Optimization Method of Machine Tool Beam Design Scheme Based on Quality Function Expansion

A quality function development and design scheme technology, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve problems such as lack of theoretical basis, difficulty in meeting the specific needs of CNC machine tools, etc., to reduce design costs and shorten research and development. effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

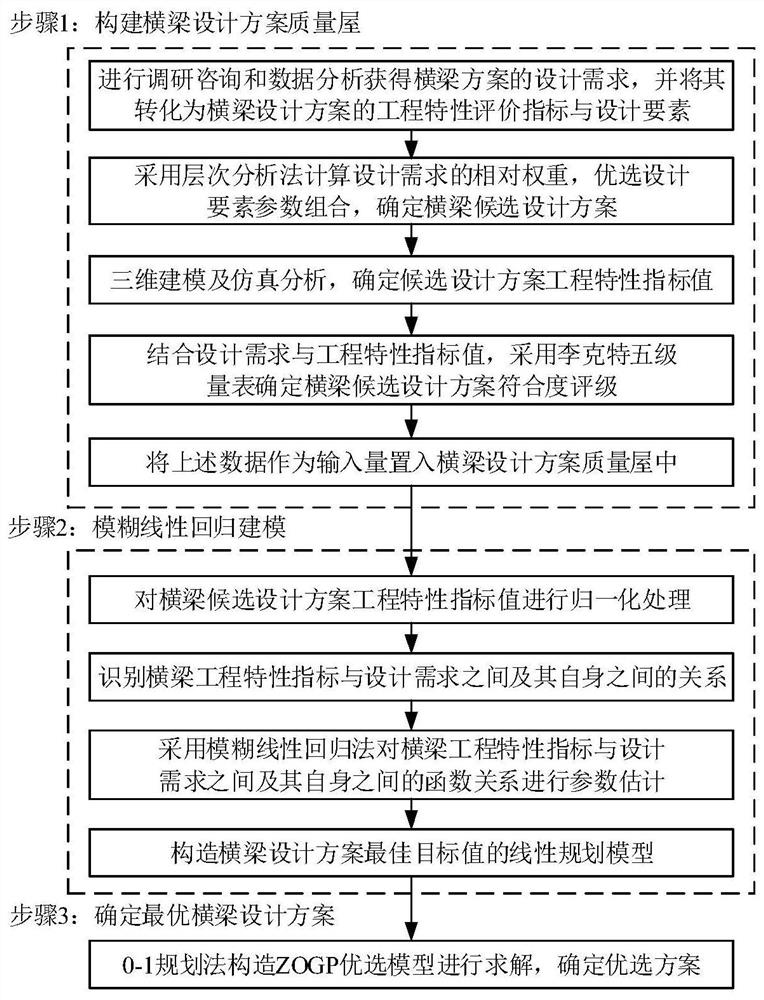

[0073] The present invention selects the optimization of bridge-type gantry milling machine crossbeam design as an embodiment, and the implementation process is as follows figure 1 shown. Firstly, the house of quality of beam design scheme is constructed, and then fuzzy linear regression modeling is performed on the data in the house of quality to obtain the optimal target value of beam design scheme. Then, the ZOGP model is constructed by using the 0-1 objective programming method to select the optimal scheme closest to the optimal target value from the beam candidate design schemes.

[0074] The specific implementation process of the beam design scheme optimization of the bridge type gantry milling machine is as follows:

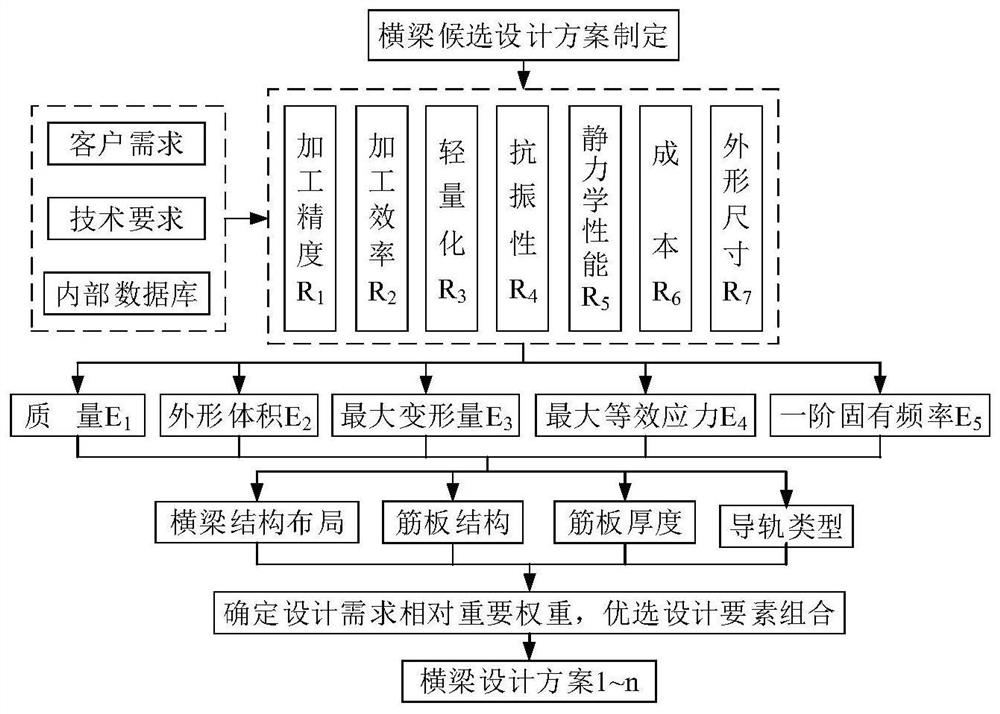

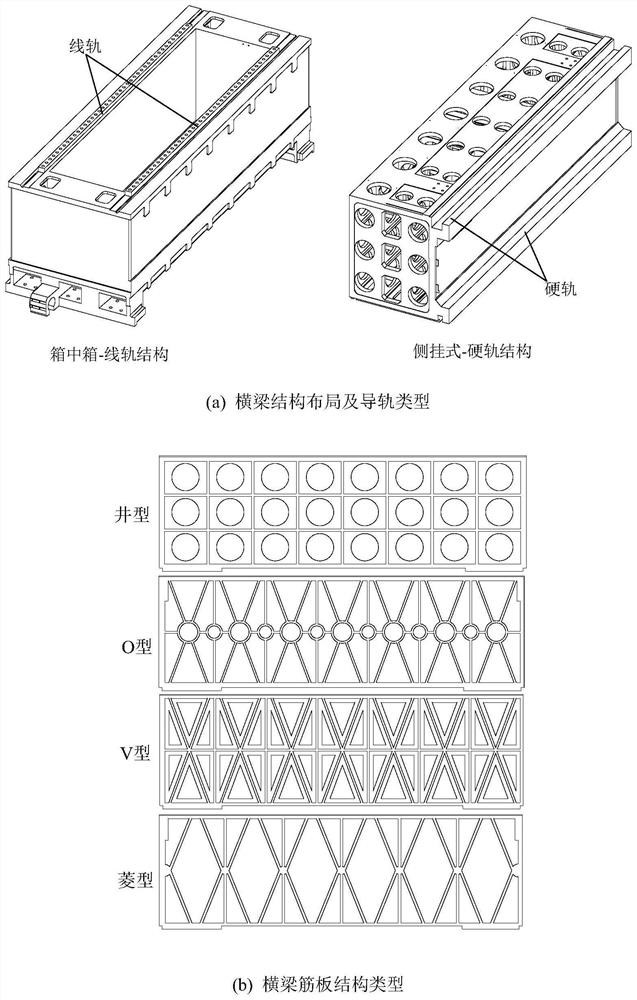

[0075] Such as figure 2 As shown, on the basis of research and consultation and internal data analysis, the requirement for obtaining the beam design scheme is the machining accuracy R 1 , Processing efficiency R 2 , lightweight R 3 , vibration resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com