High-precision mechanical hand for carrying valve bodies

A manipulator, high-precision technology, applied in manipulators, program-controlled manipulators, transportation and packaging, etc., can solve the problems of waste of human resources and low production efficiency, and achieve the effect of long service life, low cost and reduced requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

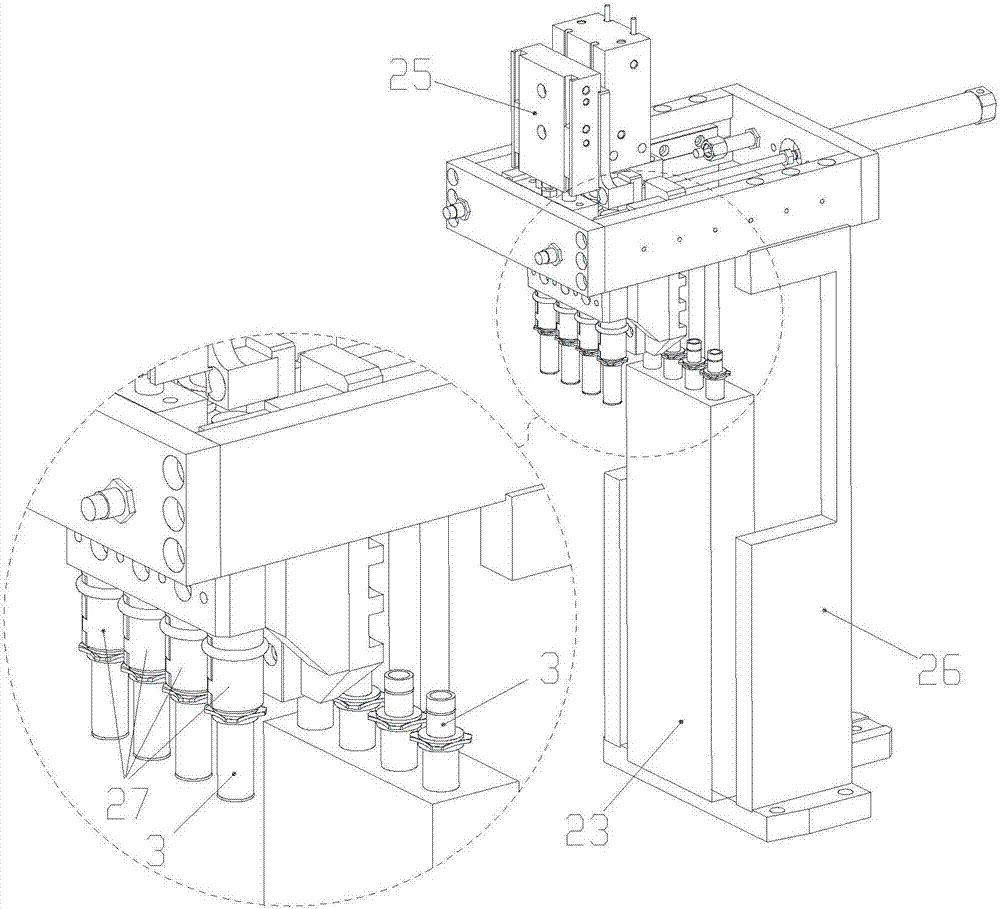

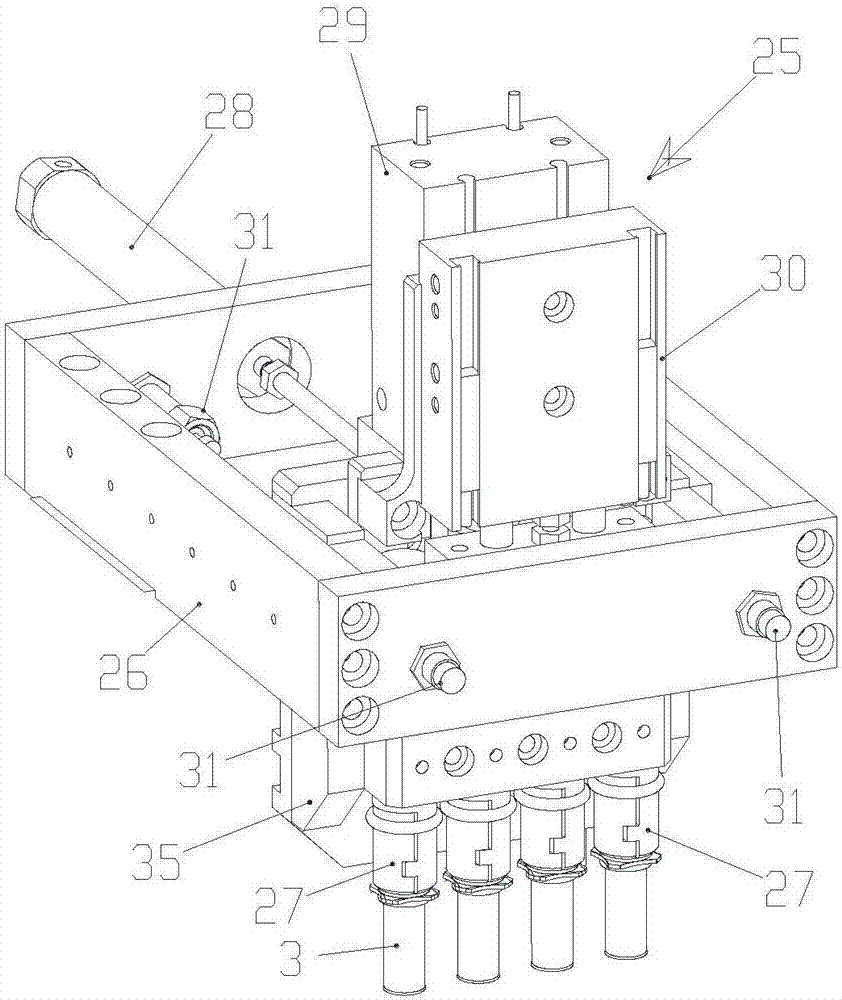

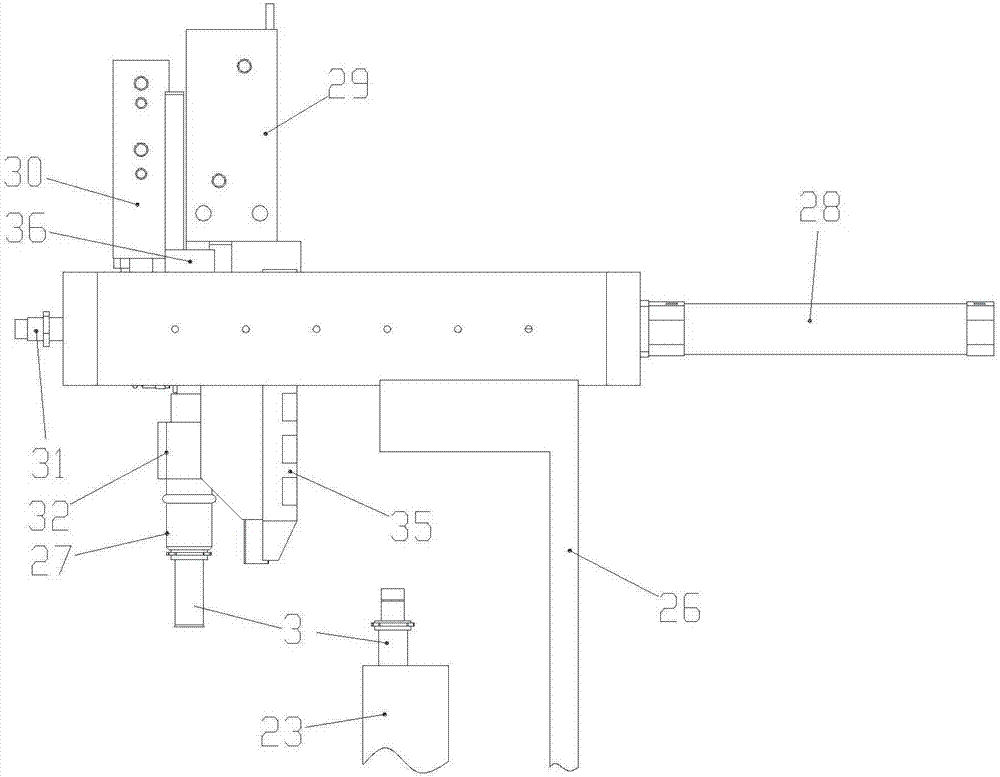

[0035] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a high precision manipulator for handling the valve body, used to move the valve body from one place to another, the valve body is grasped by the self-adaptive manipulator, and the valve body is transported to the place to be Assembly position, fully automatic operation, realize unmanned operation, with high work efficiency.

[0036] See Figure 9 , first introduce the structure of the valve body 3, the valve body 3 includes: ears 4, inner hole 5, cylinder 6, the ears 4 are located in the middle and upper parts of the valve body 3, the lower part of the ears 3 The part is the cylinder 6 , the inner hole 5 is provided at the lower part of the ear 3 , and the clamping part 24 is at the upper part of the ear 4 . The valve body 3 adopts a precision forging process to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com