Water guiding sealing device for shield tunnel joint

A sealing device, shield tunnel technology, applied in the direction of tunnel, tunnel lining, shaft equipment, etc., can solve the problems of falling off, caulking materials are easily staggered, etc., to achieve the effect of improving the guarantee rate and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

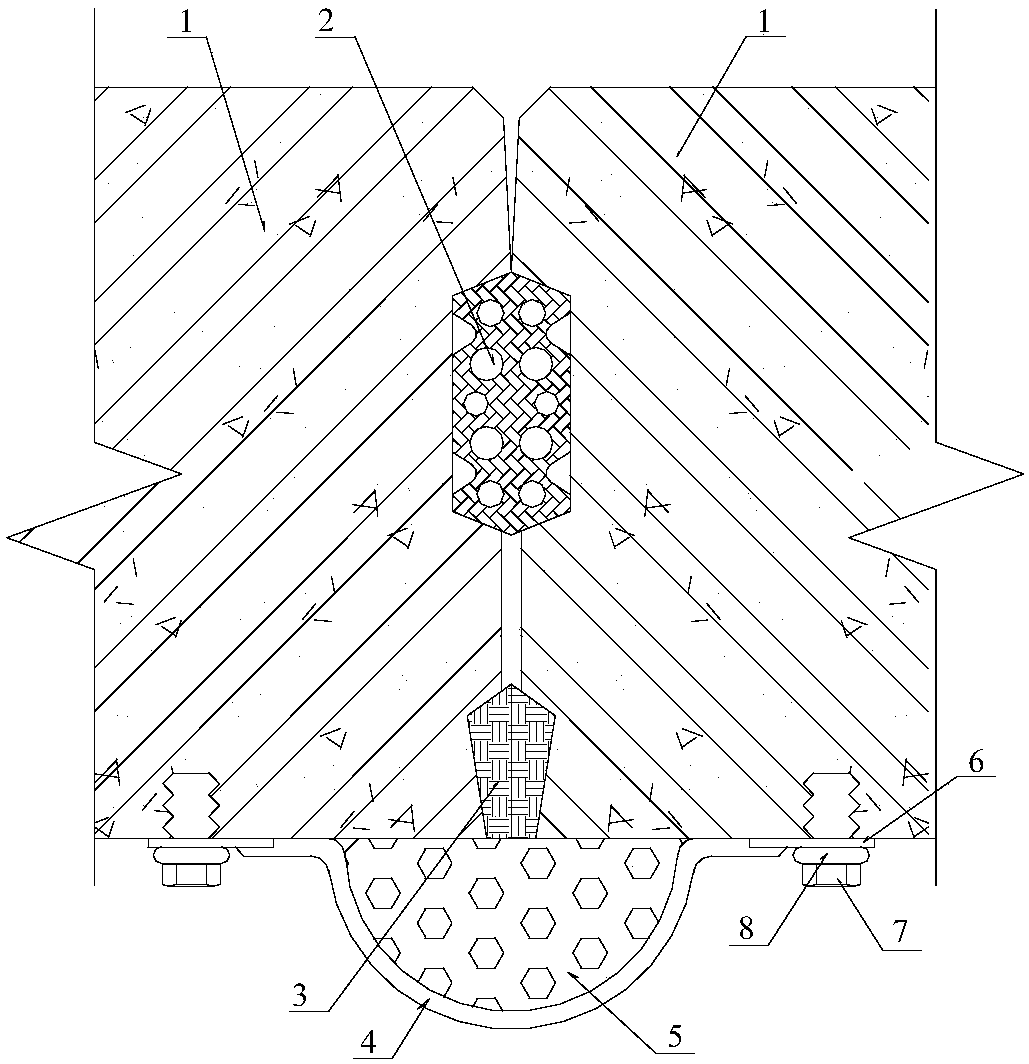

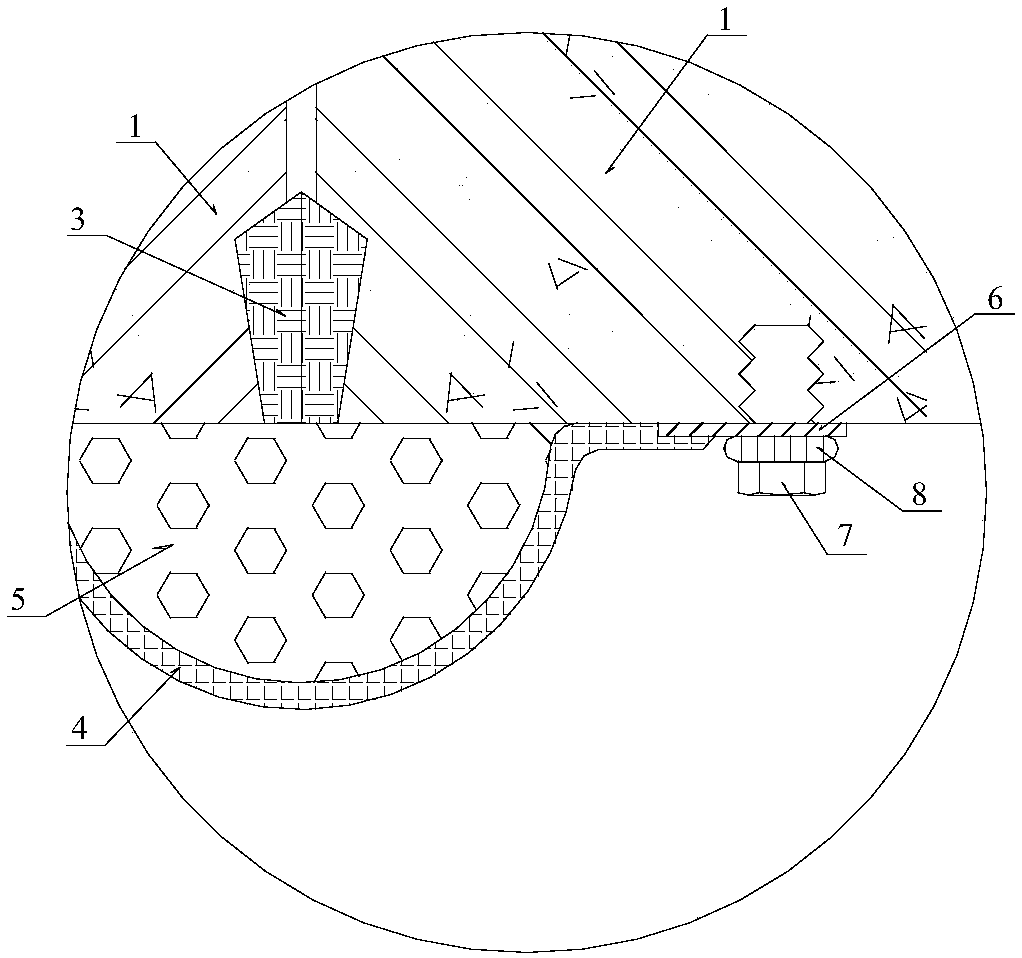

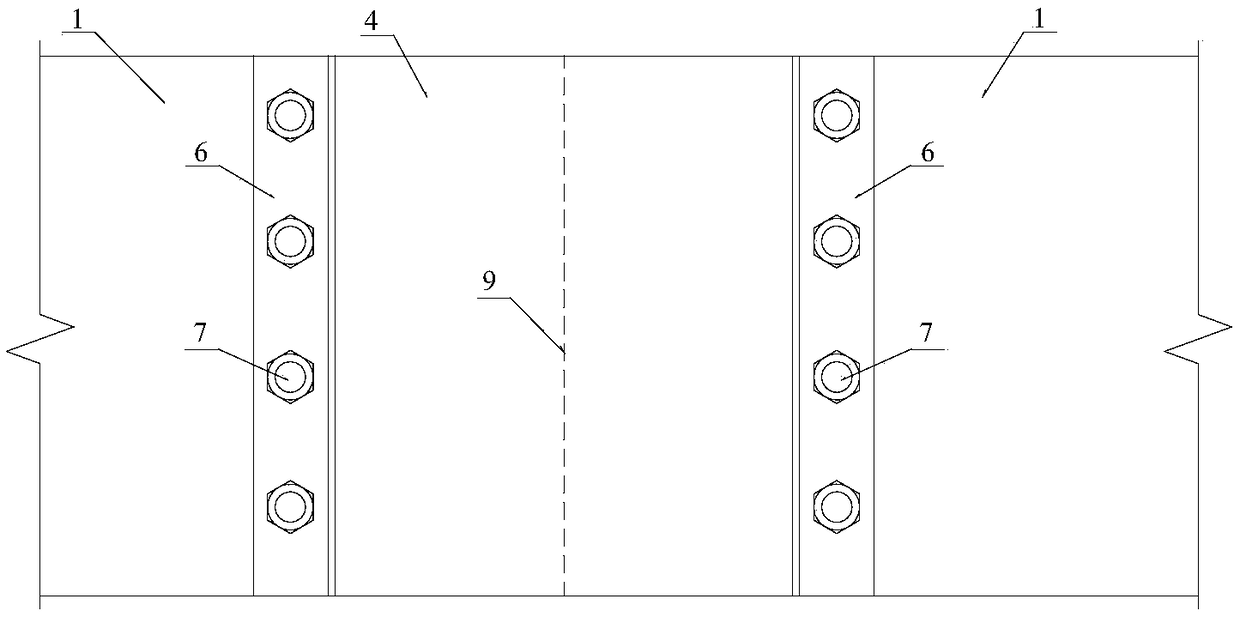

[0017] refer to Figure 1 to Figure 4 , a water-conducting sealing device for shield tunnel joints according to the present invention, comprising an arc-shaped rubber band 4 extending across the caulking 3 and along the segment joint 9, on the inner surface of the arc-shaped rubber band 4 The anti-filter layer 5 is fixedly set. The lateral sides of the arc-shaped rubber belt 4 form a detachable connection with the segment 1 through the bolts 7 arranged at vertical intervals, so that the inner surfaces of the lateral sides of the arc-shaped rubber band 4 are closely attached to the segment 1 to form a seal. The filter layer 5 is in close contact with the caulking 3 . It can realize the complete sealing and water conduction of the joints of the segments, avoiding the adverse effects of water leakage from the joints on the tunnel; the arc-shaped rubber b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com