Automatic unloading device for rear-turning cars

An automatic unloading and vehicle technology, which is applied in the direction of vehicles with inclined bearing movement, etc., can solve the problems of easily damaged piston rods, inability to ensure support, unfavorable use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

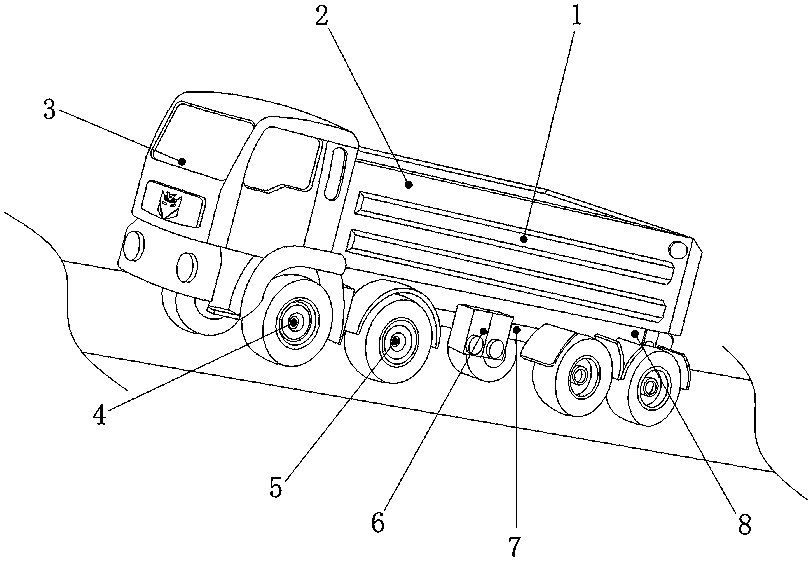

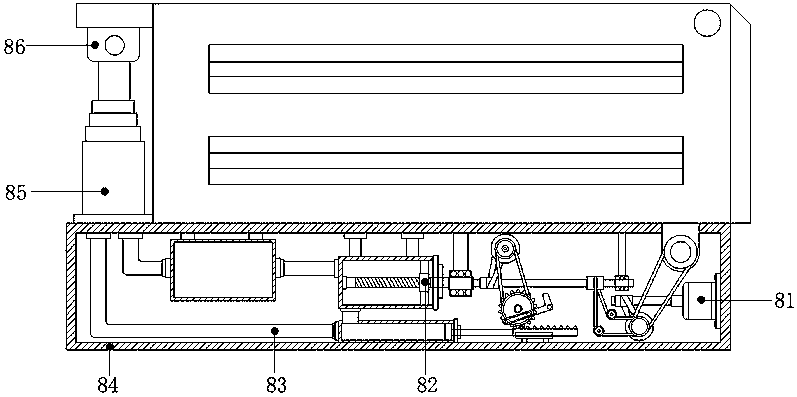

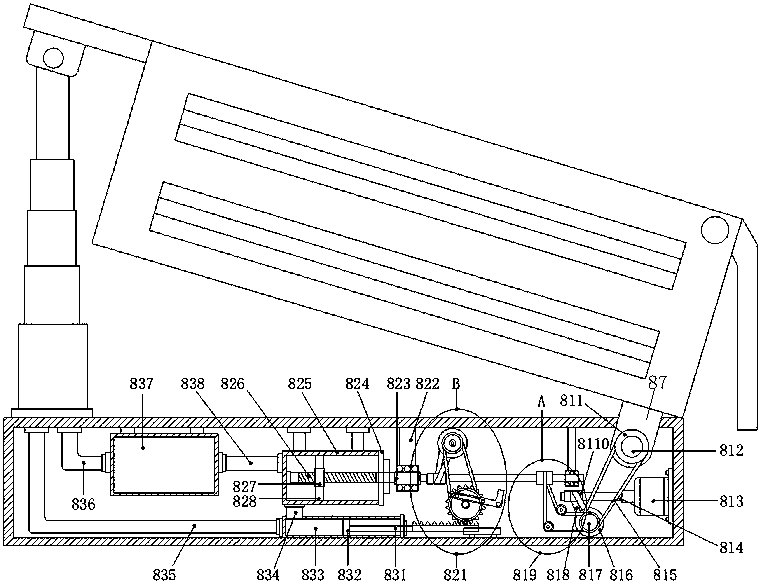

[0027] see Figure 1-Figure 5 , the present invention provides an automatic unloading device for a rear-turning car, the structure of which includes a hopper side reinforcement rib 1, a hopper 2, a driving control cabin 3, traction wheels 4, driven wheels 5, a fuel tank 6, a chassis 7, and an automatic unloading device 8, The bottom of the chassis 7 is equidistantly provided with six driven wheels 5, the driven wheels 5 and the chassis 7 adopt a clearance fit, and one side of the chassis 7 is provided with a fuel tank 6, and the two adopt an interference fit The front end of the chassis 7 is provided with a driving control cabin 3 and the two adopt a clearance fit, and the bottom of the driving control cabin 3 is evenly and equidistantly provided with two traction wheels 4, and the traction wheels 4 and the driving control cabin 3 Transmission connection, the fuel tank 6 is connected with the driving control cabin 3 through a conduit, the top of the chassis 7 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com