Crochet gear transmission device of double-weft-winding-edge weaving machine

A transmission device and crochet needle technology, which is applied in the field of crochet transmission device and loom components, can solve the problems of high equipment cost, low production efficiency, high failure rate, etc., and achieve the effect of improving production quality, reliable performance and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

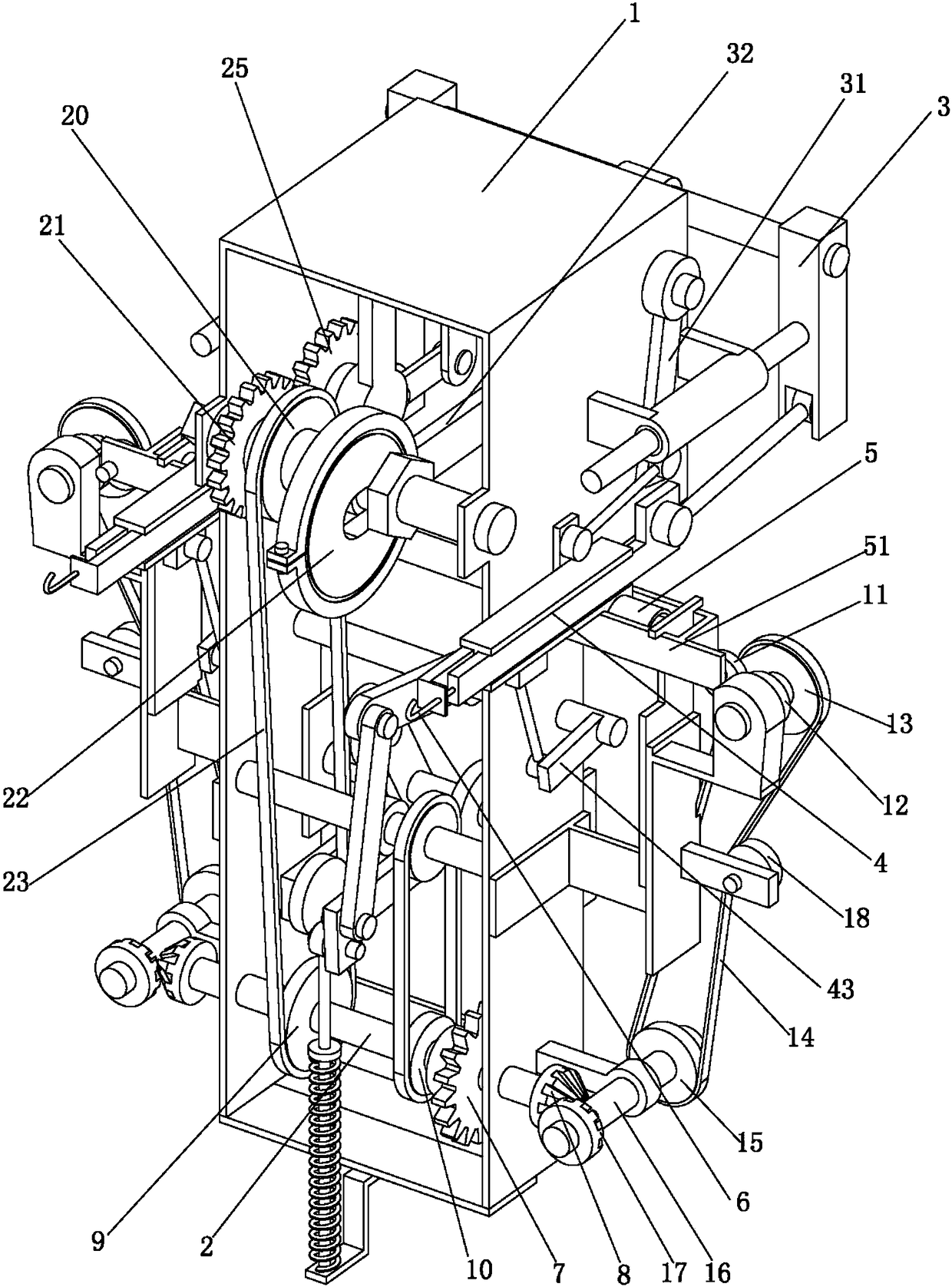

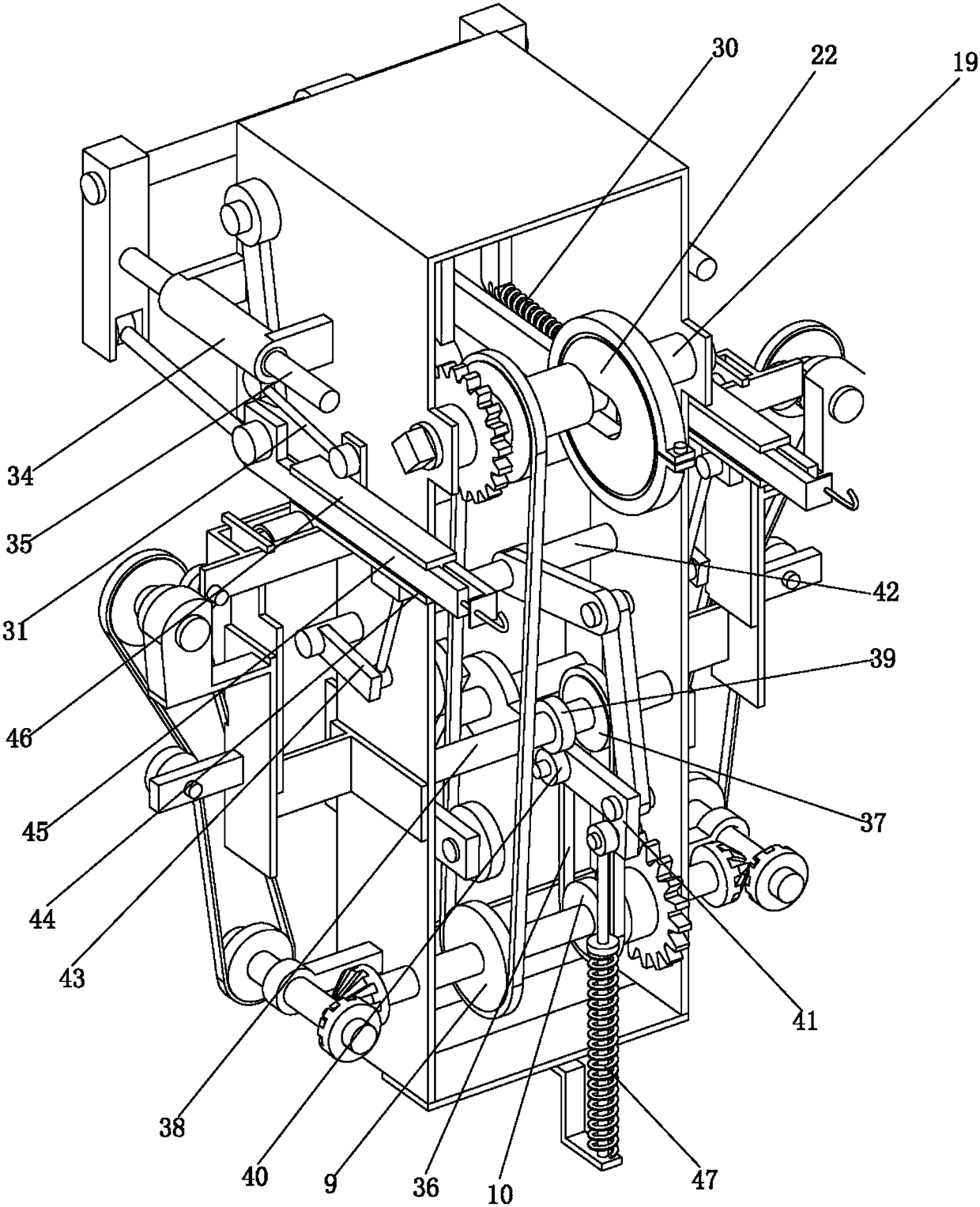

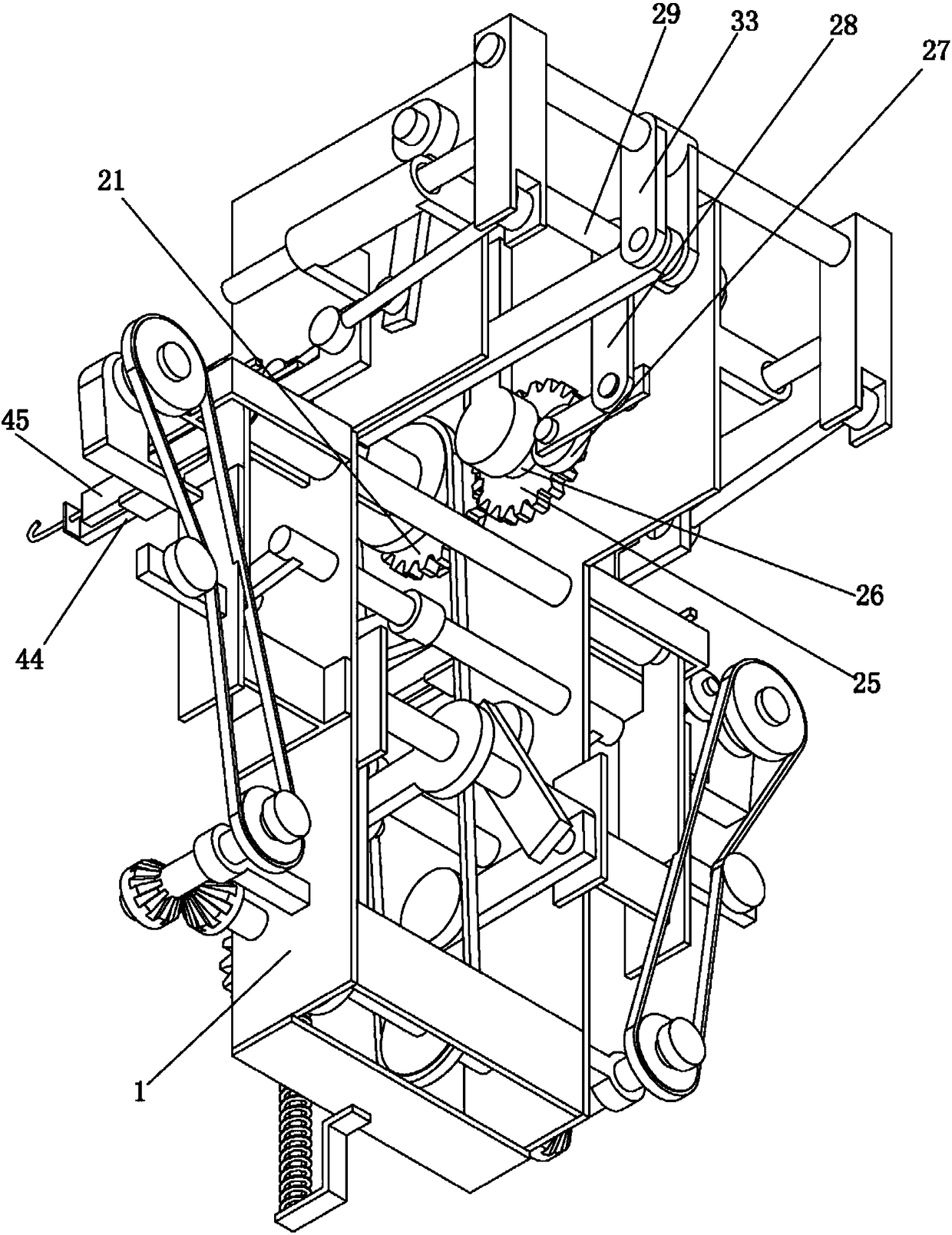

[0017] Please refer to the instruction manual figure 1 Attached image 3 As shown, the present invention is a crochet transmission device of a double-weft winding loom, which is composed of a mounting frame 1, a power input shaft 2, a crochet left and right support 3, a crochet seat 4, a telescopic shaft 5, and a crochet needle 6.

[0018] Wherein, the power input shaft 2 is pivotally connected to the mounting frame 1, and the power input gear 7, the bevel gear A8, the sprocket A9 and the sprocket B10 are mounted on it. The power input gear 7 inputs the power of the double weft winding loom into the crochet transmission device to make the whole device work.

[0019] The bevel gear A8 can drive the telescopic shaft 5 to expand and contract left and right, and the telescopic shaft 5 has a telescopic distance of 2-20 mm. The crochet holder 4 is welded to the telescopic shaft 5 and linked with the telescopic shaft 5. Specifically, a base 51 is provided at one end of the telescopic sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com