Positioning system used before rotor assembly assembling

A front positioning and assembly technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of low degree of automation in the assembly operation of micro motors, and achieve the effect of avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

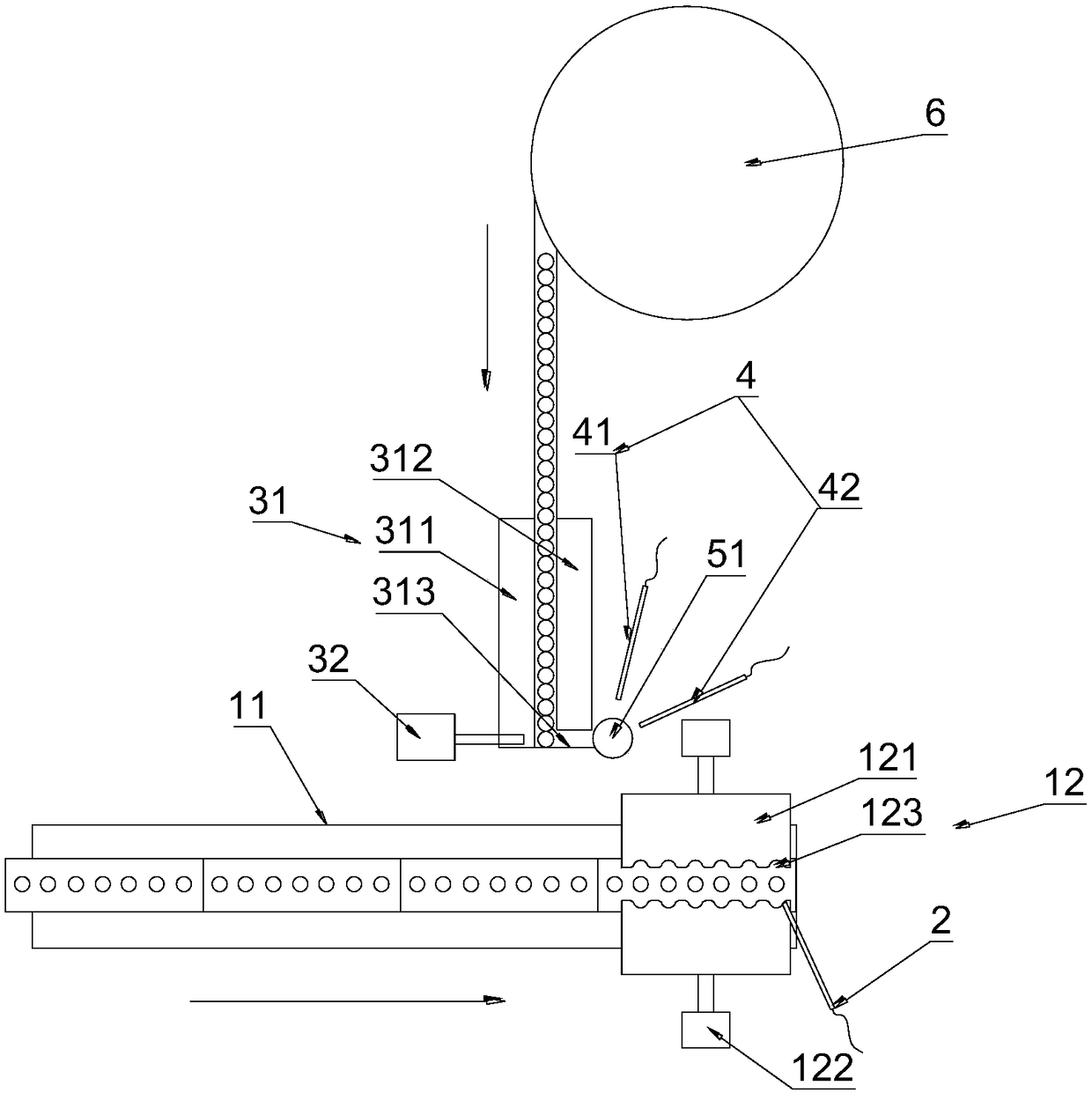

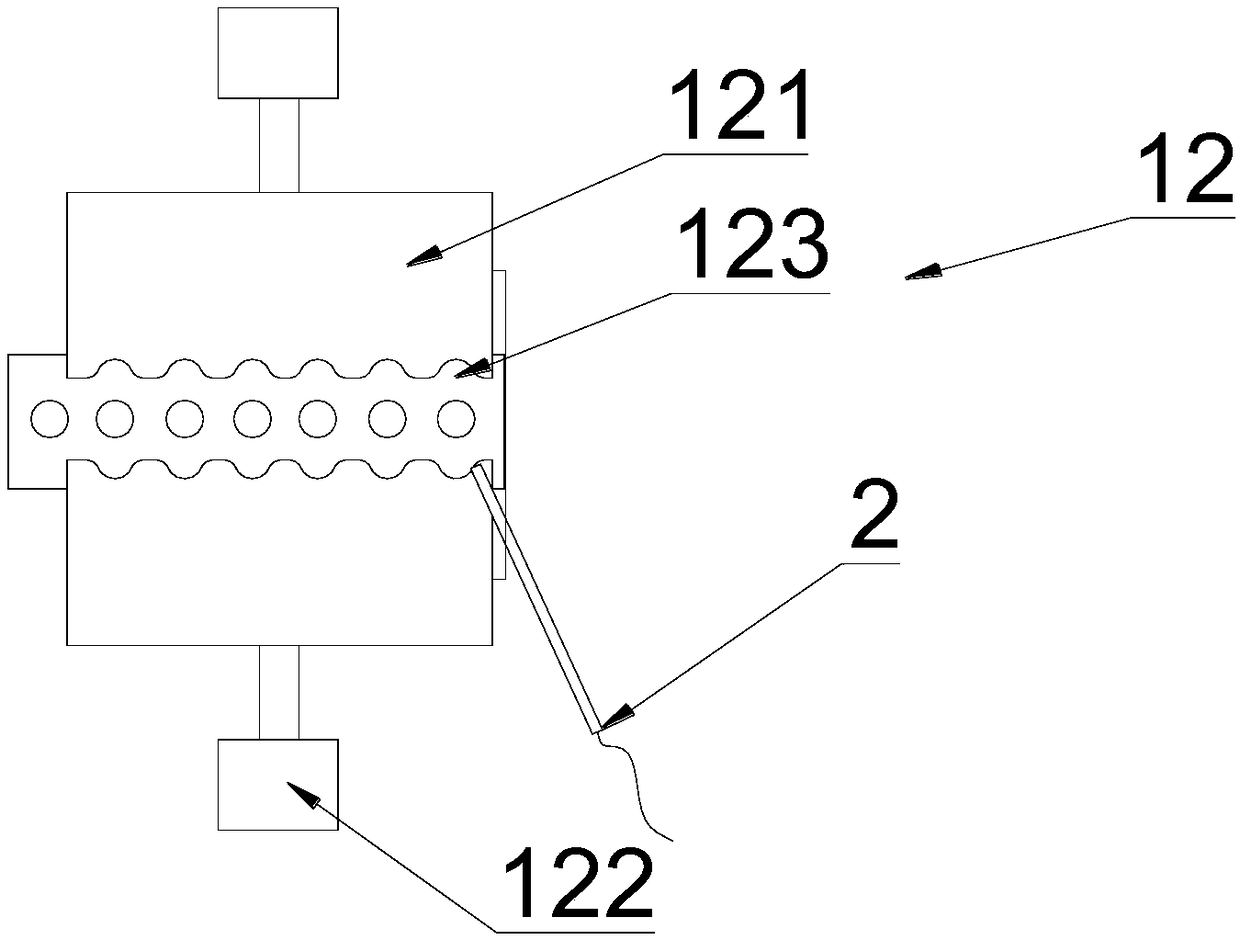

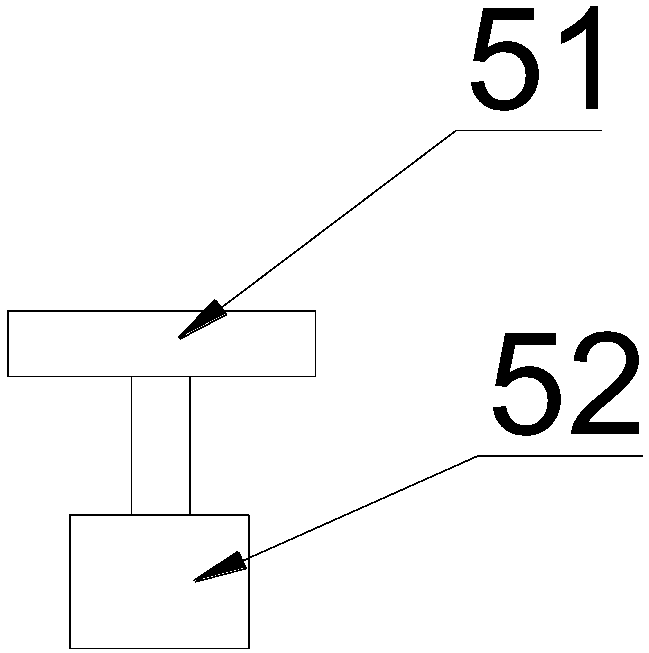

[0026] Such as figure 1 As shown, a posture adjustment system before motor casing assembly includes a first conveying device 1, a first detecting device 2, a second conveying device 3, a second detecting device 4, an angle adjusting device 5, a first manipulator, a second manipulator; controller.

[0027] The first conveying device 1 includes a first track 11 and a first drive mechanism, and the turnover bar is placed on the first track 11; the controller controls the opening and closing of the first drive mechanism according to the monitoring information sent by the first detection device 2 received, through The first driving mechanism drives the track for a single progress amount.

[0028] Such as figure 1 , figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com