a vibrating screen

A technology of vibrating sieve and vibrating spring, which is applied in the fields of filter sieve, solid separation, chemical instruments and methods, etc. It can solve the problems of high price, unsatisfactory vibration effect and low screening efficiency, so as to improve the service life and prevent structural damage , good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

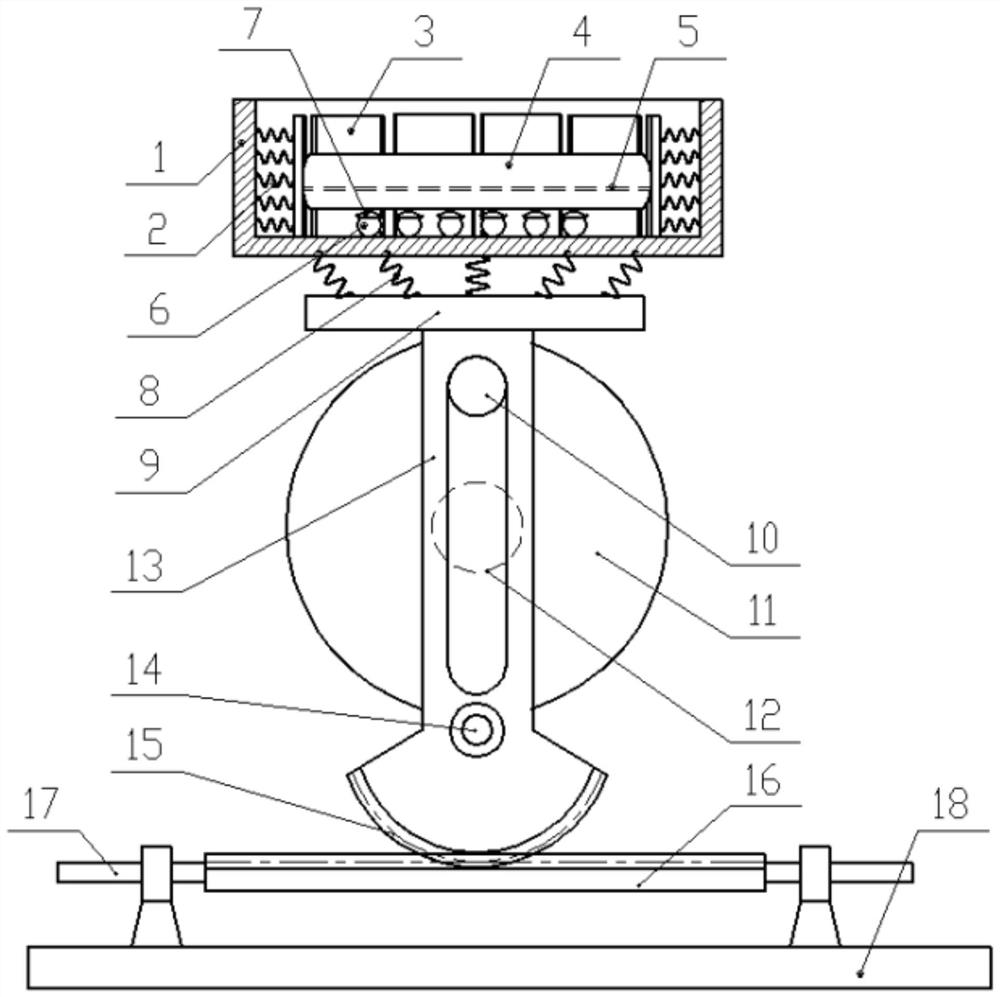

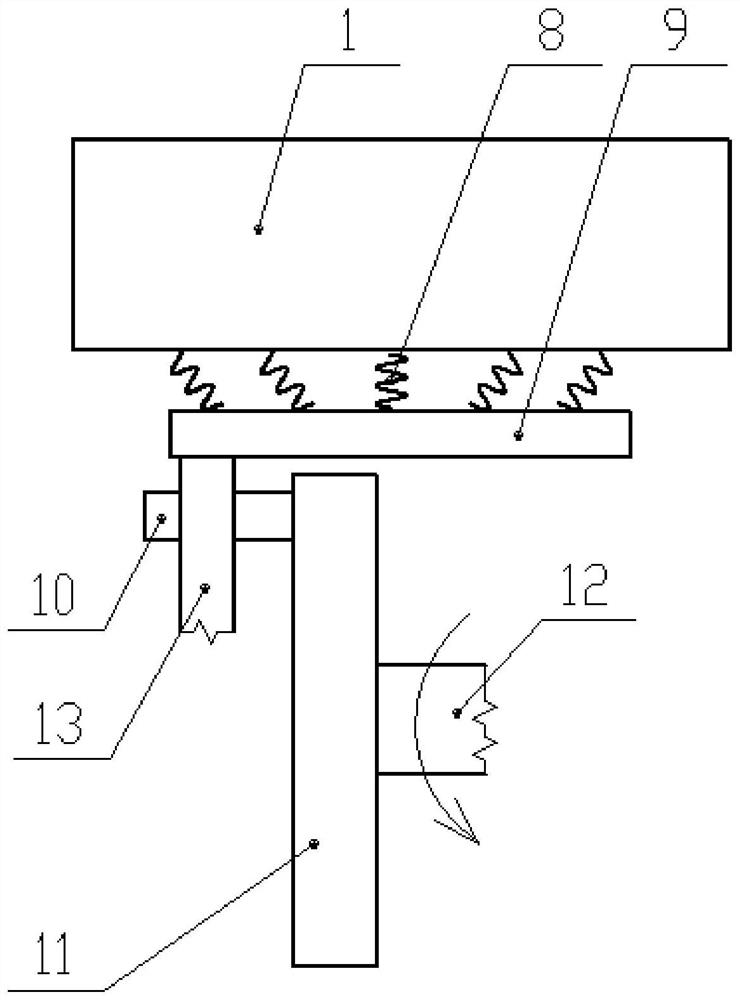

[0021] Such as figure 1 Shown in -3, a vibrating screen includes a frame, a screening component, a number of vibrating springs 8 and a vibrating mechanism from top to bottom.

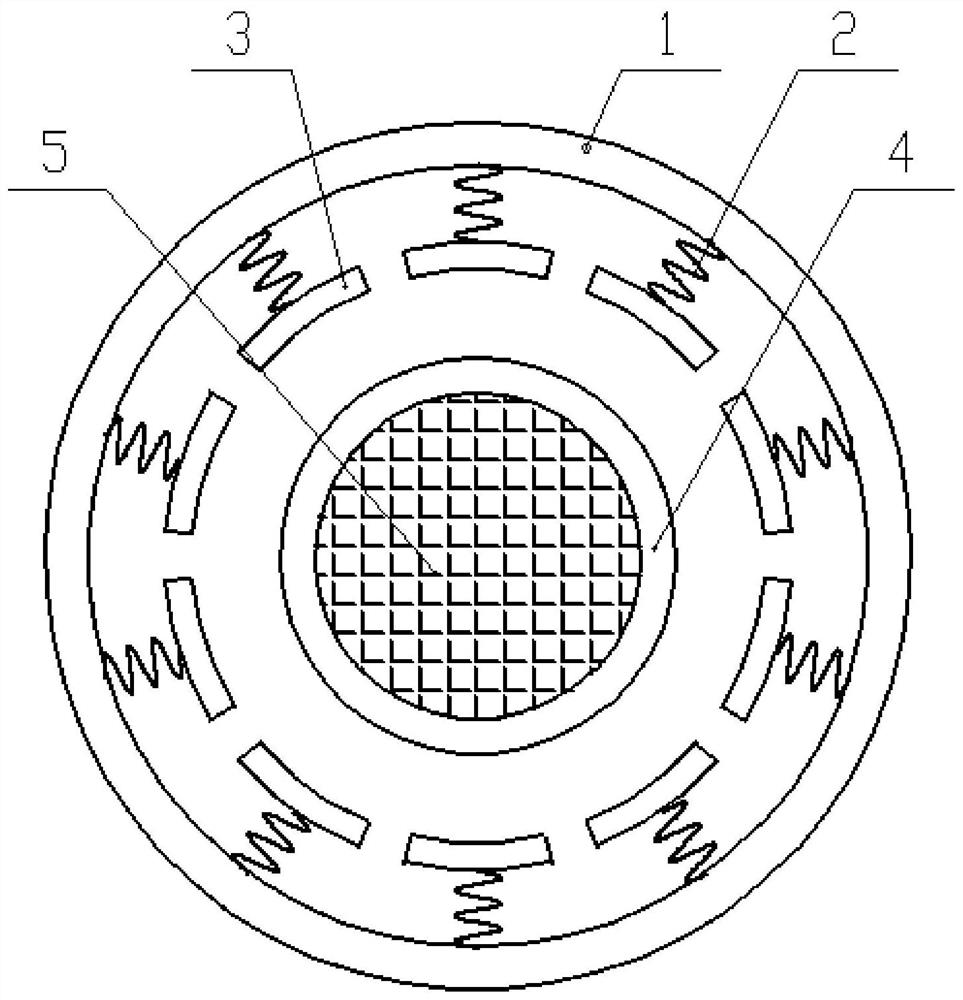

[0022] The screening part includes a round frame 1 and an impact spring 2, a baffle plate 3, and a sieve plate part 4 located in the round frame 1; one end of the impact spring 2 is fixed on the inner wall of the round frame 1 along the radial direction of the round frame 1, and the other end is connected with the tile The circular arc outer walls of the sheet-shaped baffles 3 are connected. The baffles 3 are arranged perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com