Flexible tool for laser cutting of automobile body covering parts

A technology of laser cutting and automobile body, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems such as difficulty in adapting to the fixation of body covering parts, and achieve the effect of strong adaptability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described with reference to the accompanying drawings of the specification.

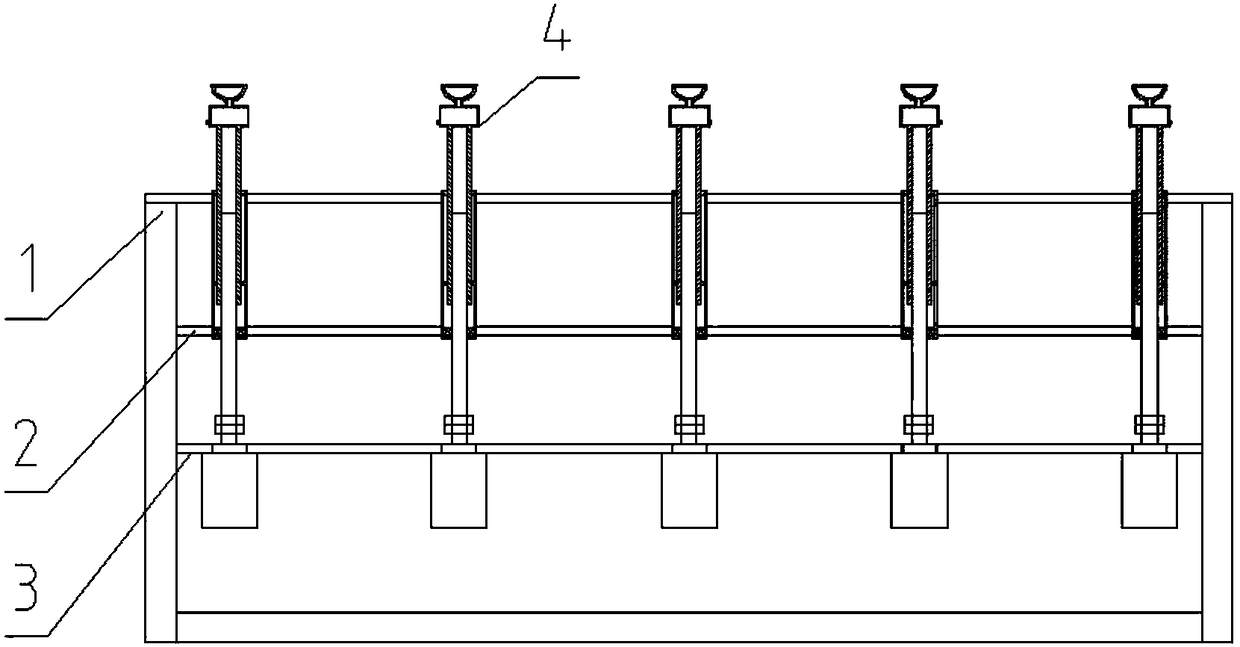

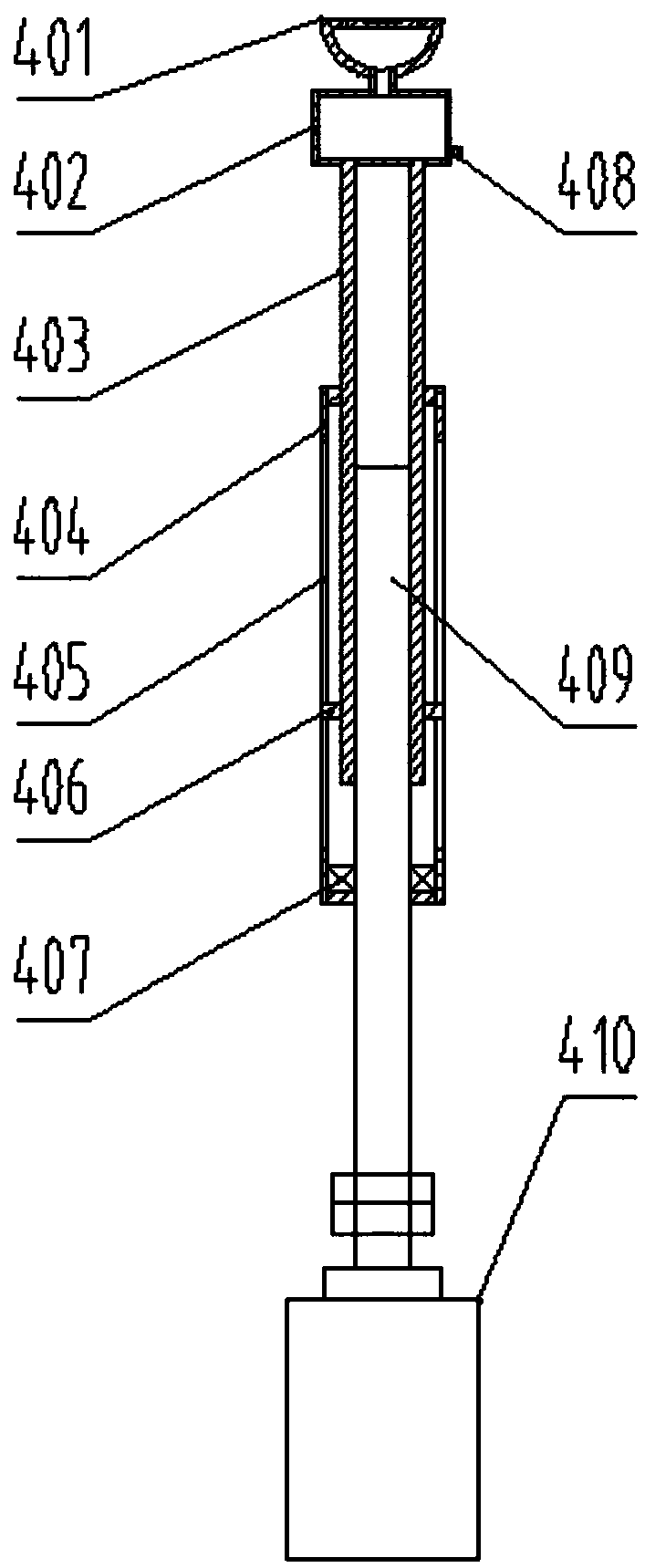

[0014] Such as figure 1 , figure 2 As shown, a laser cutting flexible tooling for automobile body covers includes a bracket 1, several sets of suction cup fixing devices 4, and the suction cup fixing device 4 includes a vacuum suction cup 401, a sliding sleeve 403, a sleeve 404, and a screw rod 409. The lower part of the sleeve 404 is provided with a sliding groove 405, the upper part of the screw 409 is provided with an external thread, the sliding sleeve 403 is of a hollow structure, and the lower part of the inner wall of the sliding sleeve 403 is provided with an internal thread, the external thread and The inner thread is matched, the outer side of the lower part of the sliding sleeve 403 is provided with a sliding blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com