A thin square plate forging method

A square plate and sleeve technology, applied in the field of thin square plate forging, can solve the problems of large blank allowance, short forging time, enlarged forgings, etc., achieve large dimensional control room, improve processing efficiency, and reduce forging allowance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

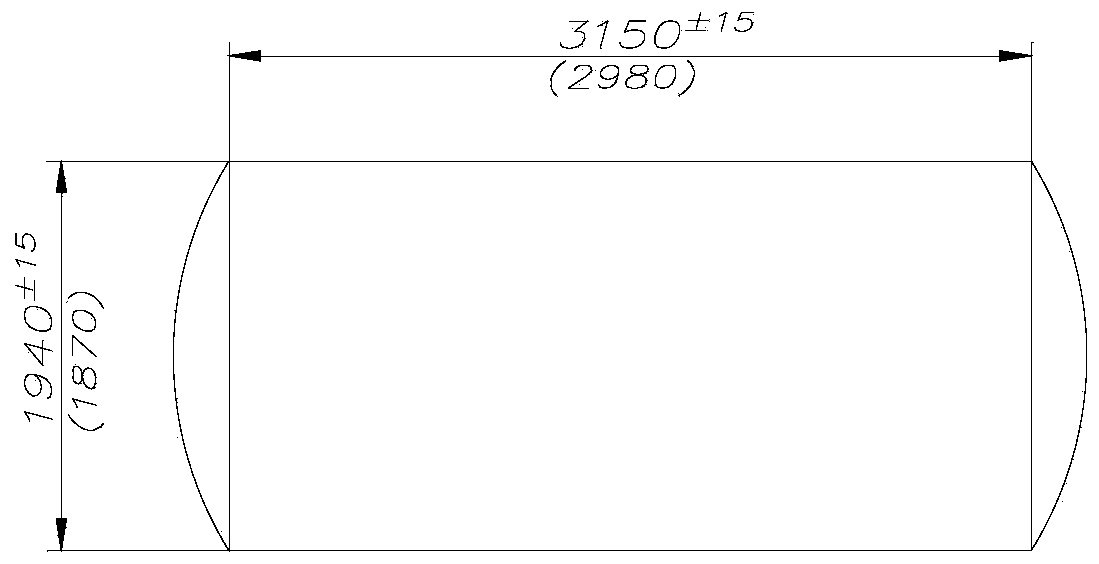

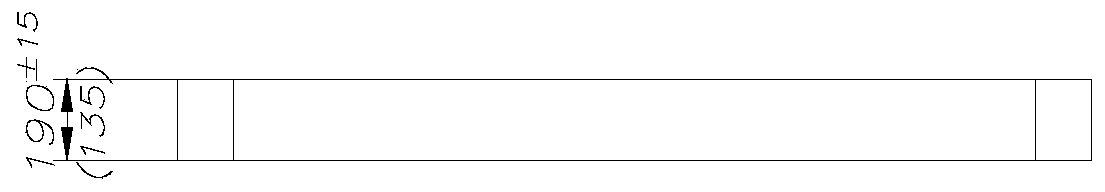

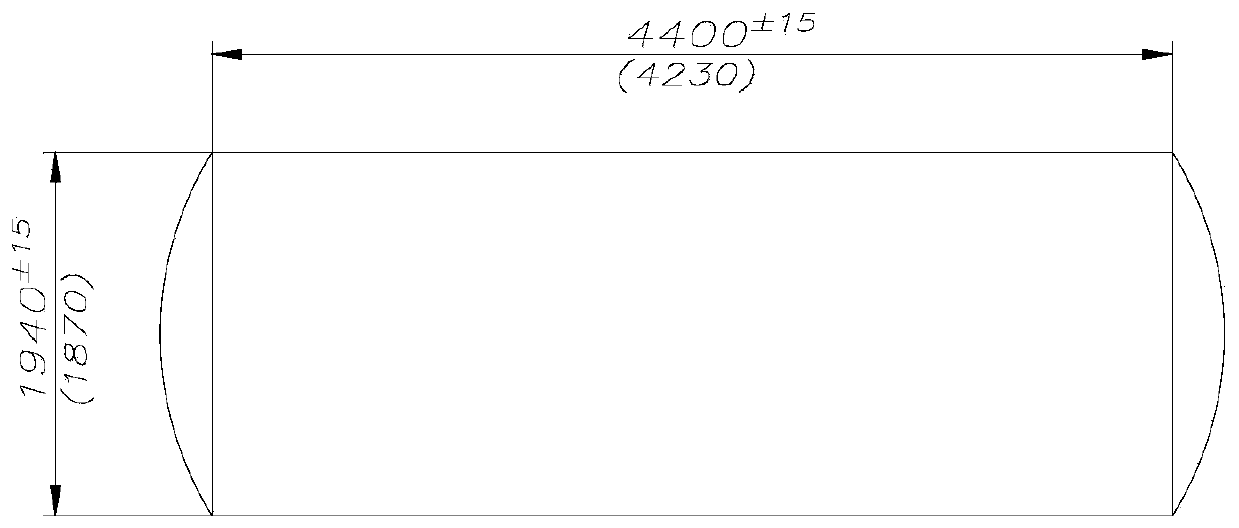

Image

Examples

Embodiment 1

[0040] Two specifications of thin square plates of embodiment 1 and piece forging comparative example 1

[0041] Forging process such as image 3 As shown, the steps include:

[0042] (a) Forged and piece sleeve

[0043] The forging process of the doubling sleeve is as follows:

[0044] S1, the billet is heated to 1200±20°C and kept for ≥15 hours;

[0045] S2, upsetting and drawing to ensure that the upsetting ratio is ≥ 4;

[0046] S3, punching, reaming and inner holes are in place;

[0047] S4, the length is pulled out in place;

[0048] S5, the height is upsetting after finishing the outer circle.

[0049] The size of the doubling sleeve is controlled according to the net size and margin of the thin square plates of two specifications in Comparative Example 1 forged by pre-bundling; wherein, the wall thickness of the doubling sleeve is the net thickness and thickness margin of the thin square plate sum, the height of the joining sleeve is the sum of the net width and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com