Oral teaching imitation head model manual pitching mechanism

A pitching mechanism and headform technology, applied to teaching models, simulators, educational appliances, etc., can solve the problems of limited use places, troublesome maintenance, limited contact area, etc., and achieve the effects of reduced failure rate, labor-saving operation, and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

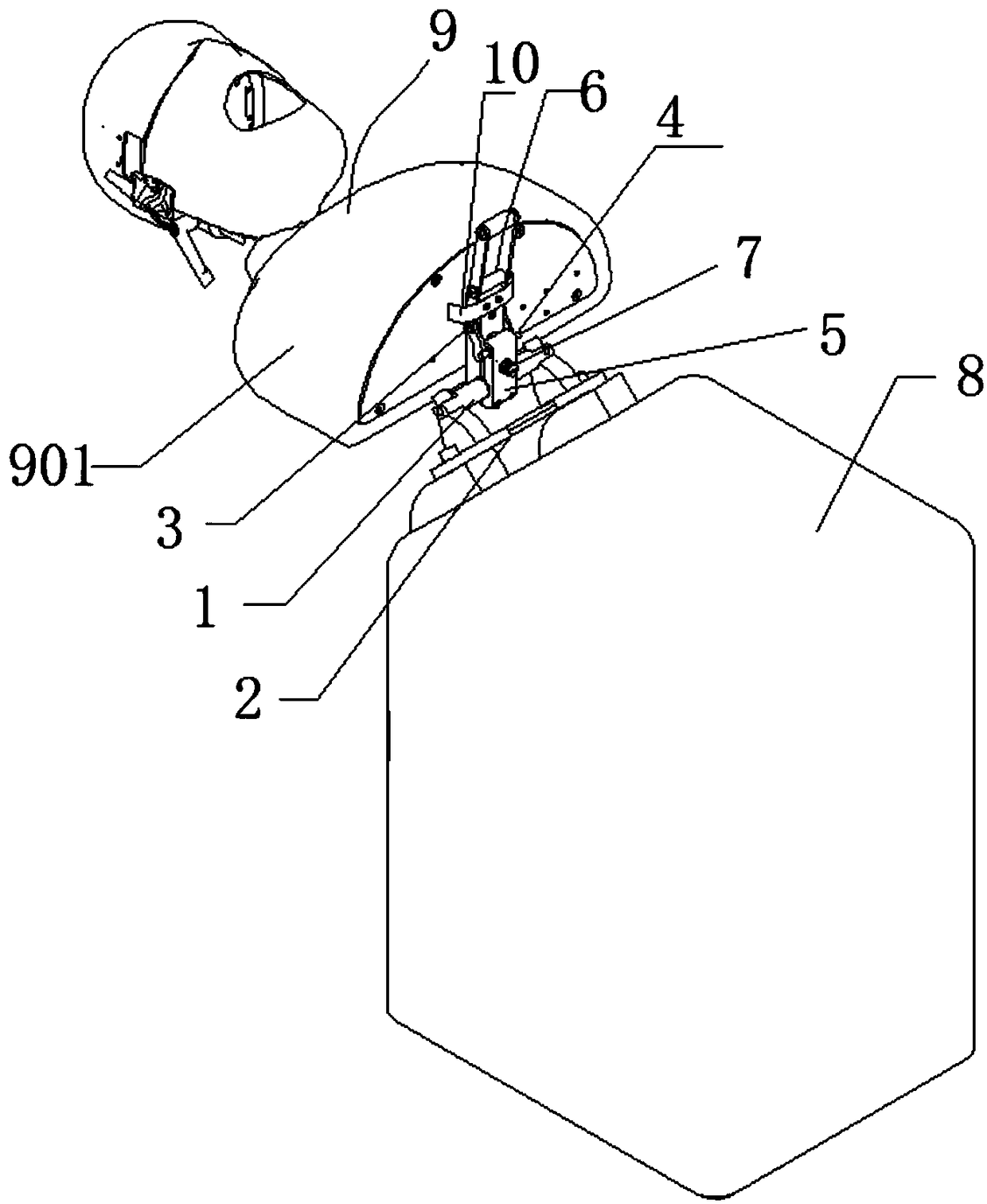

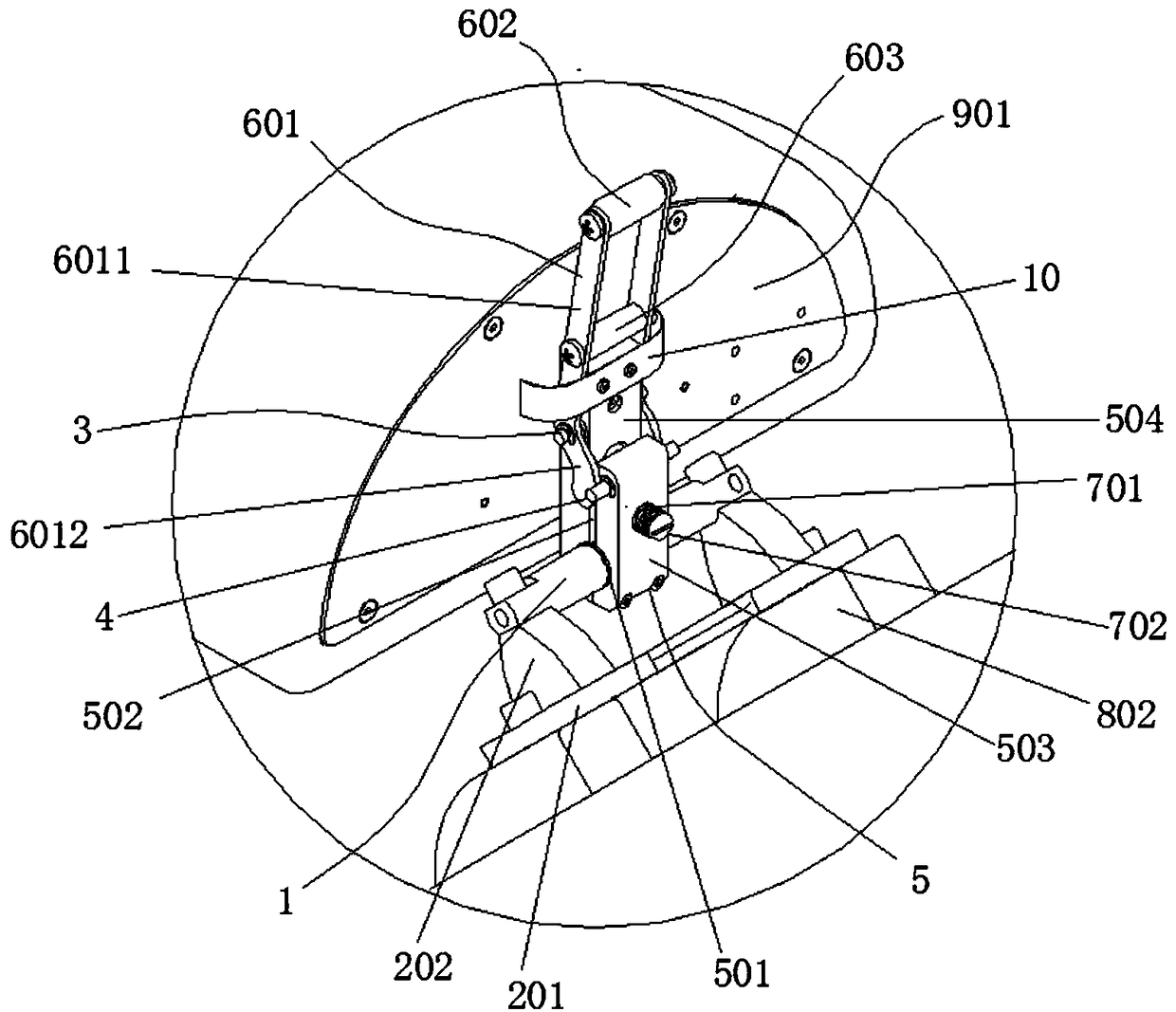

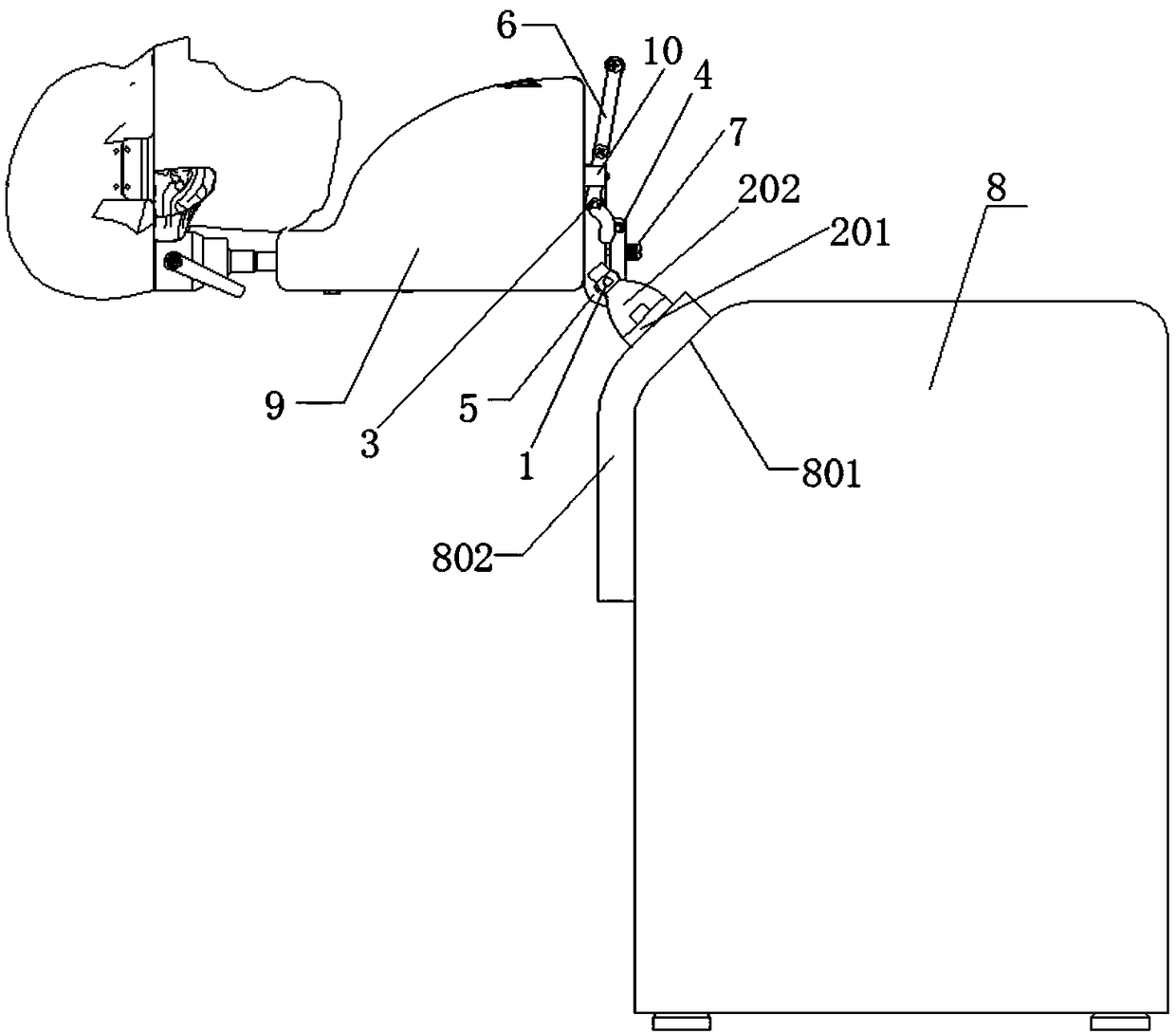

[0031] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, a manual pitching mechanism for imitating headforms for oral teaching, including a rotating shaft 1, a rotating shaft seat 2, a lever fulcrum shaft 3, a levered shaft 4, a clamping block 5, a trigger lever assembly 6 and a preload spring assembly 7. The toggling lever assembly includes two toggling levers 601 arranged at intervals, a toggling handle 602 and a connecting rod 603 connected between the two toggling levers, and the toggling lever includes a straight rod portion 6011 And an S-shaped curved rod part 6012 extending from one end of the straight rod part, that is, the curved rod part has a first bending p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com