Electromagnetic clamp for clamping cylinder sleeve

A technology of electromagnetic fixtures and cylinder liners, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve problems such as difficult flexible control of fixtures, complex structures, and deformation of cylinder liners, and achieve low manufacturing costs, simple structures, and flexible control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and examples.

[0026] Such as Figure 1-4 Indicated.

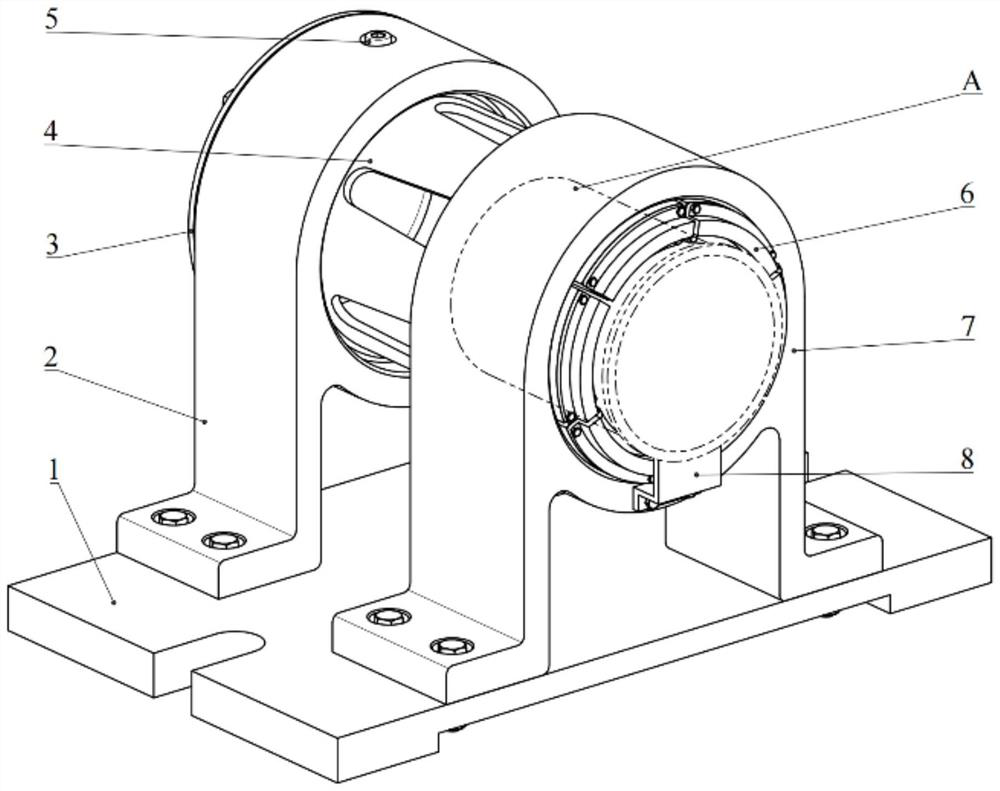

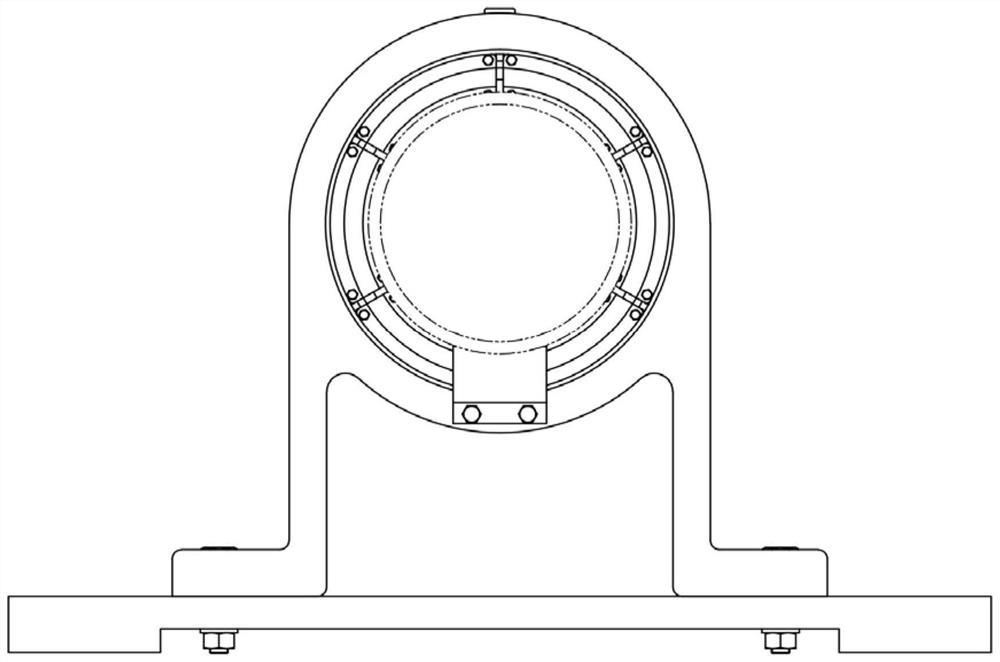

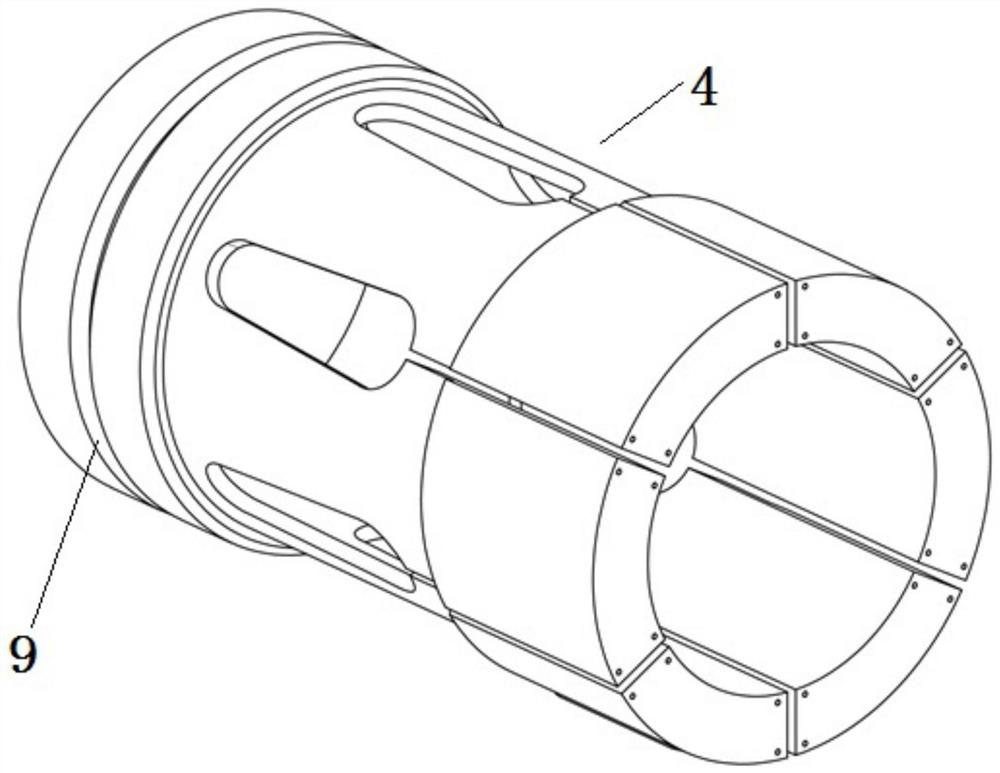

[0027] A electromagnetic clamp holding a cylinder liner comprising: a base 1, a base 1 having two supports, and the base 1 and the first support 2, the second support 7 connecting positions have a U-hole, For the mounting position of the mount; the first branch 2 end surface ( figure 2 ) And upper surface ( figure 1 It is provided with a threaded hole for mounting the end cap 3 and the lock screw 5, the end cap 3 and the lock screw 5 are used to fix clamping chuck 4, clamping the collet 4 end surface is connected to the package coil 6; second The seat 7 end surface is connected to the finite plate 8, and the limit panel 8 is used to ensure the consistency of the position of the cylinder block A. figure 1 Indicated.

[0028] Specifically, the clamping tape 4 side circumferential surface is provided with a trapezoidal groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com