Pure electric bus

A bus, pure electric technology, applied in electric vehicle charging technology, electric power device, vehicle maintenance and other directions, can solve the problems of cumbersome replacement, parking at the charging station to charge, etc., to achieve quick use, accurate positioning, and save waiting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

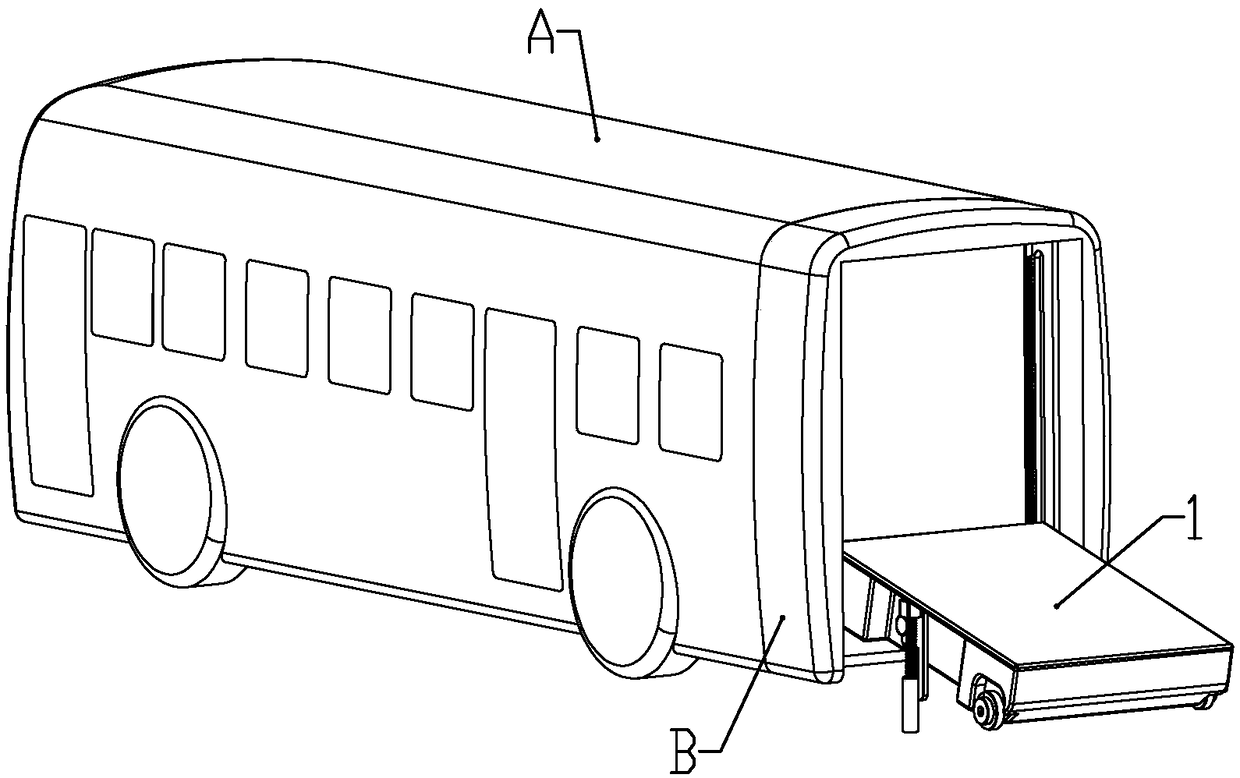

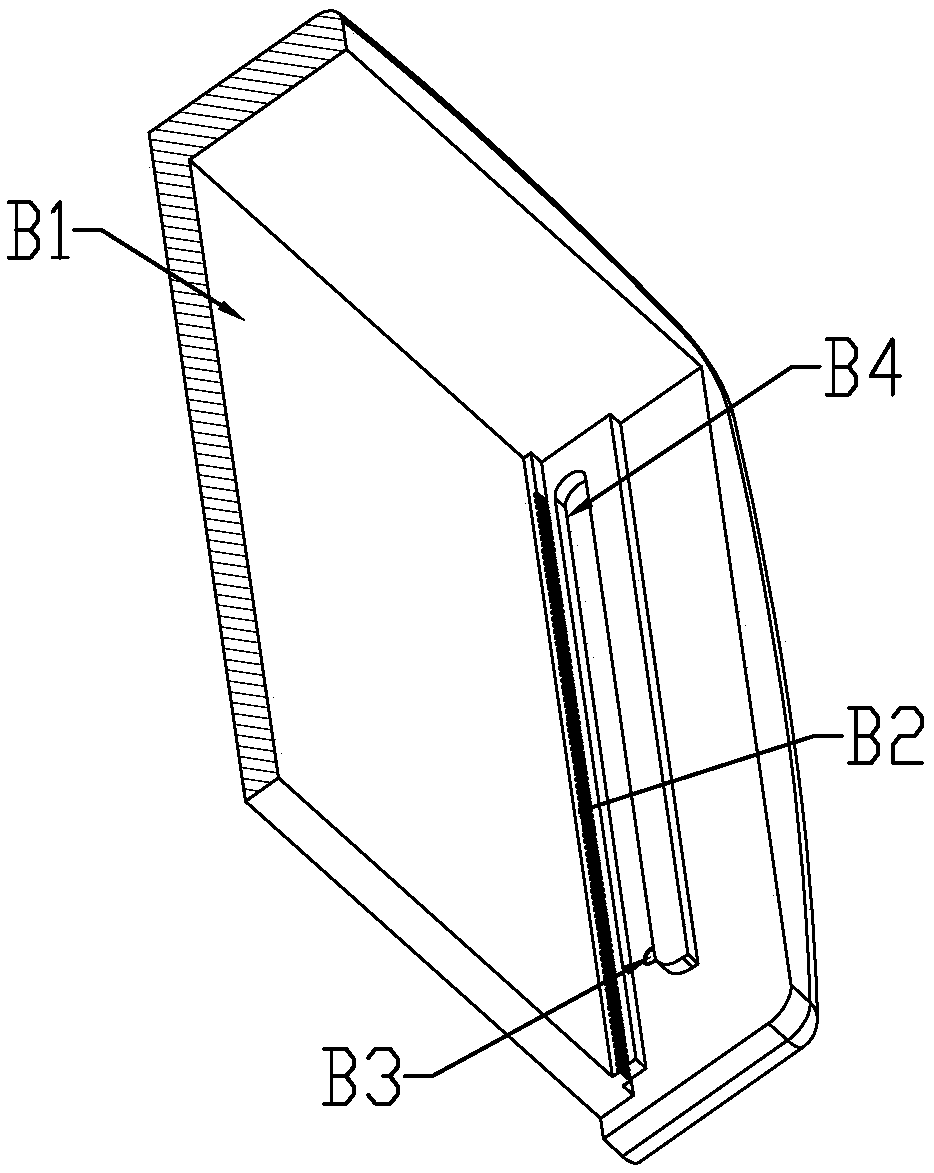

[0059] according to Figure 1 to Figure 11 As shown, a pure electric bus described in this embodiment includes a car body A, a battery assembly mounting seat B fixedly installed at the rear end of the car body, and a battery assembly movably mounted in the battery assembly mounting seat 1.

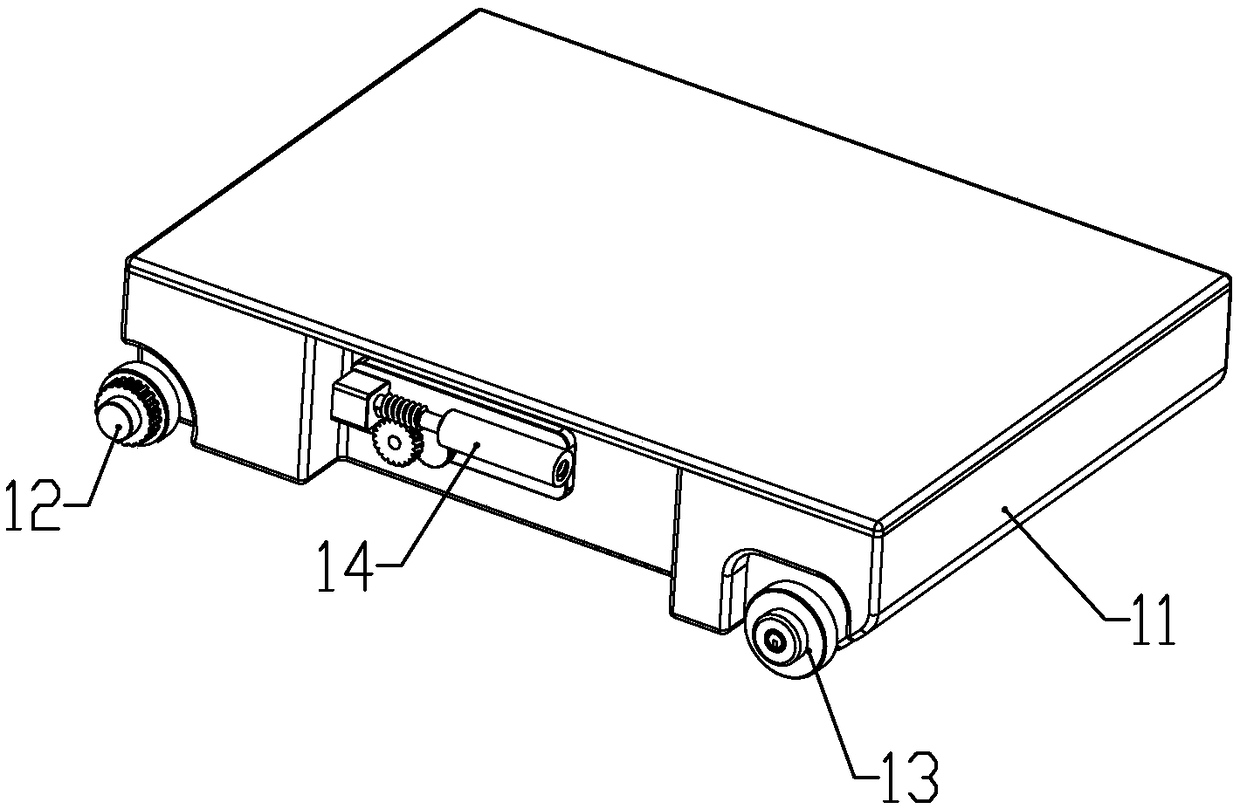

[0060] The battery assembly includes a rectangular frame 11, a front axle 12 installed at the front end of the frame, two rear axles 13 installed at the rear of the frame, and two symmetrically mounted on both sides of the frame. Rotate lift assembly 14.

[0061] The front wheel shaft is rotatably connected to the lower part of the frame body; the two ends of the front wheel shaft located outside the frame body are respectively fixedly connected with a front wheel 121, a second gear 122 and a limit guide post 123 from the inside to the outside; The front wheel, the second gear and the limiting guide post are arranged coaxially and their outer diameters are successively reduced; the dista...

Embodiment 2

[0087] combine Figures 12 to 19 As shown, this embodiment makes the following improvements on the basis of embodiment 1: a cooling assembly is installed in the battery assembly, and the cooling assembly includes a heat collecting pipe installed in the frame for absorbing the heat emitted by the battery , the radiator installed in the frame, and the cooling pump used to drive the cooling liquid to circulate between the heat collection pipeline and the radiator.

[0088] The radiator includes a heat dissipation plate 82, a heat dissipation seat 83 and a water wheel seat 84 which are sealed and connected in sequence; a heat dissipation channel 831 is opened on the end surface of the heat dissipation seat facing the heat dissipation plate, and the heat dissipation channel is arranged in a circuitous manner as shown in the figure. In the shape of a serpentine tube, the side of the cooling seat is connected with a liquid inlet joint a832 and a liquid outlet joint a833, and the liqu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap