Resource disposal method and equipment for garbage fly ash

A disposal method and technology of waste fly ash, which is applied in the field of resource disposal of waste fly ash, can solve problems such as incomplete, secondary pollution disposal, and low efficiency, and achieve scientific and accurate measurement methods, no secondary pollution, and reduced total cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

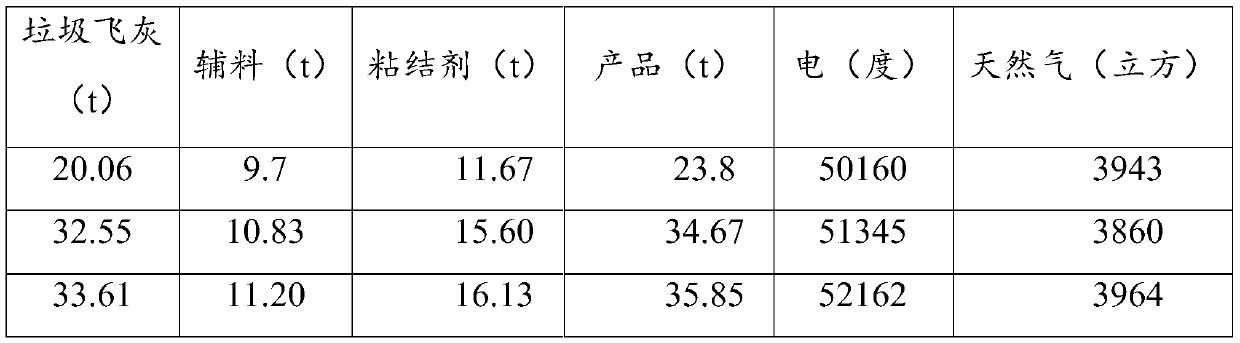

Embodiment 1

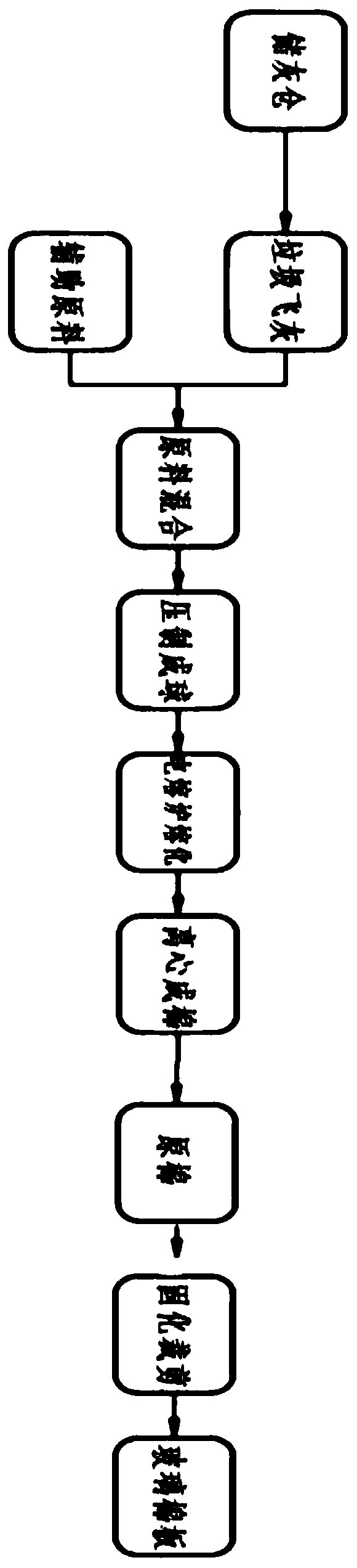

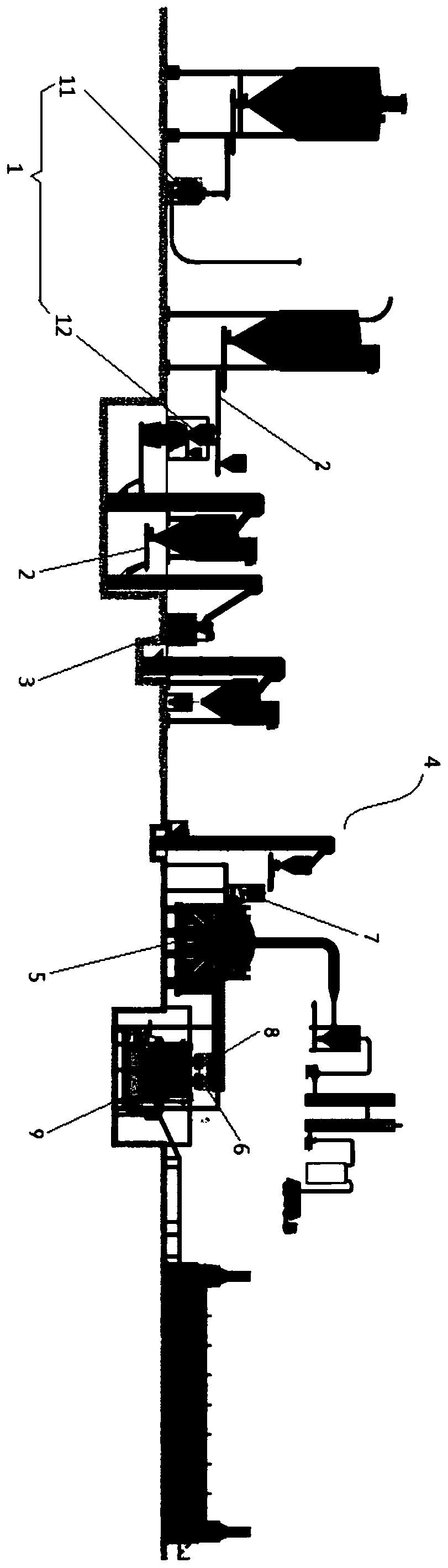

[0043] Such as figure 1 As shown, the present invention provides a resource disposal method of garbage fly ash, comprising the following steps:

[0044] (1) Mixing of raw materials: The garbage fly ash raw material to be disposed, silicate, borate, reducing agent and binder to be mixed are respectively passed through the first sealed screw conveyor from the storage bin Transport to the sealed hanging electronic weighing silo, and the sealed hanging electronic weighing silo measures the required amount of each component according to the content of each component in the garbage fly ash raw material and the predetermined viscosity range. In this embodiment Garbage fly ash raw material comes from waste incineration power plants, in which the content of CaO in fly ash raw material is 32%, SiO 2 Content is 30%, Al 2 o 3 The content is 8%. Each ton of mixed material includes 720kg of garbage fly ash raw material, 69kg of silica sand, 76kg of soda ash, 38kg of borax, 6kg of co-solv...

Embodiment 2

[0049] Such as figure 1 As shown, the present invention provides a resource disposal method of garbage fly ash, comprising the following steps:

[0050] (1) Mixing of raw materials: The garbage fly ash raw material to be disposed, silicate, borate, reducing agent and binder to be mixed are respectively passed through the first sealed screw conveyor from the storage bin Transport to the sealed hanging electronic weighing silo, and the sealed hanging electronic weighing silo measures the required amount of each component according to the content of each component in the garbage fly ash raw material and the predetermined viscosity range. In this embodiment Garbage fly ash raw materials come from waste incineration power plants, in which the content of CaO in fly ash raw materials is 25%, SiO 2 The content is 36%, Al 2 o 3 The content is 10%. Each ton of mixed material includes 800kg of garbage fly ash raw material, 75kg of silica sand, 80kg of soda ash, 30kg of borax, 7kg of c...

Embodiment 3

[0055] Such as figure 1 As shown, the present invention provides a resource disposal method of garbage fly ash, comprising the following steps:

[0056] (1) Mixing of raw materials: The garbage fly ash raw material to be disposed, silicate, borate, reducing agent and binder to be mixed are respectively passed through the first sealed screw conveyor from the storage bin Transport to the sealed hanging electronic weighing silo, and the sealed hanging electronic weighing silo measures the required amount of each component according to the content of each component in the garbage fly ash raw material and the predetermined viscosity range. In this embodiment Fly ash raw material comes from waste incineration power plants, and the content of CaO in fly ash raw material is 24%, SiO 2 The content is 40%, Al 2 o3 The content is 12%. Each ton of mixed material includes 850kg of garbage fly ash raw material, 78kg of silica sand, 83kg of soda ash, 33kg of borax, 8kg of cosolvent, and 7k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com