Direct current railway steel rail flash butt welder for rapid pressure maintaining push protruding

A technology for butt welding machine and rail, applied in the field of rail welding, it can solve the problems of inconsistent three-phase current amplitude, many joint temperature drops, three-phase unbalance, etc. structure, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

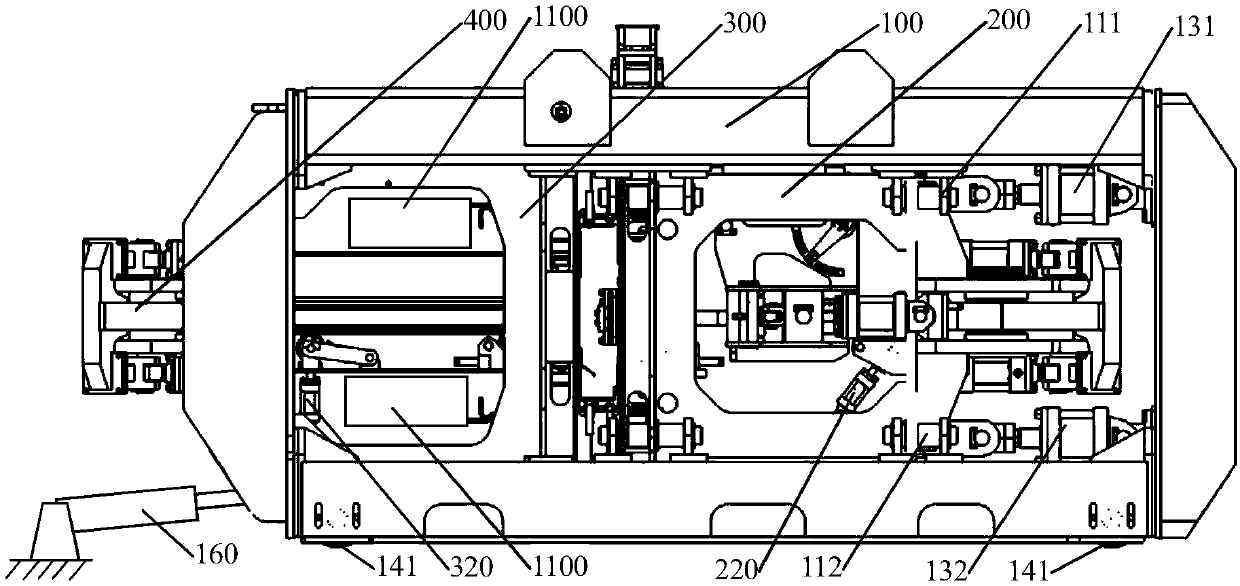

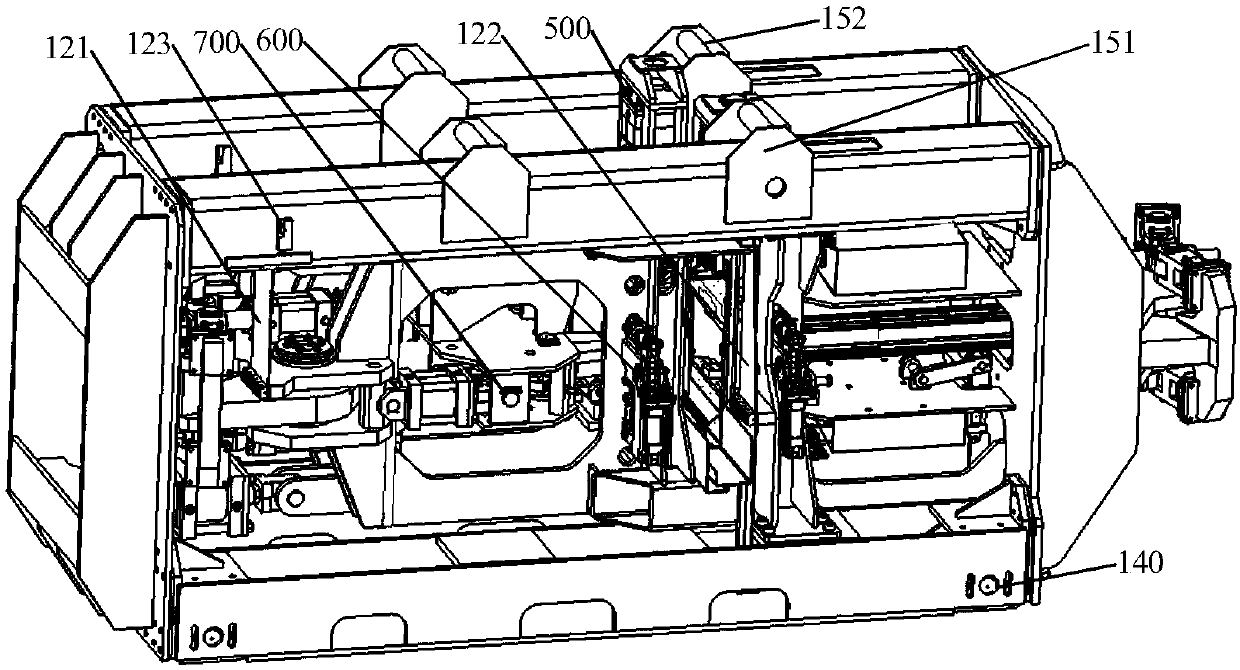

[0035] In actual work, the steel rail enters the welding machine through the side of the raceway driven frame before welding, and the parts of the rail to be welded enter the electrode side of the moving frame and the static frame respectively. At this time, in order to align the rail to be welded with the middle of the electrode, it is necessary to start the traveling oil cylinder 160 of the welding machine to drive the welder to walk longitudinally along the track on the ground until the rail to be welded is aligned with the center of the moving and static frames. Since the rail is in the middle of the upper and lower longitudinal beams of the welding machine, the horizontal and vertical bending moment components generated by the rail during welding are extremely small, which has little influence on the straightness of the joint.

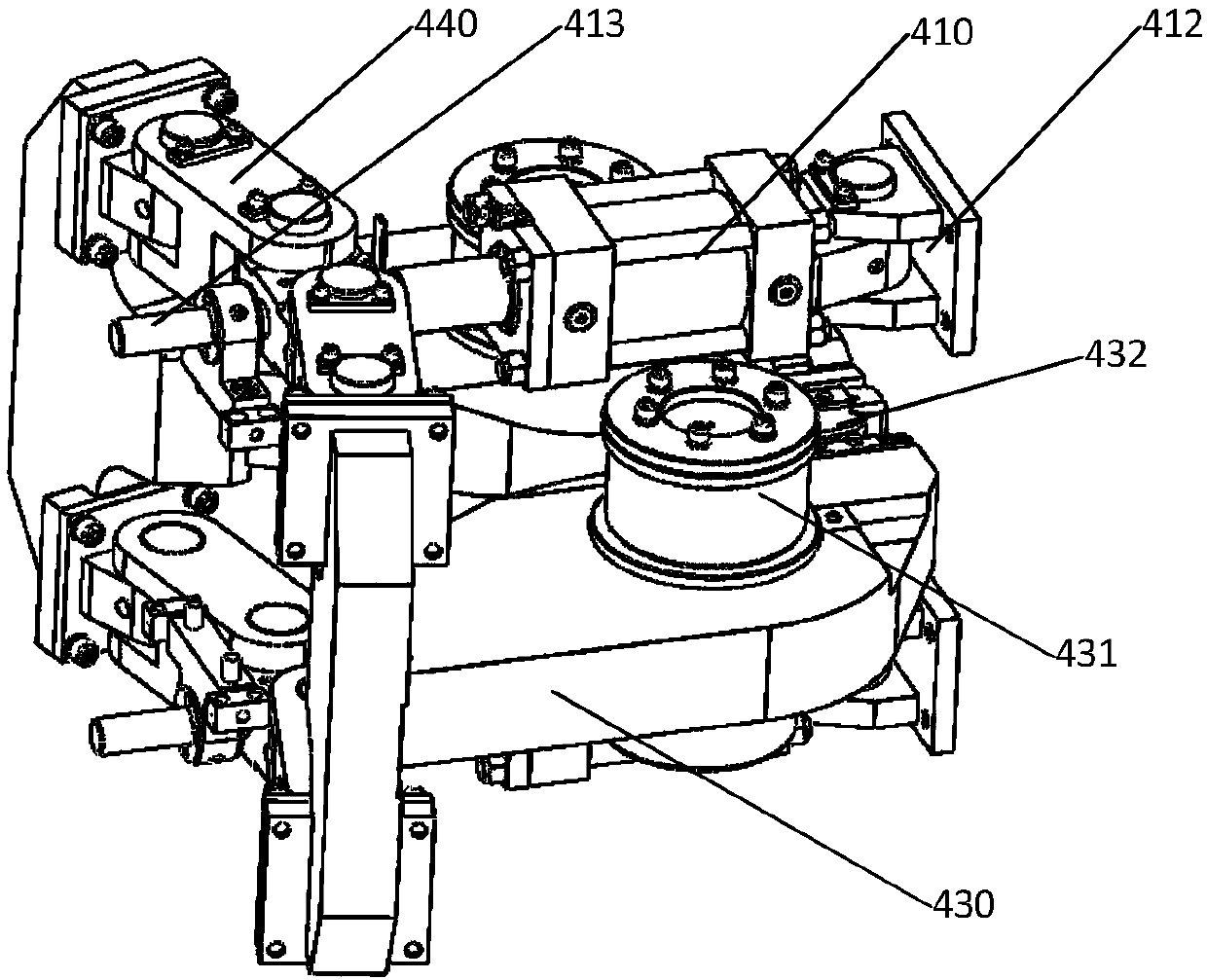

[0036] Then, start the arching wheel oil cylinders 220 and 320 at the two ends of the welding machine and the rail top clamping oil cylinders 531 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com