Superpixel-based workpiece surface defect segmentation method

A workpiece surface, super pixel technology, applied in image analysis, image enhancement, image data processing and other directions, can solve problems such as large amount of data, high requirements for image preprocessing, and complexity of image randomness, and achieve noise interference suppression , the effect of reducing the amount of calculation and simplifying the calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

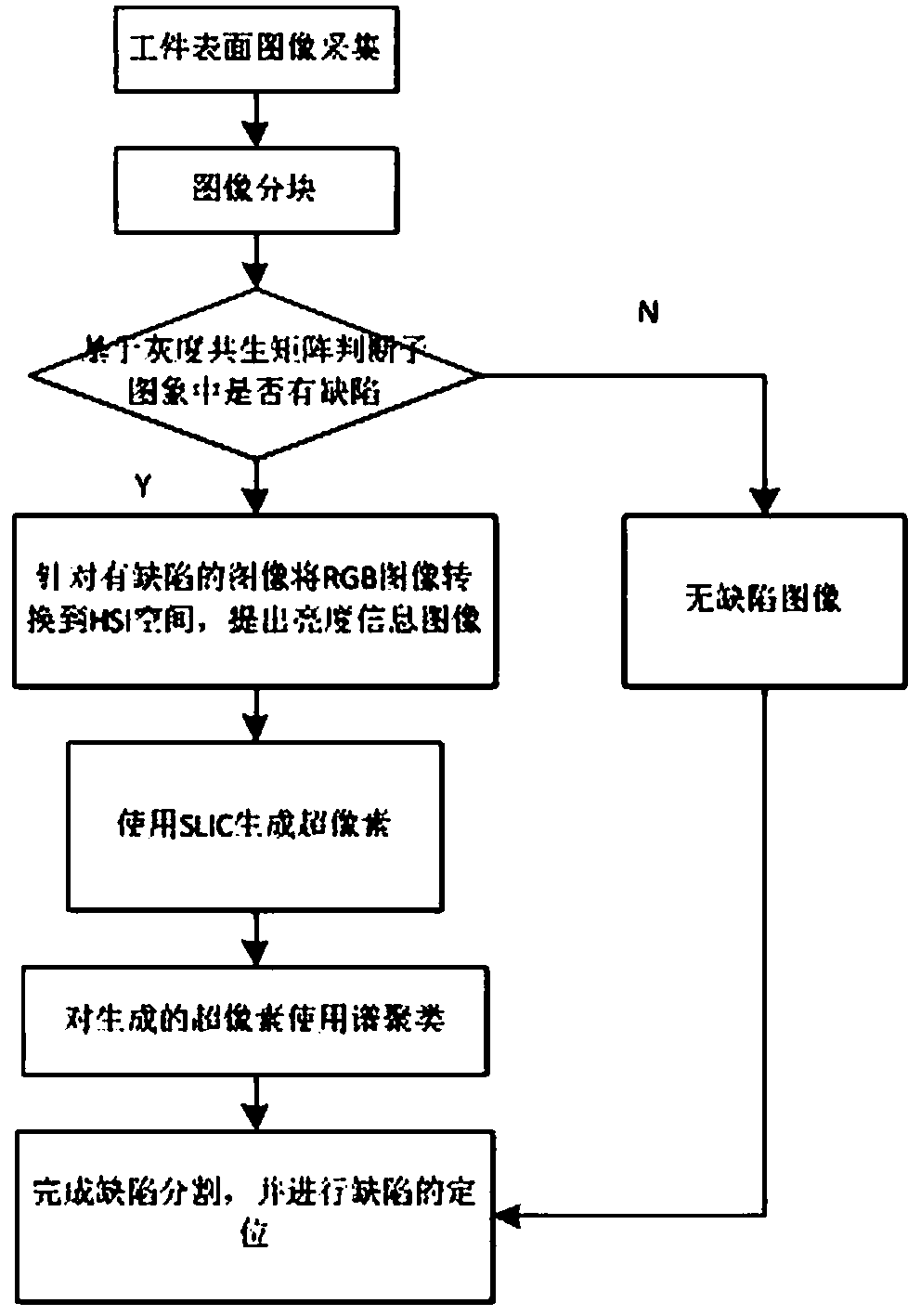

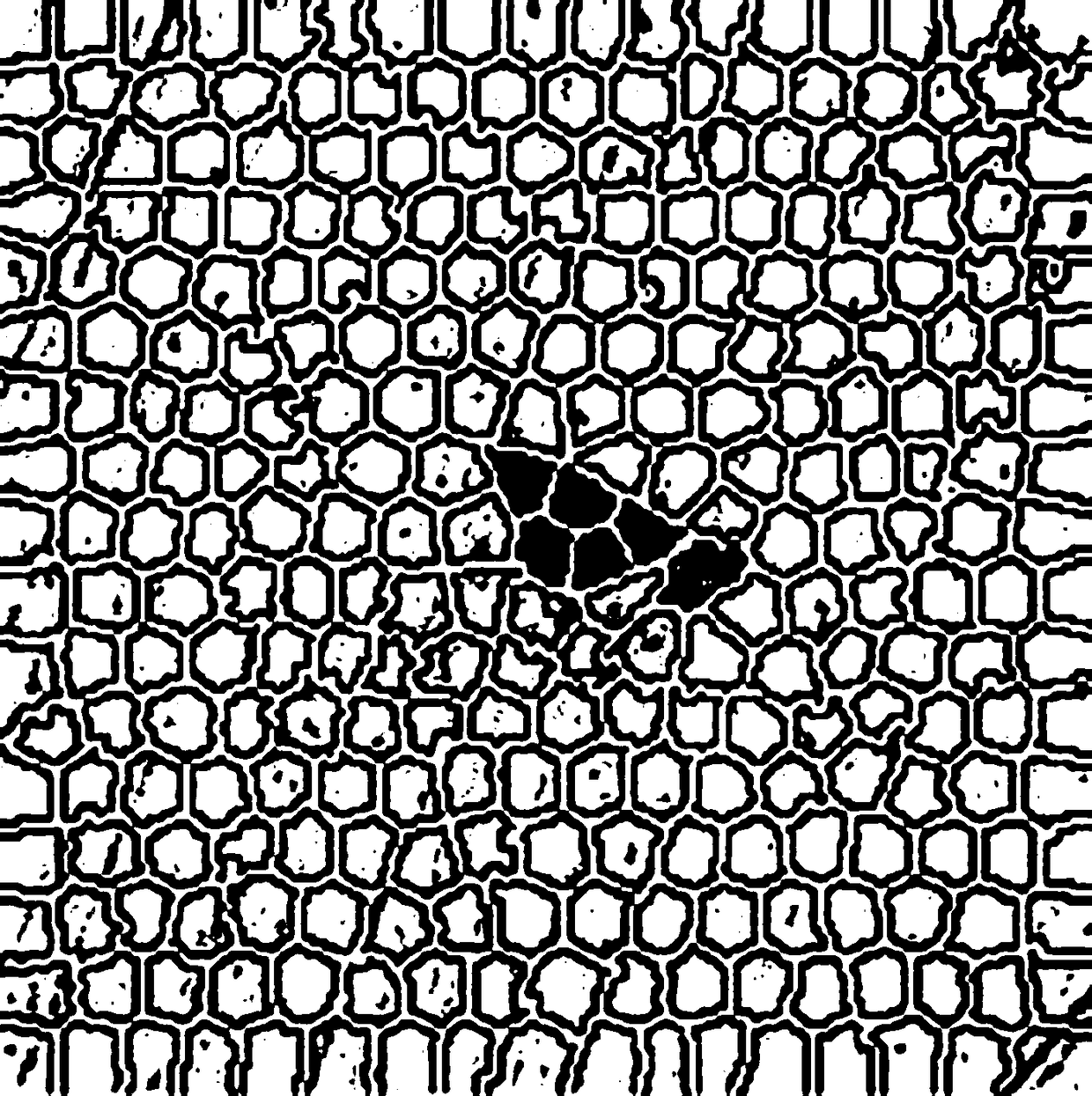

[0025] figure 1 It is a flow chart of the method for extracting surface defects of a workpiece based on superpixels in the present invention. Such as figure 1 As shown, the superpixel-based workpiece surface defect extraction method includes the following steps:

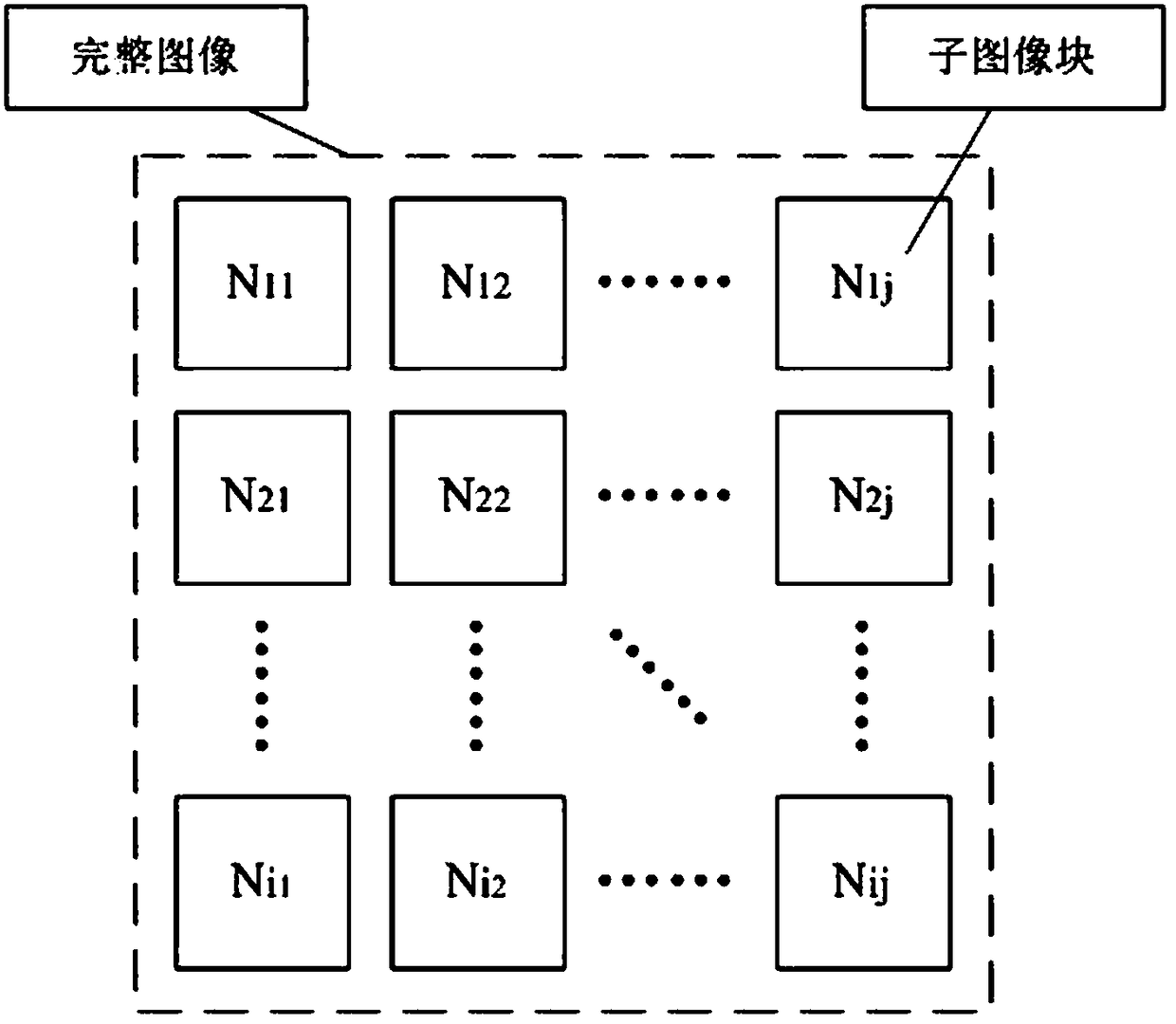

[0026] Step S1: the workpiece surface image is divided into blocks, and the processed workpiece surface image is directly collected by an industrial camera, and the acquired image is image-divided, so that the image is divided into sub-image blocks of m*m pixel size;

[0027] Use an industrial camera to collect a complete image of the surface of the workpiece to be inspected, and the size of the obtained image is 2048*1536. Select a certain side length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com