A rotary automatic spraying mechanism

A technology of automatic spraying and main rotation, applied in the direction of building structure, construction, etc., can solve the problems of hard to find, automatic painting, human injury, etc., to achieve the effect of simple structure, good anti-clogging, easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

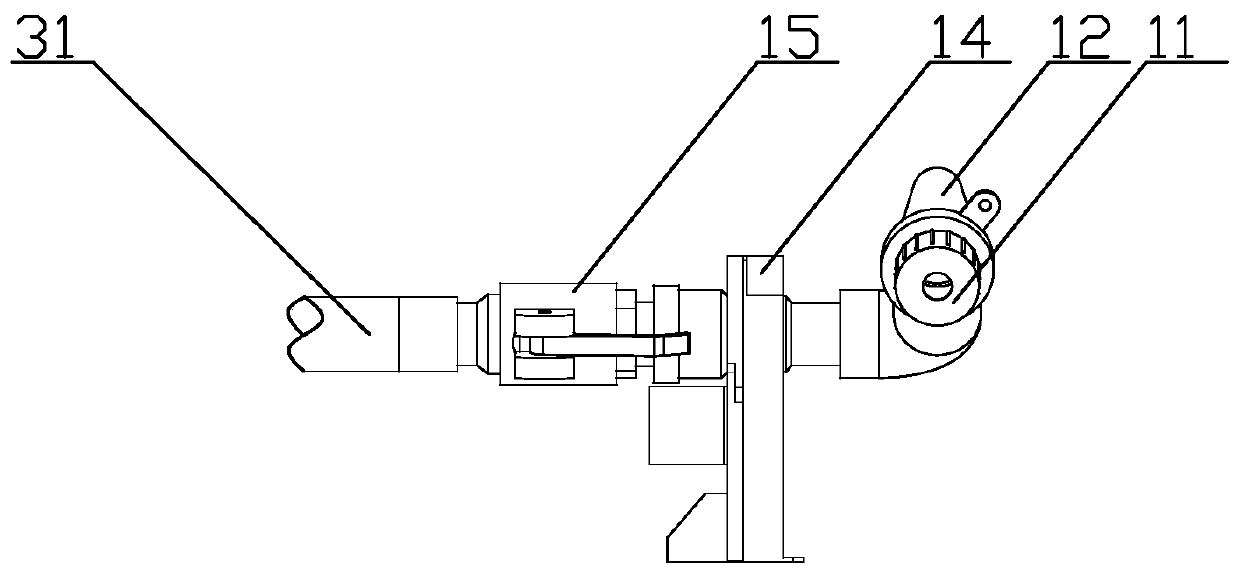

[0028] refer to figure 1 , a rotary automatic spraying mechanism, including a spray head assembly, a main conduit 13, a support frame 14, a main rotary connector 15, a main drive motor 16 and a controller, the spray head assembly includes a nozzle 11 and an air pipe coaxial with the nozzle 11 Joint 12, the main conduit 13 is connected to the nozzle 11, and an angle is formed between the axis of the main conduit 13 and the axis of the nozzle 11, and one end of the main conduit 13 is connected to the main rotary connector 15, the main rotary connector 15 is fixedly connected to the support frame 14, the main drive motor 16 is connected to the support frame 14, a gear is sleeved on the main pipe 13, and the main drive The motor 16 is connected to the main conduit 13 through gears;

[0029] The main drive motor 16 is electrically connected to the controller.

[0030] A feed pipe 31 is connected to said main rotary connection 15 .

Embodiment 2

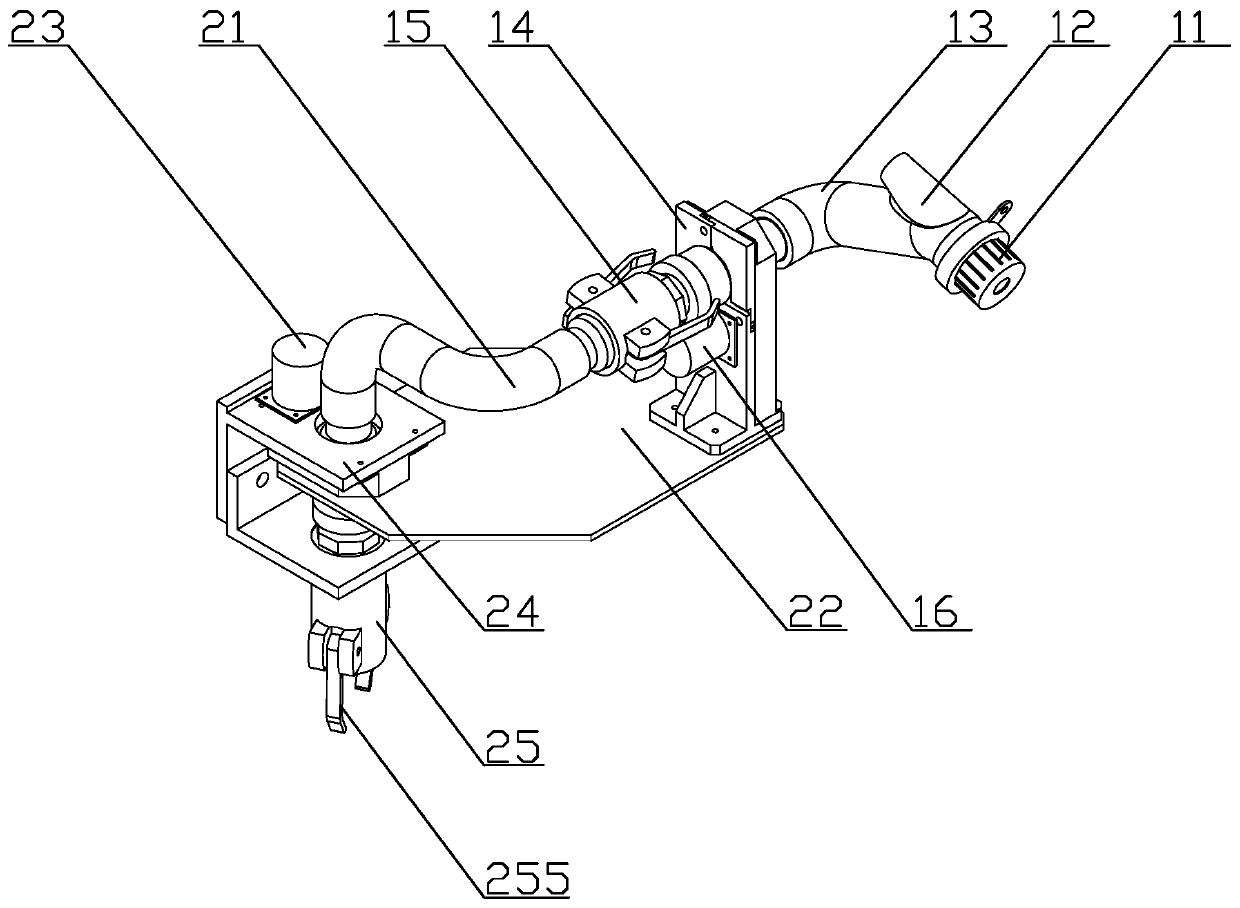

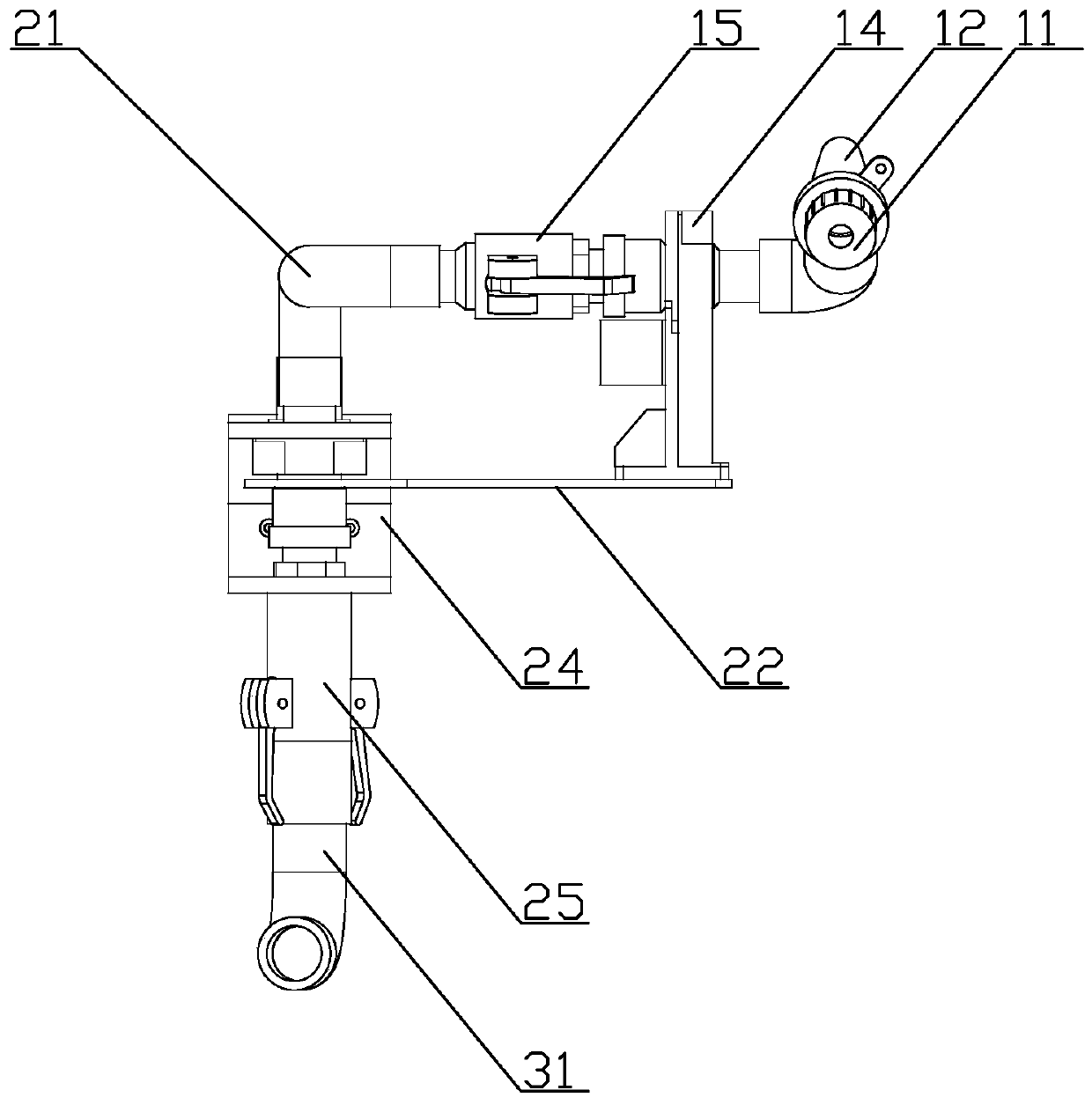

[0032] refer to figure 2 and image 3 , a rotary automatic spraying mechanism, including a spray head assembly, a main conduit 13, a support frame 14, a main rotary connector 15, a main drive motor 16 and a controller, the spray head assembly includes a nozzle 11 and an air pipe coaxial with the nozzle 11 Joint 12, the main conduit 13 is connected to the nozzle 11, and an angle is formed between the axis of the main conduit 13 and the axis of the nozzle 11, and one end of the main conduit 13 is connected to the main rotary connector 15, the main rotary connector 15 is fixedly connected to the support frame 14, the main drive motor 16 is connected to the support frame 14, a gear is sleeved on the main pipe 13, and the main drive The motor 16 is connected to the main conduit 13 through gears;

[0033] The main drive motor 16 is electrically connected to the controller.

[0034] Such as Figure 4 , the present invention also includes a supporting rotating plate 22, an auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com