Silicon carbide semiconductor assembly

A semiconductor and silicon carbide technology, applied in the field of silicon carbide semiconductor components, can solve the problem of high on-resistance and achieve the effect of reducing the on-resistance ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

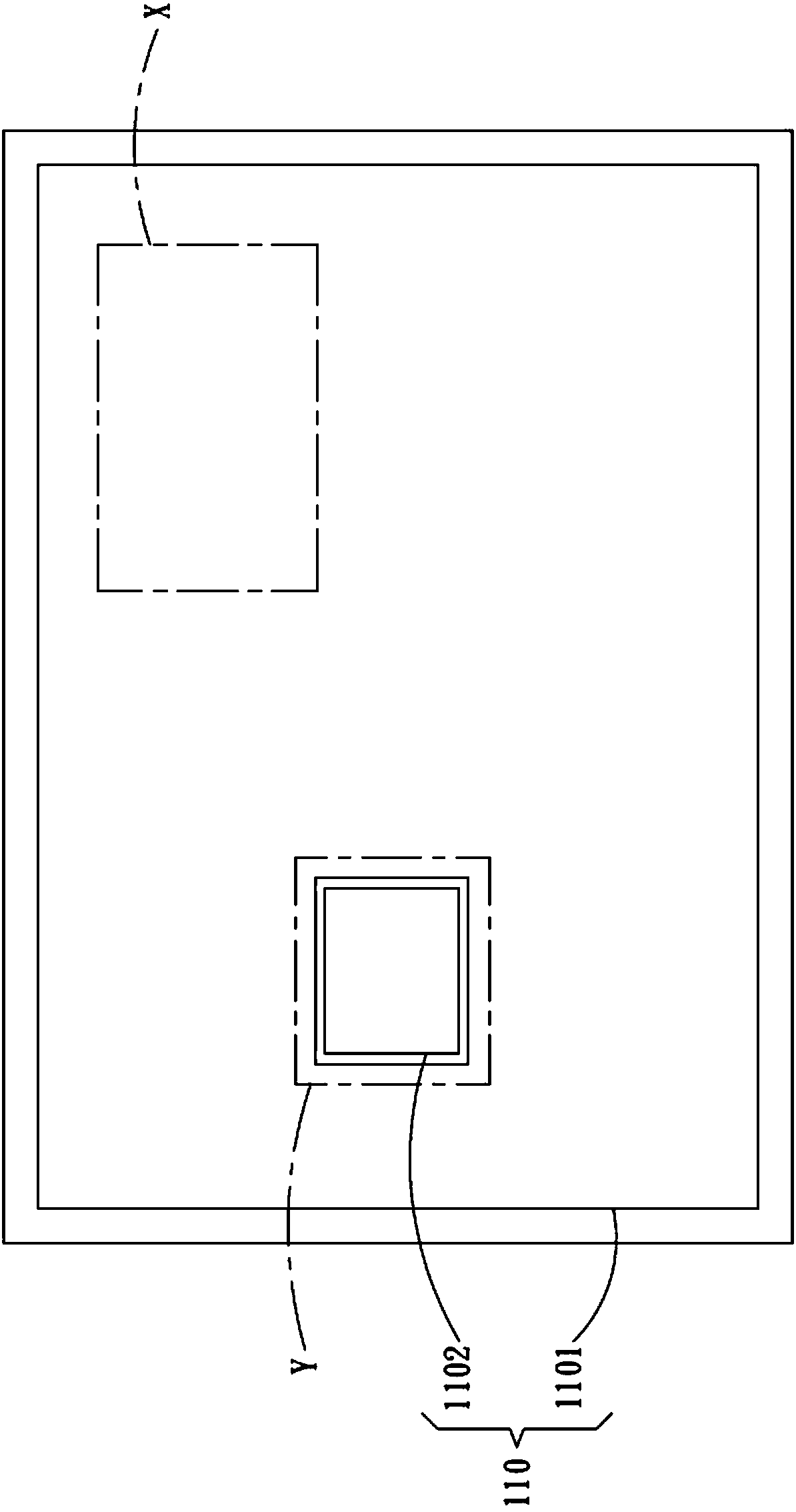

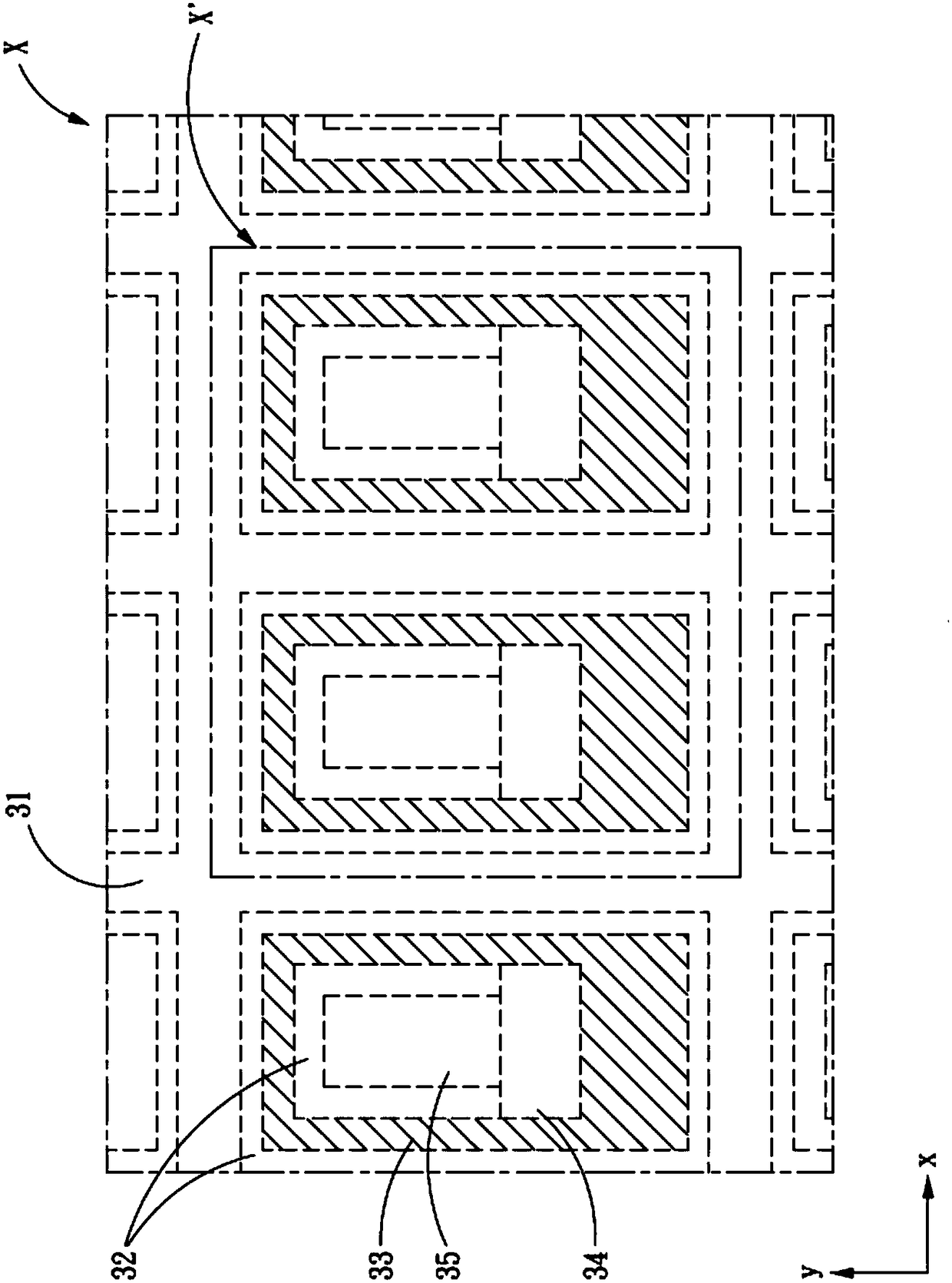

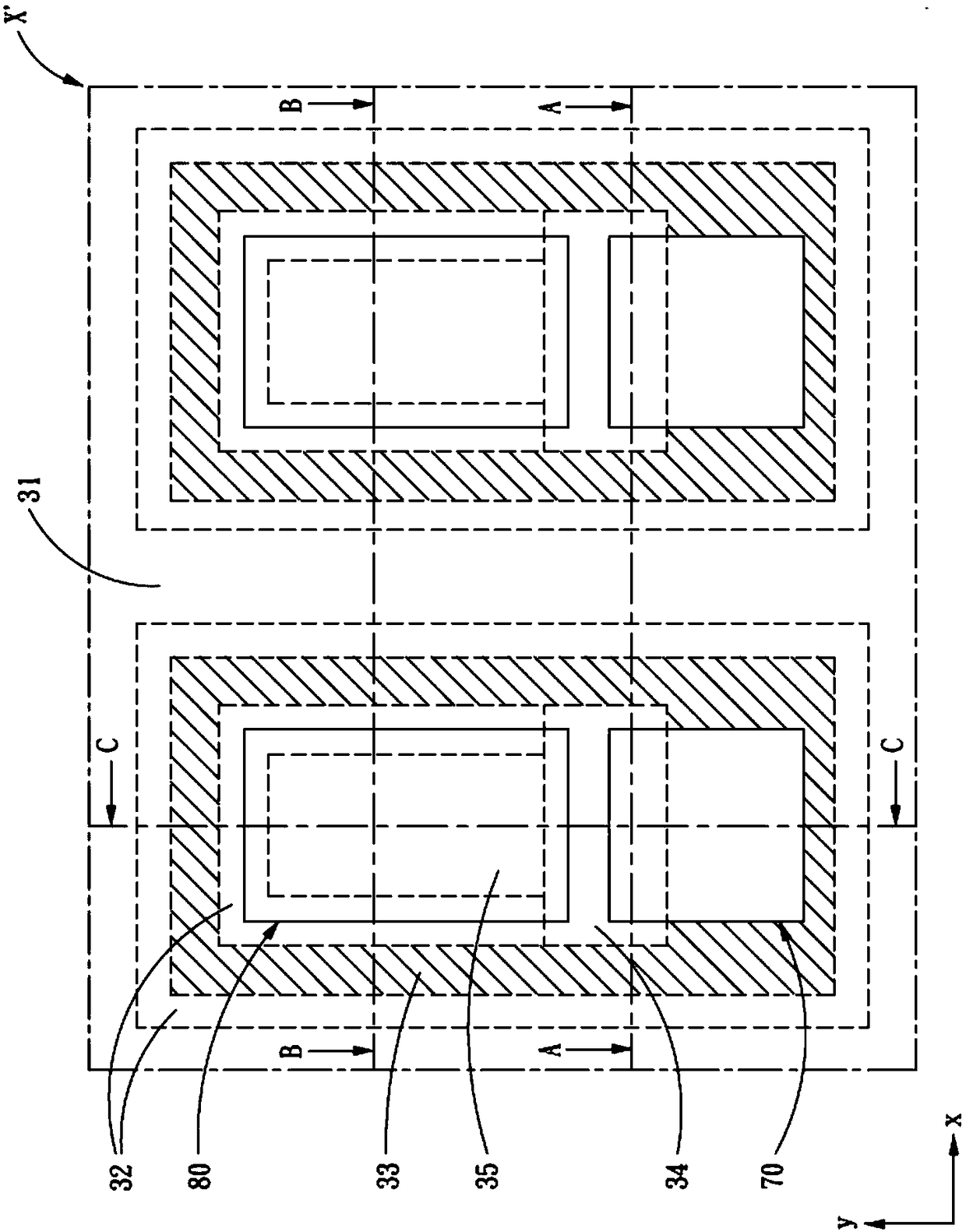

[0031] Related to the detailed description and technical contents of the present invention, now in conjunction with the accompanying drawings are described as follows: Figure 1 to Figure 3B They are respectively the schematic top view of the silicon carbide semiconductor component of the present invention, and the figure 1 The enlarged schematic diagram of the X area in the Figure 2A The enlarged schematic diagram of the X’ area in Figure 2B A-A cross-sectional schematic diagram in Figure 2B The B-B cross-sectional schematic diagram in Figure 2B The C-C sectional schematic diagram in, the embodiment of the present invention is in figure 1 The zoomed-in schematic diagram of the Y area in and Figure 3A Schematic diagram of the D-D section in . Such as Figure 1 to Figure 3B As shown, a silicon carbide semiconductor component of the present invention includes a substrate 10, an n-type drift layer 20, a plurality of doped regions 30, a gate dielectric layer 40, a gate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com