Textile manufacturing equipment

A textile and equipment technology, applied in the field of textile production equipment, can solve the problems of no installation, no shock absorption device, no anti-wrinkle device, etc., and achieve the effect of scientific and reasonable structure, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

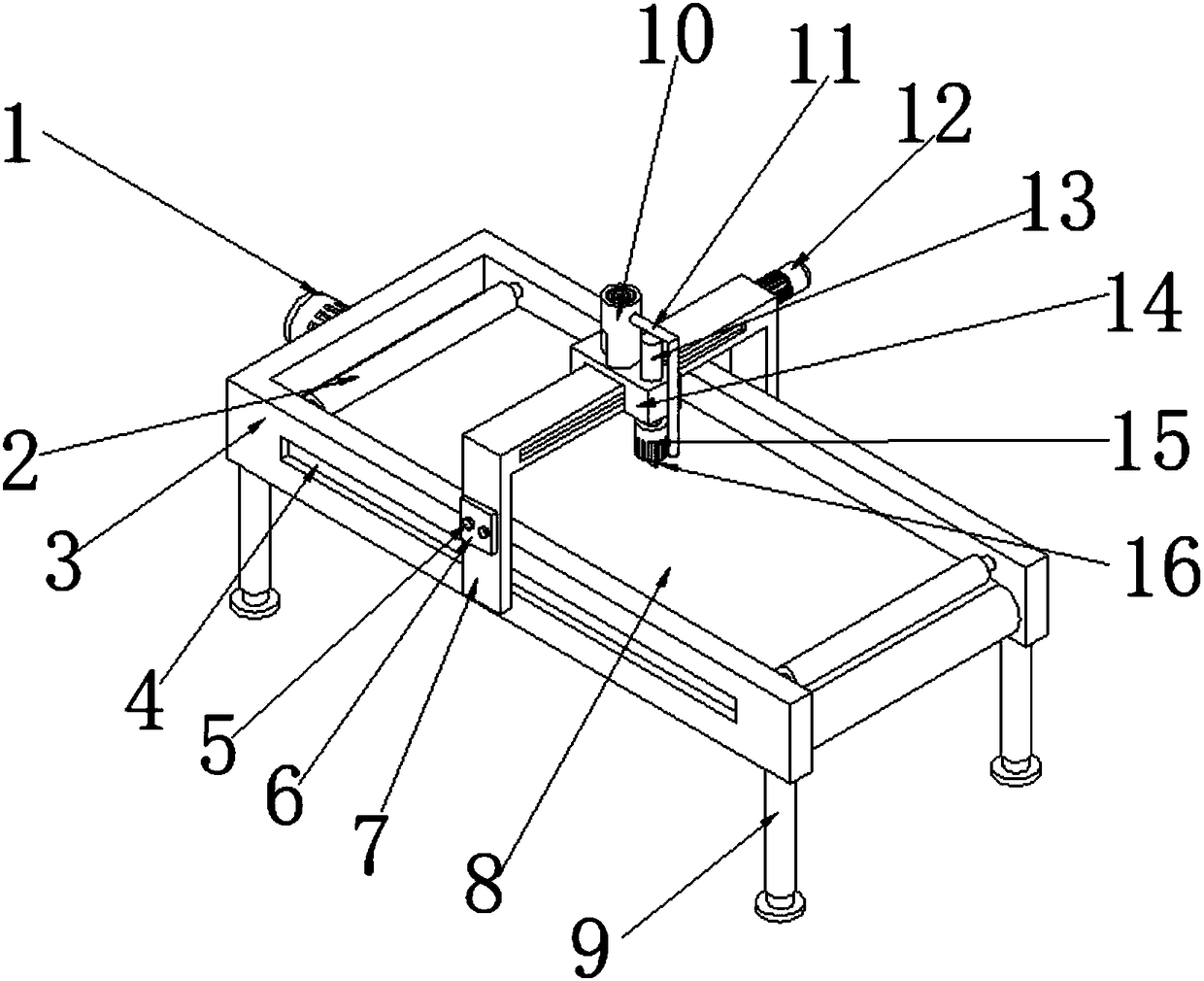

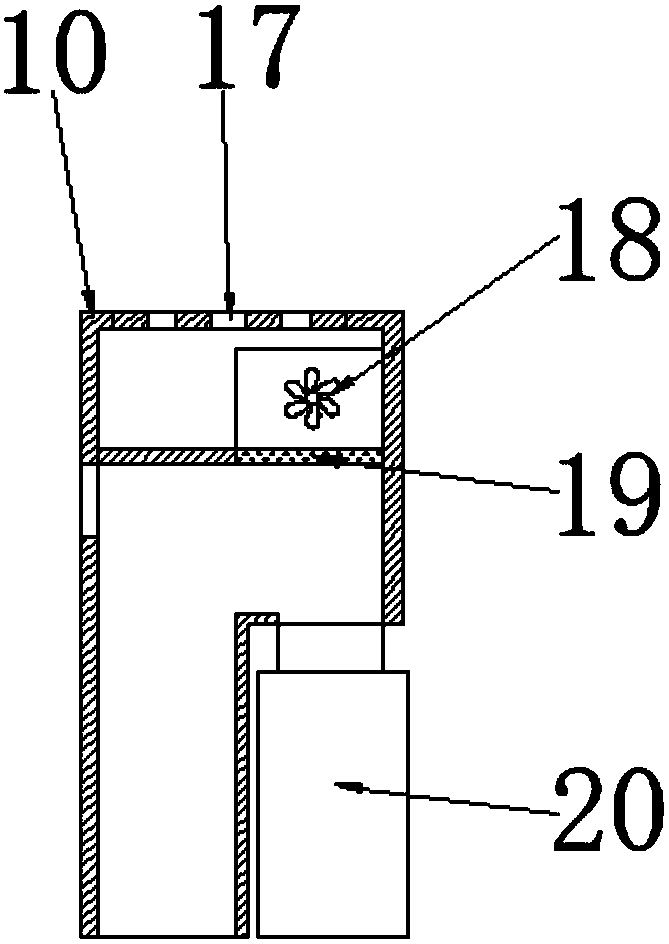

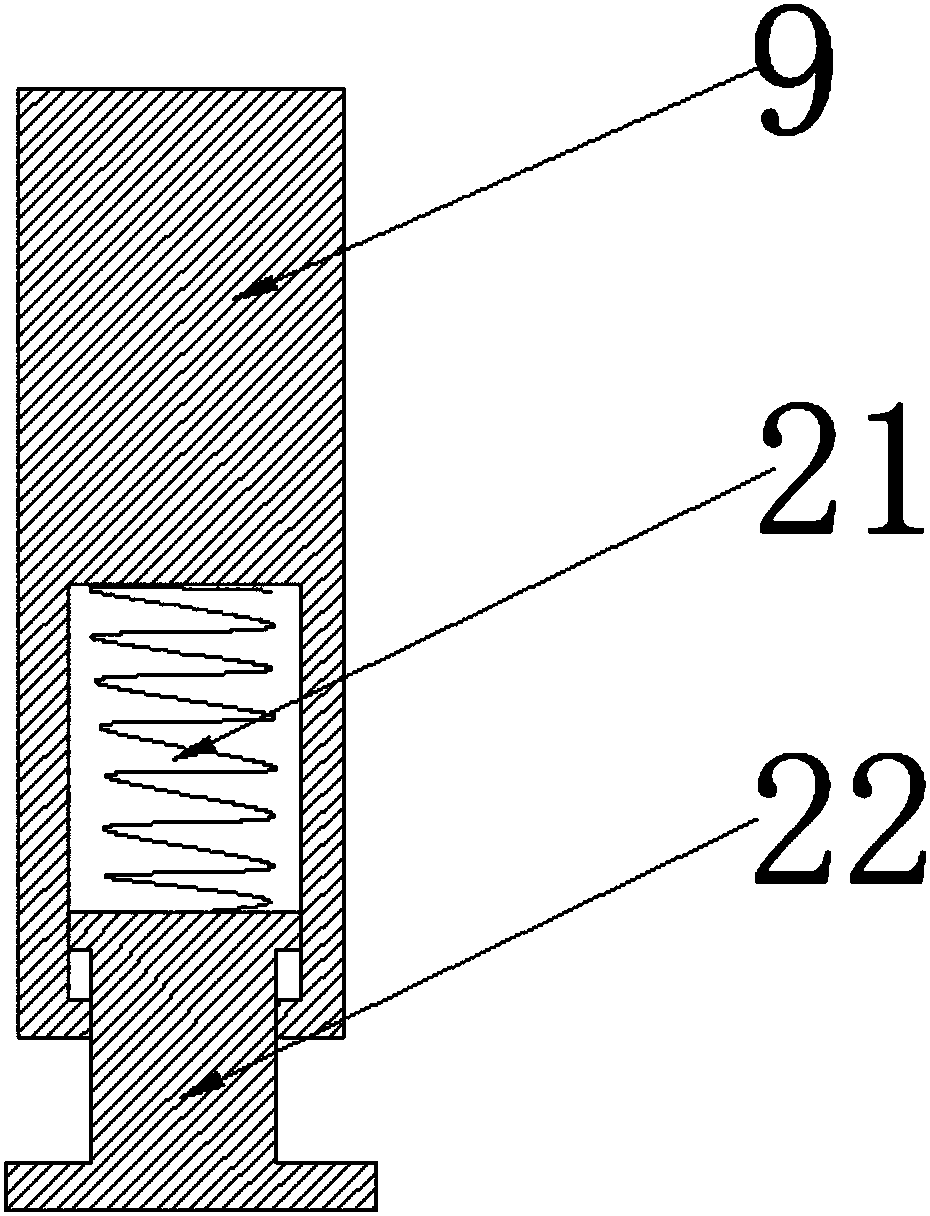

[0018] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a textile production equipment, including a first servo motor 1, a pressure roller 2, a frame 3, a slide rail 4, a control panel 5, an electric control box 6, a beam slide rail 7, Conveyor belt 8, bracket 9, housing 10, connecting pipe 11, second servo motor 12, electric push rod 13, slider 14, rotating motor 15, cutting knife 16, air outlet groove 17, fan 18, filter screen 19, ash storage Tank 20, spring 21 and support 22, a first servo motor 1 is arranged on one side of the frame 3, a conveyor belt 8 is arranged on the inner side of the first servo motor 1, and pressure rollers are arranged on the inner side of the first servo motor 1 and at both ends of the conveyor belt 8 2. Brackets 9 are provided around the bottom of the frame 3, slide rails 4 are provided on both sides of the frame 3, a crossbeam slide rail 7 is provided on one side of the slide rail 4, and an electric con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com