Sealing system of submerged pump

A sealing system and submerged pump technology, applied in the direction of pumps, components of pumping devices for elastic fluids, pump devices, etc., can solve problems such as leakage, medium pollution, and threat to the life safety of workers, and ensure life safety. , the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

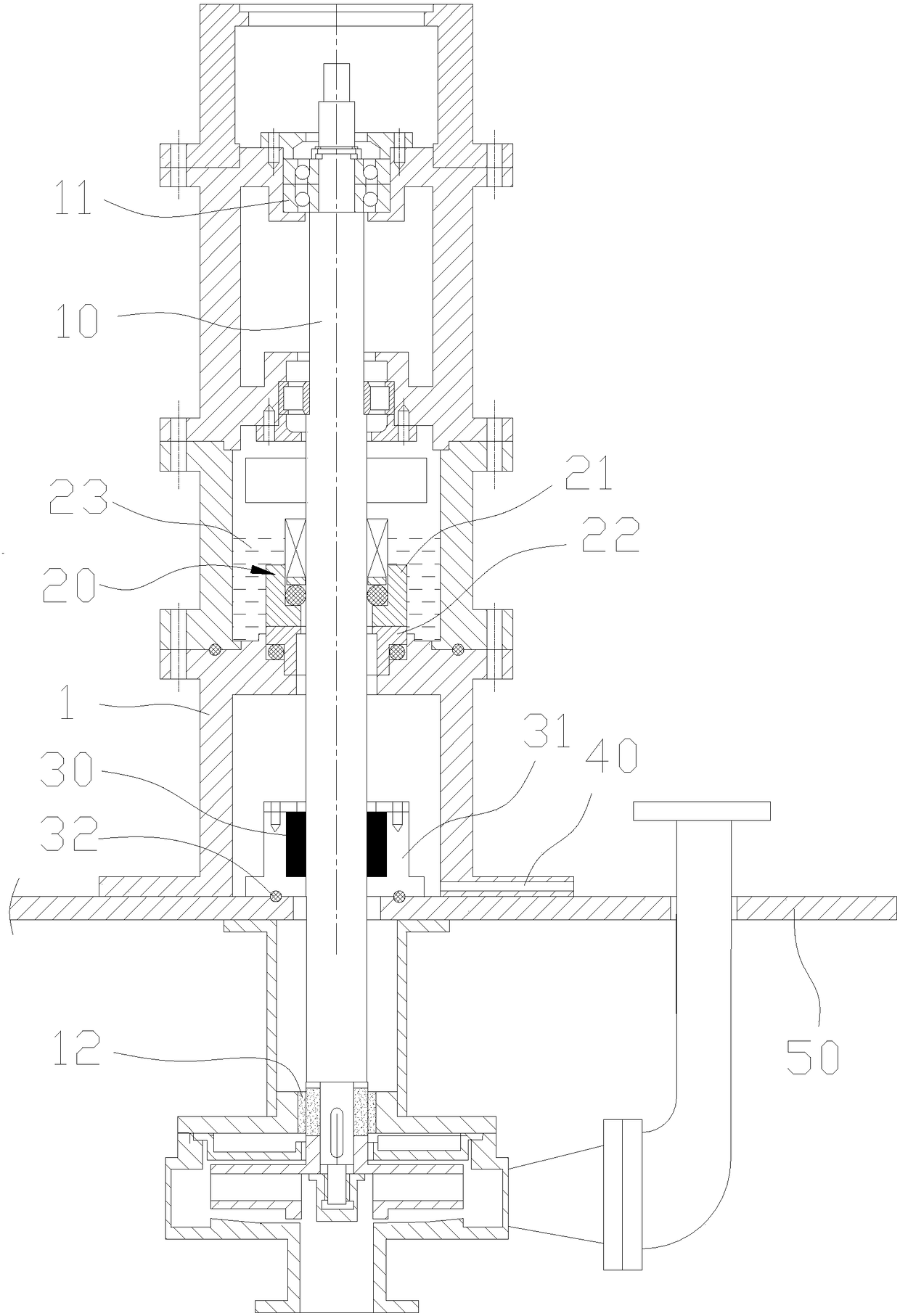

[0007] A sealing system for a submerged pump, comprising a pump shaft 10 located in a casing 1, on which there are first and second bearings 11, 12 arranged at intervals along its axial direction, between the pump shaft 10 and the casing 1 A mechanical seal 20 is provided, and the pump shaft 10 below the mechanical seal 20 is sealed with the casing 1 through a packing 30 , both of which are located above the bottom plate 50 .

[0008] In the above solution, a mechanical seal 20 is provided between the pump shaft 10 and the casing 1. When the mechanical seal 20 is damaged, since the pump shaft 10 below the mechanical seal 20 and the casing 1 are sealed through the packing 30, On the one hand, the lubricating oil used for the mechanical seal 20 is prevented from directly leaking into the medium, that is, the lubricating oil will leak to the area between the packing 30 and the casing 1 to prevent the medium from being polluted; on the other hand, because the packing 30 Excellent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com