System and method for determining a material entity to be removed from a pile and a control unit for a working machine comprising such a system

A technology of stockpiling and removal, applied in the system field of material entities to achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

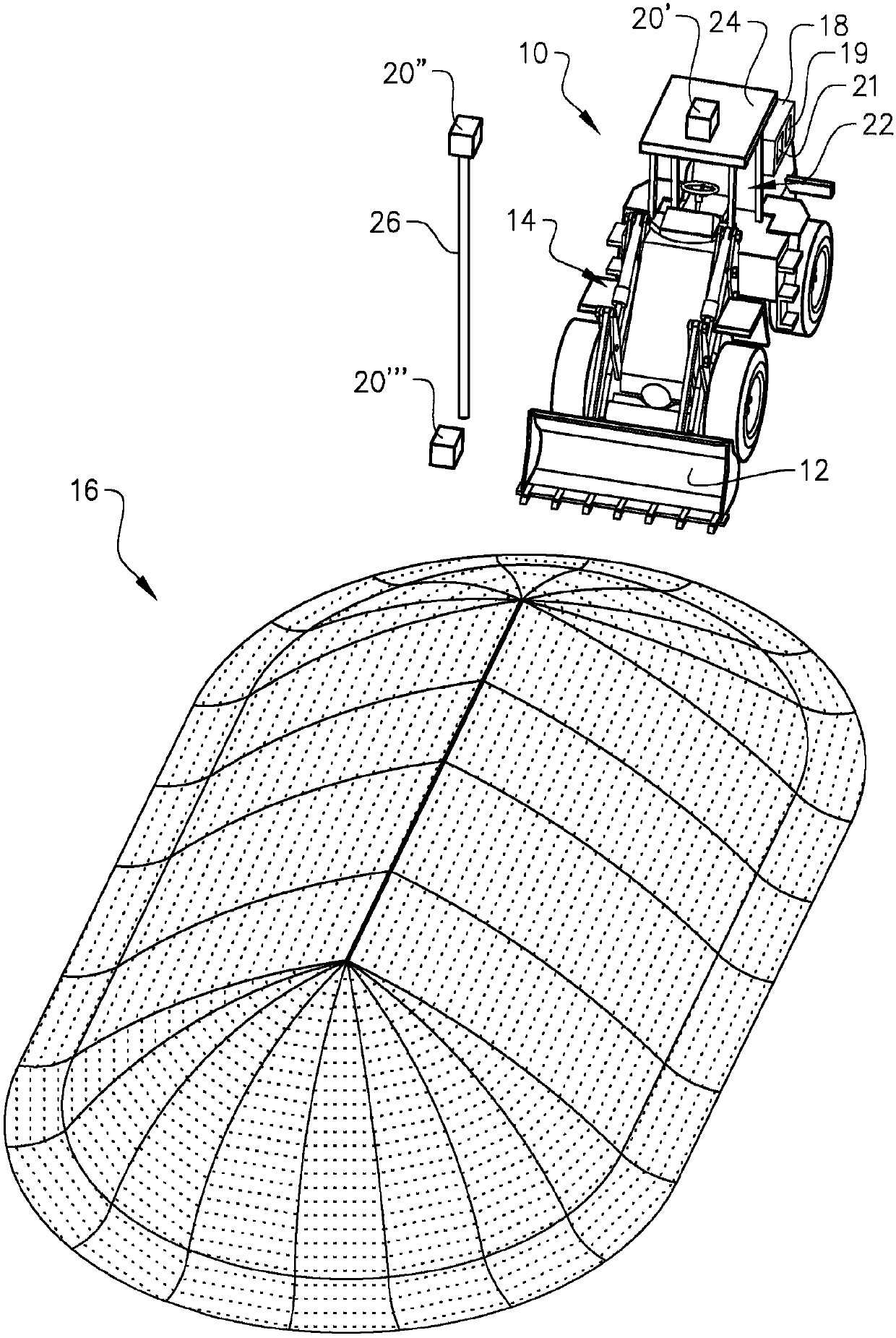

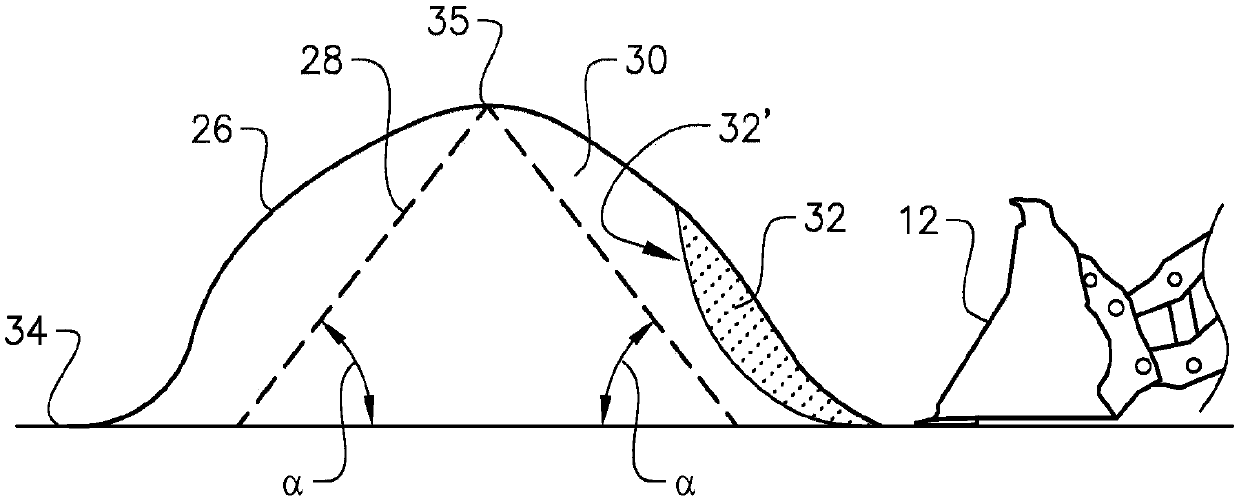

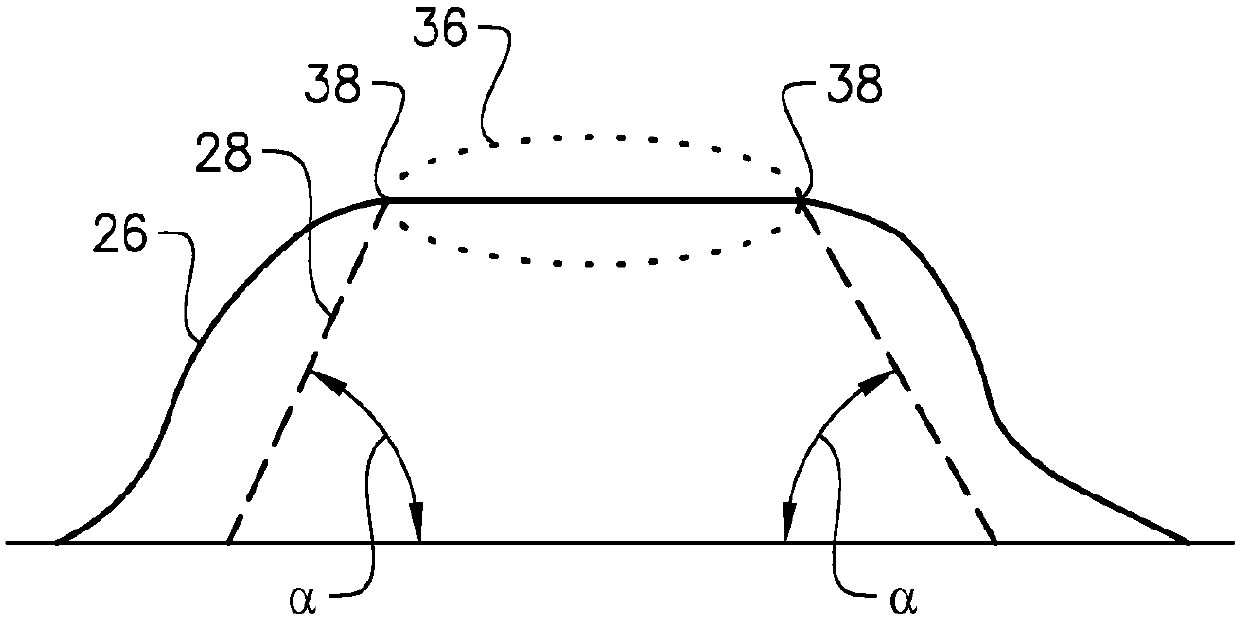

[0065] In the following, for example figure 1 The material moving machine in the form of a wheel loader 10 is shown to describe the invention. The wheel loader 10 should be considered an example of a material moving machine for which a system according to the invention is included and / or a method according to the invention can be used.

[0066] However, it is also conceivable that the invention may be practiced with other types of material moving machinery, such as excavators (not shown) or bulldozers (not shown). Furthermore, it should be emphasized that although the invention is described herein with reference to a movable material moving machine, it is also contemplated that the moving machine could be a stationary moving machine.

[0067] figure 1 The material moving machine 10 in includes tool 12, and described tool 12 is in figure 1 The embodiment is illustrated as a bucket. Furthermore, the material moving machine 10 includes an actuation device 14 for raising and / o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com