Cleaning auxiliary robot of high-voltage power transformation and distribution stations

A technology for power distribution stations and robots, applied in manipulators, manufacturing tools, etc., can solve problems such as long cycle times and increased robot research and development costs, and achieve the effects of easy movement, safe and reliable operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the specific implementation manners thereof will be described in detail below with reference to the accompanying drawings:

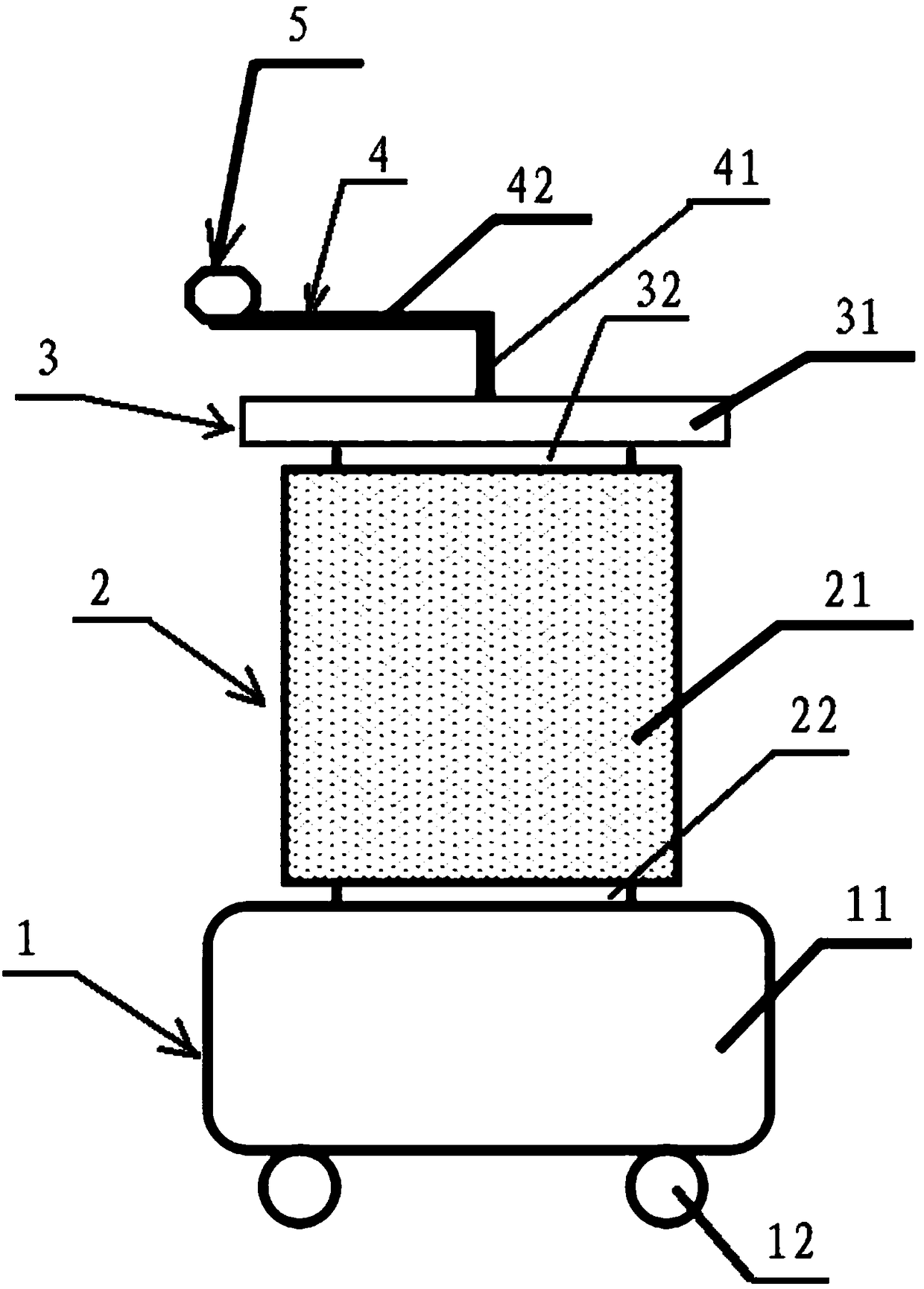

[0023] See figure 1 , The best embodiment of the present invention, a cleaning auxiliary robot for high-voltage substations, includes a mobile trolley 1, a lifting device 2, a rotating device 3, a telescopic arm 4, and a monitoring device 5 arranged in order from bottom to top.

[0024] The mobile trolley 1 includes a vehicle body 11, four supporting transmission shafts and four supporting electric cylinders. The four supporting transmission shafts are evenly distributed on the bottom of the vehicle body 11. The four supporting electric cylinders are respectively arranged in the vehicle body 11, and The supporting electric cylinder is connected to the four supporting transmission shafts one by one, and each supporting transmission shaft is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com