Knob type gear shifting switch of automobile

A car gear shifting, knob-type technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as prone to misoperation, frequent gear shifting, and potential safety hazards, and extend the service life , Guarantee driving safety and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

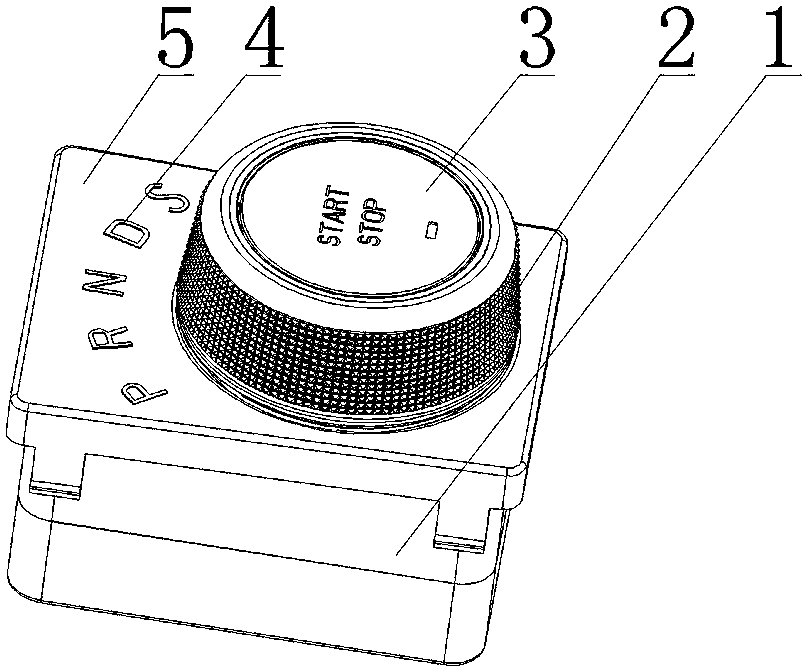

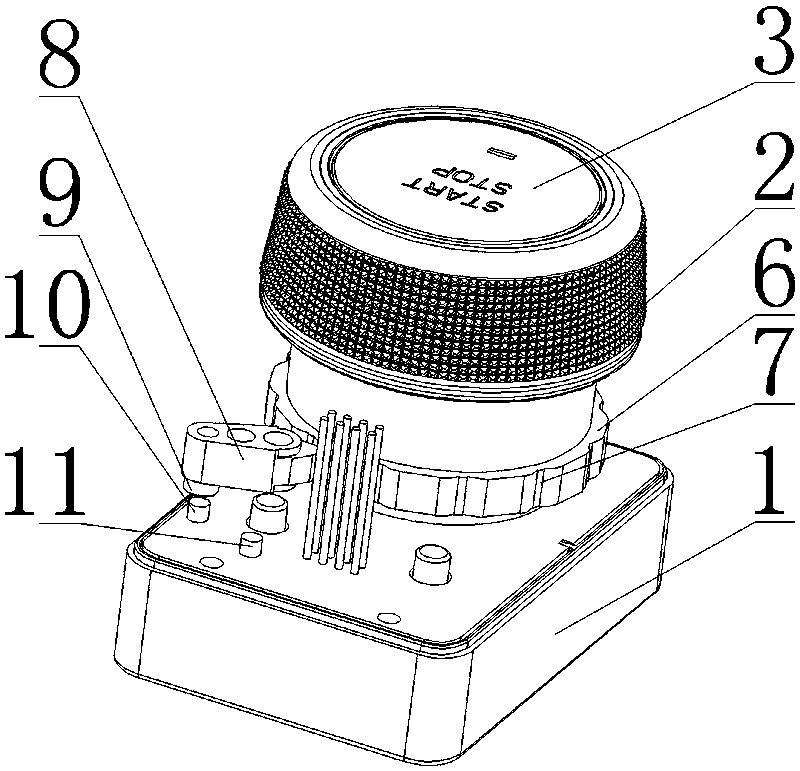

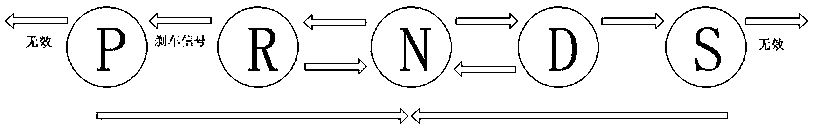

[0014] As shown in the figure, the knob-type automobile shift switch includes a housing 1, a knob 2, and a gear seat 5. The knob 2 has a hollow part, and a one-key start switch key 3 is arranged in the hollow part, which can be started by one key. The switch key 3 can turn on the power supply of the car or directly start the car; this structure of setting the one-key start switch key 3 on the shift switch makes the structure of the car more concise and compact, and more convenient to use. The gear seat 5 is fixed on the housing 1, and a gear mark 4 is provided on the gear seat 5, and an indicator light (not shown in the figure) is respectively provided under the gear mark 4. ), the indicator light displays the position of the gear on the corresponding gear. When the gear shift is valid, the corresponding indicator lights up. In this example, if figure 1 As shown, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com