Seal assembly and generator

A technology for sealing components and generators, which is applied to the sealing of engines, mechanical equipment, engine components, etc., which can solve problems such as user inconvenience, affecting the use of generators, and inaccurate gasoline detection results, so as to avoid shaking and ensure accurate detection sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

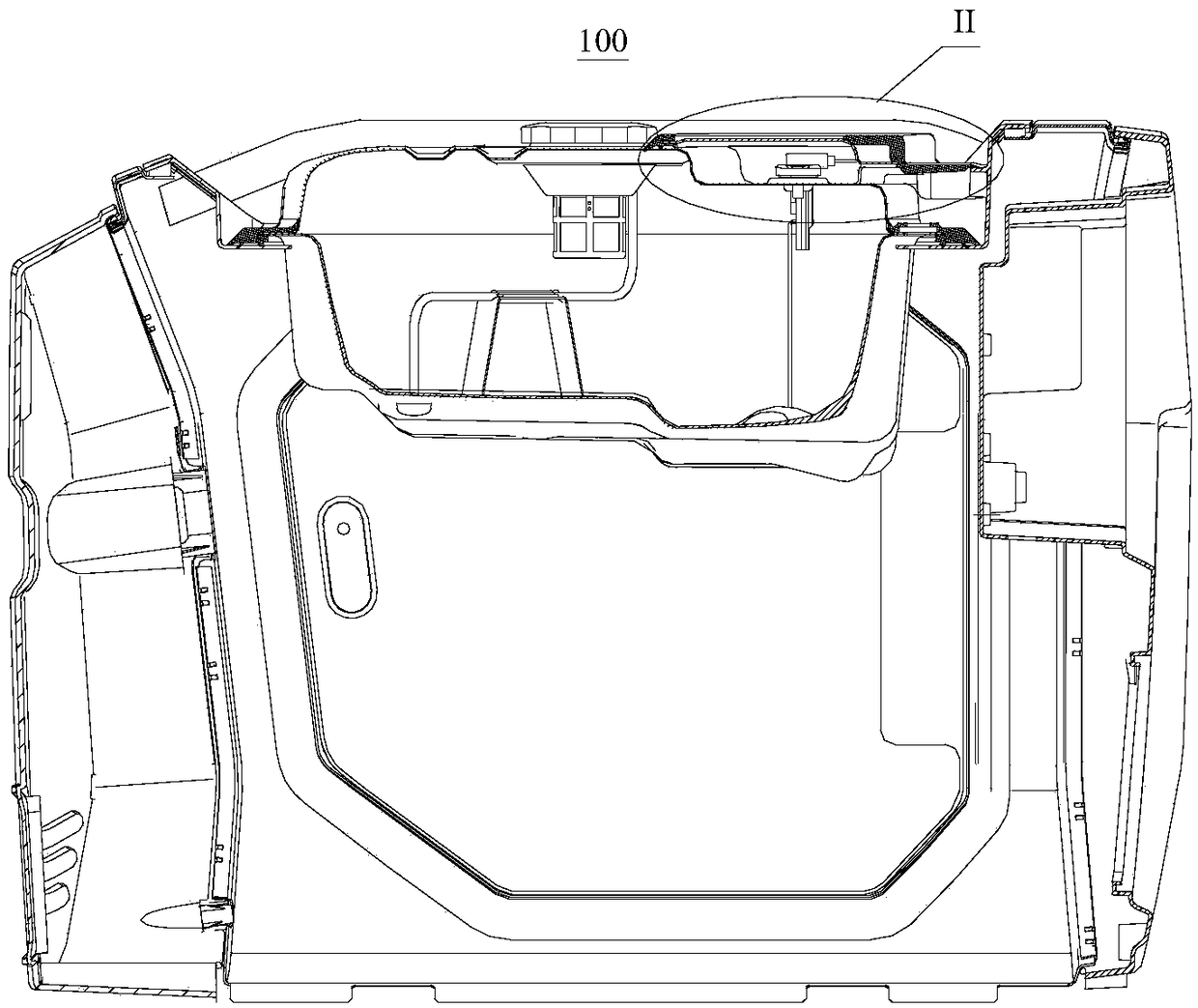

[0032] Please refer to figure 1 , figure 1 Shown is a schematic structural view of the fuel tank 100 . This embodiment provides a fuel tank 100, which is mainly used to provide fuel for the engine in the generator.

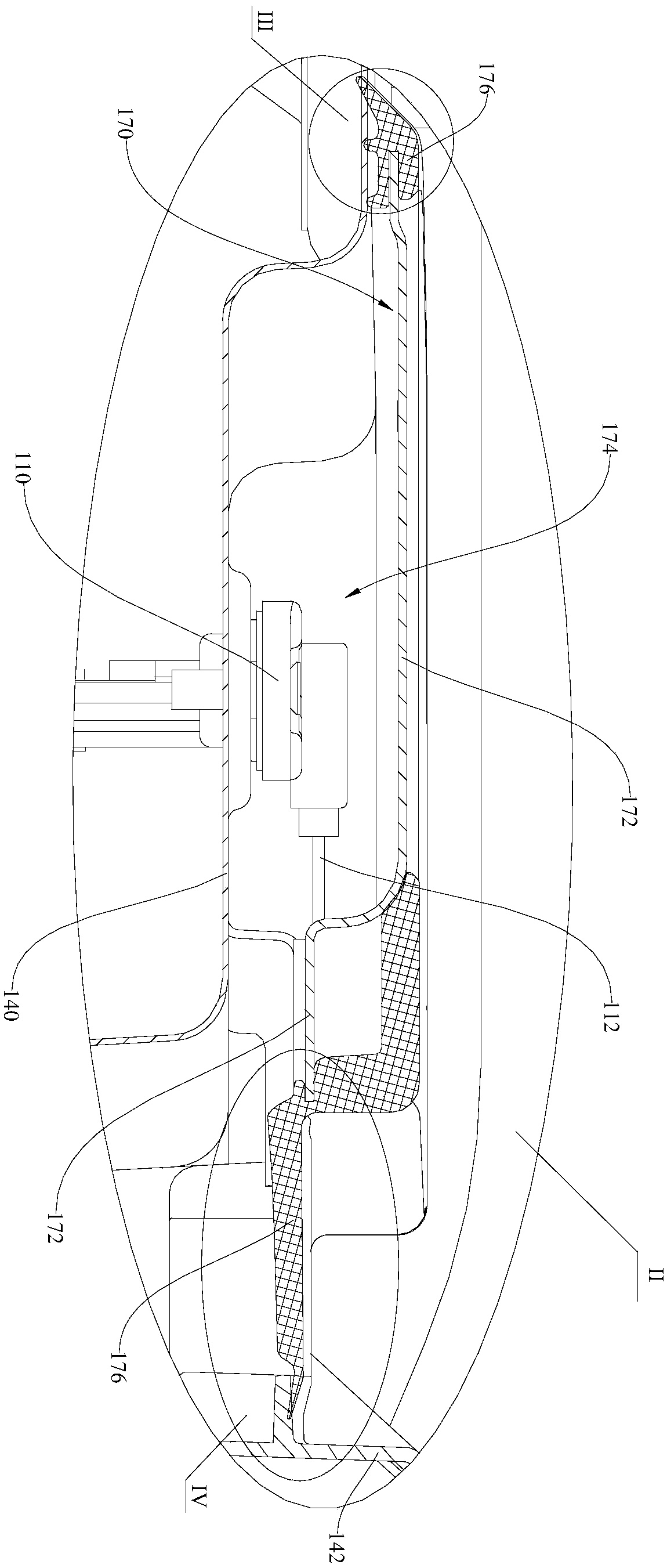

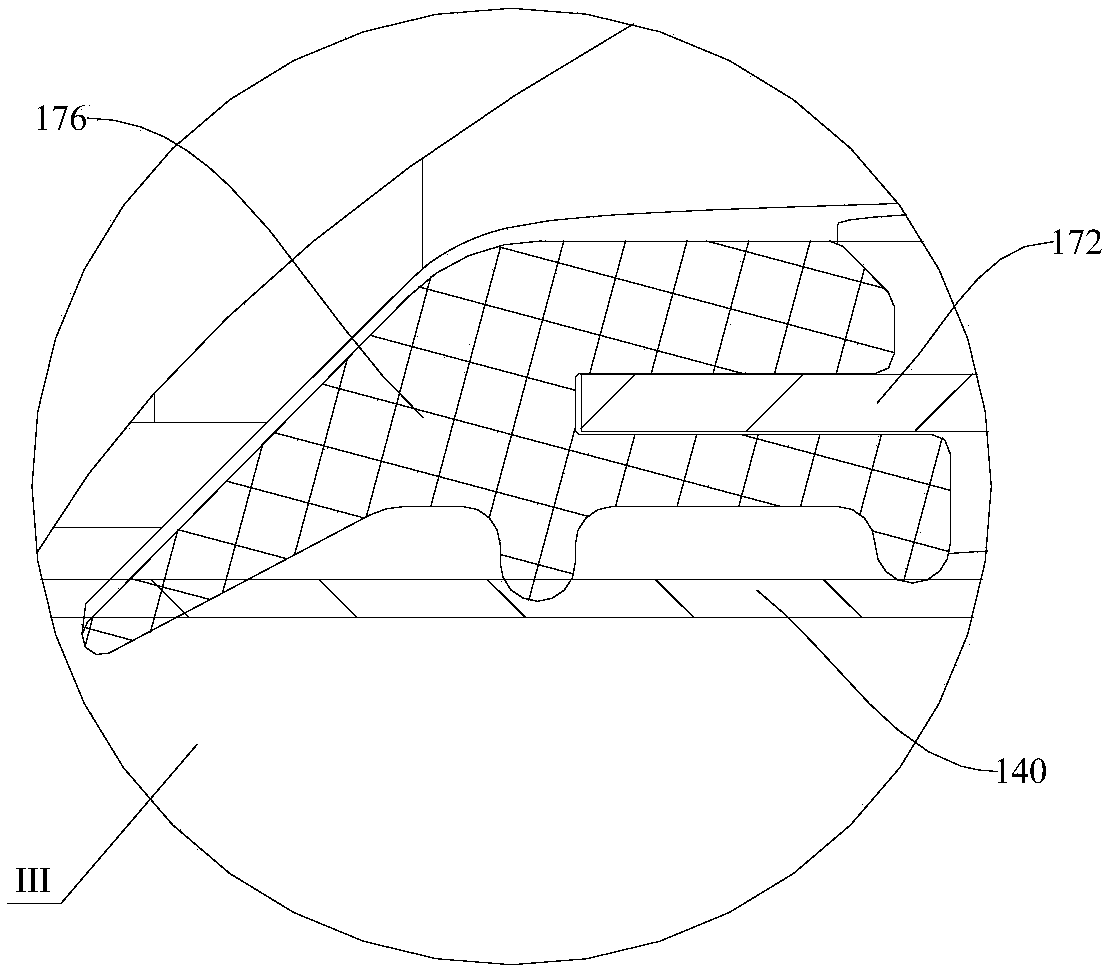

[0033] Please refer to figure 2 , figure 2 shown as figure 1 An enlarged schematic view of the middle II site. An oil level sensor 110 and a sealing assembly 170 are installed on the oil tank 100 . The fuel level sensor 110 is inserted into the fuel tank 100 for measuring the gasoline content in the fuel tank 100 . The sealing assembly 170 is connected with the oil tank 100, and the two together form a closed space for preventing the oil level sensor 110 from being exposed. The part of the oil level sensor 110 exposed from the fuel tank 100 is located in the enclosed space, which avoids the wear of the oil level sensor 110 by external adverse environmental substances (such as large particles of impurities), and achieves the purpose of protecting the oil l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com