A follow-up self-locking hydraulic reset mechanism for a follow-up self-locking booster hydraulic cylinder

A hydraulic cylinder and reset mechanism technology, applied in the field of hydraulic cylinders, can solve the problems of operator safety accidents, inability to lock in time, large size of hydraulic locks, etc., and achieve the effect of sensitive and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

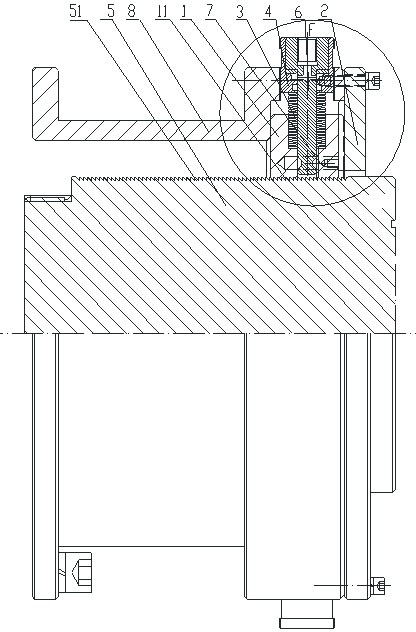

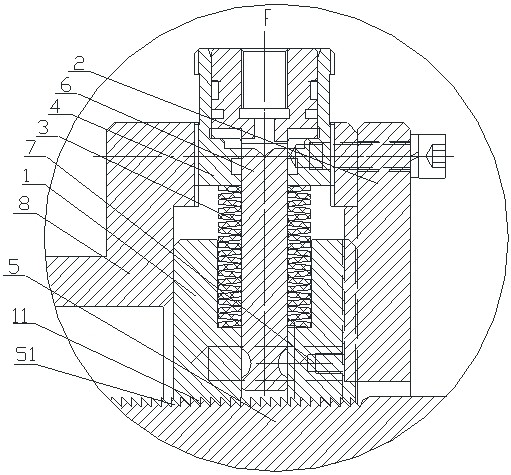

[0029] In order to deepen the understanding of the present invention, the following will be described in detail in conjunction with the accompanying drawings and specific embodiments. The embodiments described in this specification are only used to explain the present invention, and are not intended to limit the present invention.

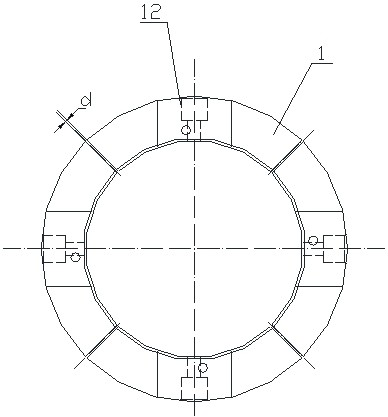

[0030] figure 1 and Figure 1a As shown, a follow-up self-locking hydraulic reset mechanism of a follow-up self-locking booster hydraulic cylinder of the present invention, the follow-up self-locking hydraulic reset mechanism includes a follow-up self-locking mechanism and a hydraulic reset mechanism, and the follow-up The self-locking mechanism includes a backstop rod 5, a backstop ring 1 and a disc spring 3. The backstop bar 5 has an outer ratchet 51 on the surface, and the outer ratchet 51 meshes with the inner ratchet 11 of the backstop ring 1. The backstop ring 1 Disc spring 3 is arranged inside.

[0031] The outer ratchet 51 of the stop rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com