Wall-through sleeve for high-voltage power switch equipment

A technology of wall-piercing bushings and switchgear, applied in the direction of electrical components, etc., can solve the problems that wall-piercing bushings cannot be used universally and the production cost is high, and achieve the effect of reducing production costs and high expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

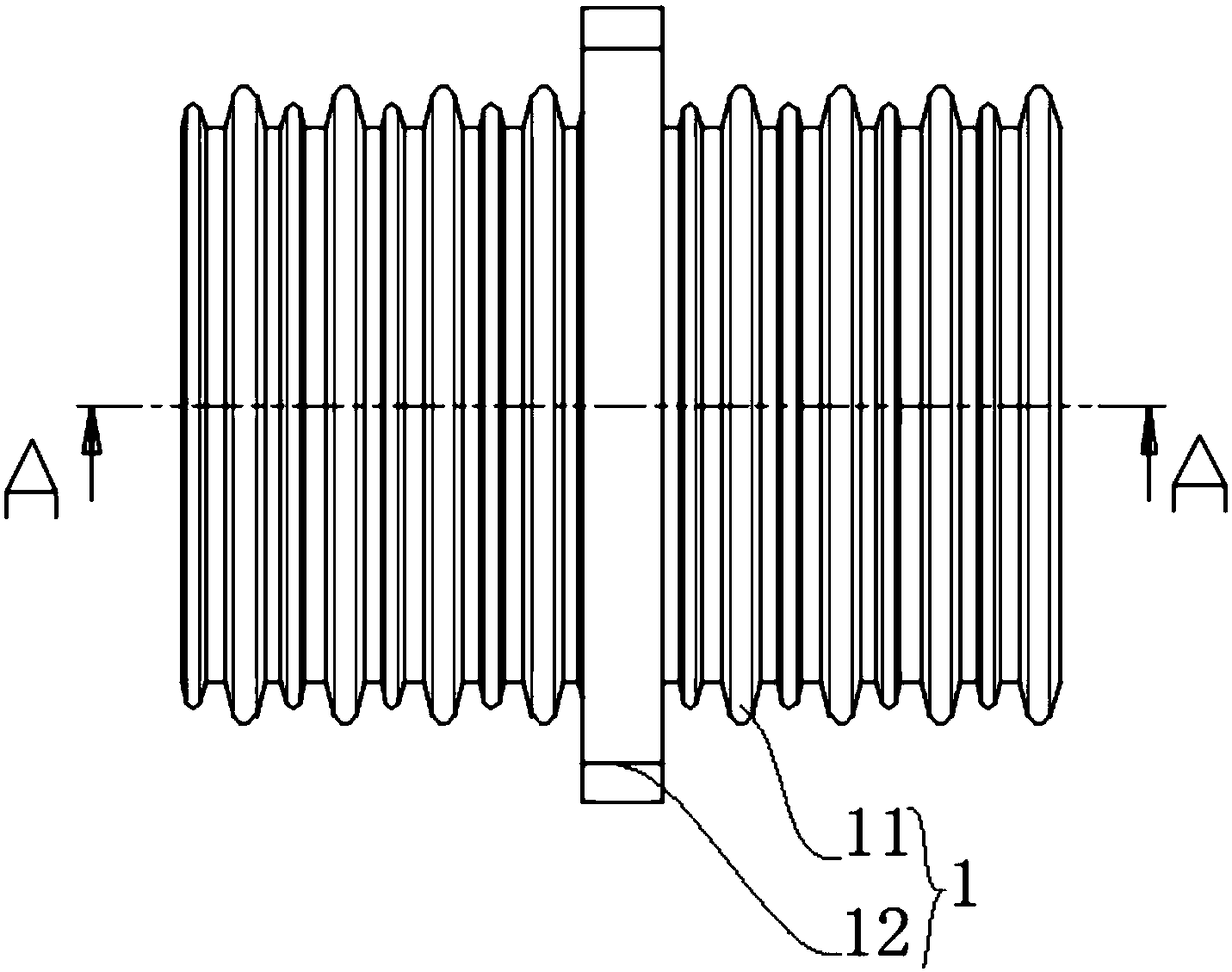

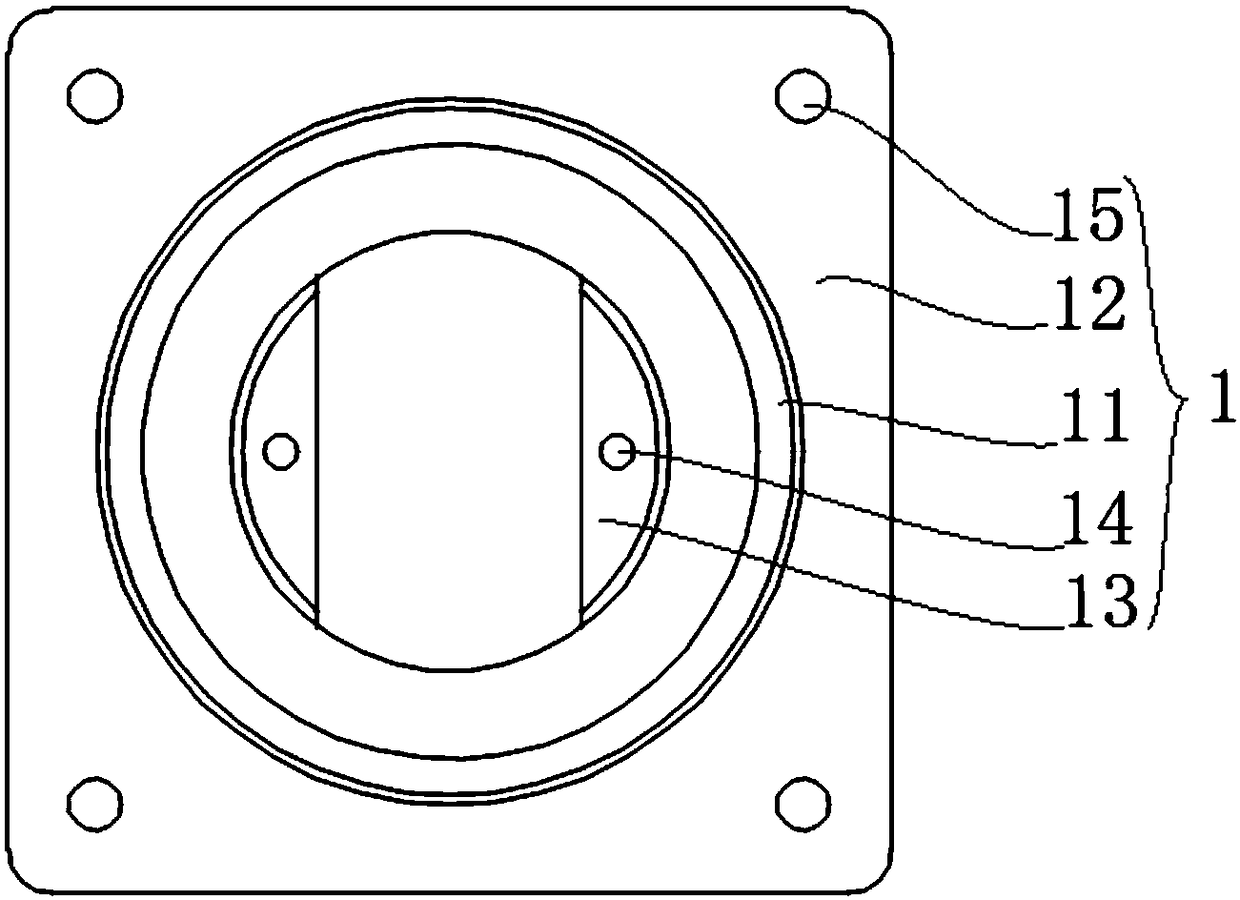

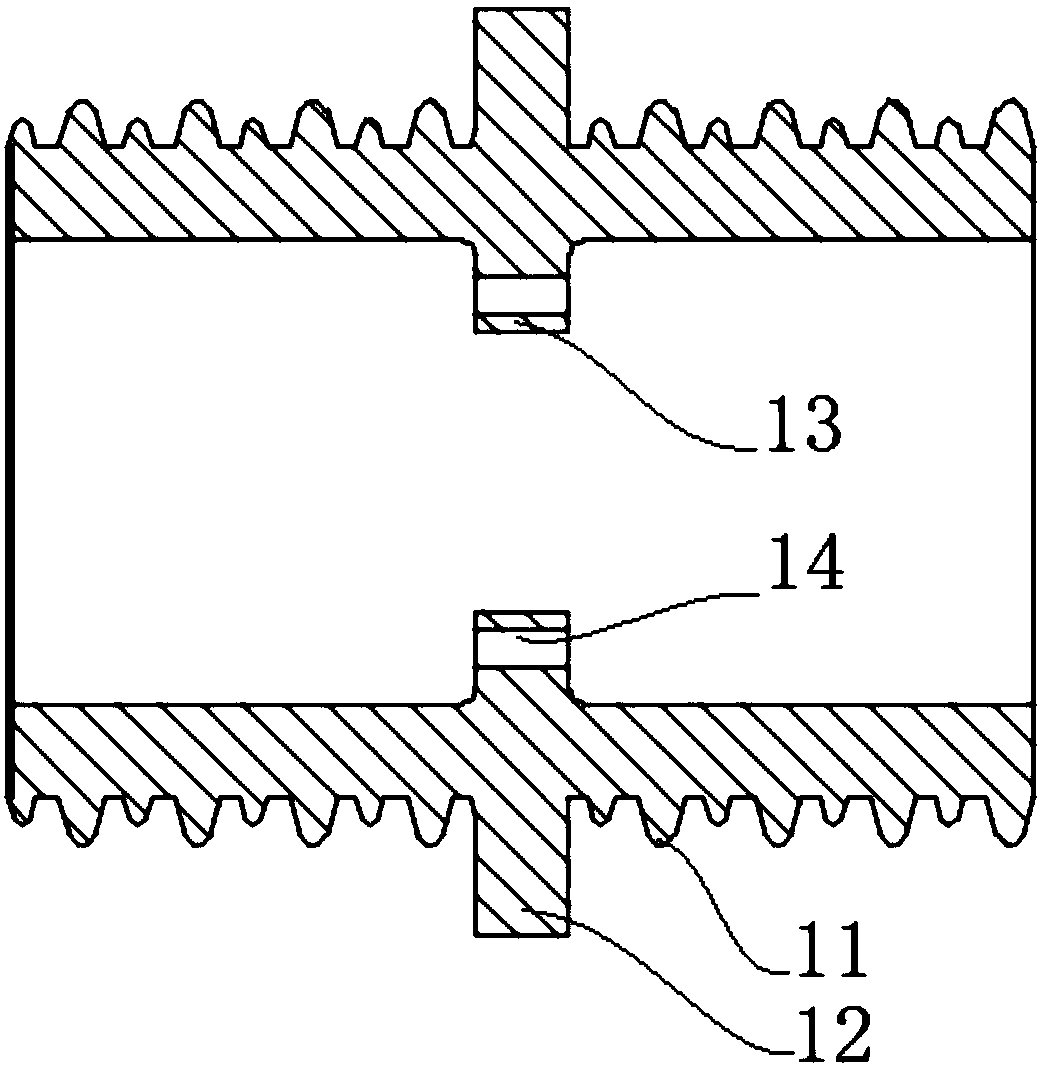

[0023] Such as Figure 1 to Figure 5 As shown, a wall bushing for high-voltage power switch equipment of the present invention includes a wall bushing body 1, a mounting flange 12 is arranged in the middle of the wall bushing body 1, and the mounting flange 12 is embedded with The brass insert 15 is provided with threaded holes. A plurality of sheds 11 are uniformly arranged on the outer wall of the wall bushing body 1 along the axial direction of the wall bushing body 1. The top of the wall bushing is arc-shaped, and the inner wall of the wall bushing body 1 is provided with two symmetrically arranged overlapping parts 13, and the overlapping parts 13 are provided with mounting holes 14. The opening direction of the mounting holes 14 is consistent with that of the wall bushing. The axial direction of the tube is parallel. A conductive member support plate 2 is also provided in the wall bushing body 1. The conductive member support plate 2 is a cylindrical structure. The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com