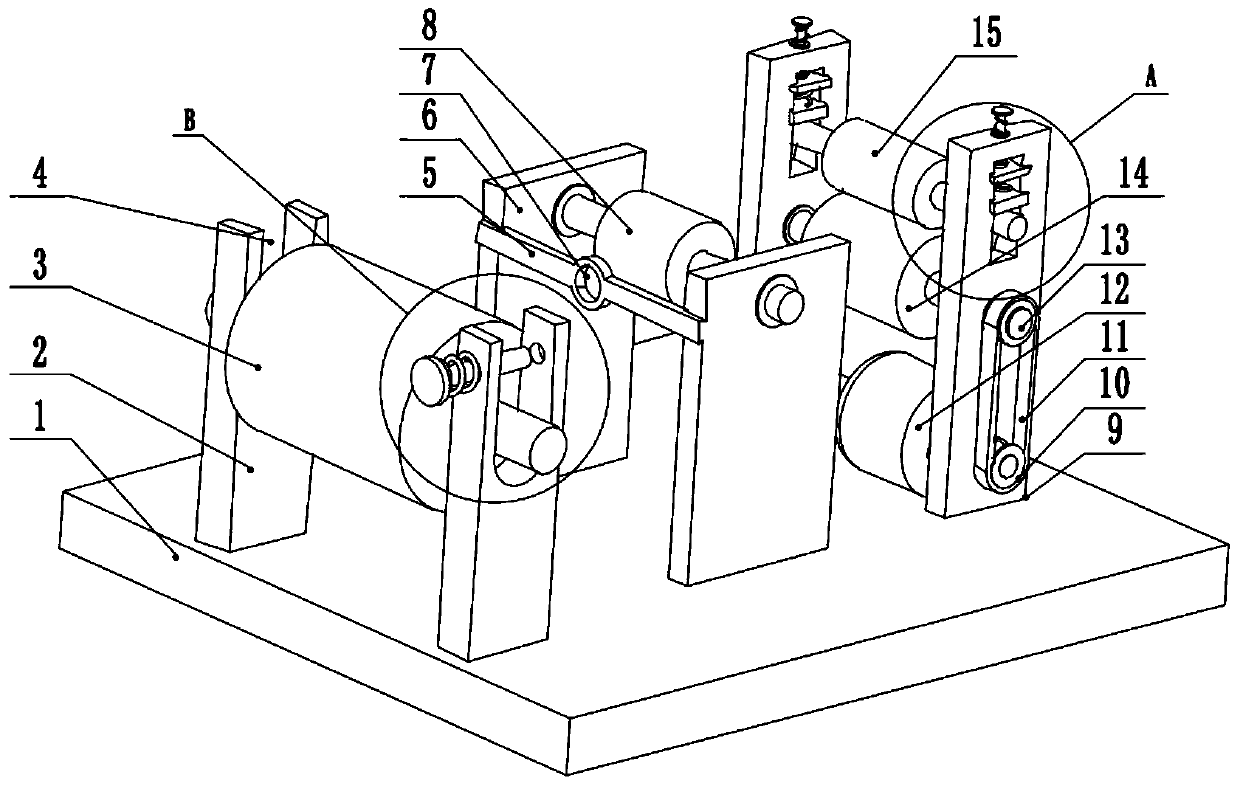

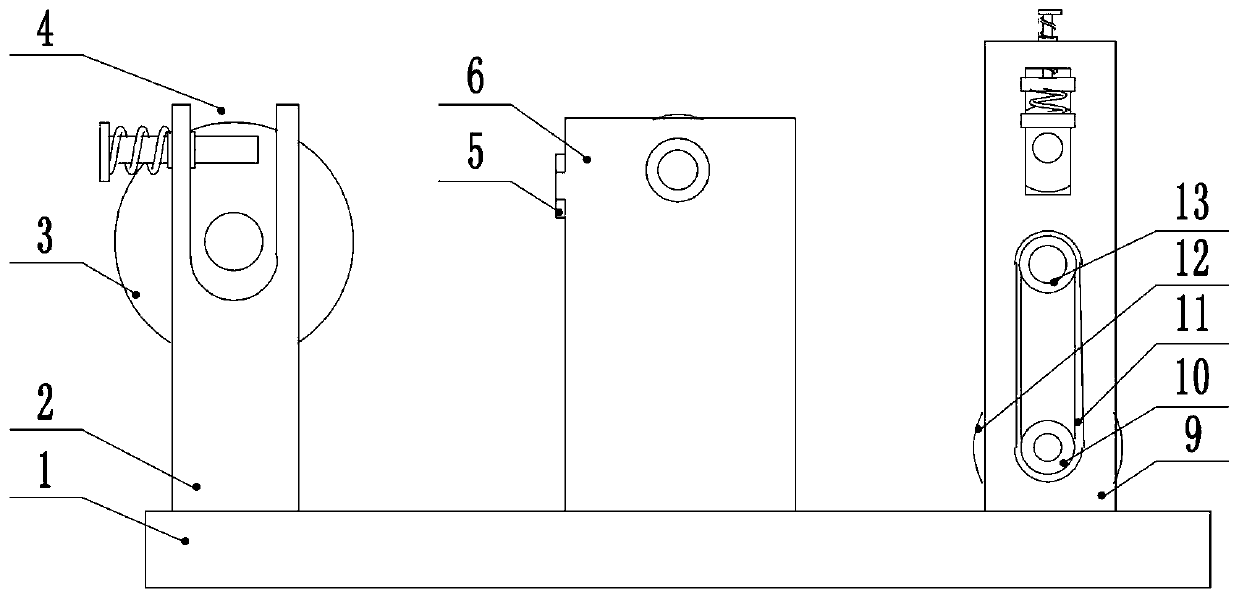

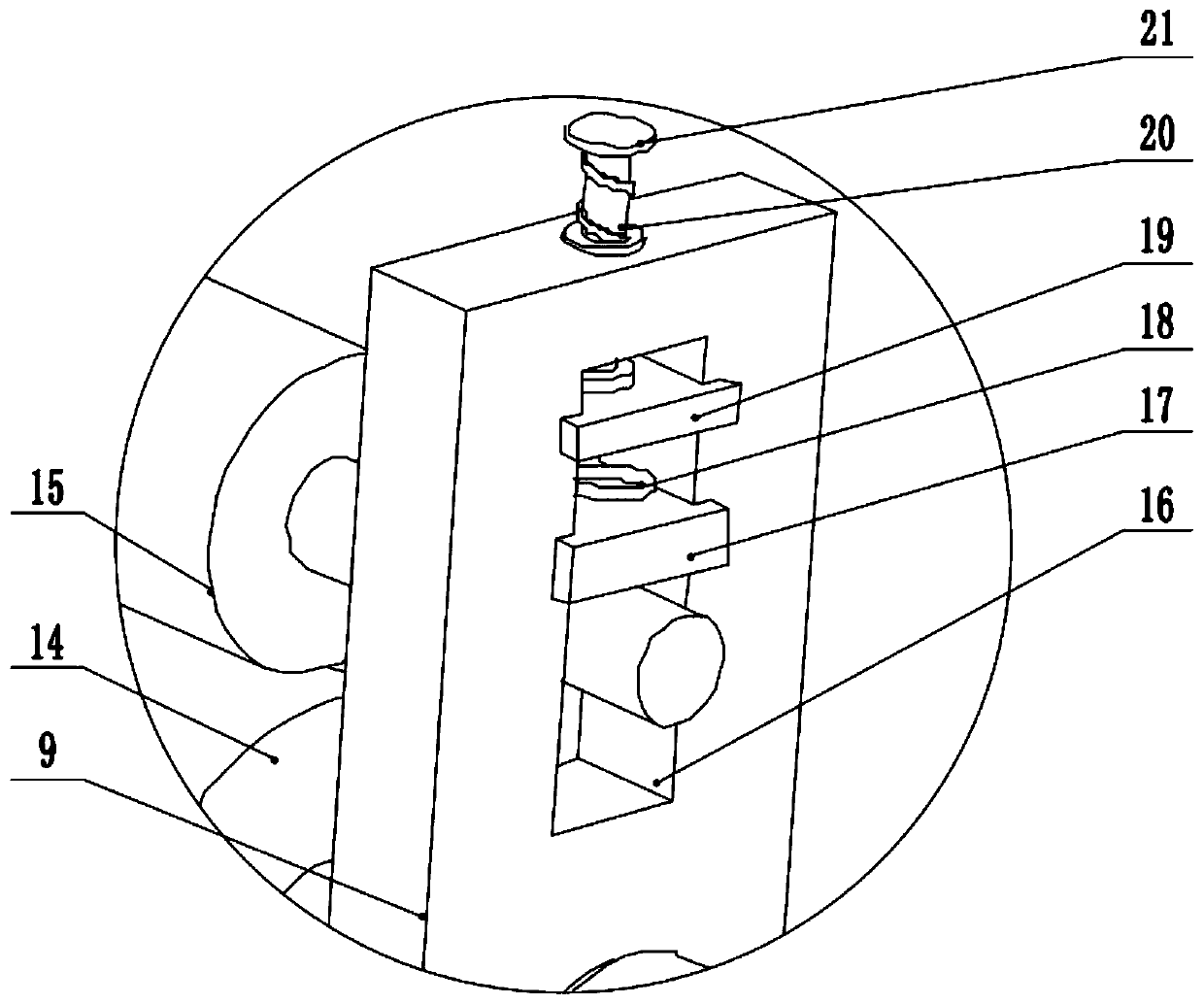

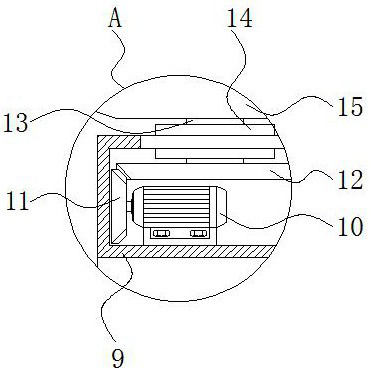

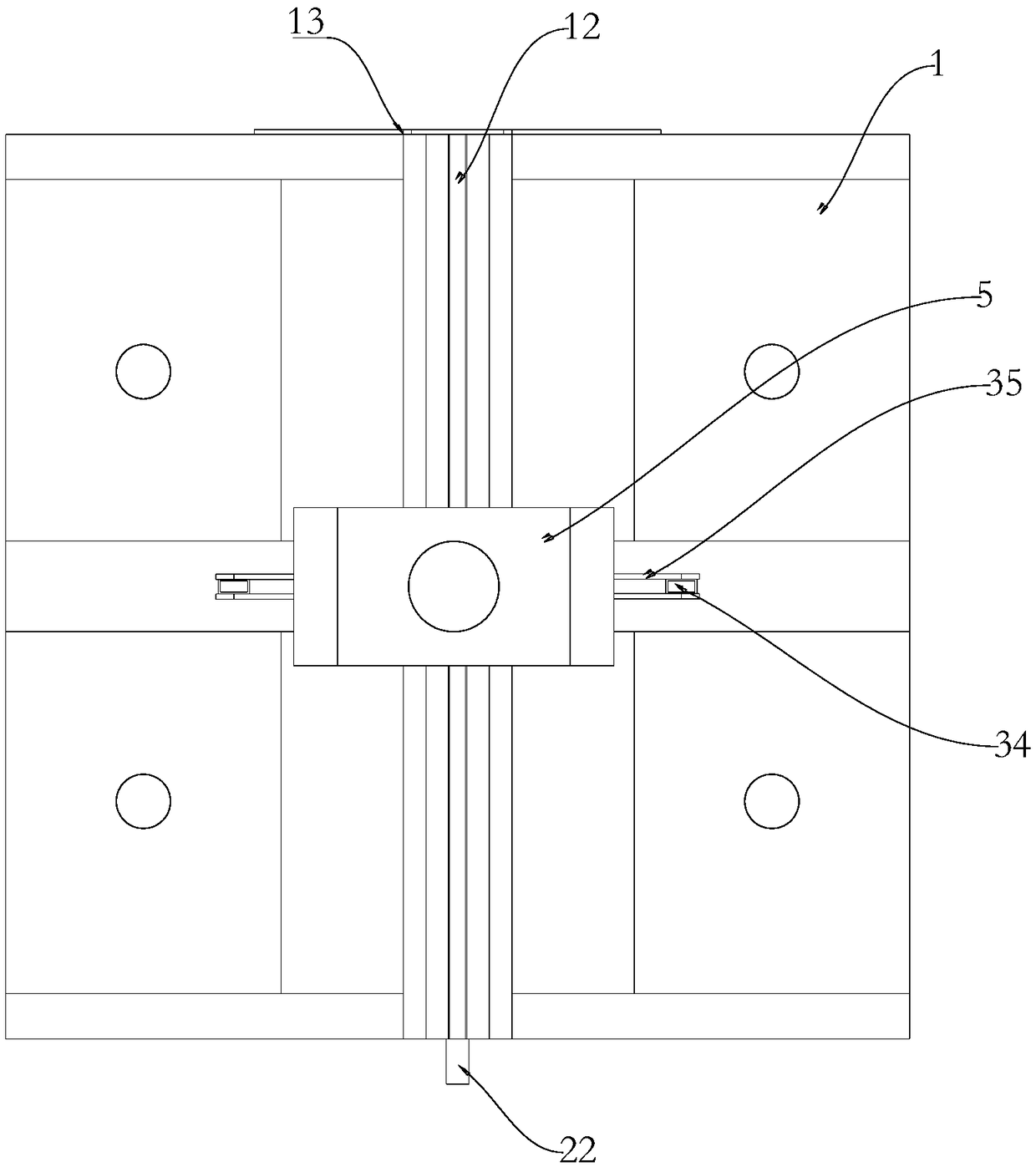

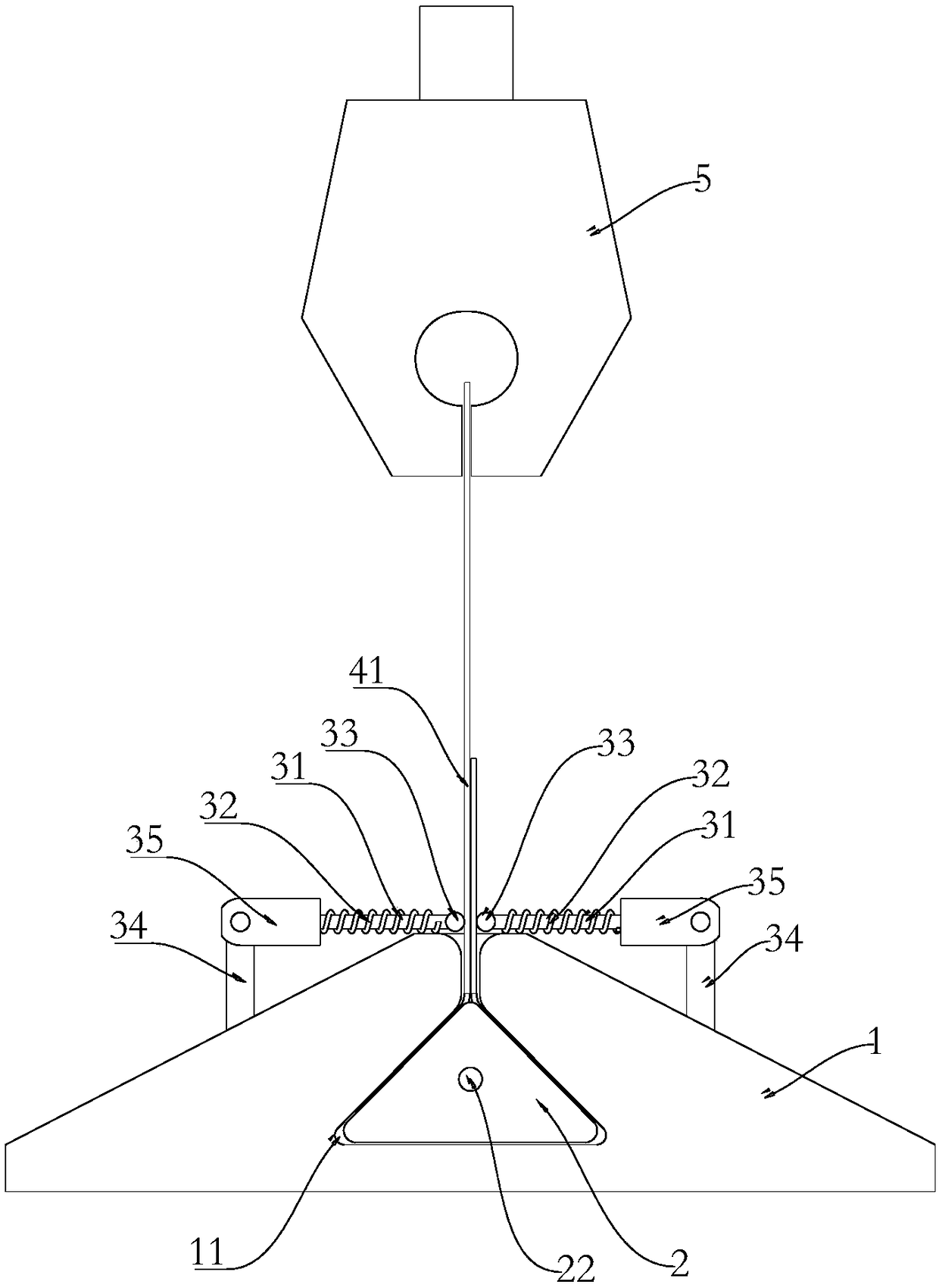

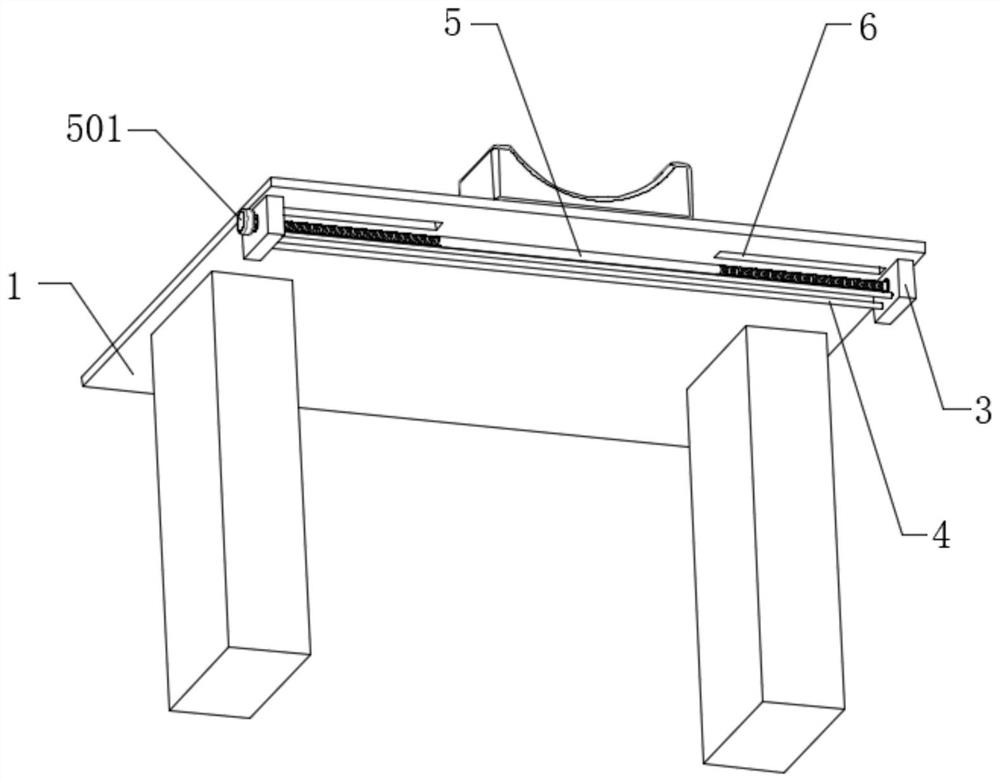

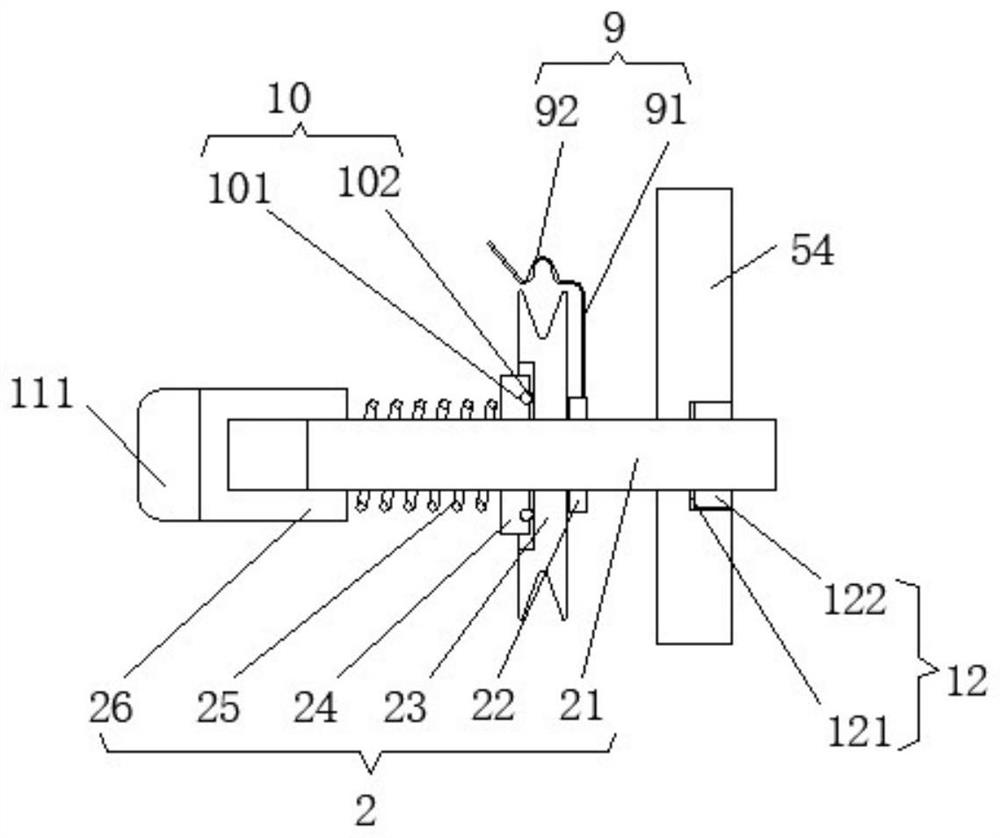

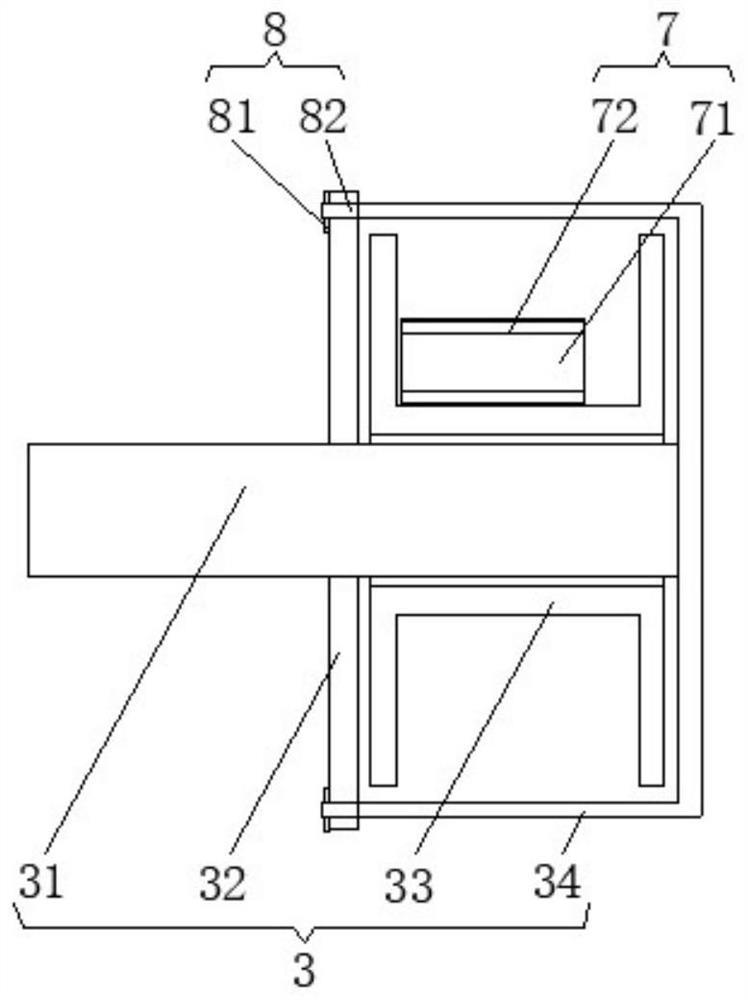

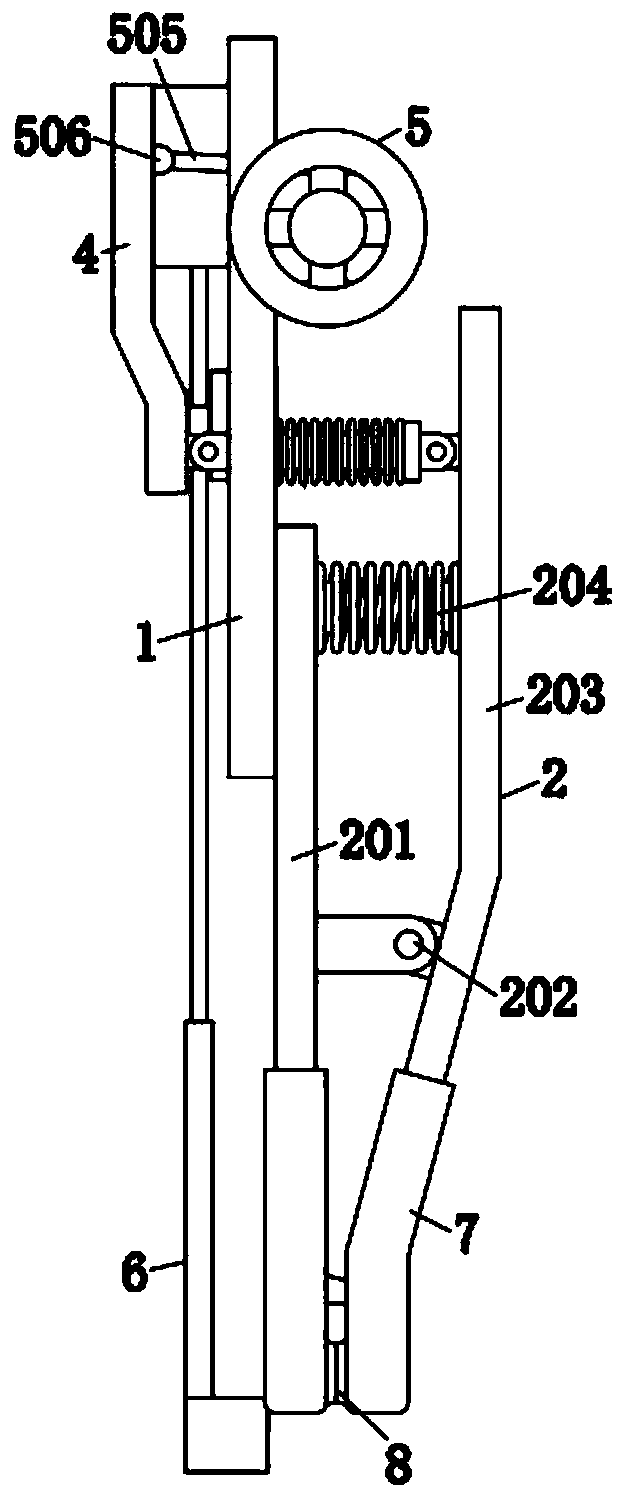

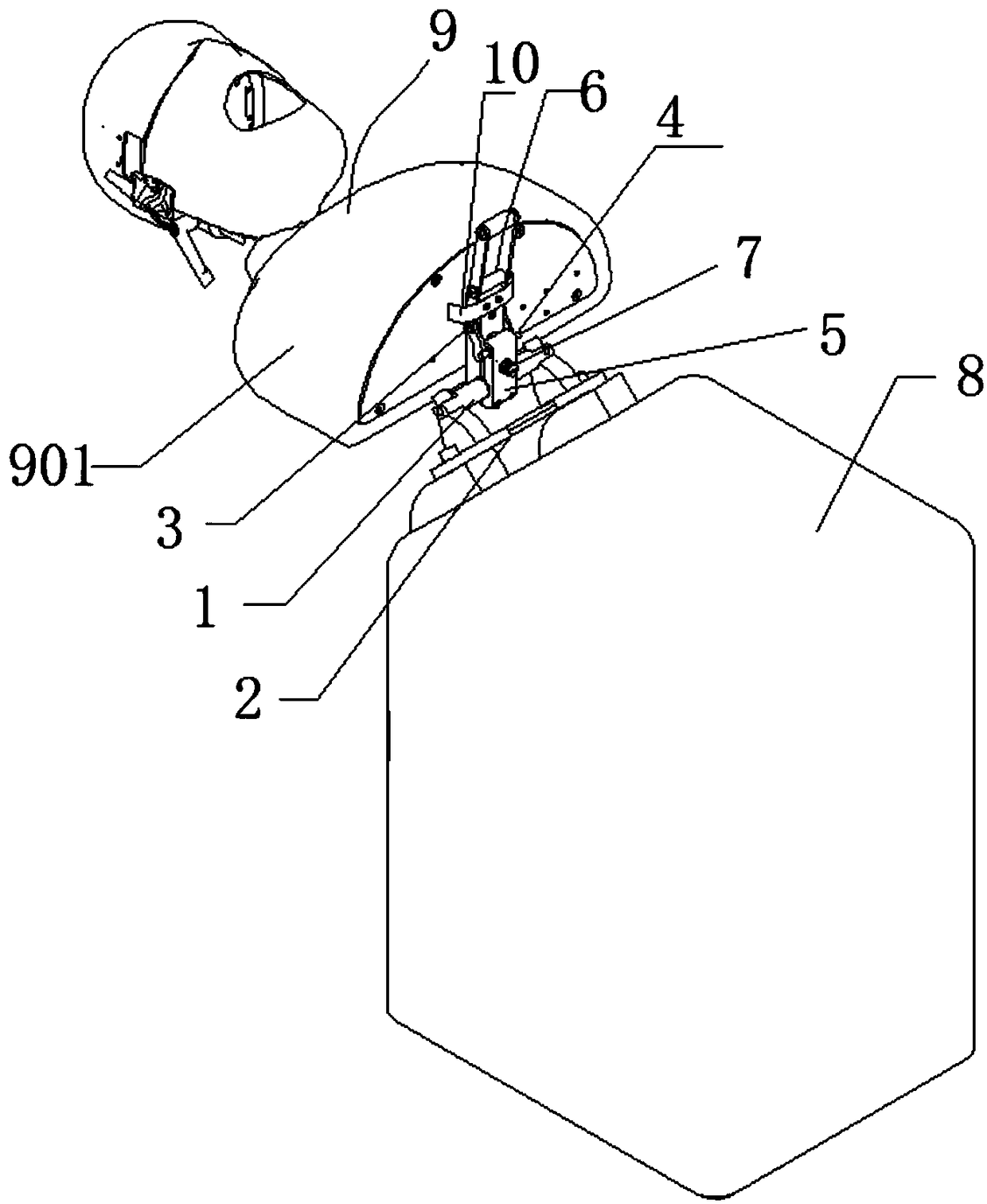

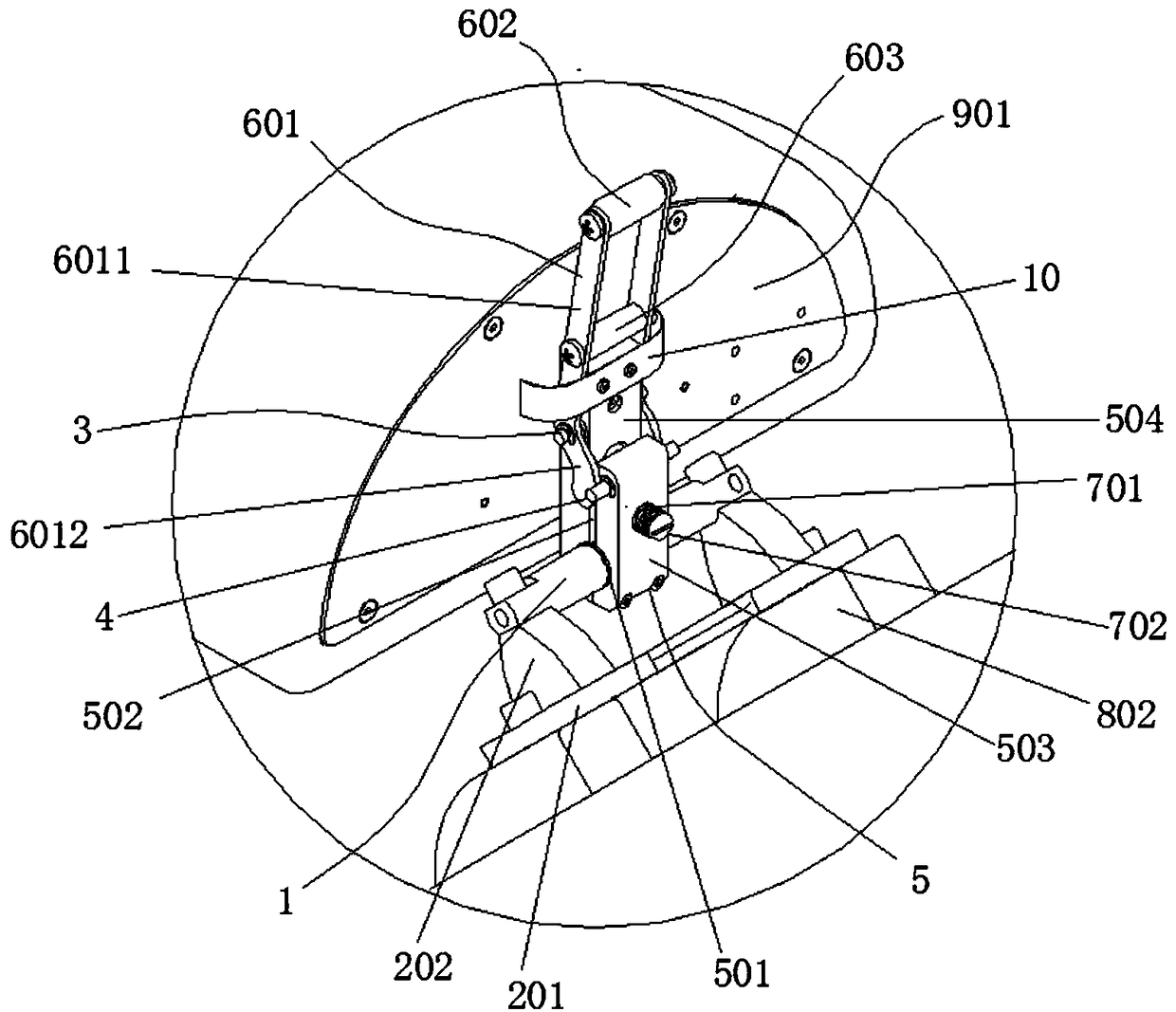

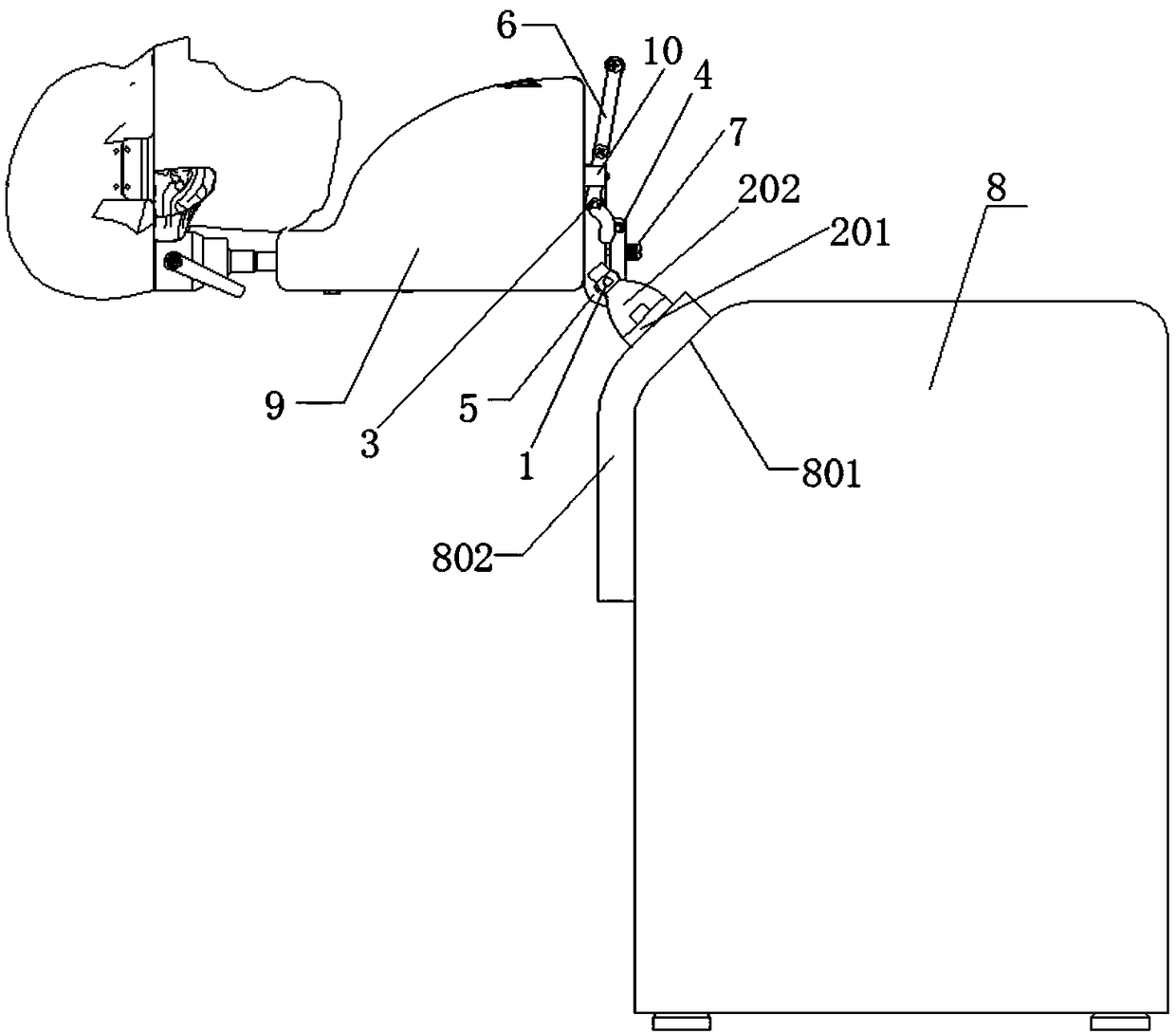

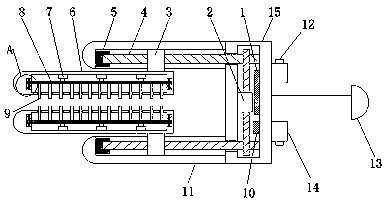

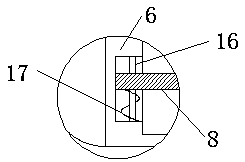

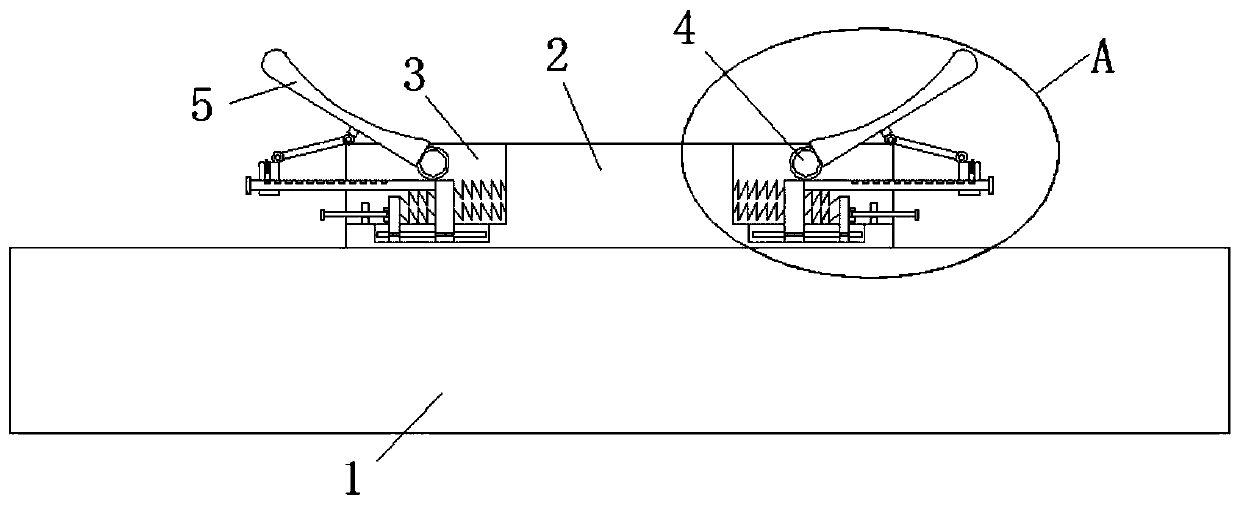

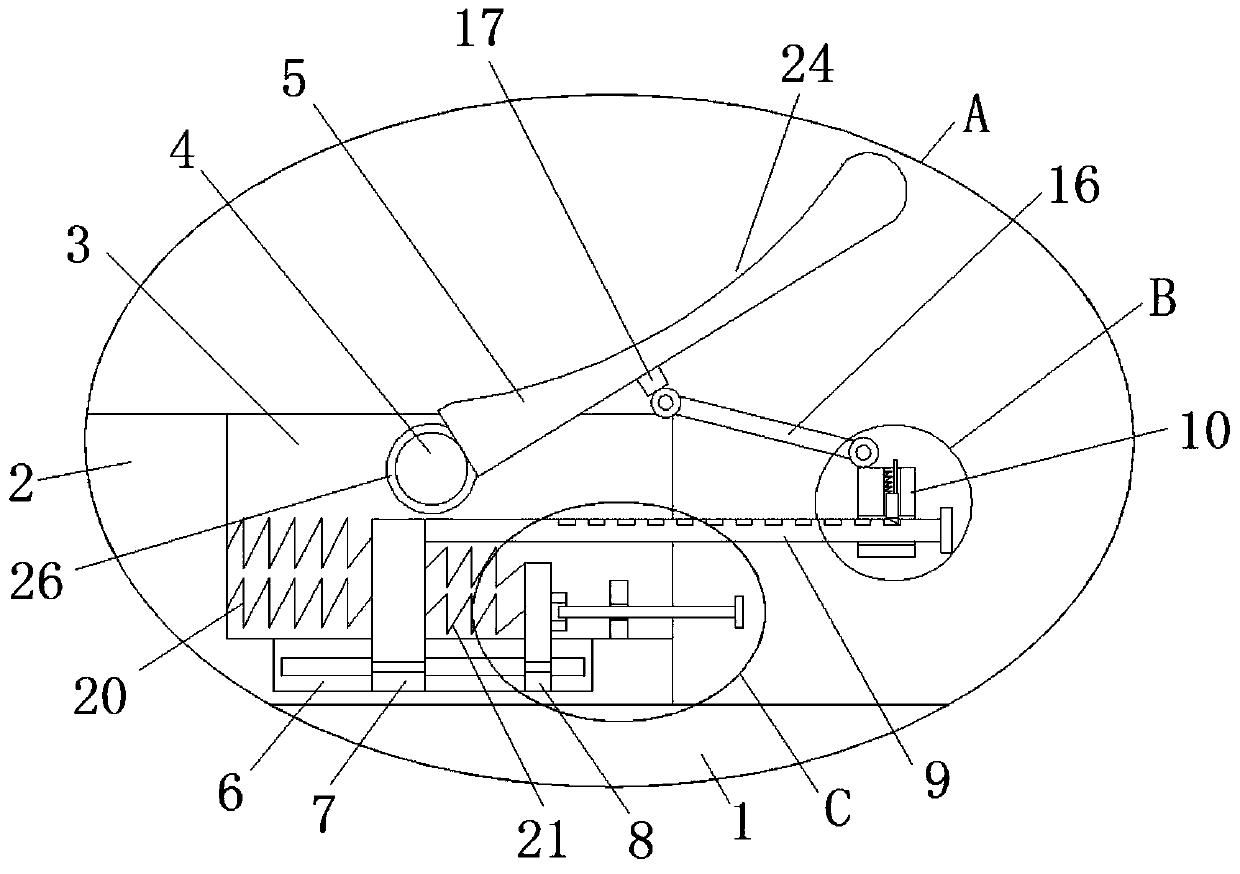

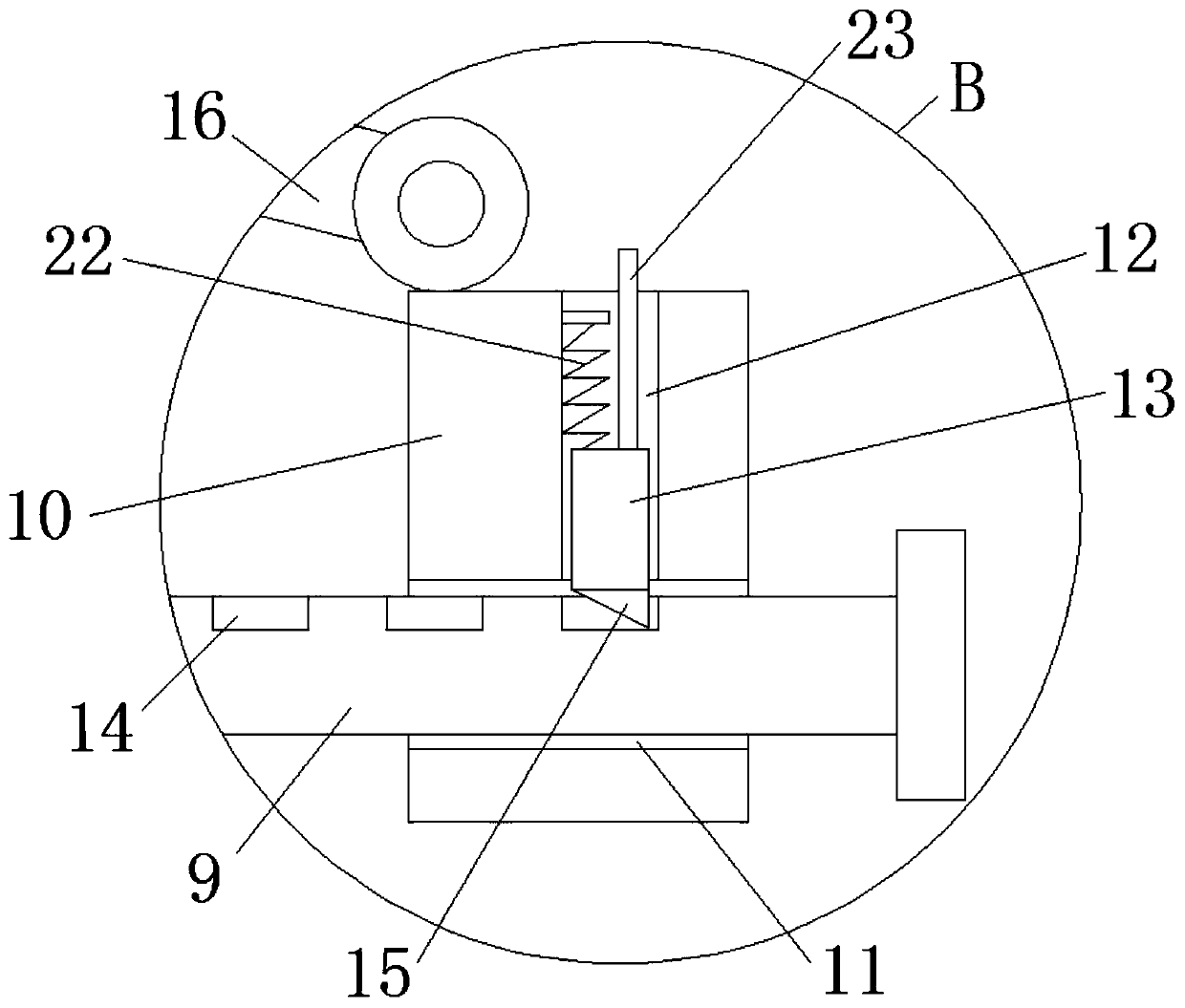

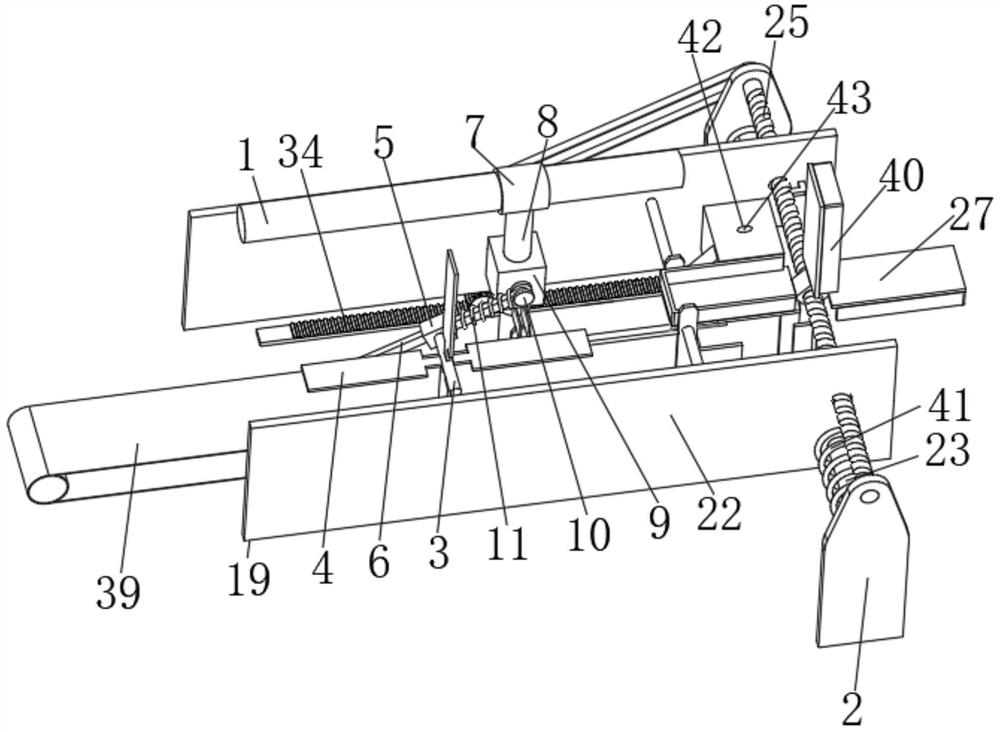

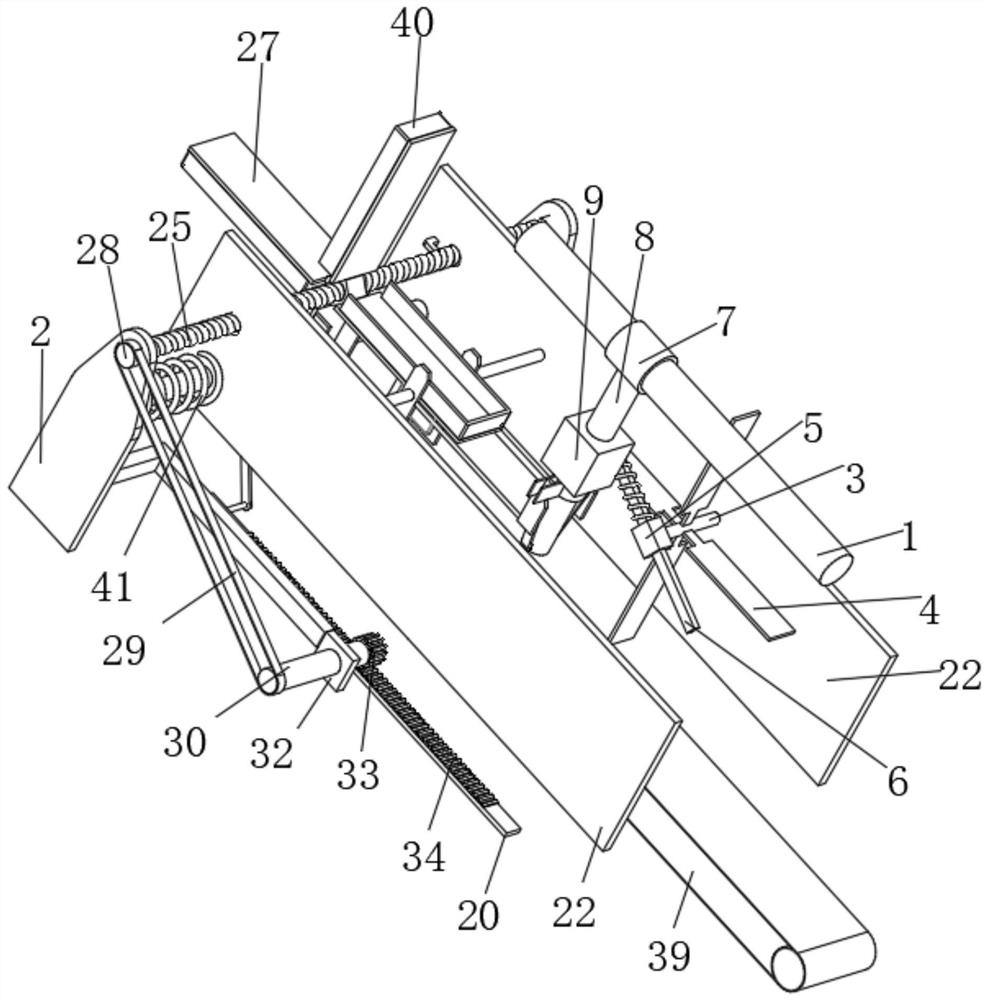

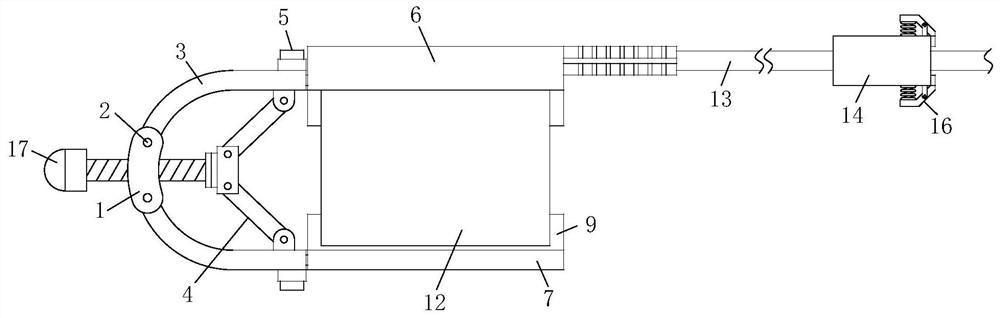

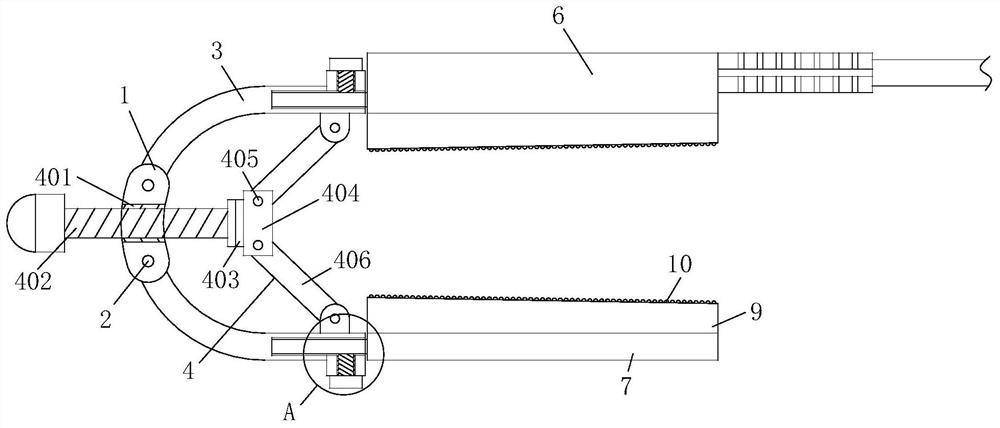

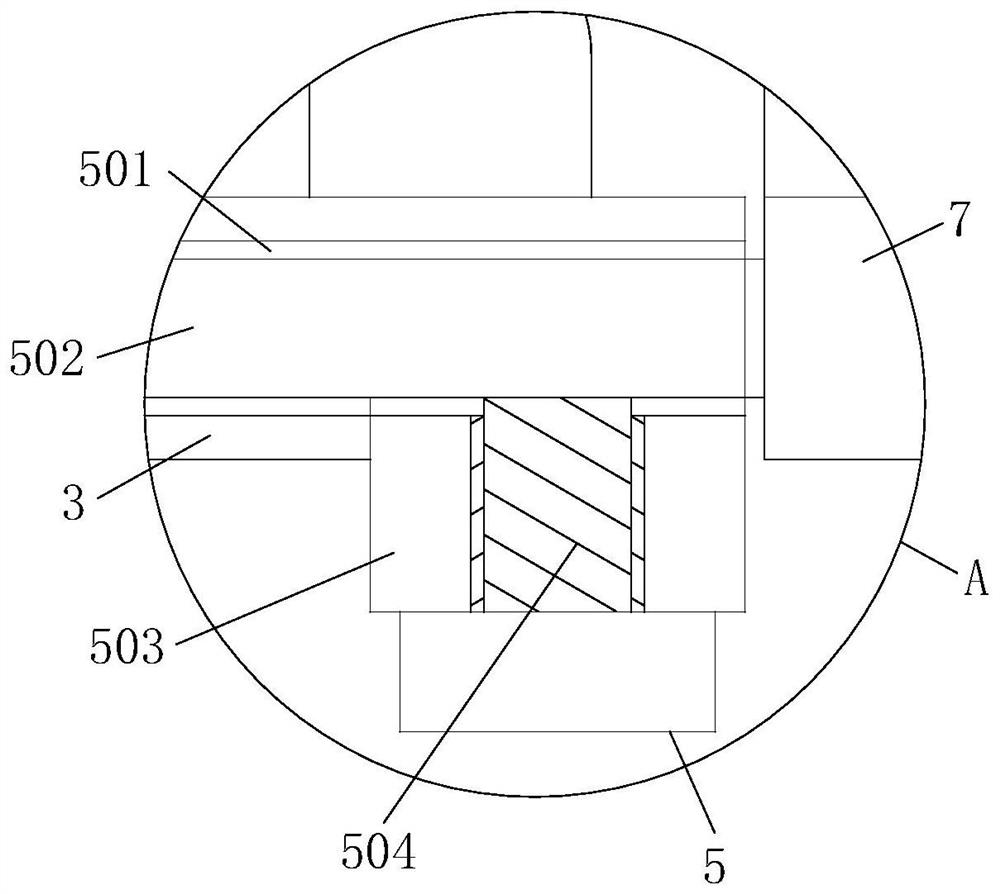

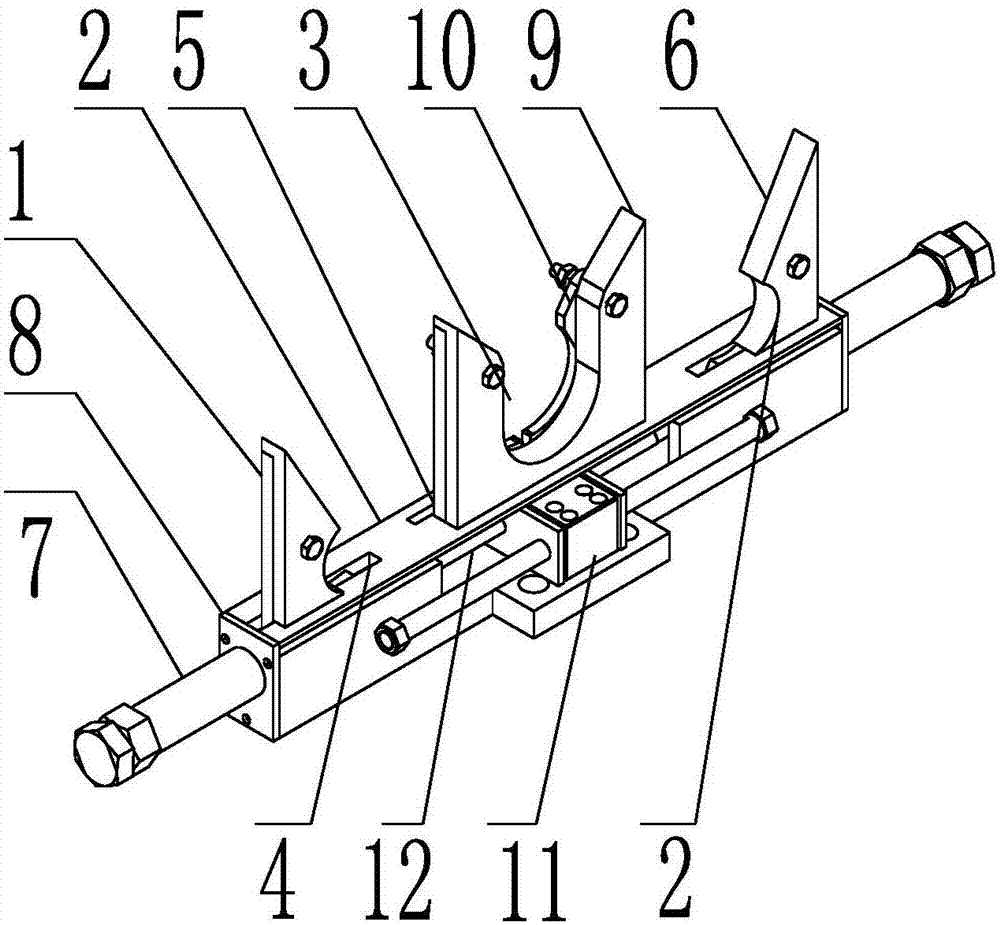

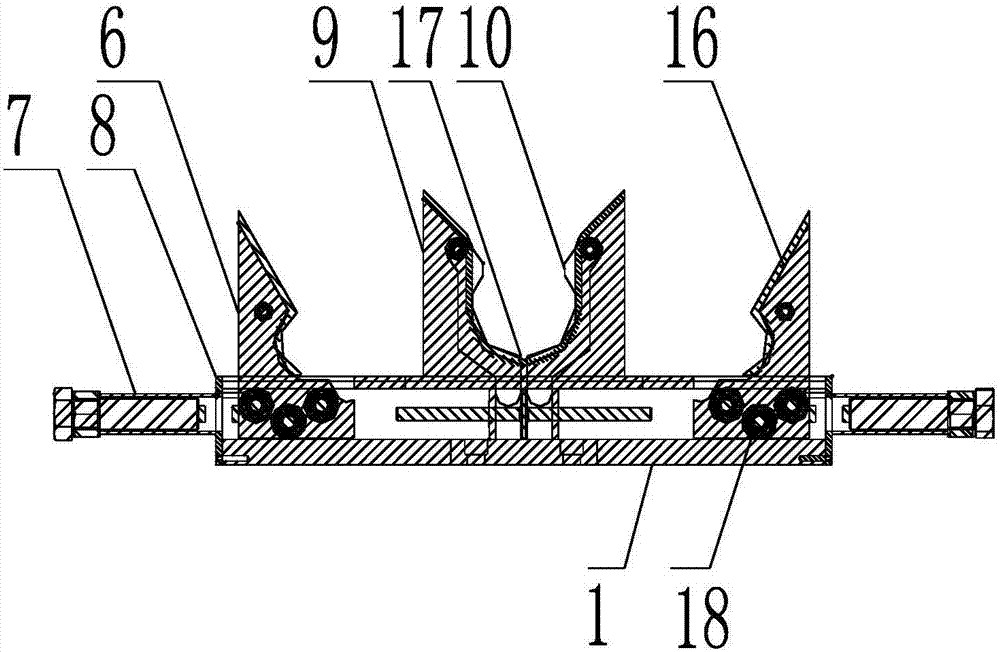

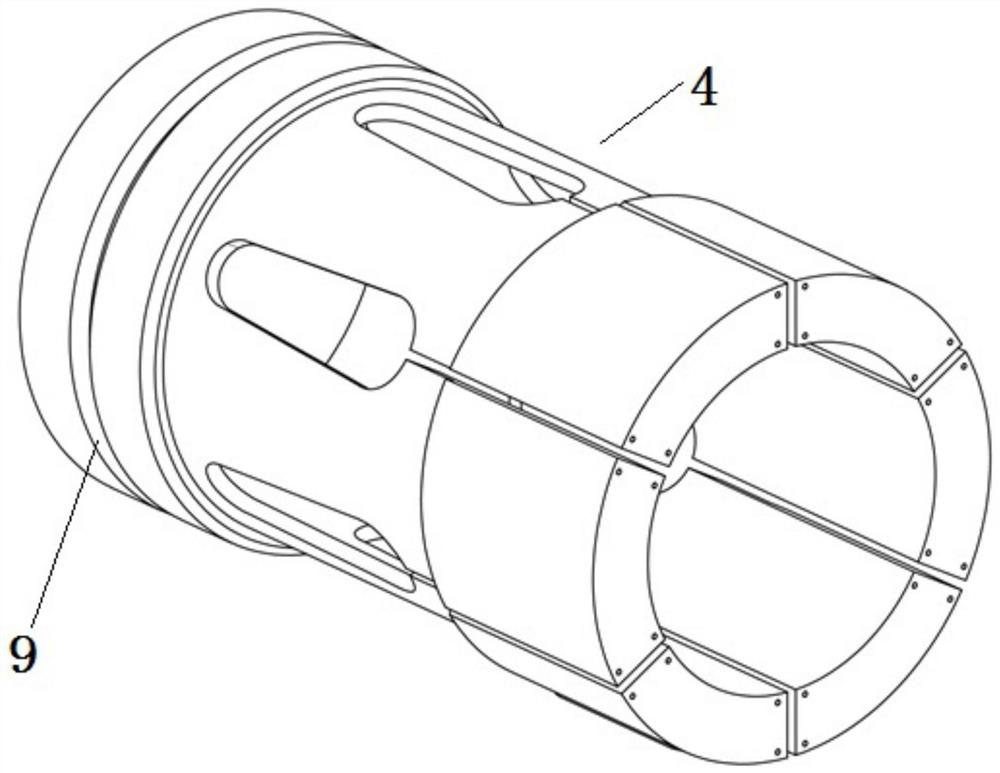

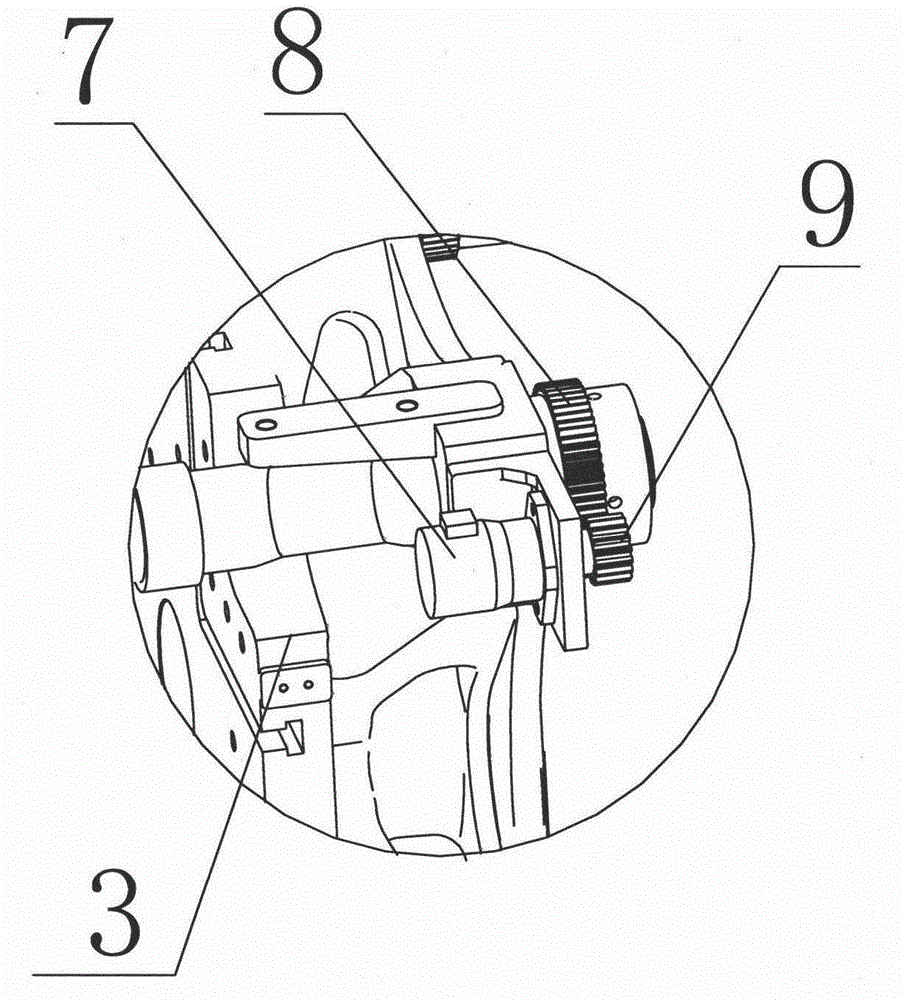

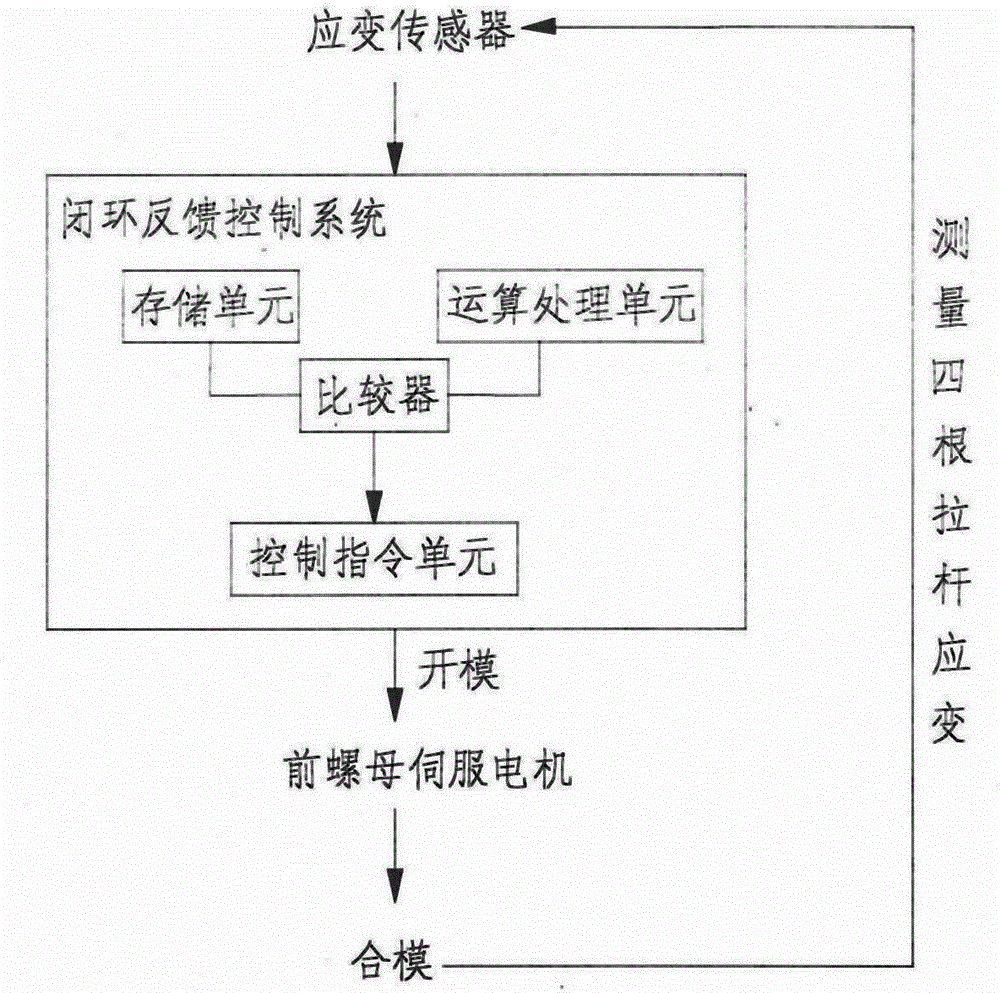

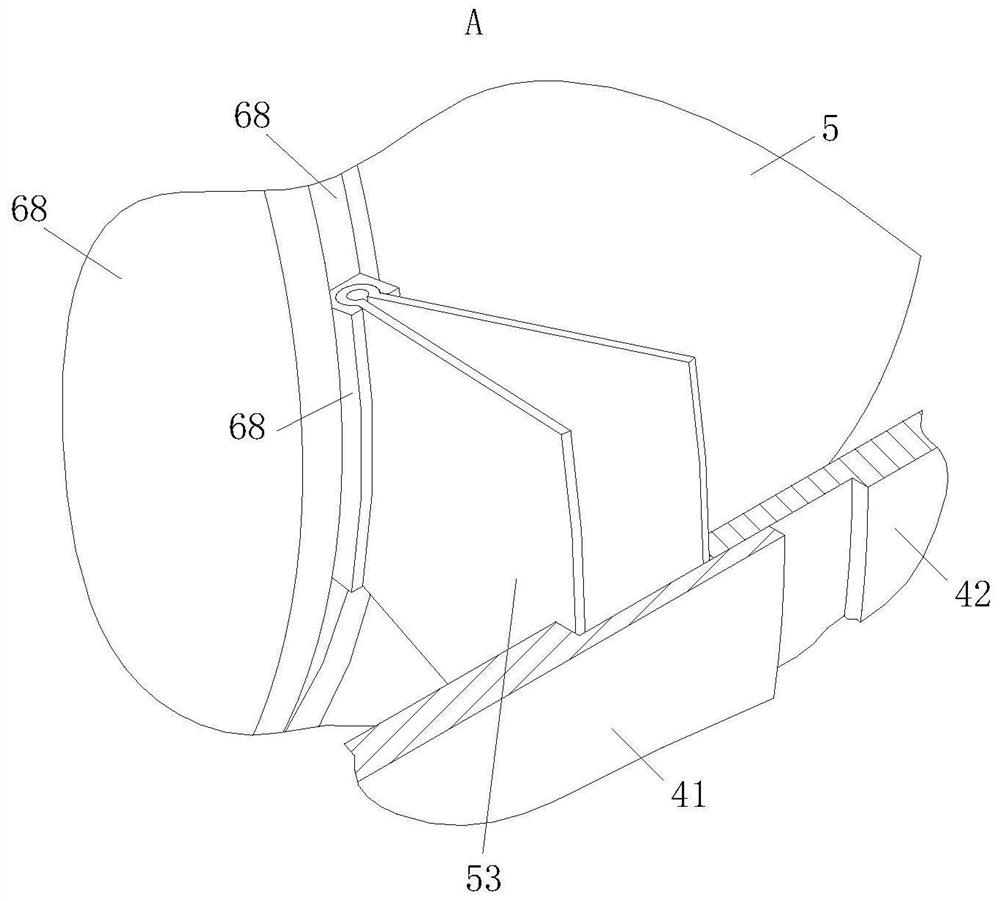

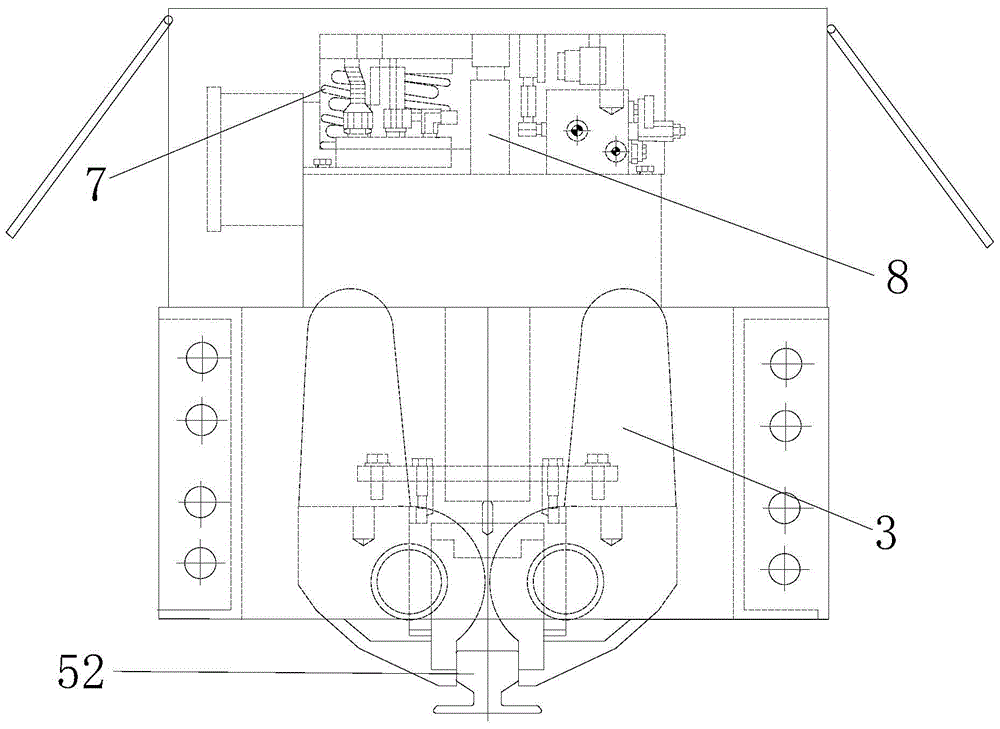

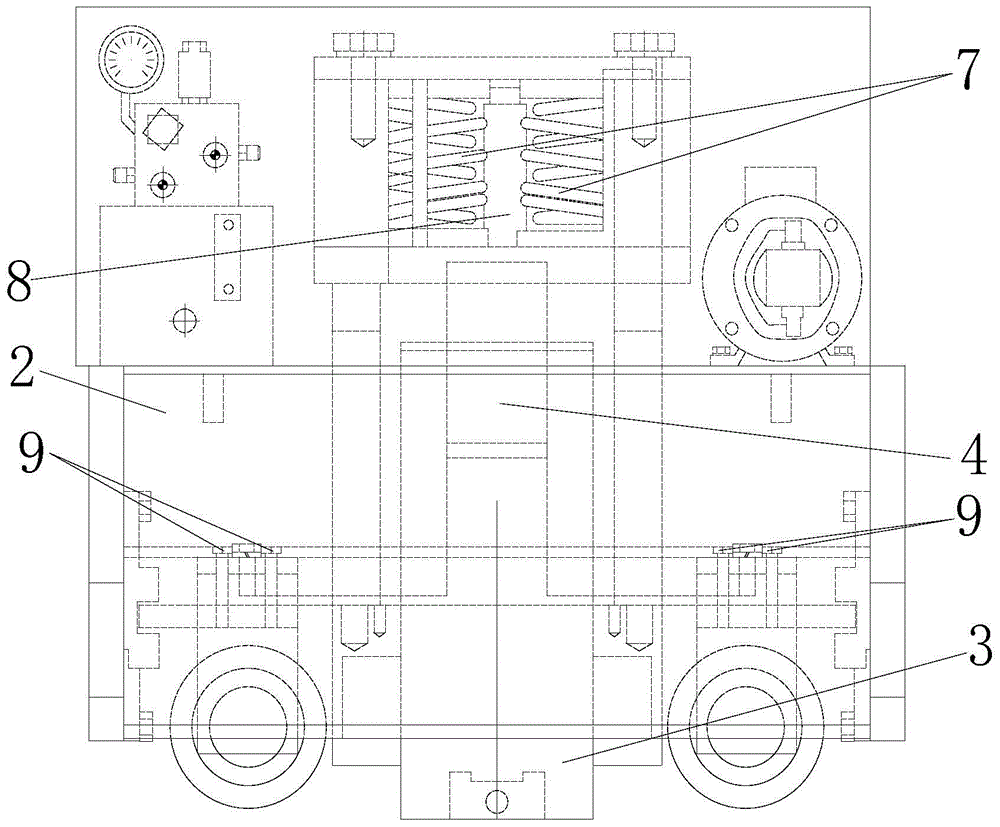

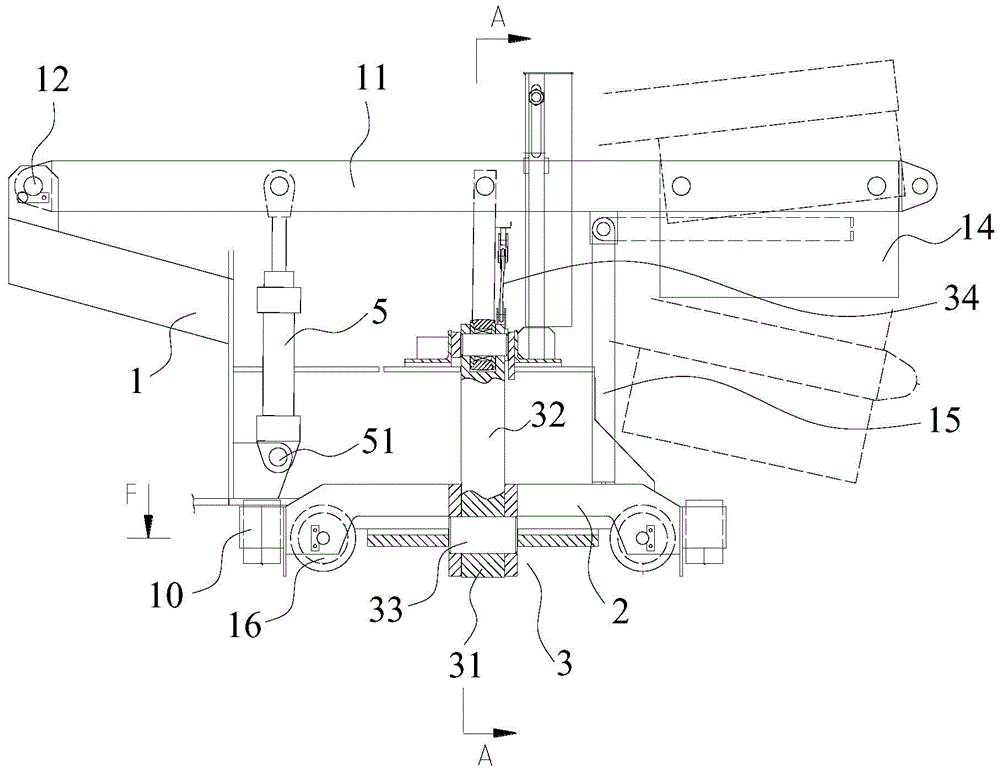

The invention discloses a mould-assembling mechanism for an injection molding machine and a balancing and adjusting method for a mould-assembling force thereof. The mould-assembling mechanism comprises a rear mould plate (1), a moveable mould plate (2), a front mould plate (3), a toggle rod mechanism (4), four pull rods (5) and a pull rod adjusting mechanism, wherein the pull rod adjusting mechanism comprises strain foils (6), servo motors (7) and front nuts (8) which are one-to-one corresponding to the four pull rods (5); the positions and directions of the strain foils (6) on the four pull rods (5) are consistent; the peripheral surfaces of the front nuts (8) are gear-shaped; driving gears (9) are connected with the servo motors (7); and the driving gears (9) are engaged with the peripheral surfaces of the front nuts (8). The uniform stress of the four pull rods is realized by adopting a closed-loop feedback control balancing and adjusting method, so that the function of balancing and adjusting the mould-assembling force is achieved, the reliability of the mould-assembling mechanism is high and the service life is long.

Owner:TEDERIC MACHINERY

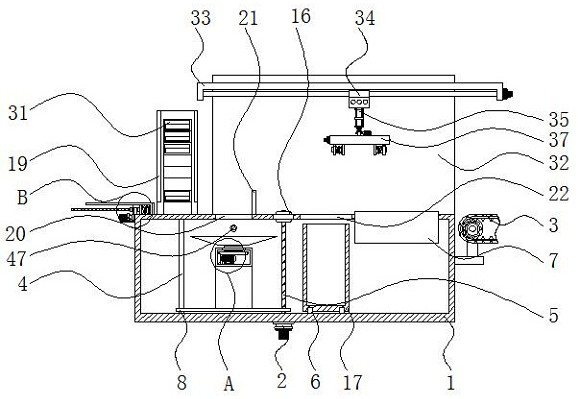

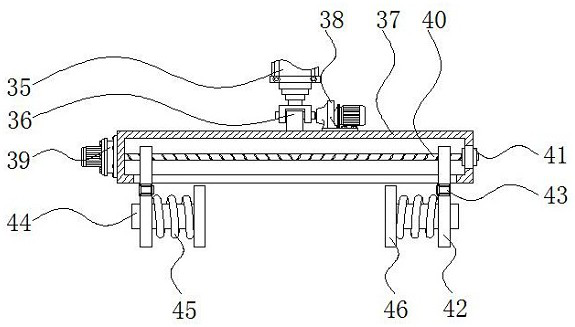

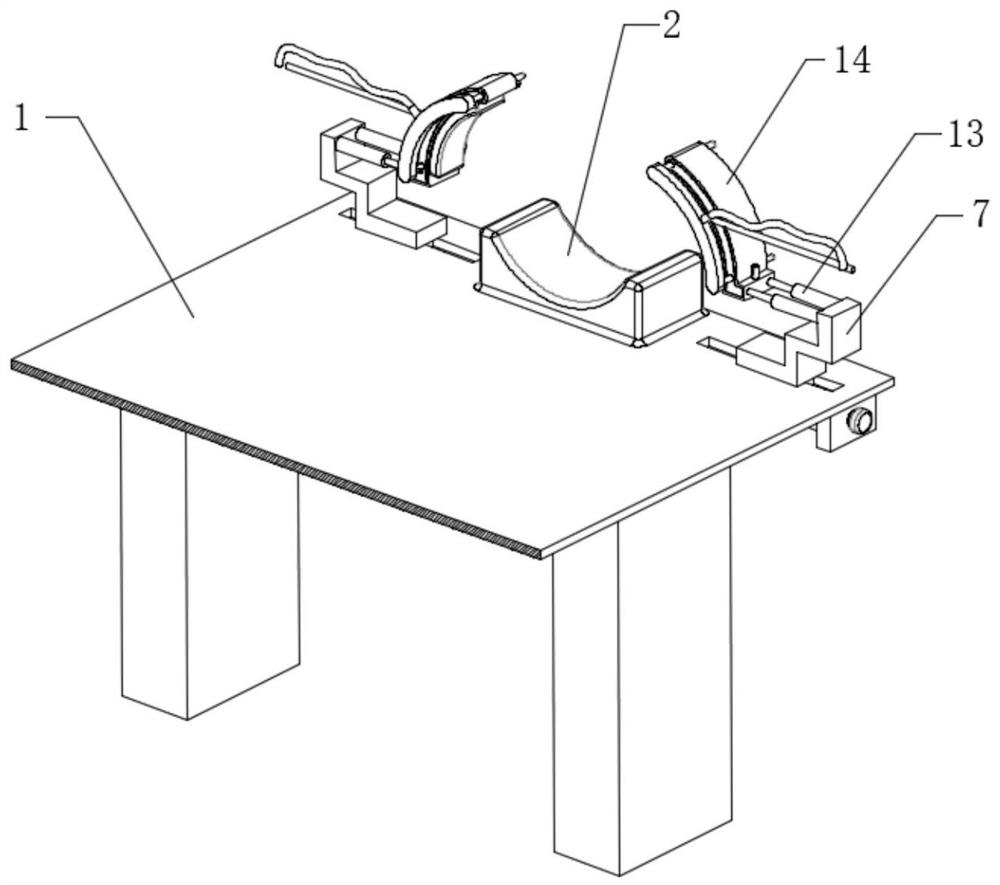

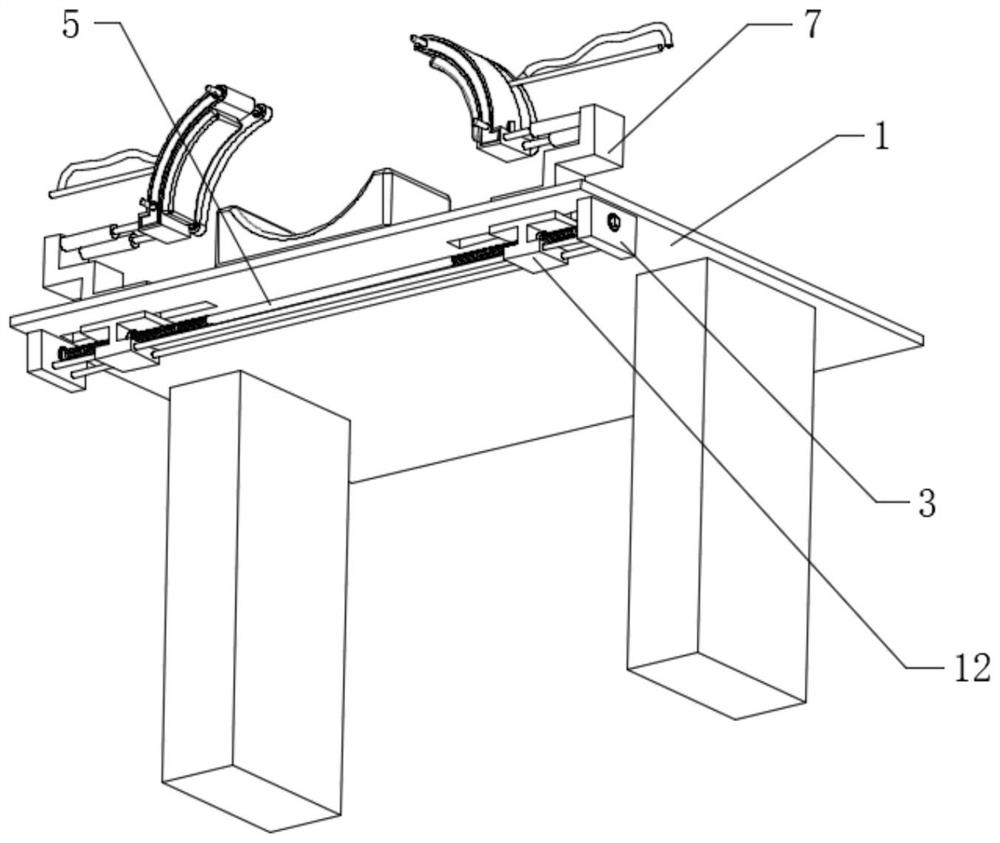

Textile machine yarn guide device

InactiveCN110980421AClamping force adjustmentReasonable structureFilament handlingYarnTextile technology

The invention relates to the technical field of textiles and discloses a textile machine yarn guide device. The textile machine yarn guide device comprises a bottom plate, a first fixing seat is arranged on the left side of the upper surface of the bottom plate, a containing groove is formed in the upper portion of the first fixing seat, a winding roller is arranged in the containing groove, a second fixing seat is arranged in the middle of the upper surface of the bottom plate, a tension roller is connected with the upper portion of the second fixing seat in a rotating mode, a third fixing seat is arranged on the right side of the upper surface of the bottom plate, a supporting roller is connected with the middle of the third fixing seat in a rotating mode, a sliding groove is formed in the upper portion of the third fixing seat, a pressing roller is connected with the lower portion of the sliding groove in a sliding mode, a pressing block is connected with the middle of the sliding groove in a sliding mode, and the upper portion of the pressing block is connected with the lower end of a spring. According to the textile machine yarn guide device, the pressing roller capable of sliding vertically is arranged on the right side of the device, and thus the free end of yarn is clamped tightly through the pressing roller and the supporting roller; and besides, the deformation amountof the spring changes along with rotation of a lead screw, and thus the clamping force of the pressing roller to the yarn can be adjusted freely.

Owner:唐红英

Butterfly spring connector

ActiveCN105514642AEasy to manufactureStrong clamping forceCoupling contact membersClamped/spring connectionsAcute angleEngineering

A butterfly spring connector comprises a framework, a butterfly spring, a supporting plate and a clamping plate, all of which are integrated. The framework has a first frame and second and third frames on the two sides of the first frame, and the first, second and third frames define a bottom side. The butterfly spring includes an upper elastic piece, a lower elastic piece and a side elastic piece which are connected in sequence, wherein the upper elastic piece and the lower elastic piece form an included angle which is an acute angle, the lower elastic piece and the side elastic piece form an included angle, the side elastic piece faces a direction vertical to the bottom side, and at least part of the edge of the side elastic piece is connected with the first frame. The supporting plate is formed at the third frame, and can abut against the lower elastic piece when the upper elastic piece of the butterfly spring is deformed under external force. The clamping plate is formed at the second frame, and is used for clamping a cable together with the upper elastic piece of the butterfly spring. The extending directions of the supporting plate and the clamping plate are the same with the extending direction of the side elastic piece when the side elastic piece is bent from the first frame.

Owner:DINKLE ENTERPRISE CO LTD

Cardiopulmonary cerebral resuscitation rescue device for emergency department

The invention discloses a cardiopulmonary cerebral resuscitation rescue device for the emergency department. The device comprises a treatment table, a pad block is fixedly arranged at the top of the treatment table, and grooves with openings in the tops are formed in the two sides of the pad block; a same rotation shaft is rotatably arranged on the inner walls of the two sides of each groove, aslant-arranged neck protection plates are fixedly arranged at the outer sides of the rotation shafts, and sliding grooves are formed in the inner walls of the bottoms of the grooves; pushing plates and sliding plates are slidingly arranged in the sliding grooves, the two pushing plates are located between the two sliding plates, and sliding rods are welded to the sides, away from each other, of the two pushing plates; the sliding plates are located below the sliding rods, sliding blocks are slidingly arranged at the outer sides of the sliding rods, and sliding rod holes are formed in the sides ofthe sliding blocks. The cardiopulmonary cerebral resuscitation rescue device for the emergency department is high in practical performance, simple in structure and convenient to operate, the positionof the neck of a patient is conveniently limited, the force of clamping the neck can be adjusted, the neck is prevented from moving, and the device helps medical personnel to treat the patient.

Owner:江苏天凤源食品有限公司

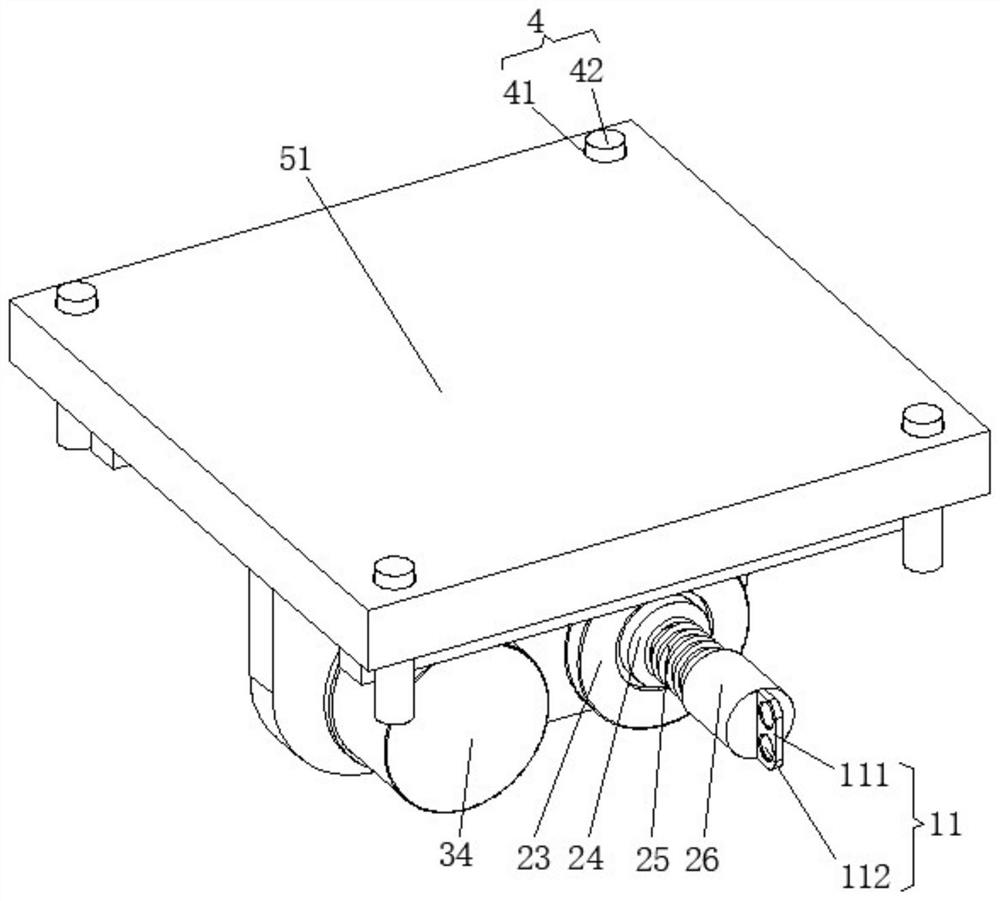

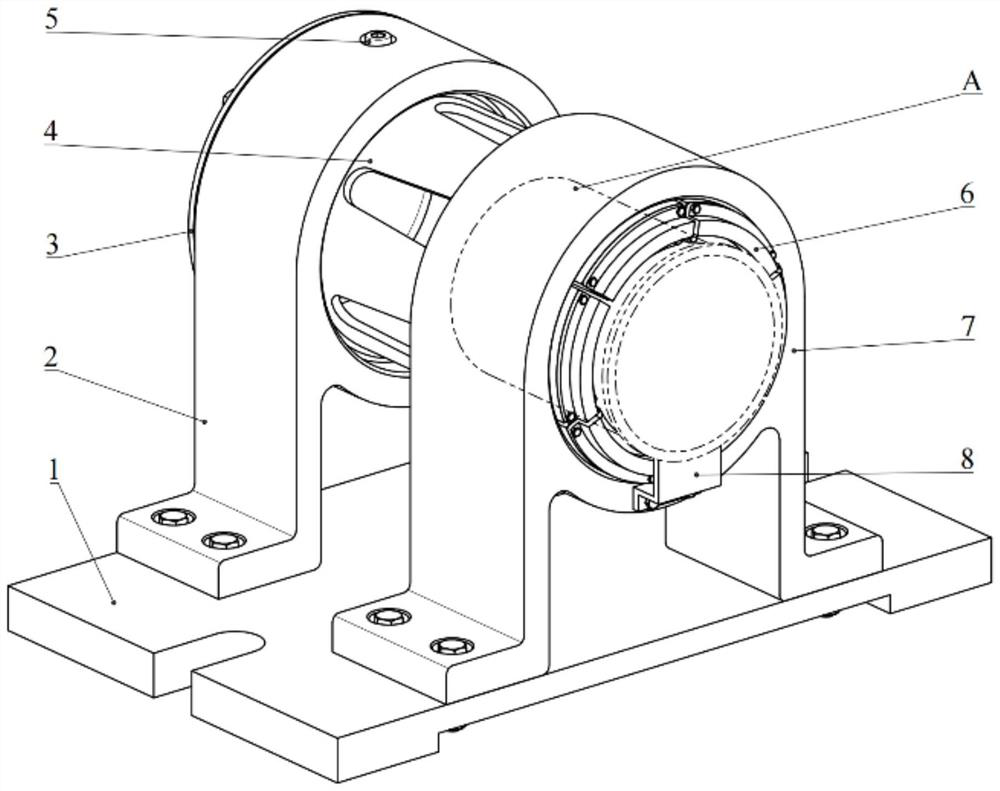

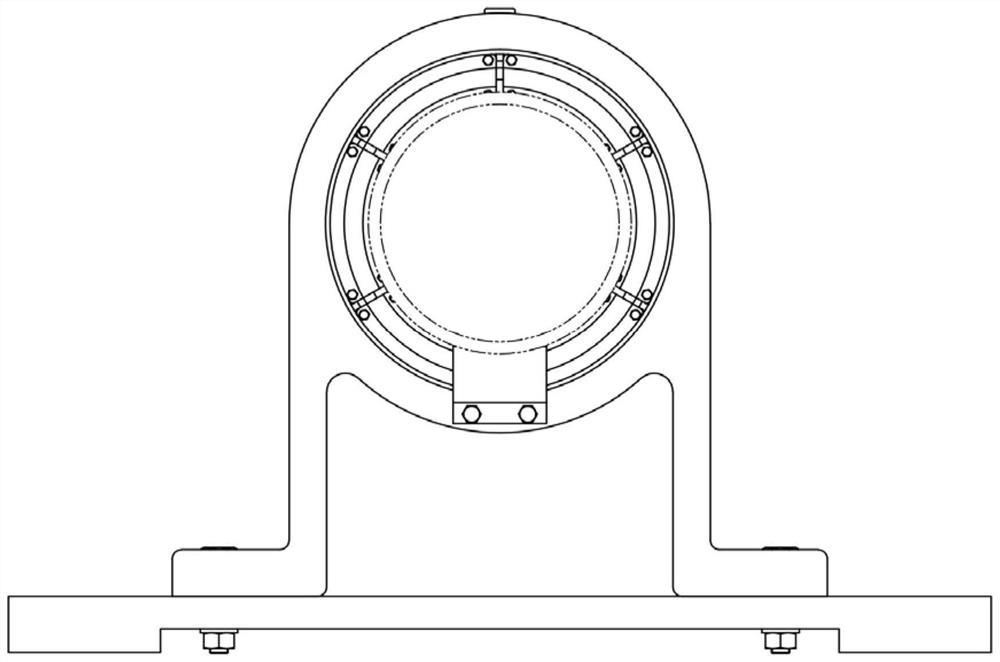

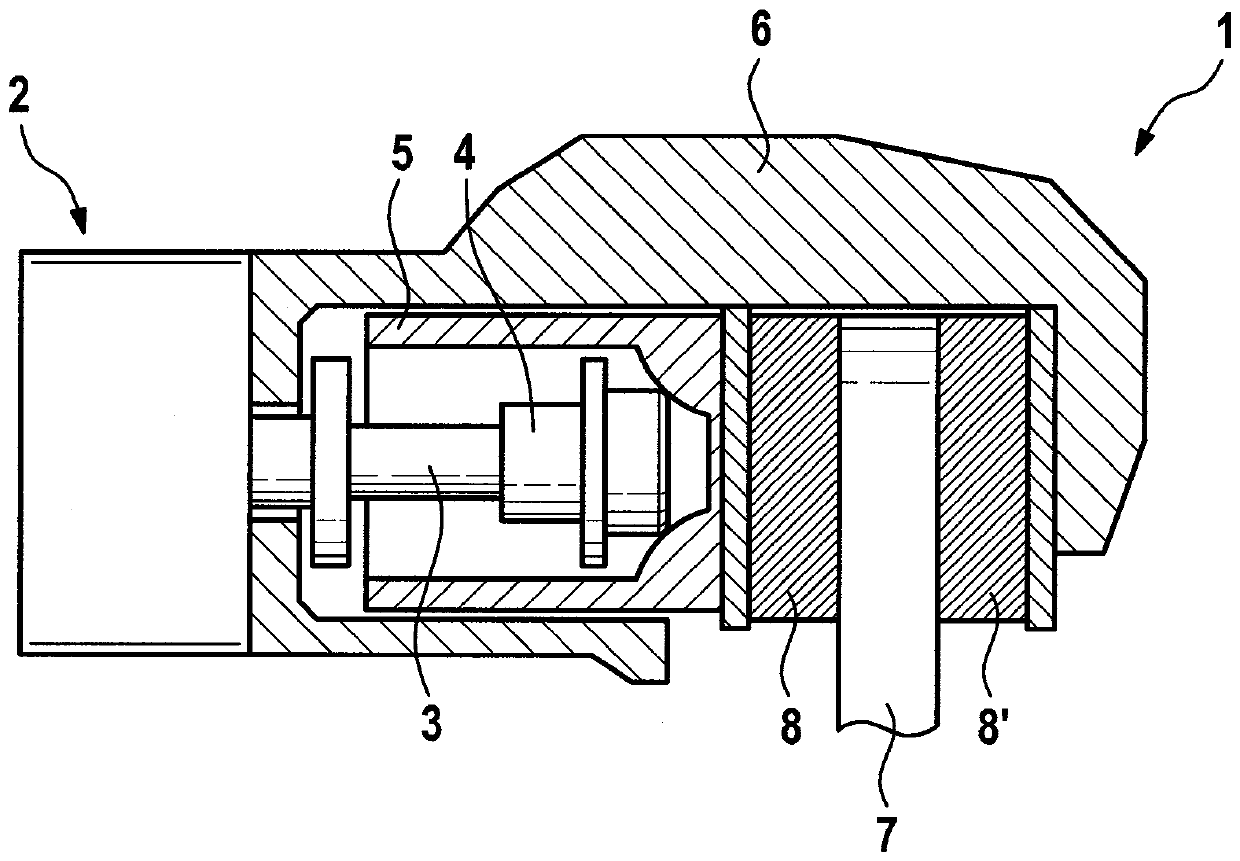

Clamp used for processing thin-wall sleeve component

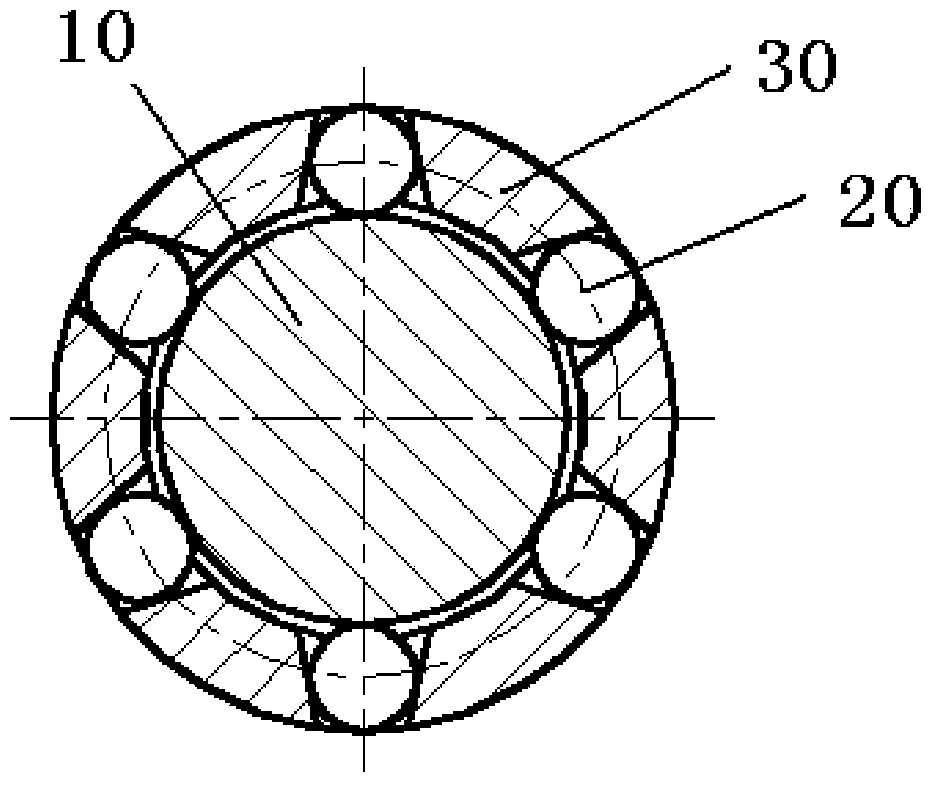

ActiveCN103737404AClamping force adjustmentEasy to adjustPositioning apparatusMetal-working holdersEngineeringMechanical engineering

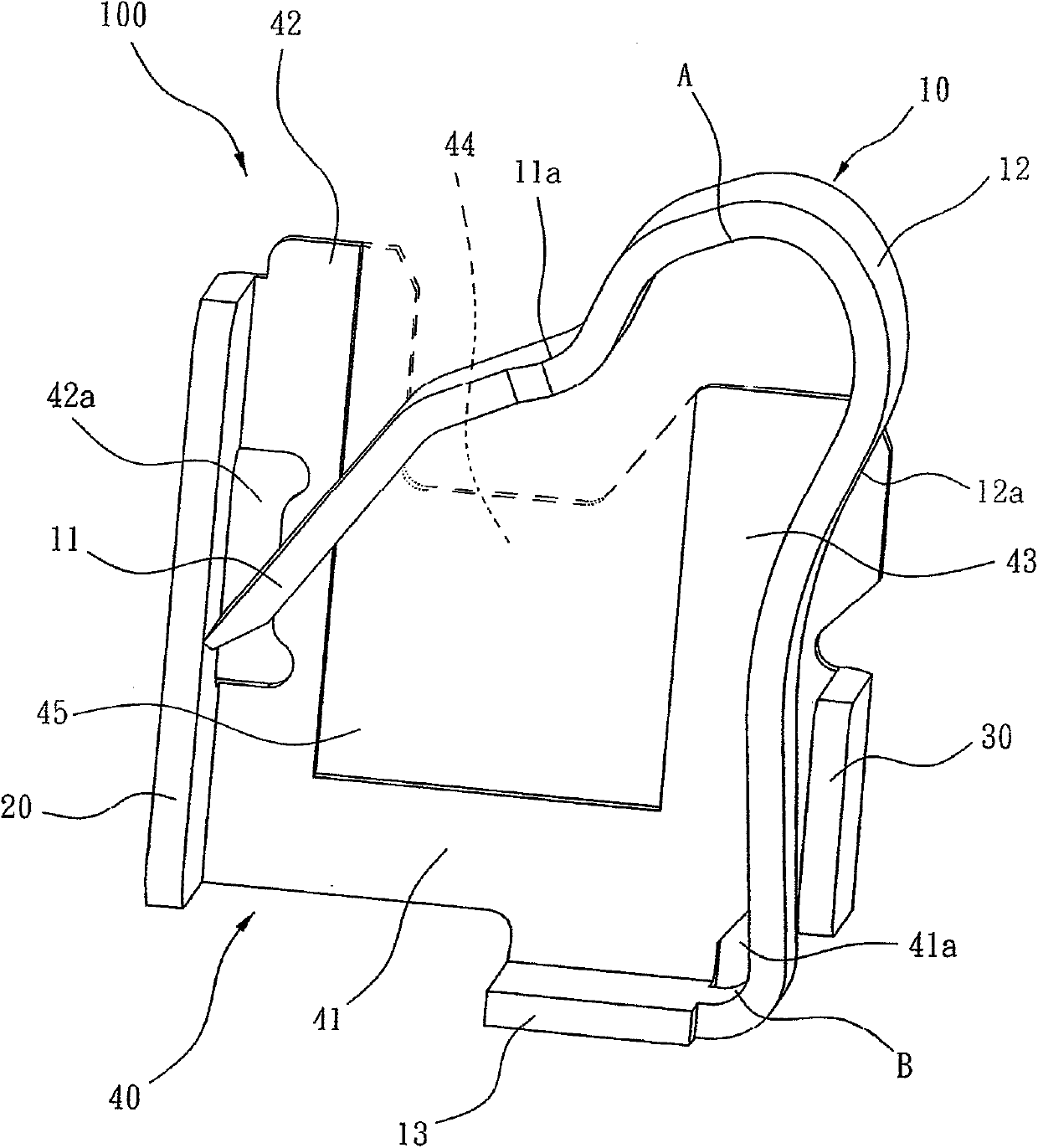

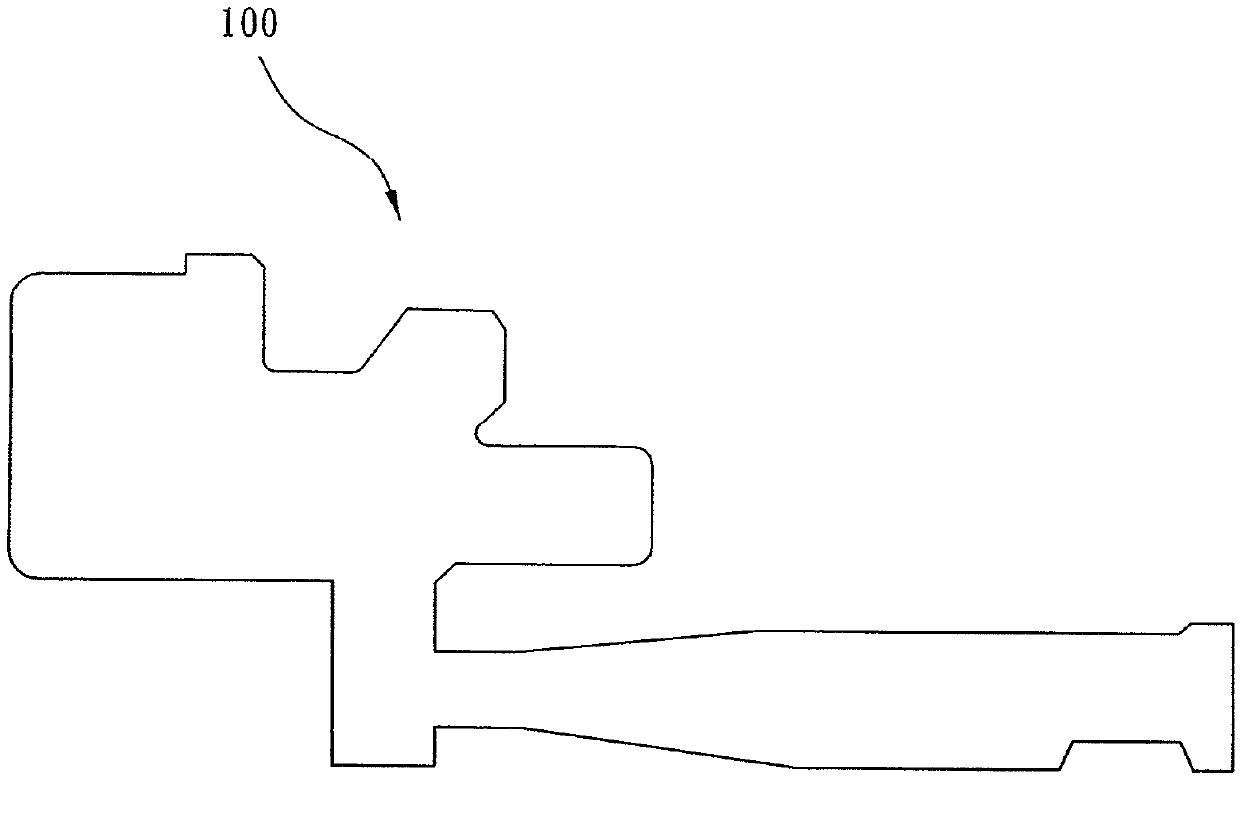

The invention discloses a clamp used for processing a thin-wall sleeve component. The clamp comprises a main body portion (10). An installation portion (11) used for installing the clamp on a processing machine and a work-piece arrangement portion used for clamping the thin-wall sleeve component (60) are formed in the main body portion (10). The clamp is characterized in that the work-piece arrangement portion comprises a cone-shaped portion (14) which becomes smaller from the installation portion (11), and balls (20). The balls (20) can abut against the thin-wall sleeve component (60) and move along the axial direction of the cone-shaped portion (14) so as to protrude outwards and exert centring effect on the thin-wall sleeve component (60), and therefore the clamping force exerted on the thin-wall sleeve component (60) can be adjusted accurately, and the thin-wall sleeve component does not deform.

Owner:ZOOMLION HEAVY IND CO LTD

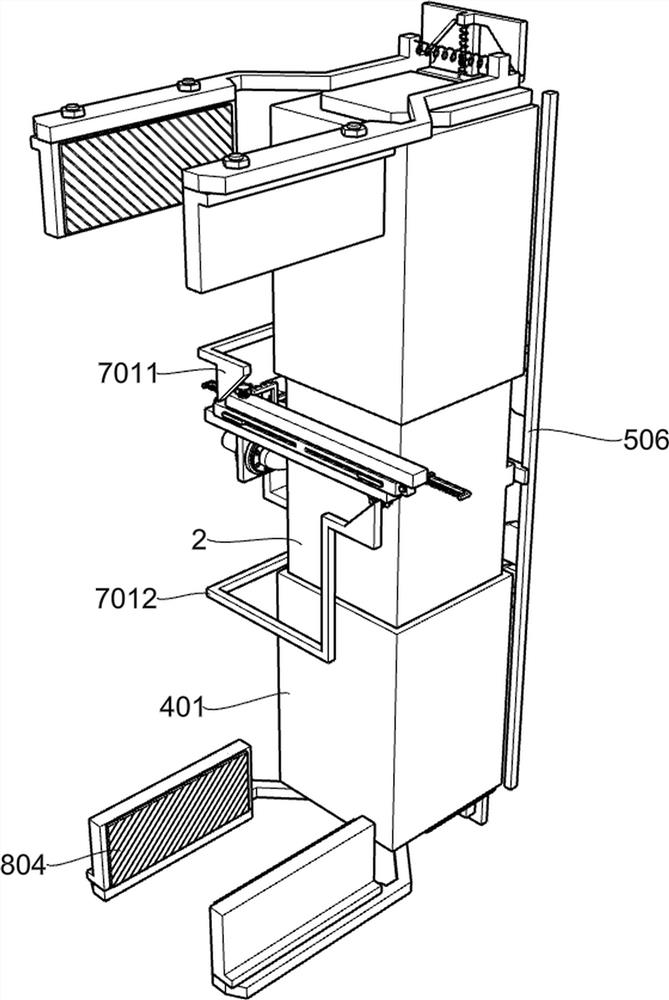

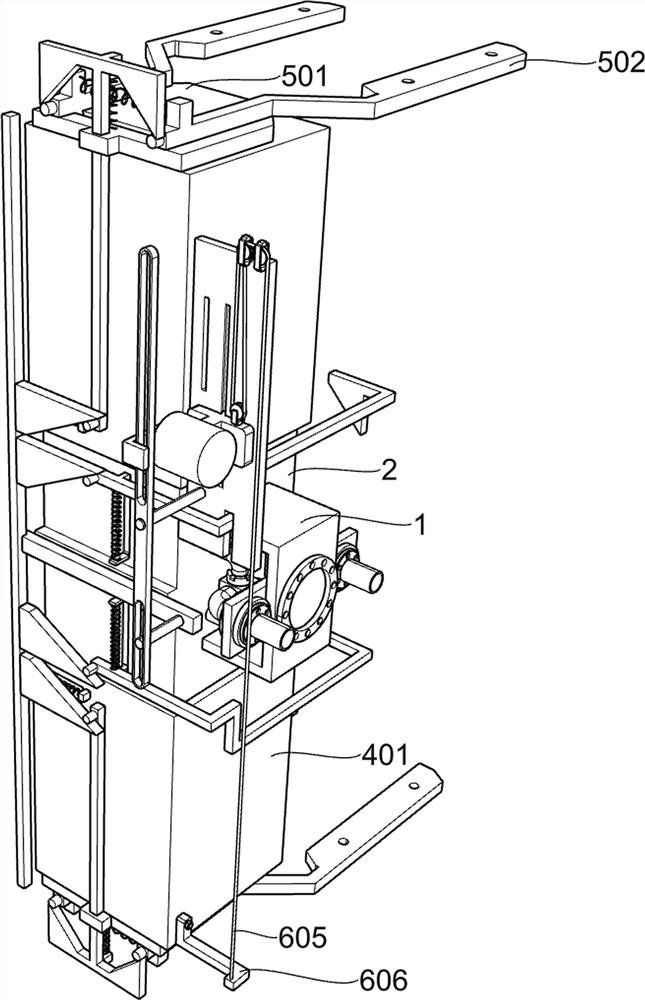

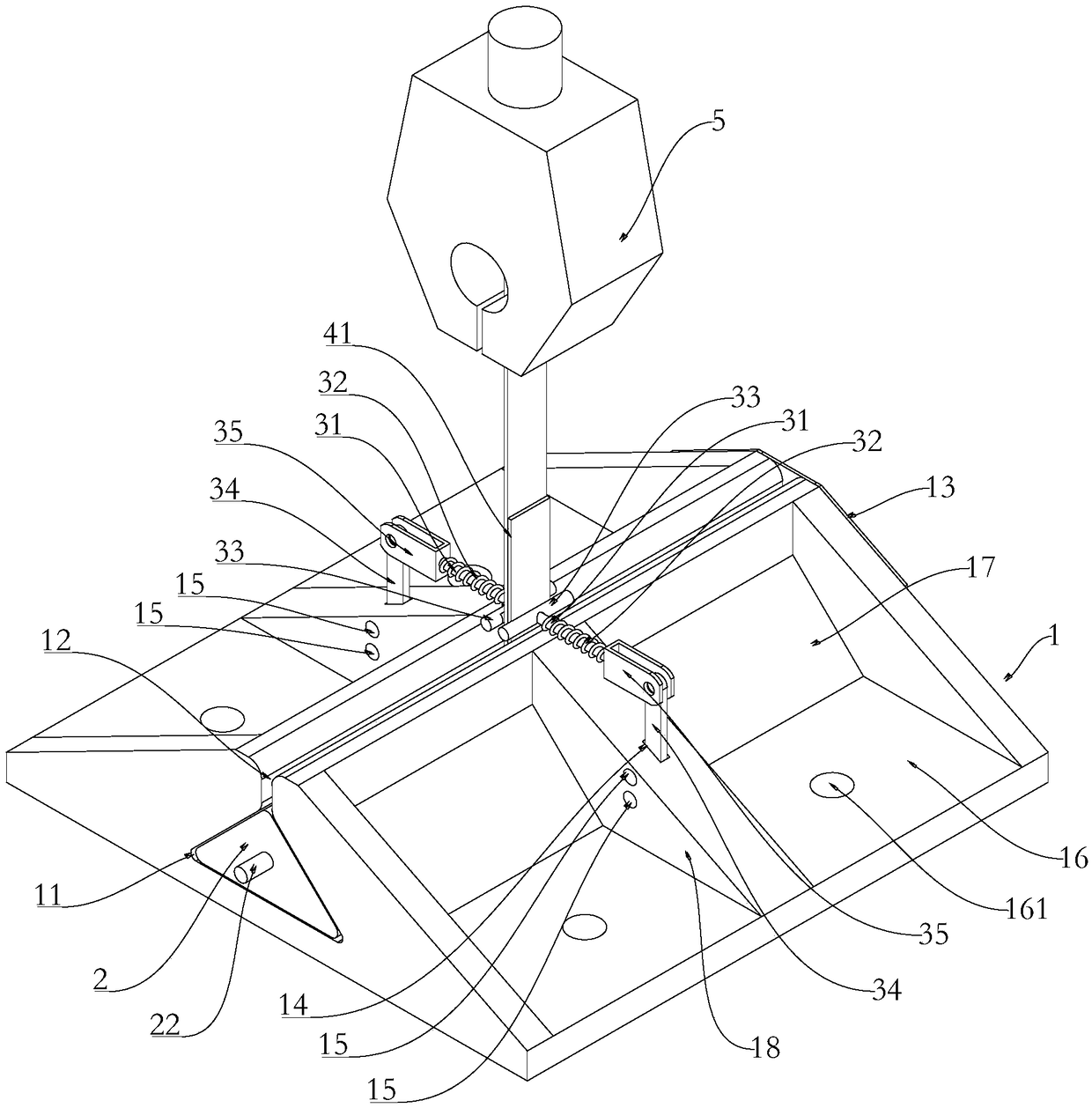

Direct current railway steel rail flash butt welder for rapid pressure maintaining push protruding

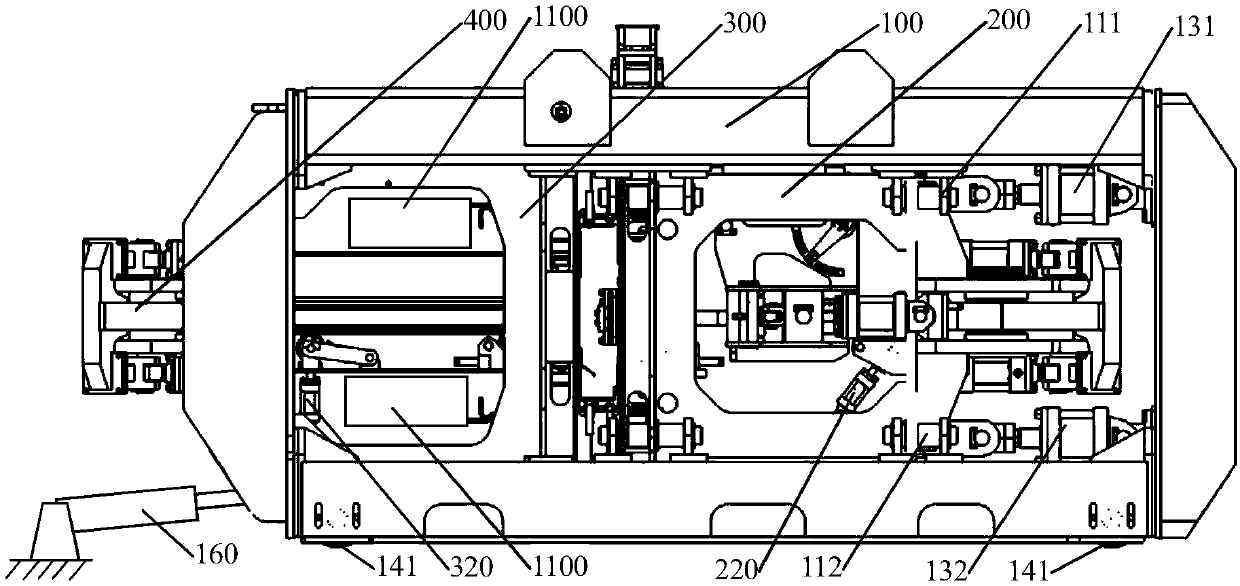

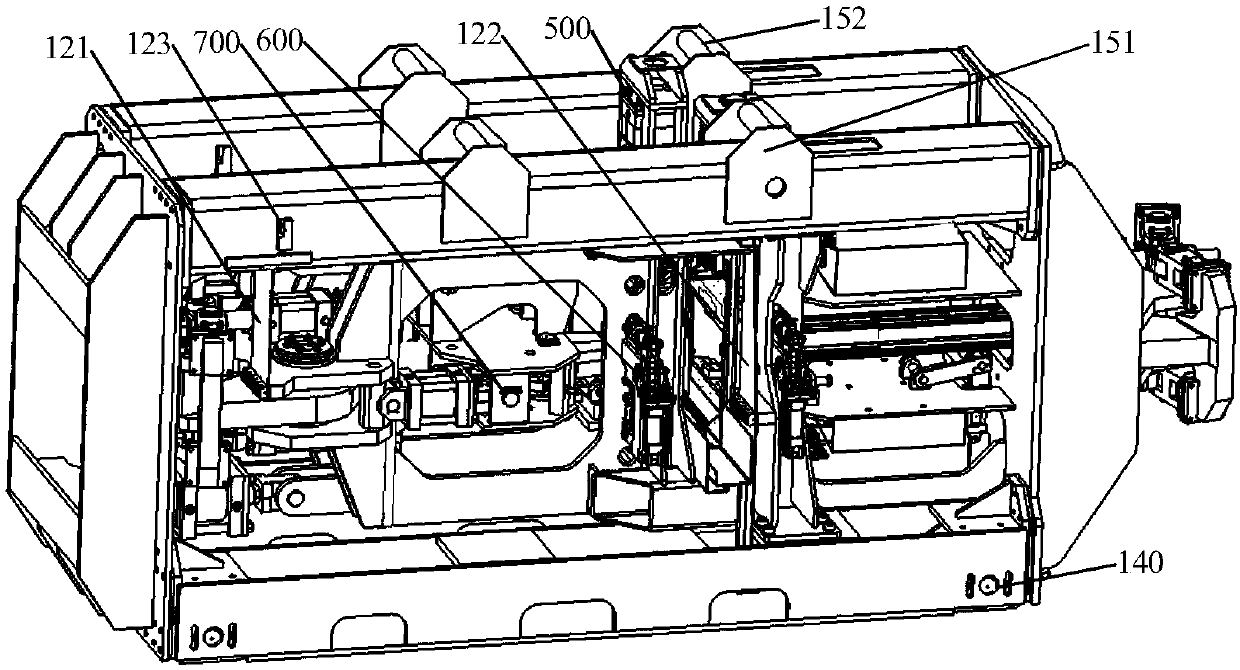

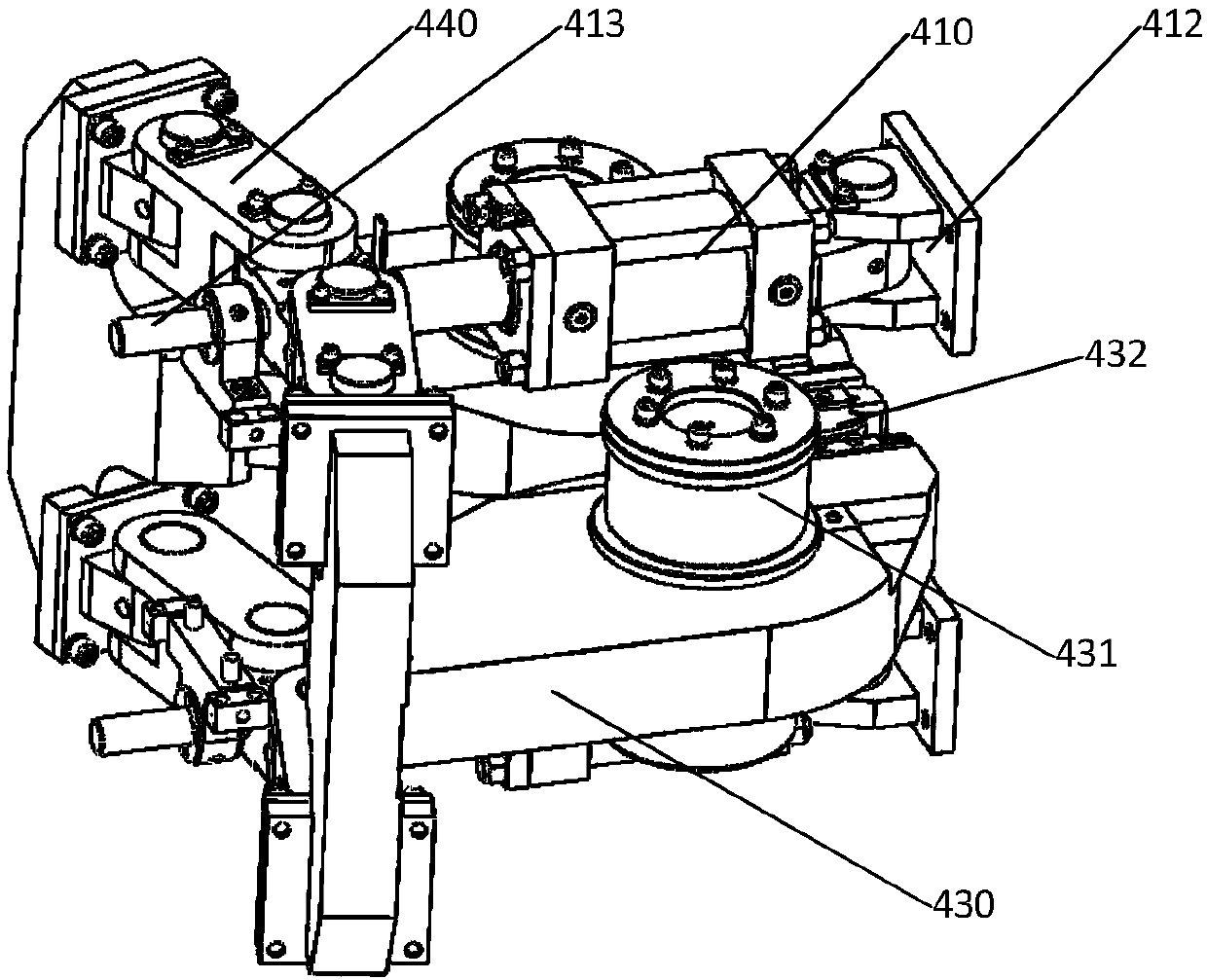

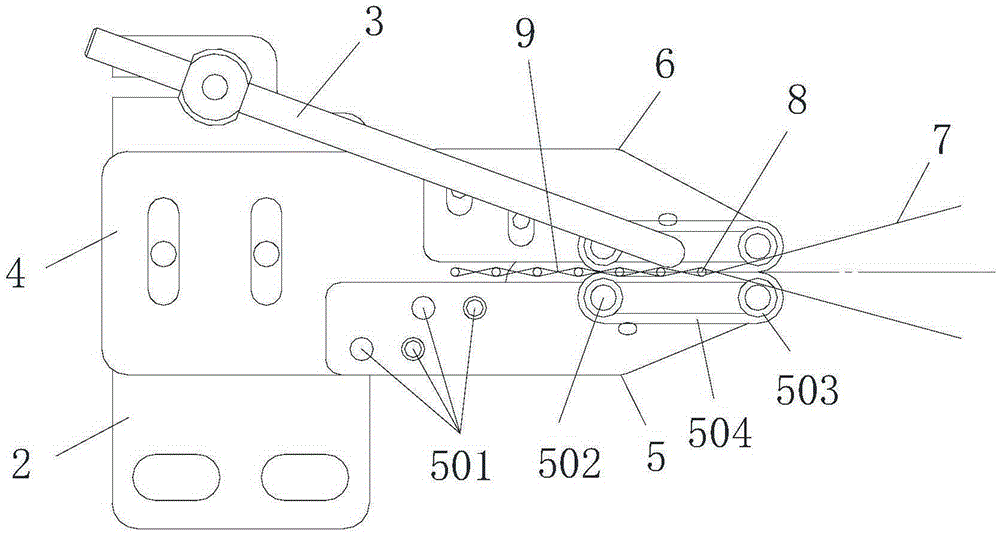

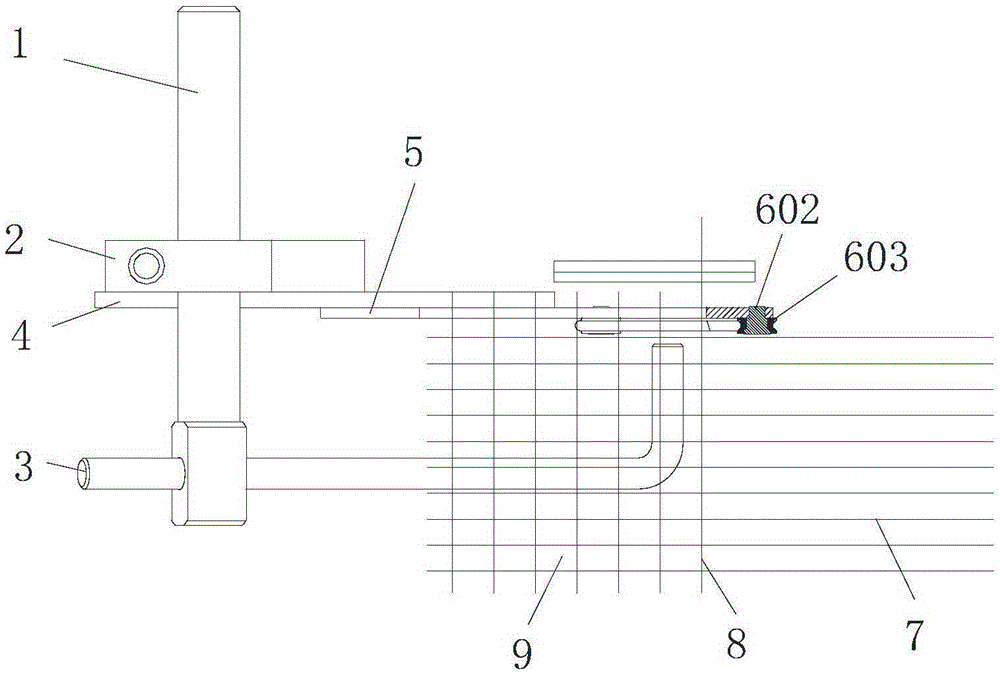

ActiveCN107671403AClamping force adjustmentImprove reliabilityRailsResistance electrode holdersFixed frameEngineering

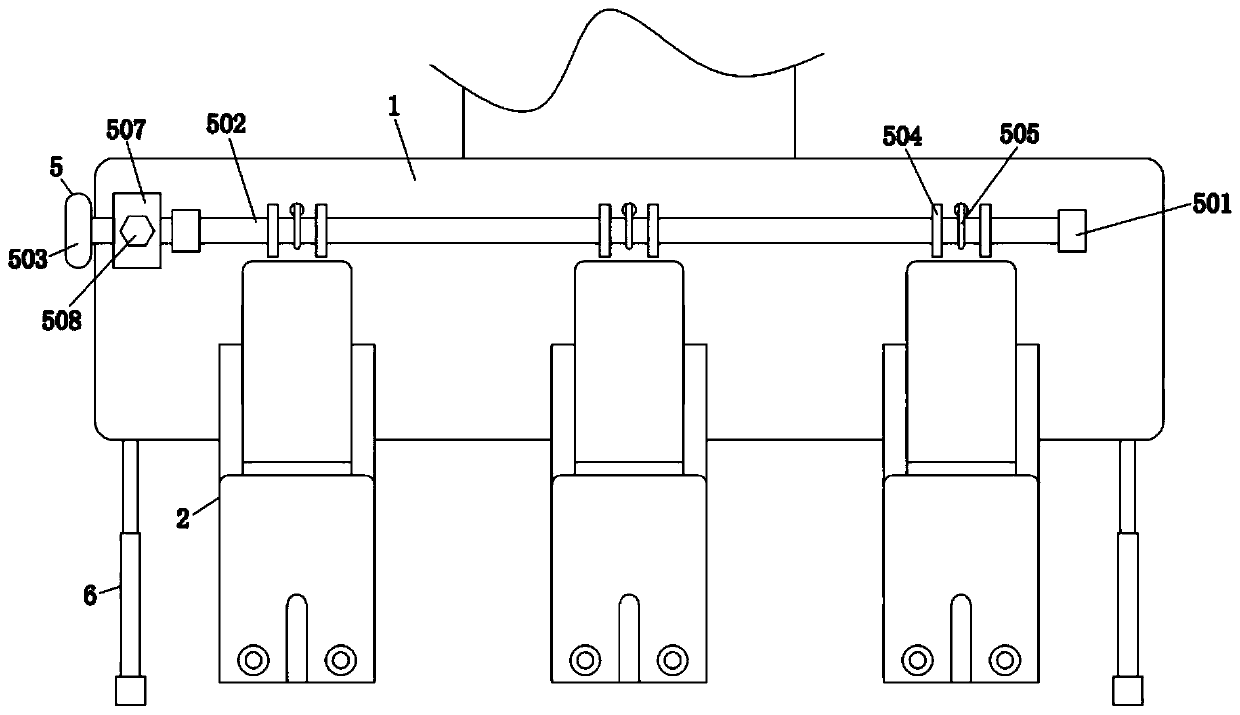

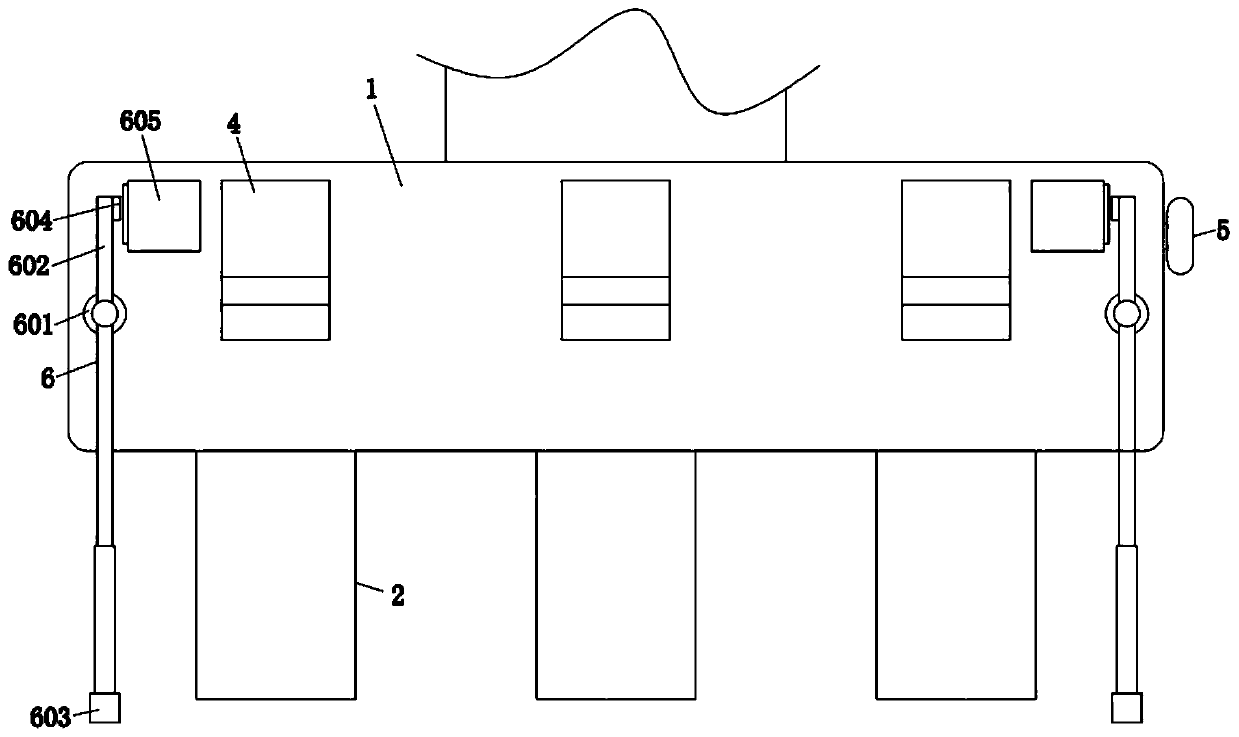

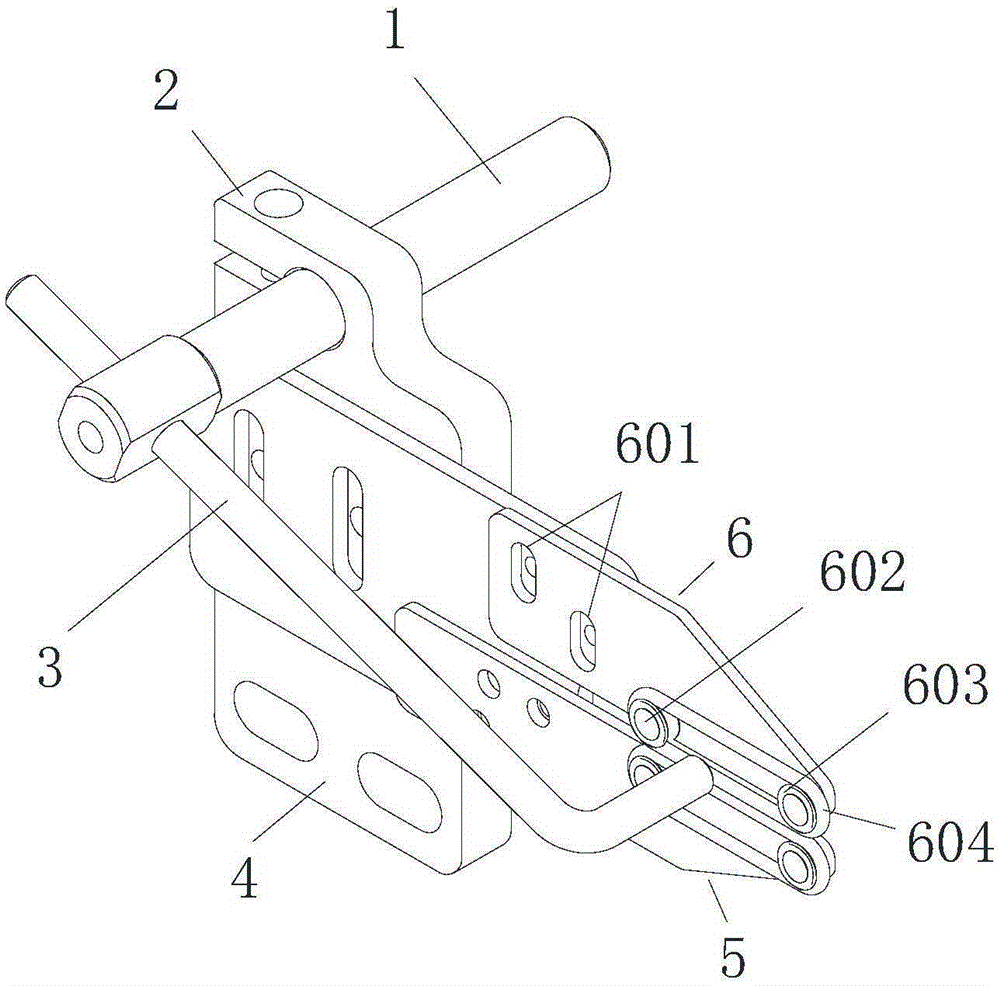

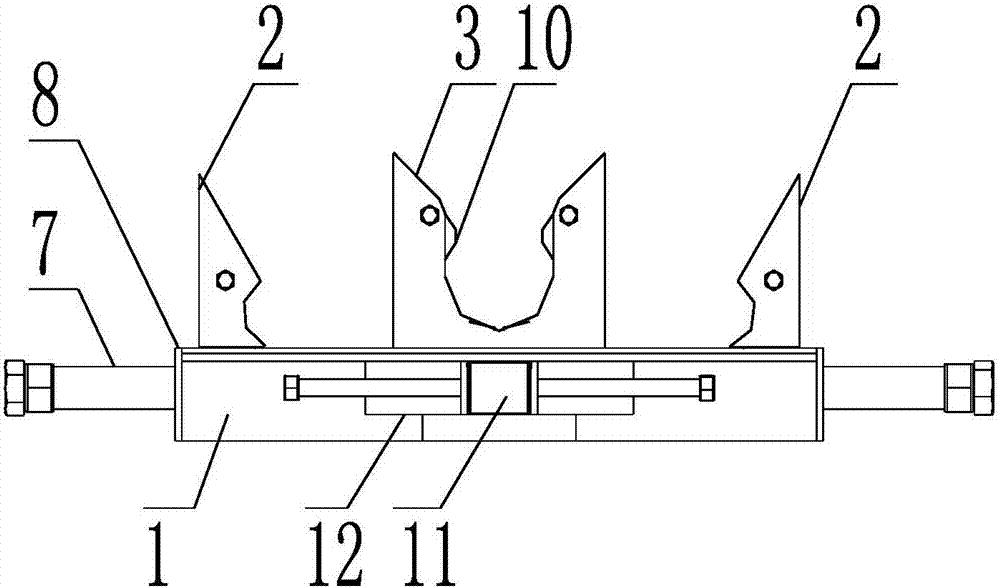

The invention provides a direct current railway steel rail flash butt welder for rapid pressure maintaining push protruding. The direct current railway steel rail flash butt welder comprises a frame (100), a movable frame (200), a fixed frame (300), a rail web clamping mechanism (400), a vertical electrode clamping mechanism (500), a horizontal steel rail adjusting mechanism (600) and a steel railwelding connector push protruding mechanism (700). By means of the direct current railway steel rail flash butt welder for rapid pressure maintaining push protruding, during welding upsetting, a connector is evenly stressed up and down, the bending moment caused by upsetting is eliminated, and accordingly straightness of a steel rail flash welding head is ensured. Through an independent push protruding mechanism and a special push protruding oil cylinder, push protruding in the state of vertical and horizontal connector displacement locking (connector pressure maintaining) is achieved, and the situation of connector pulling at the high temperature is avoided; and through a steel rail web connecting rod clamping mechanism, the steel rail web clamping efficiency is further improved, and meanwhile the clamping force can be adjusted by adjusting the connecting rod angle.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +3

Self-clamping lifting mechanism

PendingCN108928737AClamping force adjustmentAdjust the clamping strokeLoad-engaging elementsNew energyEngineering

The invention relates to the technical field of production and assembling of a gearbox housing of a new energy automobile, in particular to a self-clamping lifting mechanism comprising a fixed shaft,a bracket, a clamping arm, a clamping claw, a sliding sleeve, a lifting ring, a connecting sleeve, an internal thread rotating sleeve, and a screw rod. The bracket is arranged at the bottom of the fixed shaft; and a chute is formed in the bracket. The clamping arm is hinged to the chute; and the clamping claw is connected to the clamping arm. According to the invention, an external device hooks the lifting ring and drives the sliding sleeve to slide on the fixed shaft in a sleeving manner; the screw rod is dragged to drive the clamping arm to rotate along a hinge part with the bracket, therebyrealizing clamping and thus realizing automatic clamping during the lifting process. With the internal thread rotating sleeve, the screw rod, and the connecting sleeve, the internal thread rotating sleeve rotates to drive the screw rod in threaded connection to move along the axial direction of the connecting sleeve, thereby realizing adjustment of the clamping force of the clamping arm; and withthe adjusting mechanism, adaptability to lifting of gearbox housings with different sizes is enhanced.

Owner:安徽航科自动化设备有限公司

Telescopic manipulator claw arm structure

The invention relates to a telescopic manipulator claw arm structure and belongs to the field of manipulators. The telescopic manipulator claw arm structure comprises a U-shaped connecting plate, a concentric-square-shaped frame, a partition plate, a telescopic adjusting component and the like. The hollow-square-shaped frame is fixedly connected to the rear side of the U-shaped connecting plate, the partition plate is fixedly connected to the middle in the hollow-square-shaped frame, the telescopic adjusting component is arranged on the hollow-square-shaped frame, and through cooperation of a movable pulley and other devices, the telescopic manipulator claw arm structure is adjusted to extend, meanwhile, the position of a pushing plate can move upwards, and the force application point of the pushing plate on a slotting swing rod moves upwards, so that a power arm is lengthened; therefore, the clamping force of the clamping strip to an object is increased, and the purpose of adjusting the clamping force according to the length of the object is achieved.

Owner:湖南力云智能科技有限公司

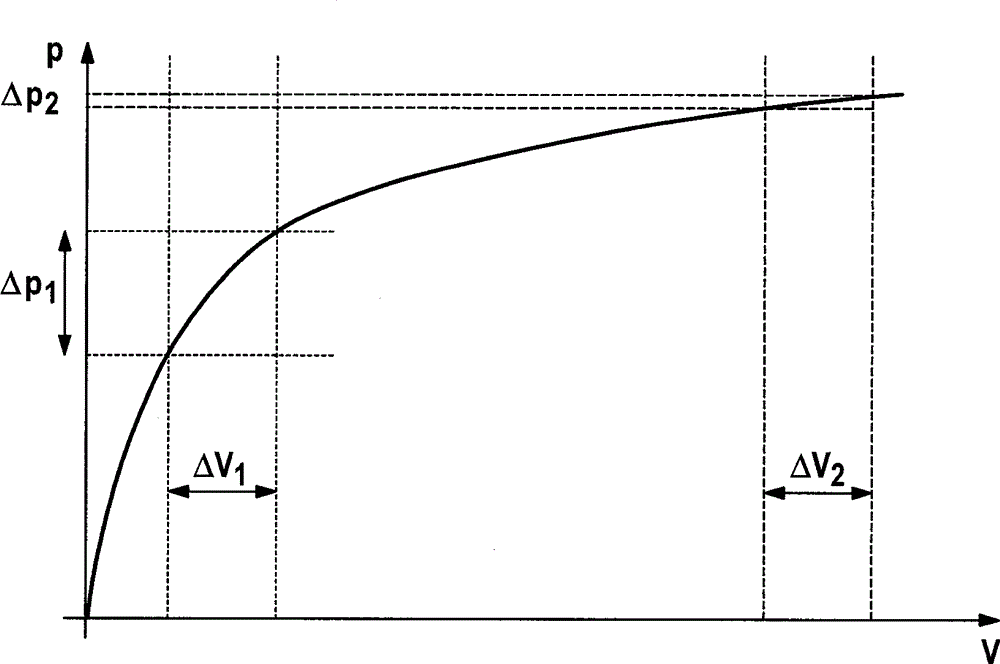

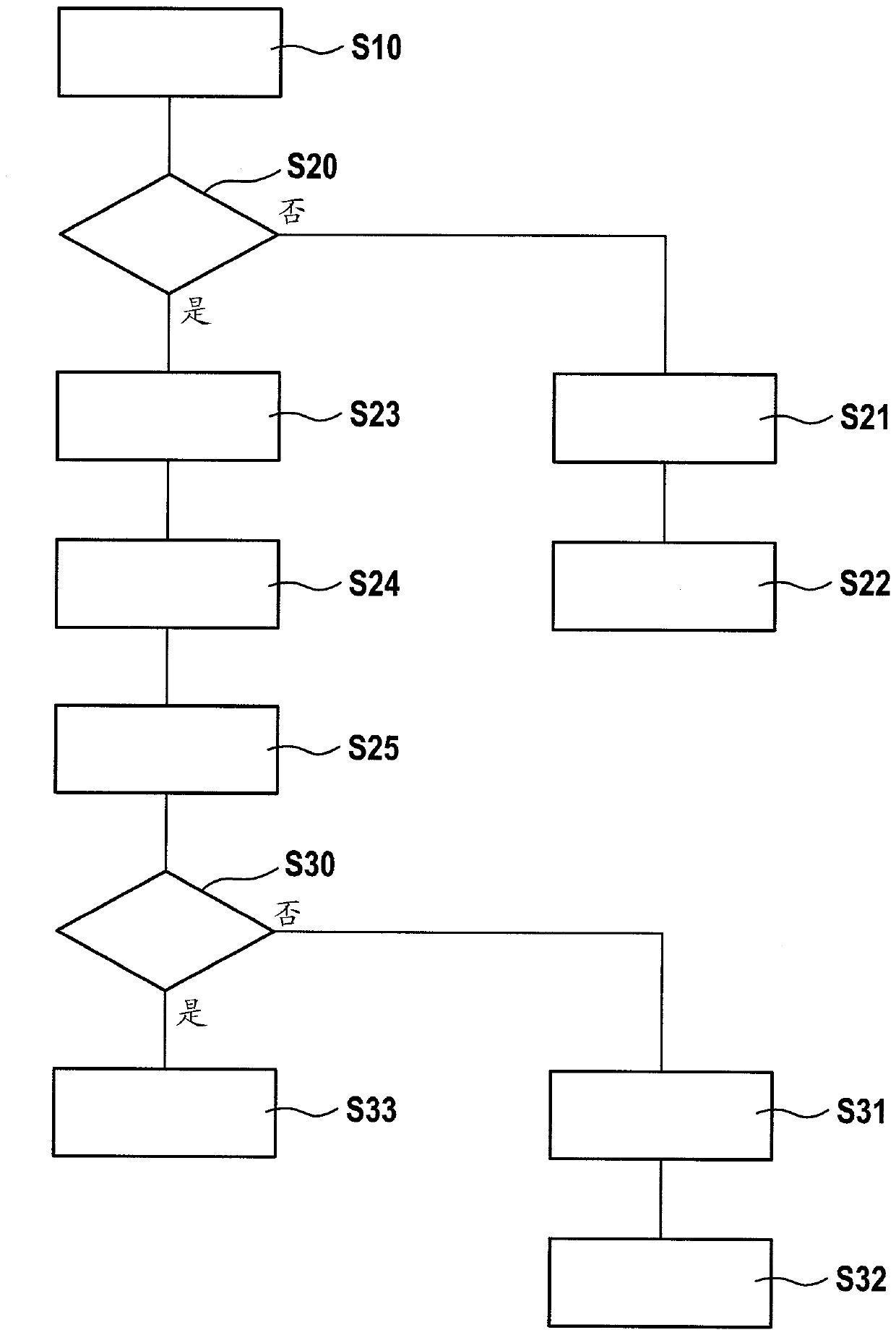

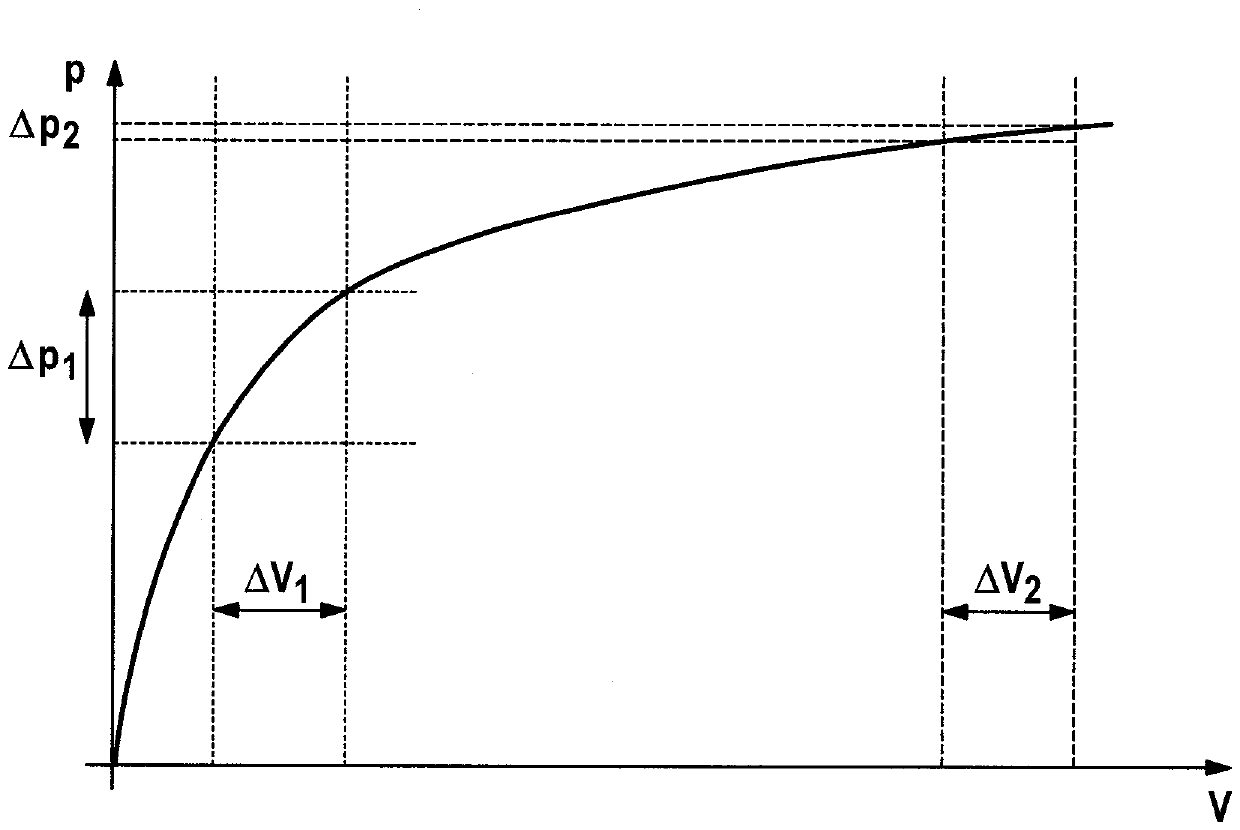

Method for Providing a Clamping Force that is Generated by Means of an Automatic Parking Brake for a Vehicle

ActiveCN104828055AEasy to operateGood for running braking characteristicsAxially engaging brakesBraking action transmissionControl theoryParking brake

A method for providing a clamping force that is generated with an automatic parking brake for a vehicle using a brake motor and a brake piston that acts upon a brake disk, includes building up a hydraulic pressure in a braking circuit of the vehicle after the automatic parking brake is applied. The method further includes determining a pressure loss gradient in the braking circuit of the vehicle. The method further includes performing or not performing a further application of the automatic parking brake based in part upon the determined pressure loss gradient.

Owner:ROBERT BOSCH GMBH

Detection device convenient to adjust and clamp for processing electronic parts for communication

InactiveCN112044813AEasy to insertPrecise positioningWork holdersStatic storageGear wheelElectric machinery

The invention relates to a detection device convenient to adjust and clamp for processing electronic parts for communication. The detection device comprises an equipment box body and a connecting gear, wherein a first motor is arranged below the equipment box body, a first guide rod, a first threaded rod and a guide rail are sequentially arranged in the equipment box body from left to right, a supporting block is fixed at the upper end of a connecting plate, one end of a second motor is connected with a first bevel gear, a first wheel shaft is arranged outside a first rotating shaft, and a limiting fixing block, a storage box, a telescopic opening, a positioning baffle, a collecting opening and a USB expansion block are sequentially arranged at the upper end of the equipment box body fromleft to right. The detection device convenient to adjust and clamp for processing the electronic parts for communication has the beneficial effects that a clamping structure is prevented from being loosened during clamping force adjustment through a spring, the clamping force of the equipment is converted into the telescopic amount of the spring through the spring, so that the clamping force of the clamping structure can be visually measured and adjusted.

Owner:王睿

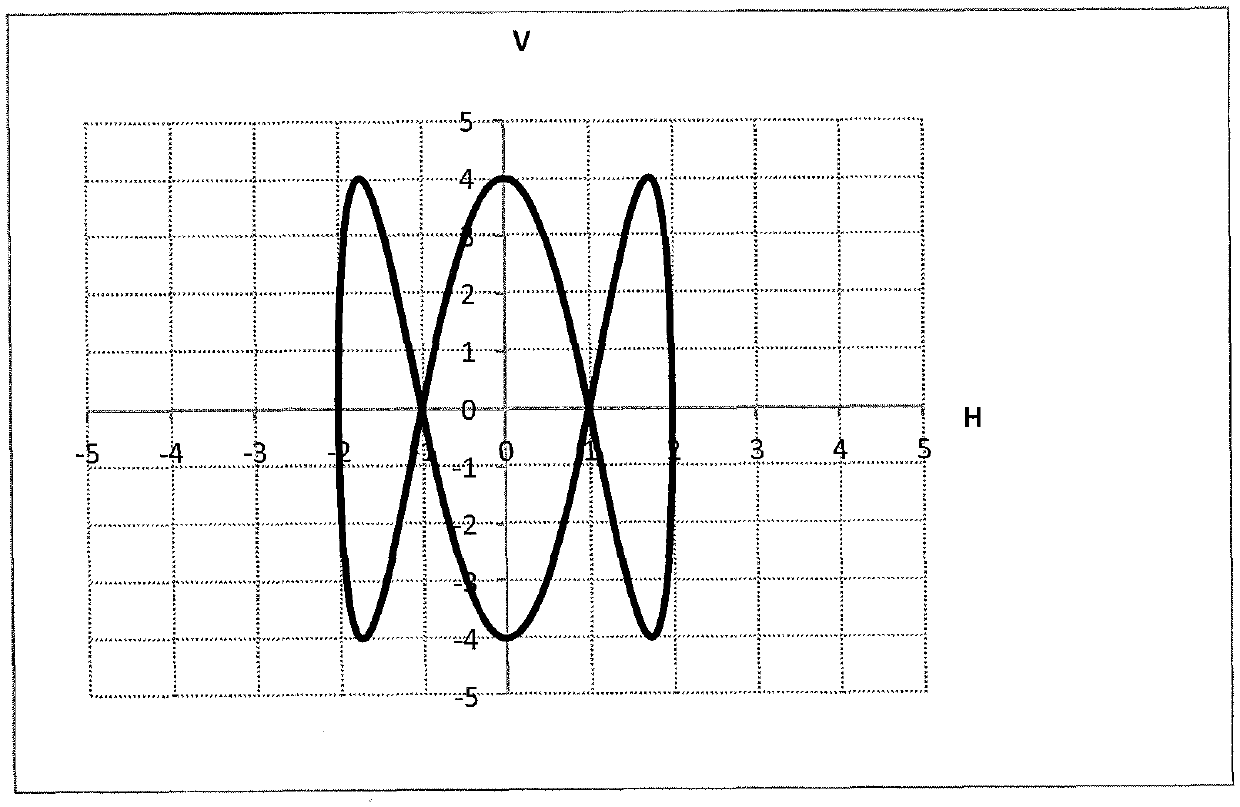

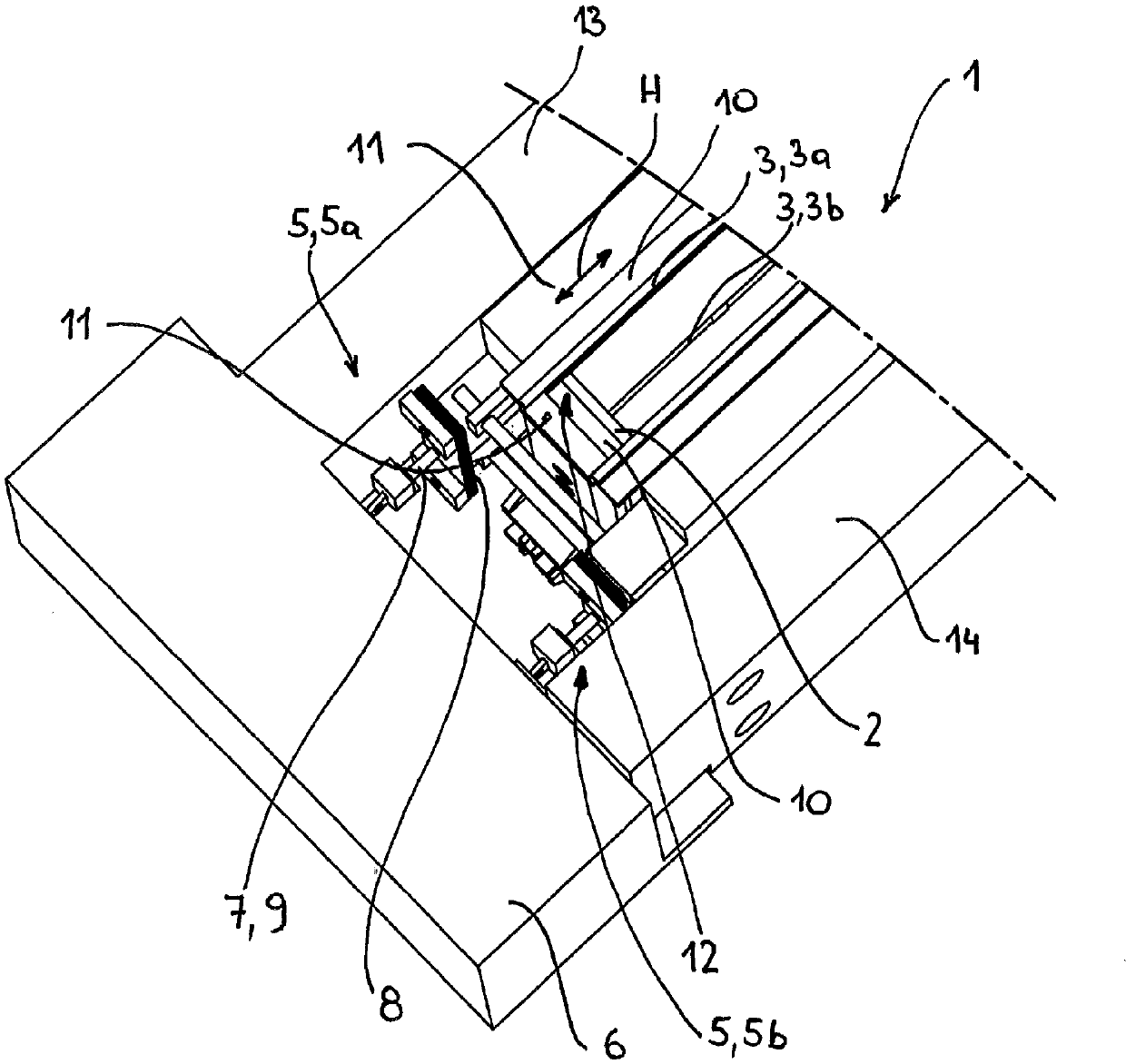

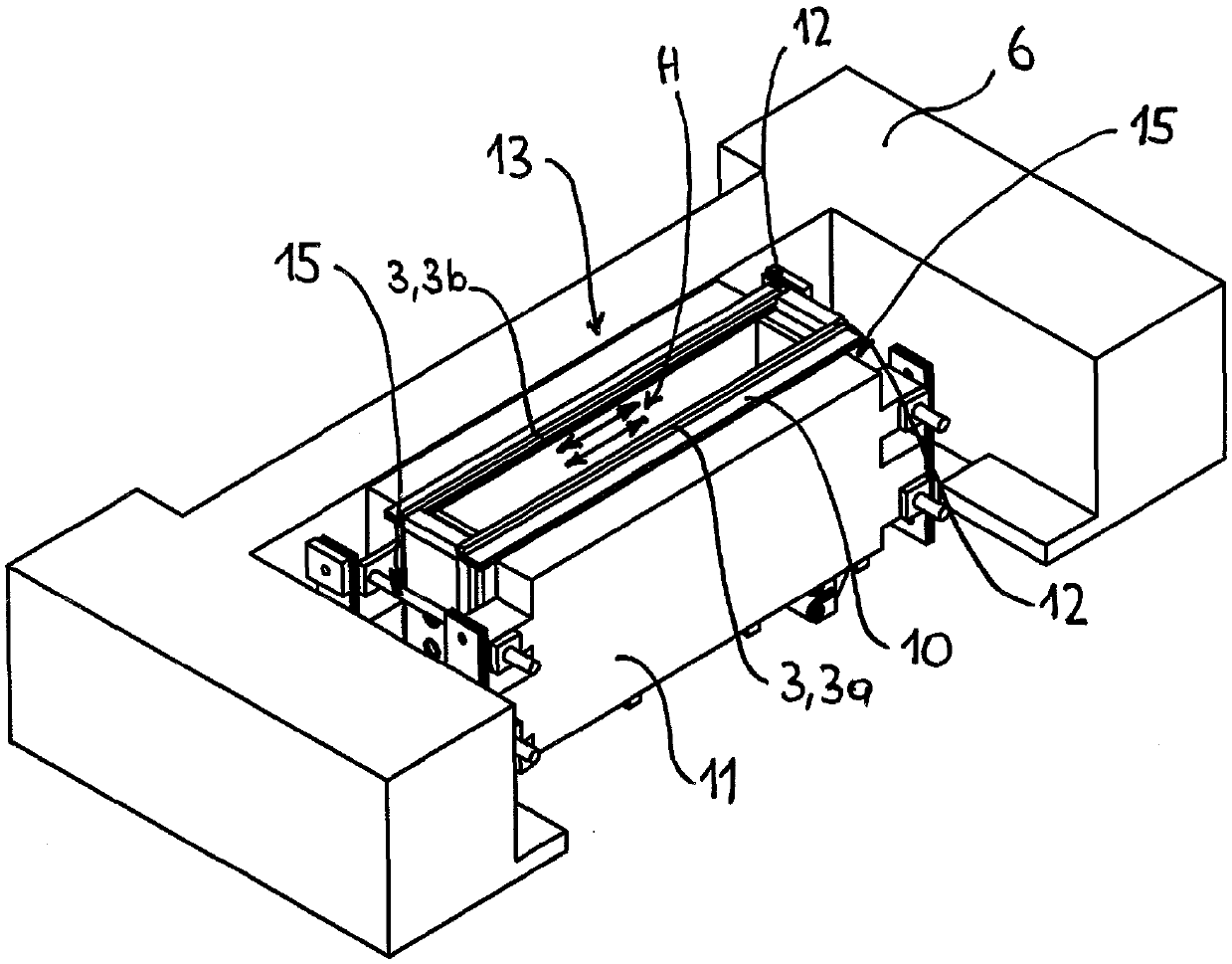

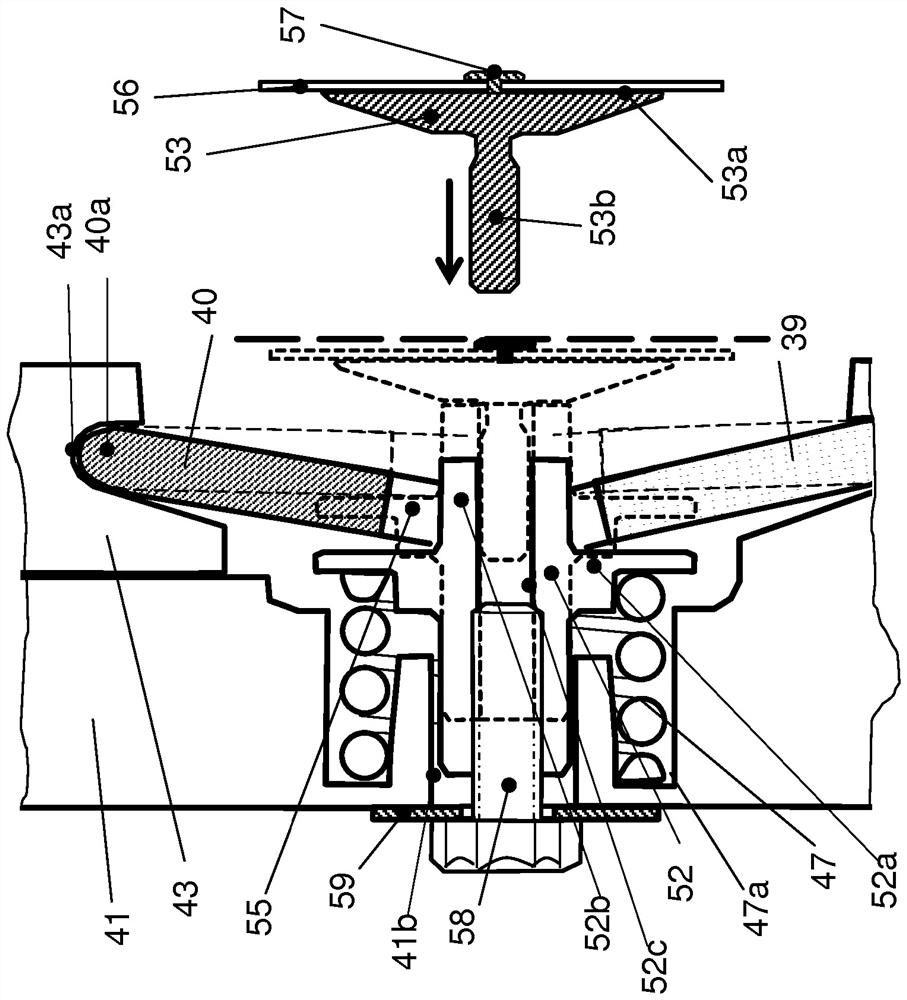

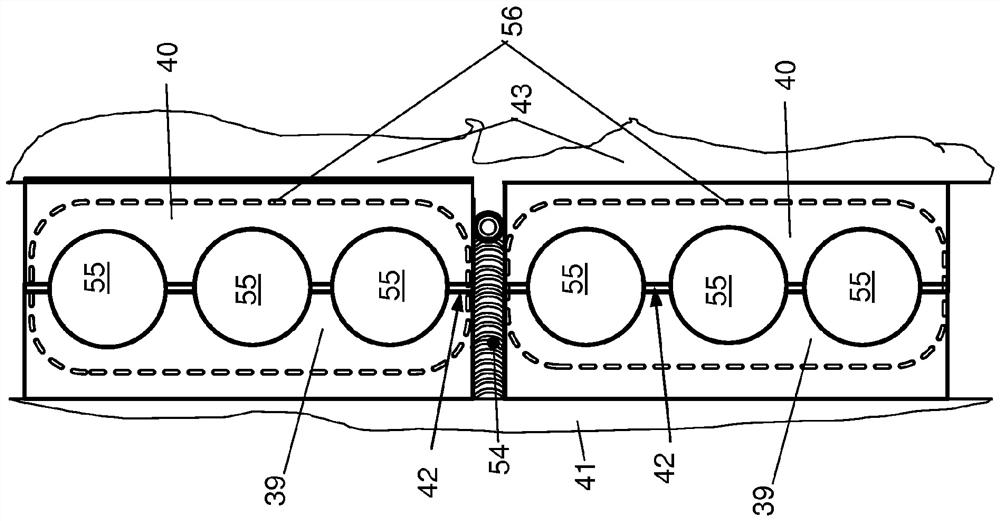

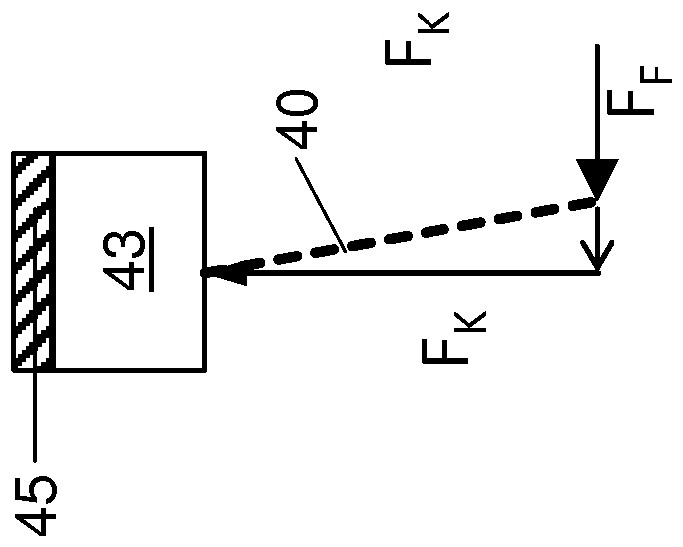

Two-dimensional oscillation of a continuous casting mould

The invention relates to a method and a device for oscillating a mould (1) of a continuous casting machine. The object of the invention is to provide a method for oscillating a mould (1) of a continuous casting machine, wherein the strand is better lubricated by the casting powder, and the strand has fewer oscillation marks. To achieve this object, at least one long-side plate (3, 3a, 3b) of the mould (1) oscillates horizontally in the direction of the length (H) of the long-side plate (3, 3a, 3b) with f[H] , where f[v] is not equal to f[H] , and for all points of the locus curve of the long-side plate (3) the magnitude of the velocity in numerical formula (I) is greater than 0.

Owner:PRIMETALS TECH AUSTRIA GMBH

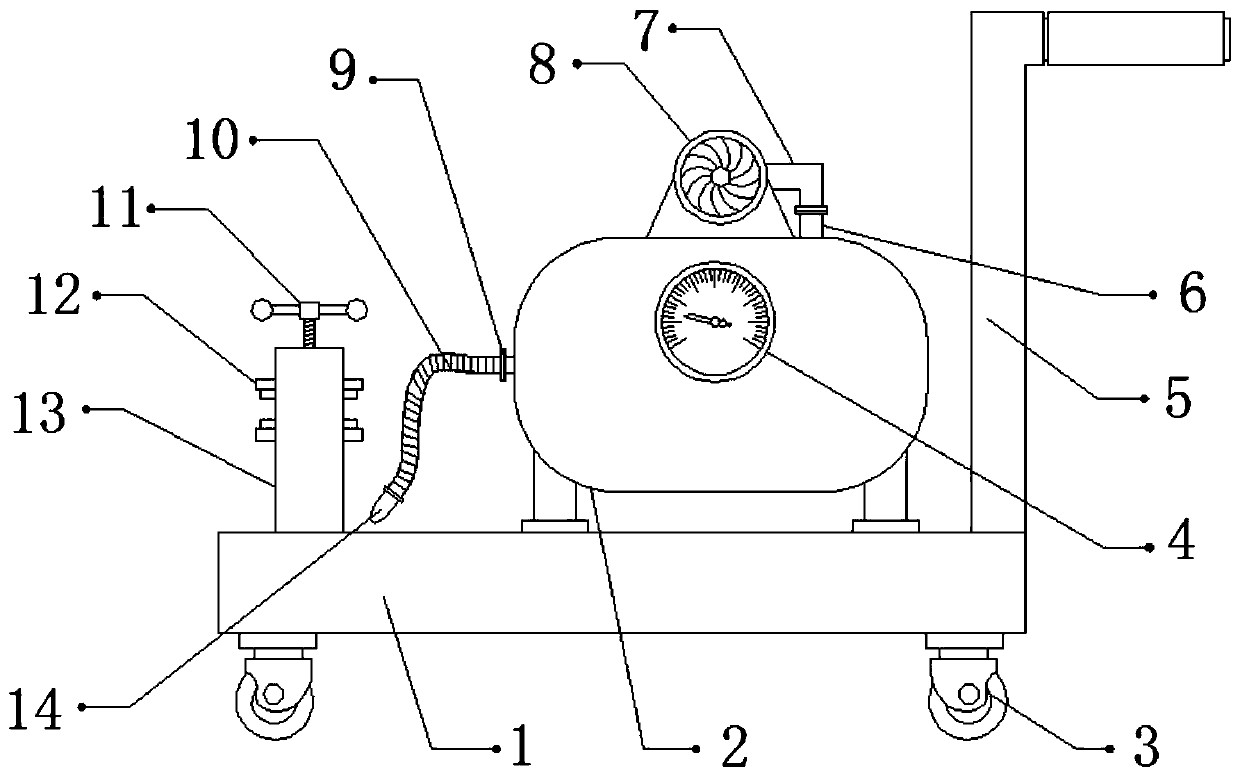

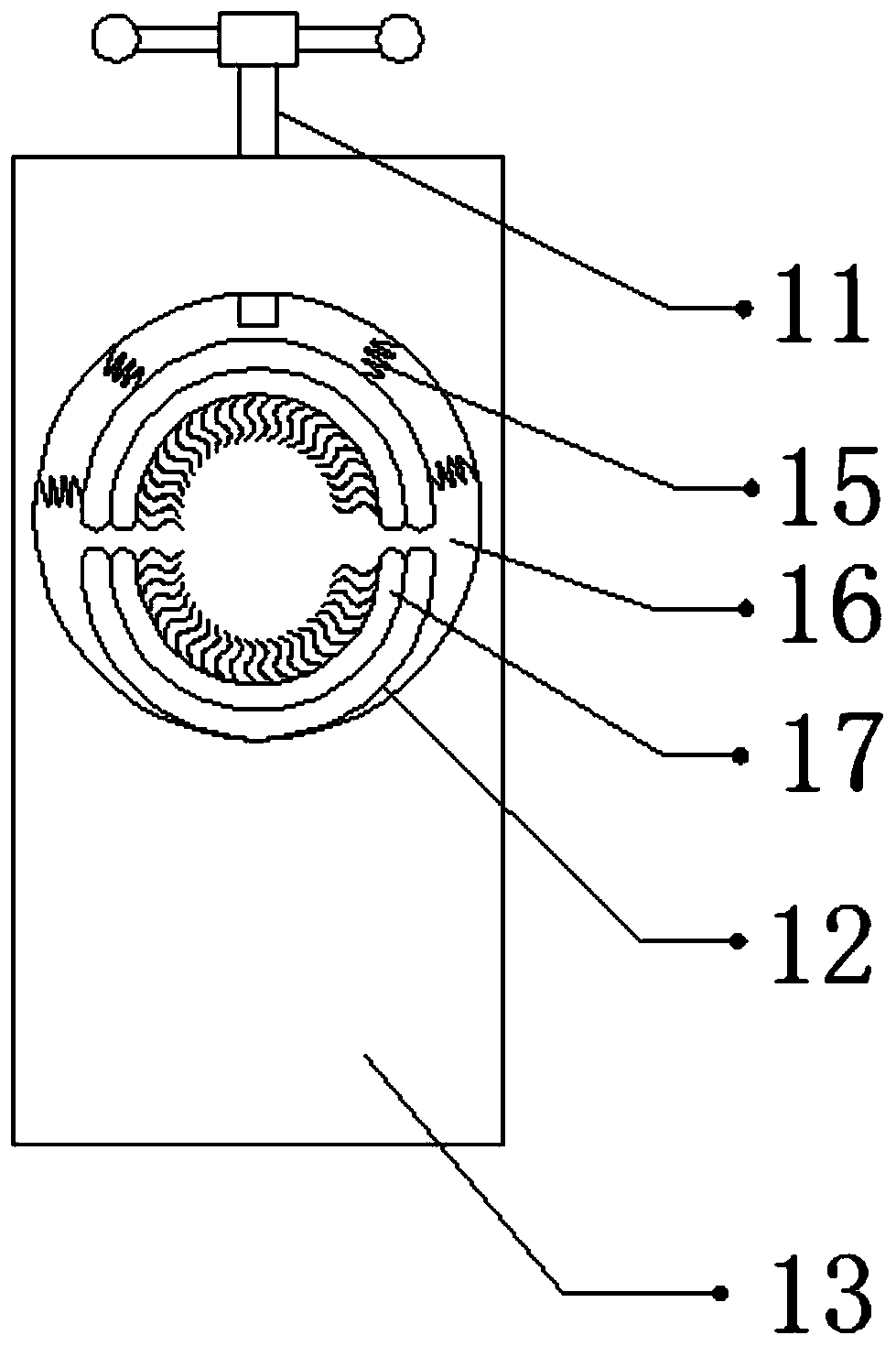

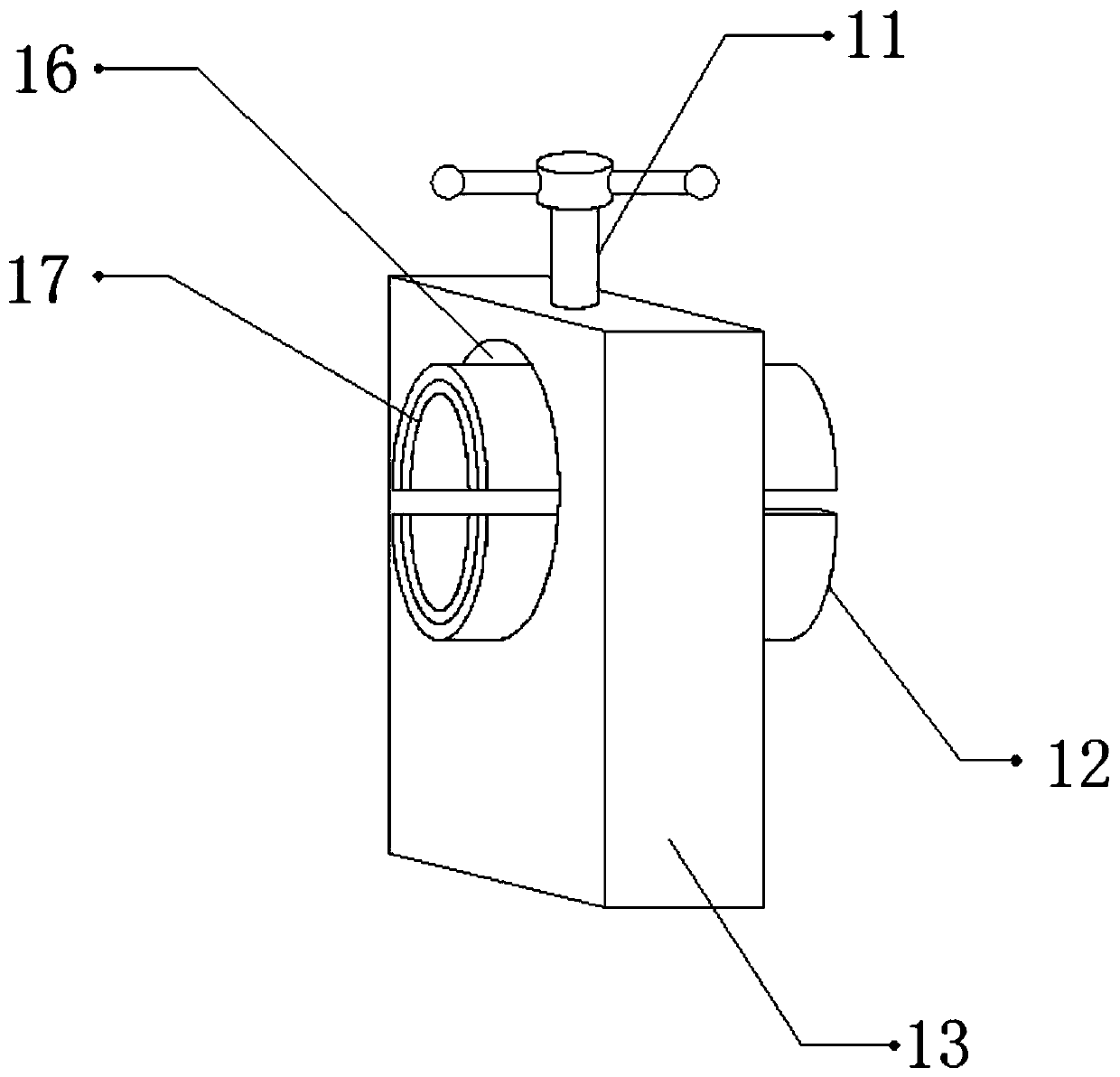

Method for removing dust on surface of steel wire rope for building hoist

InactiveCN110813910AClamping force adjustmentIntensity adjustmentCleaning using toolsCleaning using gasesArchitectural engineeringMutual position

The invention discloses a method for removing dust on the surface of a steel wire rope for a building hoist. According to the method, the steel wire rope is made to pass through a cleaning port; a pair of clamping plates are arranged in the cleaning port; cleaning cotton is fixed on the clamping plates; one of the clamping plates is radially and movably matched with the inner wall of the cleaningport; and the clamping force of the steel wire rope can be adjusted through mutual position adjustment of the pair of clamping plates so as to clean the surface of the steel wire rope. The method hasthe beneficial effects that the dust adhering to the surface of the steel wire rope can be removed through the clamping plates, the cleaning port, a cleaning plate and cleaning cotton to facilitate the operation of the hoist, so that the steel wire rope is prevented from being broken due to the corrosion caused by the dust to affect the operation of the hoist.

Owner:湖北比力工程机械有限公司

Rapid testing tool for pulling force of self-tightening type binding tape

PendingCN109443929ARealize the self-tightening processReduce gapMaterial strength using tensile/compressive forcesDislocationPull force

The invention relates to a rapid testing tool for a pulling force of a self-tightening type binding tape. The rapid testing tool comprises a base, a wire winding rod and a limiting device, wherein thebase is internally provided with a through groove which is transversely arranged and is provided with openings at two ends; an opening, which is communicated with the inner part of the through groove, is formed in the upper end of the base; the wire winding rod is adaptively inserted into the through groove; the limiting device is mounted on the base and is close to the opening; after two ends ofthe binding tape winds around the wire winding rod, the binding tape stretches out from the opening and a stretching-out part of the binding tape is clamped through the limiting device. According tothe rapid testing tool provided by the invention, the wire winding rod, the through groove and the limiting device are matched, so that the binding tape is wound on the wire winding rod; in a processof upward lifting the wire winding rod, the tool can ensure that slippage and dislocation of the binding tape do not occur in an initial upward movement process; when the binding tape moves upward under the action of an external force, the wire winding rod slides upward along the through groove of the base, and a gap between the wire winding rod and the through groove of the base is reduced, so that a self-tightening process of the binding tape is realized.

Owner:江苏和中普方新能源科技有限公司

Head fixing device based on surgical nursing

PendingCN114288116AConvenient surgical care operationEasy clamping forceMedical devicesNursing bedsPhysical therapyHead fixation

The invention discloses a head fixing device based on surgical nursing, and relates to the field of surgical nursing. The head fixing device based on surgical nursing comprises a surgical nursing bed, two sets of sliding arms and an arc-shaped clamping seat. When the head fixing device for surgical nursing is used, the head of a patient can be conveniently fixed, so that surgical nursing operation is facilitated, and when the head of the patient is fixed, the patient only needs to lie on a surgical nursing bed and the head is placed on a head pillow, so that the head of the patient is fixed. The two sets of sliding arms, the arc-shaped clamping seat and the arc-shaped rubber elastic blocks can be controlled to move by rotating the rotating handle, so that the head of the patient is clamped between the two sets of arc-shaped rubber elastic blocks and the head pillow, and the head of the patient can be heated by installing and fixing an arc-shaped electric heating block and a heat ventilation pipe in the arc-shaped clamping seat.

Owner:高宛红

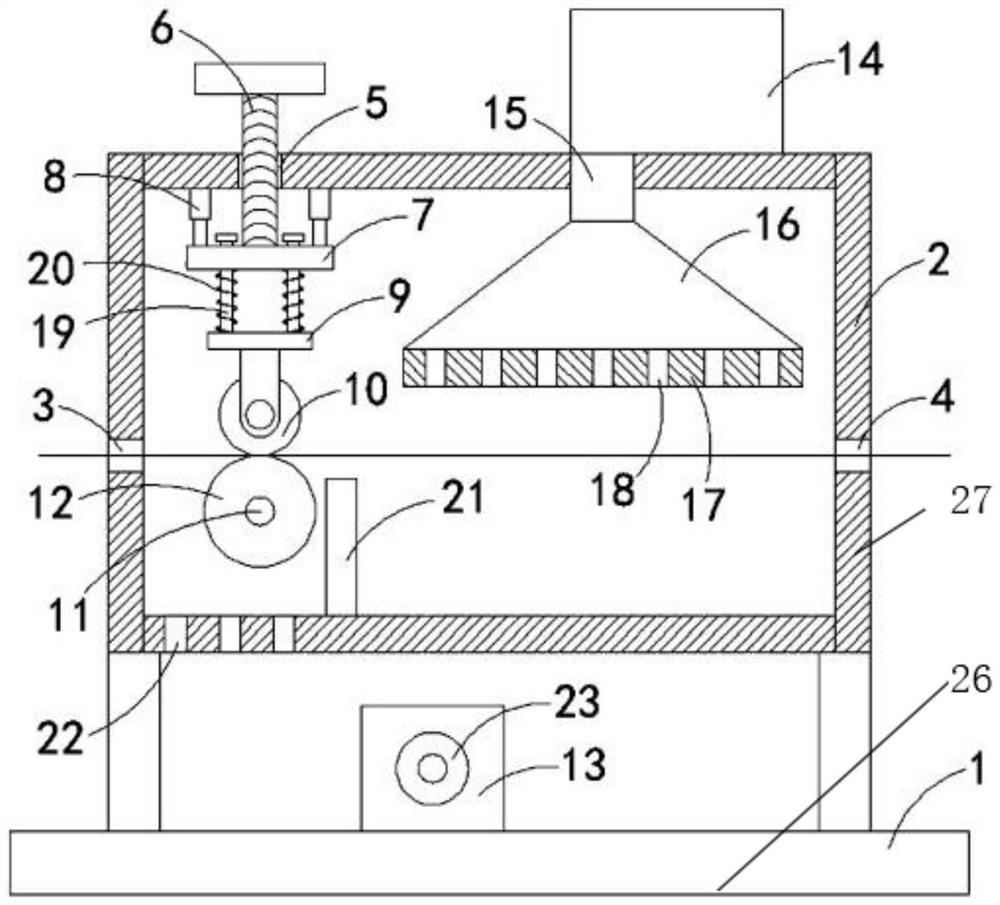

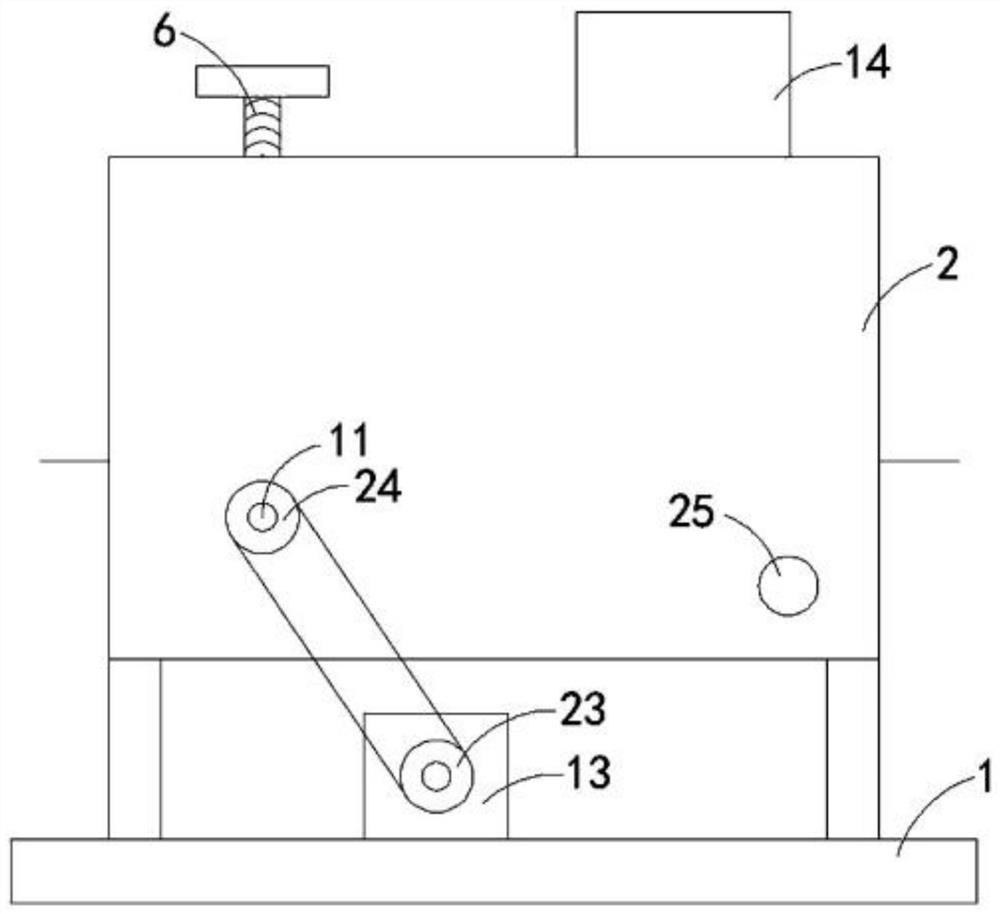

Drying device for cotton yarn production

InactiveCN112746418APrevent looseningClamping force adjustmentLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsYarnSpinning

The invention discloses a drying device for cotton yarn production, and relates to the field of spinning. The drying device comprises a bottom plate and a box body, wherein the box body is fixedly connected to the upper end of the bottom plate through a plurality of supporting rods, a yarn inlet and a yarn outlet are formed in the left side wall and the right side wall of the box body correspondingly, an extrusion mechanism and a drying mechanism are arranged in the box body, the extrusion mechanism comprises a threaded hole formed in the upper end of the box body in a penetrating mode, and a threaded rod is in threaded connection with the interior of the threaded hole. By arranging the extrusion mechanism, cotton yarn to be dried can be pretreated, the cotton yarn with high liquid content is extruded, and thus later drying time is shortened; by arranging the threaded rod, the clamping force between a pressing roller and a rotating roller can be adjusted; meanwhile, by arranging a spring, the threaded rod can be prevented from loosening, so that the pressing roller keeps downward pressure all the time; and by arranging a flow guide cover and a flow guide plate, disordered hot air generated by a hot-air blower can be treated, and thus the drying efficiency is improved.

Owner:湖北弘利纺织有限公司

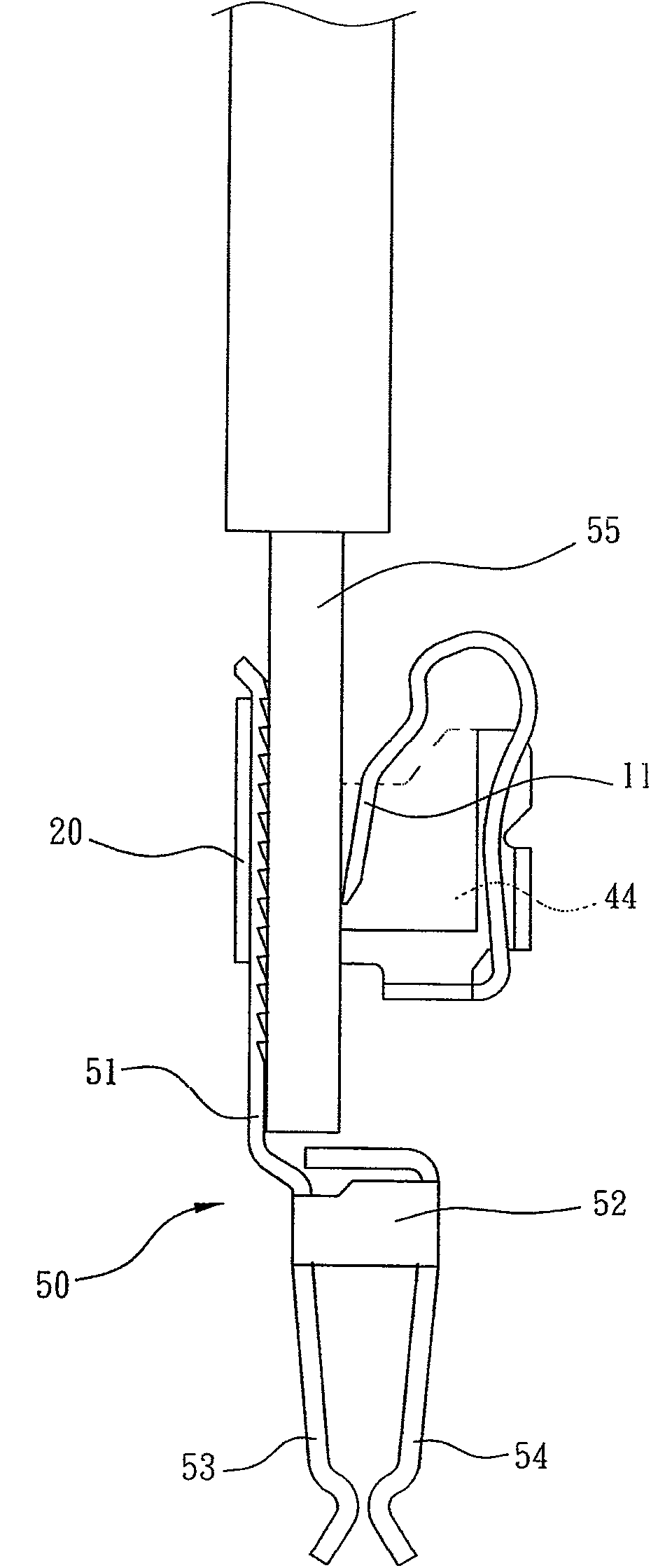

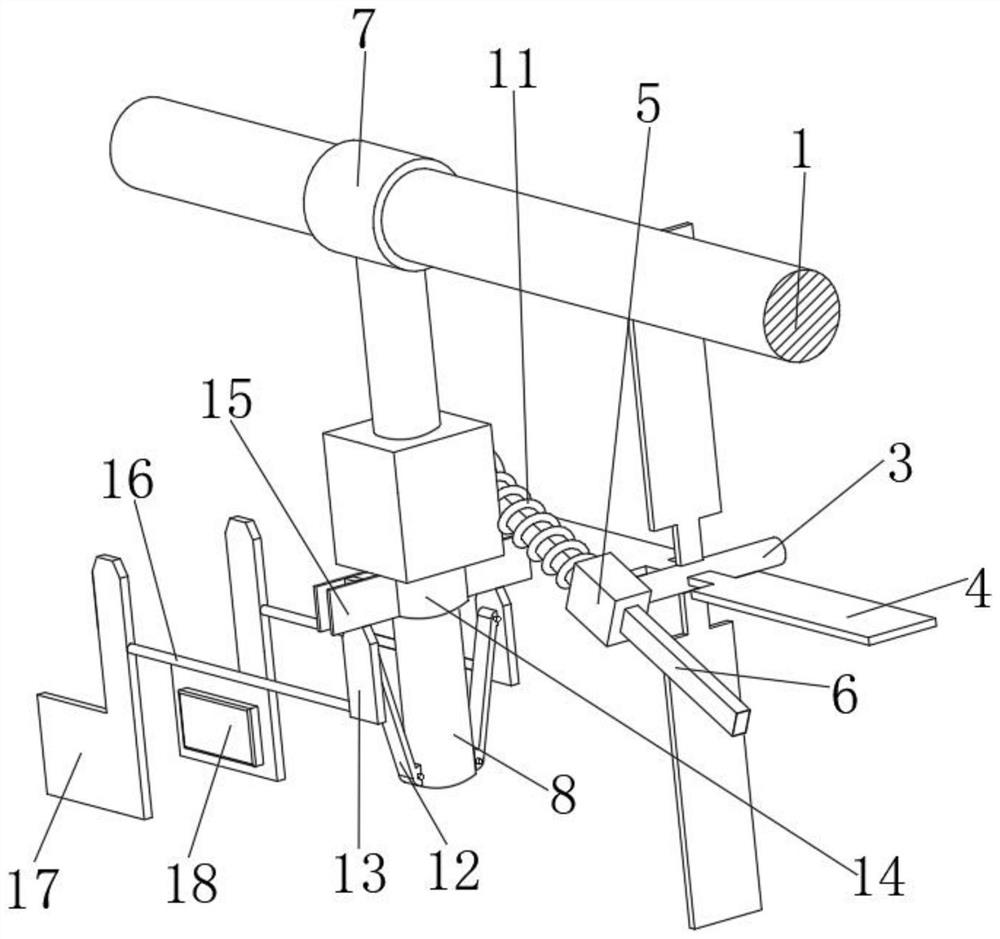

Auxiliary thread clamping mechanism of sewing machine

The invention discloses an auxiliary thread clamping mechanism of a sewing machine. The auxiliary thread clamping mechanism comprises a mounting structure, an auxiliary thread clamping structure and athread roller structure. The mounting structure comprises a mounting plate, a first fixing structure is arranged on the mounting plate, a U-shaped sliding groove is fixedly formed at the bottom sideof the mounting plate, a sliding plate is slidably connected to the interior of the U-shaped sliding groove, a supporting plate is fixedly arranged at the bottom side of the sliding plate, and a limiting structure is arranged at the position, located at the left of the sliding plate, of the bottom side of the mounting plate; and the auxiliary thread clamping structure comprises a first installation column, a baffle ring is fixedly arranged on the side face of the first installation column, a thread limiting structure is arranged on the side face of the baffle ring, and a thread clamping blockis connected to the position, located on the outer side of the baffle ring, of the side face of the first installation column through a bearing. The auxiliary thread clamping mechanism of the sewing machine is simple in structure, the clamping force of the thread clamping mechanism can be adjusted, use is convenient, in addition, the wire clamping mechanism can be rapidly installed, and disassembly and maintenance are facilitated.

Owner:TAIAN DONGSHENG CLOTHING CO LTD

Hanging device for electroplating printed circuit board

InactiveCN110699737AAvoid damageIncrease clamping strengthElectrolysis componentsEngineeringStructural engineering

The invention discloses a hanging device for electroplating a printed circuit board, and relates to the technical field of circuit boards. The hanging device comprises a mounting plate, wherein threesets of clamping mechanisms are uniformly and fixedly mounted on the portion, close to the lower side, of the front side face of the mounting plate, and a guide mechanism is fixedly connected to the position, close to the upper side, of the rear side faces of the clamping mechanisms; the guide mechanism is inserted into the rear side face of the mounting plate, and the rear side face of the guidemechanism is fixedly connected with a movable plate; and an adjusting mechanism capable of adjusting the tightness of the clamping mechanisms is fixedly connected to the position, close to the top, ofthe front side face of the movable plate, and the portions, close to the left side and the right side, of the rear side face of the mounting plate are each provided with an alarm mechanism. The clamping force of the clamping plate can be strengthened through the guiding mechanism, so that clamping is firmer, and the clamping force is conveniently adjusted through the cooperation of the adjustingmechanism; meanwhile, the opening and closing of the multiple sets of clamping mechanisms can be synchronously operated, and then the alarm mechanism is installed on the mounting plate, so that the alarm mechanism is safer to use, and the use is safer.

Owner:陕西安易信息科技有限公司

Oral teaching imitation head model manual pitching mechanism

PendingCN109389876ALabor-saving operationEasy to installCosmonautic condition simulationsEducational modelsWrenchFastener

The invention discloses an oral teaching imitation head model manual pitching mechanism, and the mechanism comprises a rotating shaft, a rotating shaft seat, a lever fulcrum shaft, a prized shaft, a clamping block, a wrench rod assembly, and a pre-pressing spring assembly. The wrench rod assembly comprises two wrench rods which are set at an interval, a wrench handle and a connecting rod, whereinthe wrench handle and the connecting rod are connected between the two wrench rods. Each wrench rod comprises a straight rod part and an S-shaped curved rod part which is formed at one end of the straight rod in an extending manner. The pre-pressing spring assembly comprises a pre-pressing spring and an adjustment fastening part. According to the invention, the wrench rod assembly and the prized shaft and the lever fulcrum shaft installed on the clamping block form a lever and eccentricity dual-labor-saving mechanism, and the pre-pressing spring assembly is used for providing a clamping forceso that the clamping block clamps the rotating shaft tightly, thereby forming the manual and labor-saving mechanism provided by the invention which is convenient to install, is firm in structure and is low in fault rate.

Owner:NISSIN EDUCATION PROD KUNSHAN CO LTD

Varanus salvator tooth imitation clamping device

ActiveCN110811867ARealize the clamping effectAchieve releaseInstruments for stereotaxic surgeryPhysical medicine and rehabilitationForceps

The invention belongs to the technical field of bionic devices, and in particular relates to a varanus salvator tooth imitation clamping device. The device comprises a fixing plate, and two fixing rods are symmetrically fixed on one side of the fixing plate; a hollow cavity is arranged in the fixing plate, and a battery and a controller are fixedly connected to the interior of the hollow cavity; afirst switch and a second switch are fixedly connected to the outer side of the fixing plate; and object storage grooves are arranged in opposite sides of the two fixing rods, the interior of each object storage groove is provided with a threaded rod, and a slide block is in screw connection with each threaded rod. The device has a reasonable and novel structure, by simulating occlusion of varanus salvator teeth, in the entire operation process, compared with mechanical surgical forceps, the device provided by the invention reduces the holding strength of a medical worker during use, at the same time, the holding strength can be adjusted, the length of the device can be adjusted, and the device has a good use effect.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Yarn gripper for air-jet loom

The invention discloses a yarn clamping device for an air-jet room. The yarn clamping device comprises an upper pressing plate and a lower supporting plate. Both the upper pressing plate and the lower supporting plate are arranged on a connection plate. Two upper rolling wheel shafts are arranged on the upper pressing plate. Upper rolling wheels are arranged on all the upper rolling wheel shafts respectively in a sleeved mode. First grooves are formed in the circumferences of all the upper rolling wheels respectively. The two upper rolling wheels are connected through upper rubber belts. The upper rubber belts are arranged in the first grooves. Two lower rolling wheel shafts are arranged on the lower supporting plate. Lower rolling wheels are arranged on all the lower rolling wheel shafts respectively in a sleeved mode. Second grooves are formed in the circumferences of all the lower rolling wheels respectively, the two lower rolling wheels are connected through lower rubber belts, and the lower rubber belts are arranged in the second groove. Weft yarn clamping gaps are formed through match of the upper rubber belts and the lower rubber belts, and both the contact pressure and the contact length of the upper rubber belts and the lower rubber belts can be adjusted. By means of the yarn clamping device, effective weft yarn clamping can be achieved, and quality of finished fabric is guaranteed.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

Cardiopulmonary resuscitation rescue device for emergency department

Owner:江苏天凤源食品有限公司

A mechanical fixture for mechanical automation production that facilitates automatic control of clamping force

ActiveCN113290404BRealize automatic controlClamping force adjustmentPositioning apparatusMetal working apparatusAutomatic controlEngineering

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

High-comfort blood oxygen probe structure with adjustable clamping force

InactiveCN112426152AEasy to replaceGood flexibilityDiagnostic recording/measuringSensorsEngineeringSilica gel

The invention relates to the field of blood oxygen probes, in particular to a high-comfort blood oxygen probe structure with adjustable clamping force. The structure comprises a mounting block, arc-shaped connecting plates are fixedly mounted on the upper side face and the lower side face of the mounting block through first hinge pieces, and the inner walls of the arc-shaped connecting plates arein transmission connection with the mounting block through adjusting mechanisms. Connecting mechanisms are arranged on the right side faces of the arc-shaped connecting plates correspondingly, an upper clamping assembly and a lower clamping assembly are fixedly installed on the right side faces of the upper connecting mechanism and the lower connecting mechanism correspondingly, and light emittingdiodes are arranged on the opposite side faces, close to the middle, of the upper clamping assembly and the lower clamping assembly correspondingly. The clamping force can be adjusted conveniently, meanwhile, the softness and friction force are increased through the skin-friendly silica gel pad and the small protruding particles, clamping is more comfortable, falling is not likely to happen, theskin-friendly silica gel pad can be replaced conveniently, use is more sanitary, the clamping length can be adjusted, the requirement of different people for use can be met, the adapter is not likelyto fall off, and connection is firm.

Owner:深圳市优品医疗设备有限公司

Oil pipe tripping device and method of use thereof controlled by two people in oil well workover operations

InactiveCN105888582BAchieve positioningSolve insufficient clamping forceDrilling rodsDrilling casingsEngineeringManipulator

The invention relates to a double-control tubing device for petroleum workover operation and a using method thereof. The device comprises a shell, a lifting block assembly and a tubing clamp assembly, wherein lifting block assembly opening mounting grooves are respectively formed in two ends of the shell; a tubing clamp assembly mounting groove is formed between the lifting block assembly opening mounting grooves; the lifting block assembly comprises a lifting clamping block, a lifting clamping block driving device and a lifting clamping block baffle which are correspondingly mounted in the lifting block assembly opening mounting grooves; the tubing clamp assembly comprises a manipulator main body, a manipulator tubing clamp and a manipulator tubing clamp limiting piece which are mounted in the tubing clamp assembly; the manipulator tubing clamp is rotationally arranged on the manipulator main body by virtue of a pin shaft; a through slot used for mounting the manipulator tubing clamp limiting piece is formed in the shell; the manipulator tubing clamp limiting piece comprises a tubing spring guide rail, a tubing spring push plate and a spring. The double-control tubing device has the advantages of simple structure, reasonable design, convenience in use and simplicity in repair and maintenance, the equipment cost is reduced, the labor intensity of manual labor is alleviated, and the field operating efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Electromagnetic clamp for clamping cylinder sleeve

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method of producing clamping force for a vehicle produced by an automatic parking brake

ActiveCN104828055BEasy to operateGood for running braking characteristicsAxially engaging brakesBraking action transmissionParking brakePiston

Owner:ROBERT BOSCH GMBH

plate tension rail

ActiveCN108430778BEfficient designClamping force adjustmentPrinting press partsStructural engineeringMechanical engineering

Owner:MAN ROLAND MASCHINEN AG

Clamping Mechanism of Injection Molding Machine and Its Clamping Force Balance Adjustment Method

The invention discloses a mould-assembling mechanism for an injection molding machine and a balancing and adjusting method for a mould-assembling force thereof. The mould-assembling mechanism comprises a rear mould plate (1), a moveable mould plate (2), a front mould plate (3), a toggle rod mechanism (4), four pull rods (5) and a pull rod adjusting mechanism, wherein the pull rod adjusting mechanism comprises strain foils (6), servo motors (7) and front nuts (8) which are one-to-one corresponding to the four pull rods (5); the positions and directions of the strain foils (6) on the four pull rods (5) are consistent; the peripheral surfaces of the front nuts (8) are gear-shaped; driving gears (9) are connected with the servo motors (7); and the driving gears (9) are engaged with the peripheral surfaces of the front nuts (8). The uniform stress of the four pull rods is realized by adopting a closed-loop feedback control balancing and adjusting method, so that the function of balancing and adjusting the mould-assembling force is achieved, the reliability of the mould-assembling mechanism is high and the service life is long.

Owner:TEDERIC MACHINERY

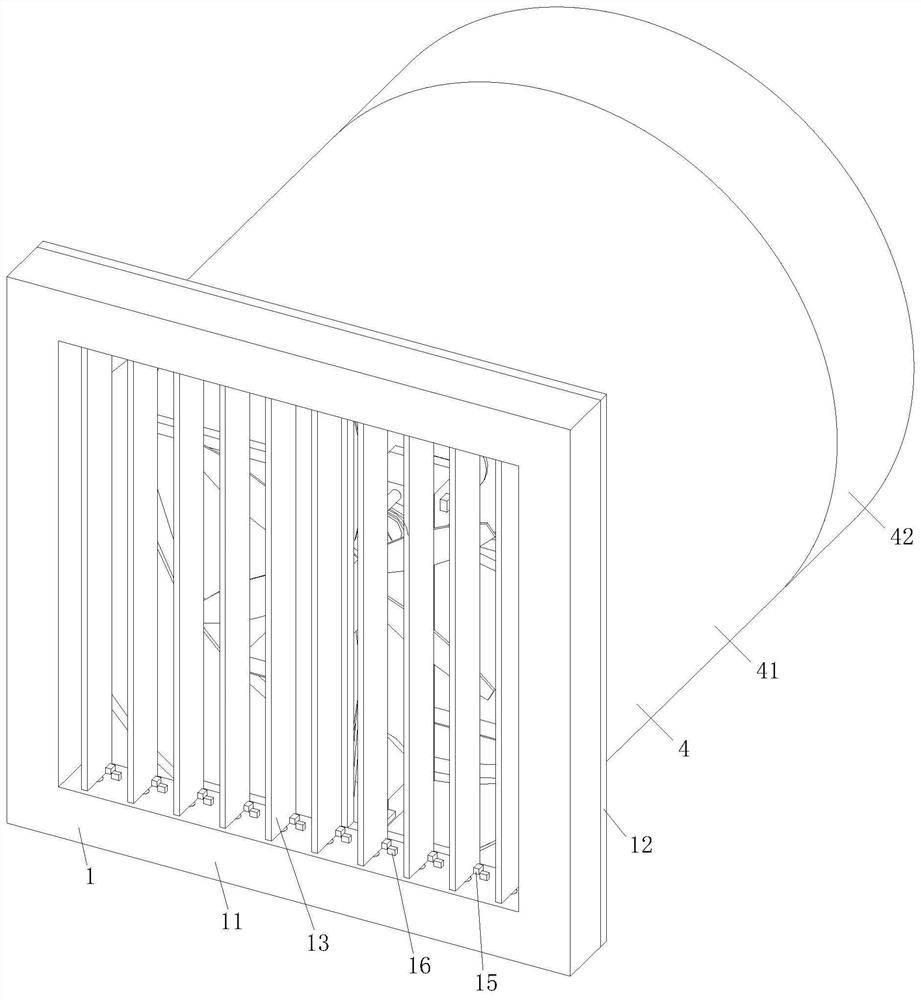

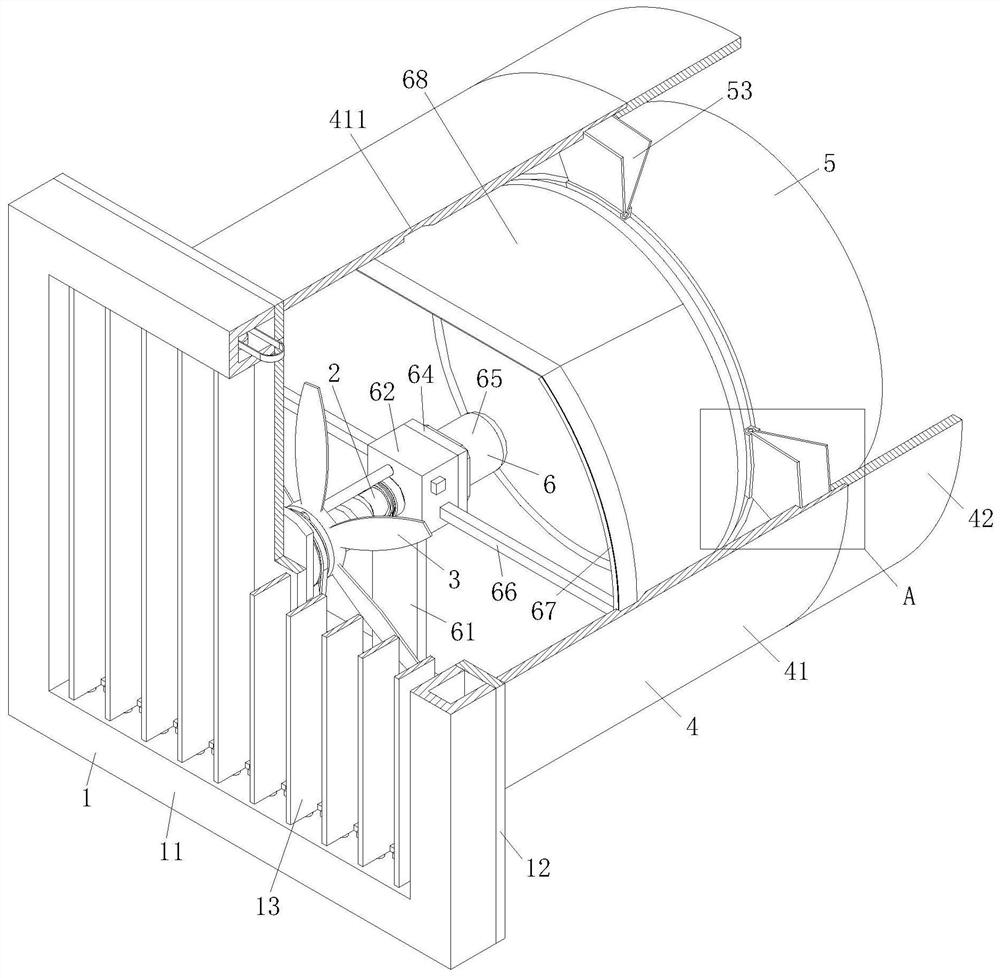

Multi-mode ventilation and exhaust fan for granary

ActiveCN111720350BImprove the storage environmentRealize inner loopPump componentsPower-operated mechanismElectric machineryStructural engineering

Owner:江苏珏盛机械科技有限公司

Rail clamp and track running mechanism

ActiveCN103991460BReasonable structure layoutAvoid Weight ConcentrationTravelling gearTrack-braking member co-operationEngineeringMechanical engineering

Owner:CHINA SHENHUA ENERGY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com