Odd number slot motor rotor and winding method thereof

A winding method and slot motor technology, applied in the magnetic circuit rotating parts, the shape/style/structure of the winding conductor, the magnetic circuit shape/style/structure, etc., can solve the problem of the inability to use symmetrical winding and the increase in the amount of balanced glue , balance the amount of glue and other problems, to reduce the risk of falling off or friction to the stator, low noise, and a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

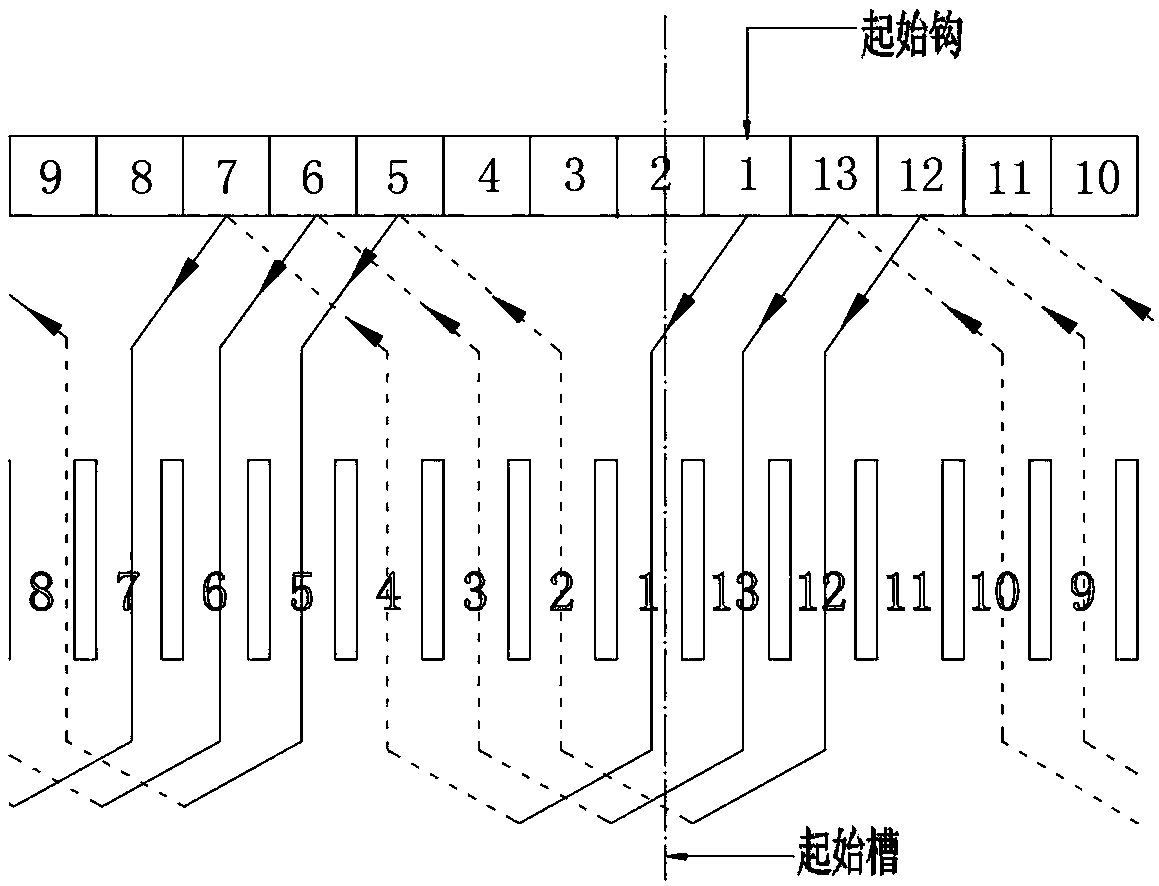

[0042] Such as figure 1 As shown, take n=13, j=1, y=3: the rotor slot number n of the motor rotor is 13, the hook number m of the commutator is 13, the pitch of the coils in the first and second coil windings Take 3, and take 6 as the distance k between adjacent coils in the first and second coil windings.

[0043] The first coil winding includes 13 coils in series, wherein the first coil starts from the No. 1 hook, and hangs on the No. 7 hook after winding between the No. 1 slot and the No. 4 slot; 2 Coil starts from hook No. 7, and hangs on hook No. 13 after winding between slot No. 7 and slot No. 10; ... Coil No. 13 starts from hook No. After winding between the groove and the No. 11 groove, the wire is hung on the No. 1 hook.

[0044] The second coil winding includes 13 coils in series, wherein the first coil starts from the No. 7 hook, and hangs on the No. 13 hook after being wound between the No. 7 slot and the No. 10 slot; 2. Coil starts from hook No. 13, and hangs o...

Embodiment 2

[0046] Get n=15, j=2, y=4: the rotor slot number n of the motor rotor is 15, the hook number m of the commutator is 30, and the pitch of the coils in the first and second coil windings is 4, The distance k between adjacent coils in the first and second coil windings is 8.

[0047] The first coil winding includes 15 coils in series, wherein the first coil starts from the No. 1 hook, and hangs on the No. 17 hook after winding between the No. 1 slot and the No. 5 slot; 2 Coil starts from hook No. 17, and hangs on hook No. 3 after winding between slot No. 9 and slot No. 13; ... Coil No. 15 starts from hook No. 15 and passes through hook No. 8 After winding between the groove and the No. 12 groove, the wire is hung on the No. 1 hook.

[0048] The second coil winding includes 15 coils in series, wherein the first coil starts from the No. 17 hook, and hangs on the No. 3 hook after winding between the No. 9 slot and the No. 13 slot; Coil 2 starts from hook No. 3, and hangs on hook N...

Embodiment 3

[0051] Take n=19, j=3, y=5: the rotor slot number n of the motor rotor is 19, the hook number m of the commutator is 57, and the pitch of the coils in the first and second coil windings is 5, The distance k between adjacent coils in the first and second coil windings is 10.

[0052] The first coil winding includes 19 coils in series, wherein the first coil starts from the No. 1 hook, and hangs on the No. 31 hook after being wound between the No. 1 slot and the No. 6 slot; 2 Coil starts from hook No. 31, and hangs on No. After winding between the groove and the No. 15 groove, the wire is hung on the No. 1 hook.

[0053] The second coil winding includes 19 coils connected in series, wherein the first coil starts from the No. 31 hook, and hangs on the No. 4 hook after being wound between the No. 11 slot and the No. 16 slot; Coil 2 starts from hook No. 4, and hangs on hook No. 34 after winding between slot No. 2 and slot No. 7; ... Coil No. 19 starts from hook No. After winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com