Self-positioning plastic vacuum tank

A vacuum tank and self-positioning technology, which is applied to the layout of reservoirs, brakes, transportation and packaging, etc., can solve the problems of complex processing procedures, uneven parallelism of installation bolts, easy corrosion, etc., and achieve good appearance consistency and convenience The effect of high flatness in processing, production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

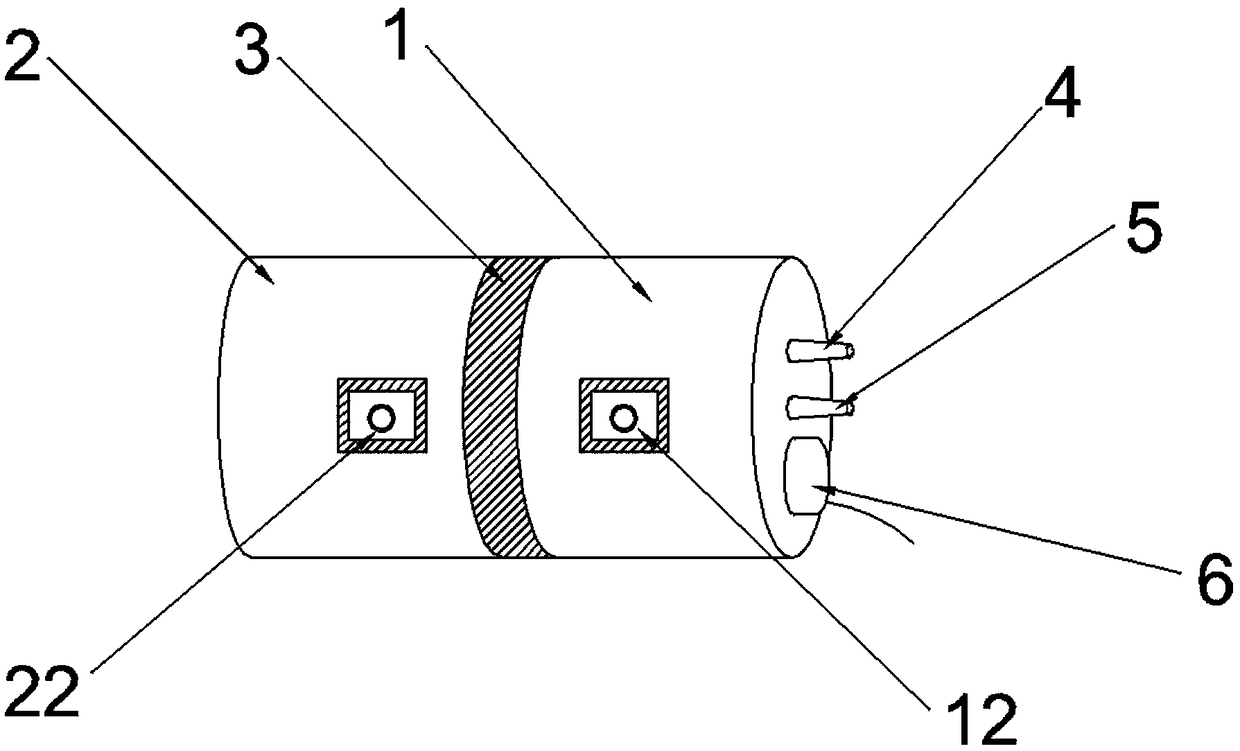

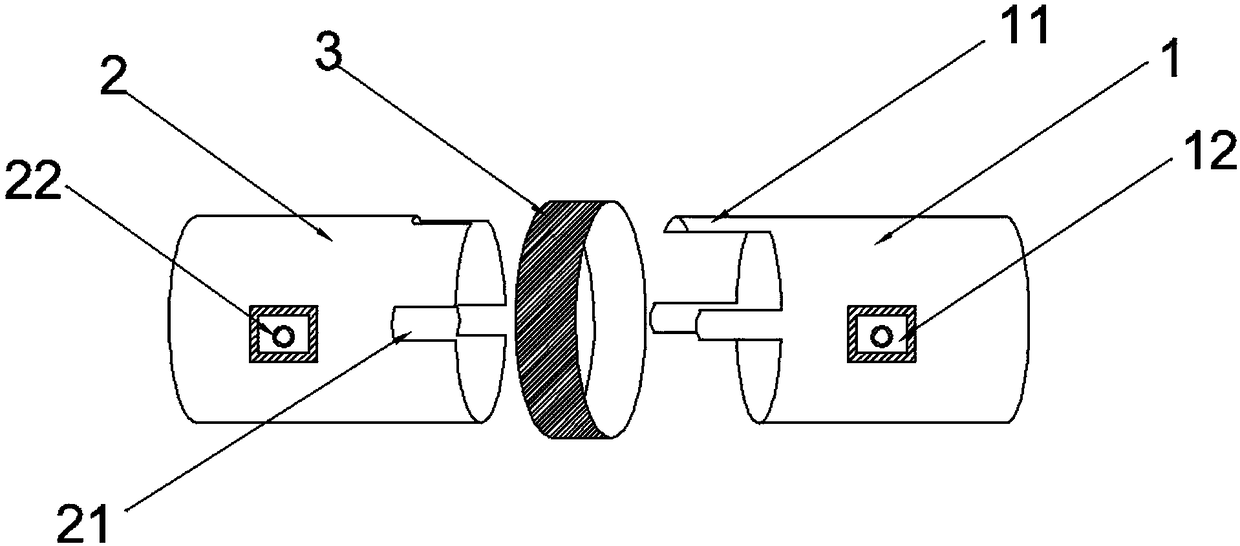

[0019] Embodiment 1 discloses a self-positioning plastic vacuum tank, such as figure 1 As shown, it includes an upper cover 1, a lower cover 2 and a sealing ring 3. The upper cover 1 and the lower cover 2 are sealed and connected by the sealing ring 3. The top of the upper cover 1 of the plastic vacuum tank is also provided with an air inlet 4 and an air outlet 5 respectively. The joints with the pressure sensor 6, the upper cover 1 and the lower cover 2 are respectively provided with self-positioning devices that cooperate with each other, and the sealing ring 3 covers the joints. like figure 2 As shown, the self-positioning device is composed of a protruding plug 11 at the end face of the upper cover 1 and a recessed slot 21 at the end face of the lower cover 2. The size of the plug 11 and the slot 21 are corresponding, and the plug 11 The length does not exceed the width of the sealing ring 3, so that the sealing ring 3 can completely wrap and seal the connection port. I...

Embodiment 2

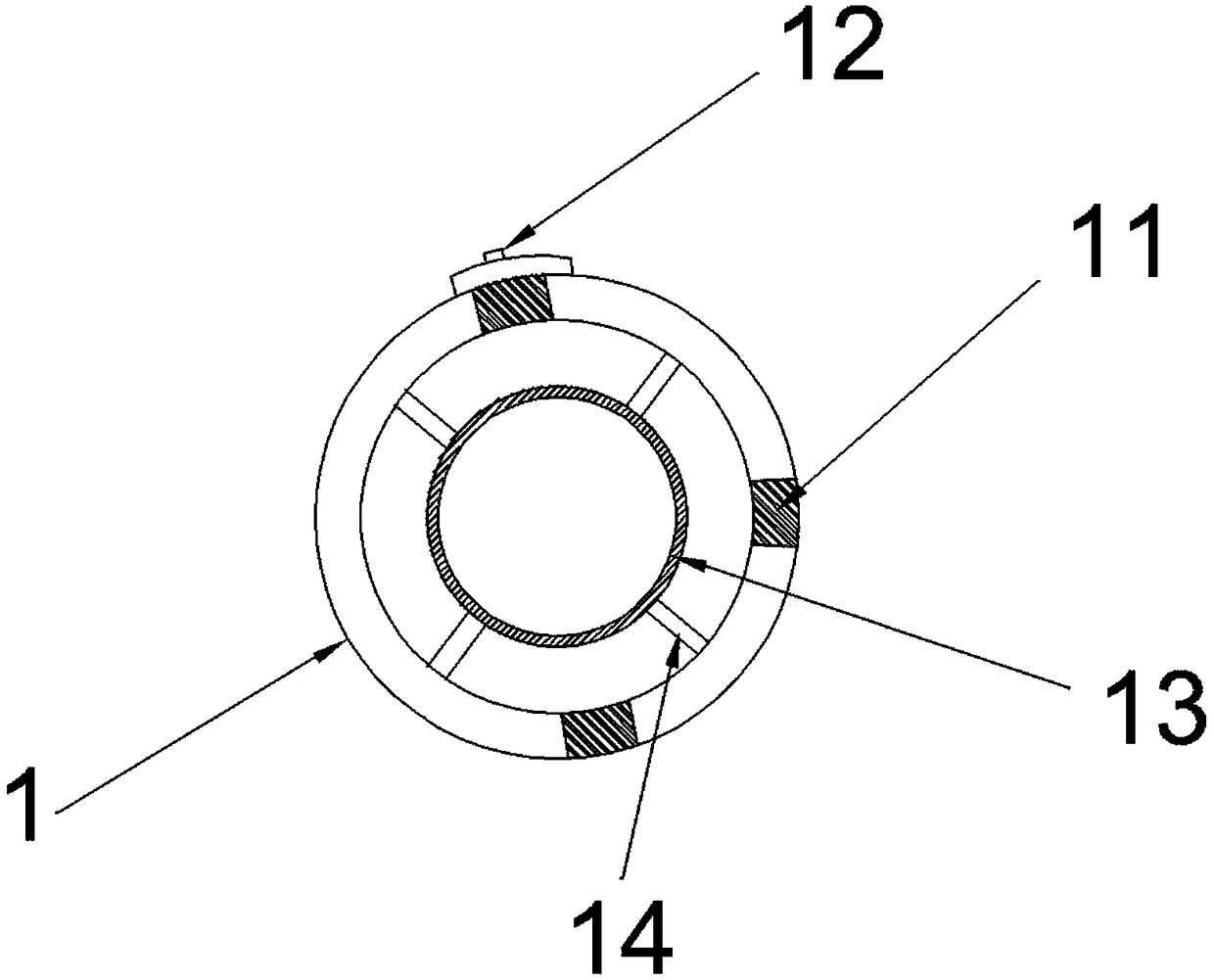

[0021] Embodiment 2 discloses a self-positioning plastic vacuum tank, including an upper cover 1, a lower cover 2 and a sealing ring 3, the upper cover 1 and the lower cover 2 are sealed and connected by the sealing ring 3, and the tank body of the plastic vacuum tank is also provided with There are air inlet holes 4, air outlet holes 5 and pressure sensors 6, and the joints of the upper cover 1 and the lower cover 2 are respectively provided with self-positioning devices that cooperate with each other, and the sealing ring 3 covers the joints. The self-positioning device is composed of a protruding insert 11 at the end face of the upper cover 1 and a recessed slot 21 at the end of the lower cover 2. The size of the insert 11 and the slot 21 are corresponding, and the length of the insert 11 is different. The width of the sealing ring 3 is exceeded, so that the sealing ring 3 can completely wrap and seal the connection port. In this embodiment, there are three inserting blocks...

Embodiment 3

[0023] Embodiment 3 discloses a self-positioning plastic vacuum tank, including an upper cover 1, a lower cover 2 and a sealing ring 3, the upper cover 1 and the lower cover 2 are sealed and connected by the sealing ring 3, and the tank body of the plastic vacuum tank is also provided with There are air inlet holes 4, air outlet holes 5 and pressure sensors 6, and the joints of the upper cover 1 and the lower cover 2 are respectively provided with self-positioning devices that cooperate with each other, and the sealing ring 3 covers the joints. The self-positioning device is composed of a protruding insert 11 at the end face of the upper cover 1 and a recessed slot 21 at the end of the lower cover 2. The size of the insert 11 and the slot 21 are corresponding, and the length of the insert 11 is different. The width of the sealing ring 3 is exceeded, so that the sealing ring 3 can completely wrap and seal the connection port. In this embodiment, there are three inserting blocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com