Three-dimensional lifting and pulling forming device

A three-dimensional and triangular technology, applied in the field of three-dimensional forming devices and pull-type three-dimensional forming devices, can solve the problems of difficult parts processing, air holes, insufficient pouring, etc., and achieve the effect of avoiding internal defects and ensuring strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

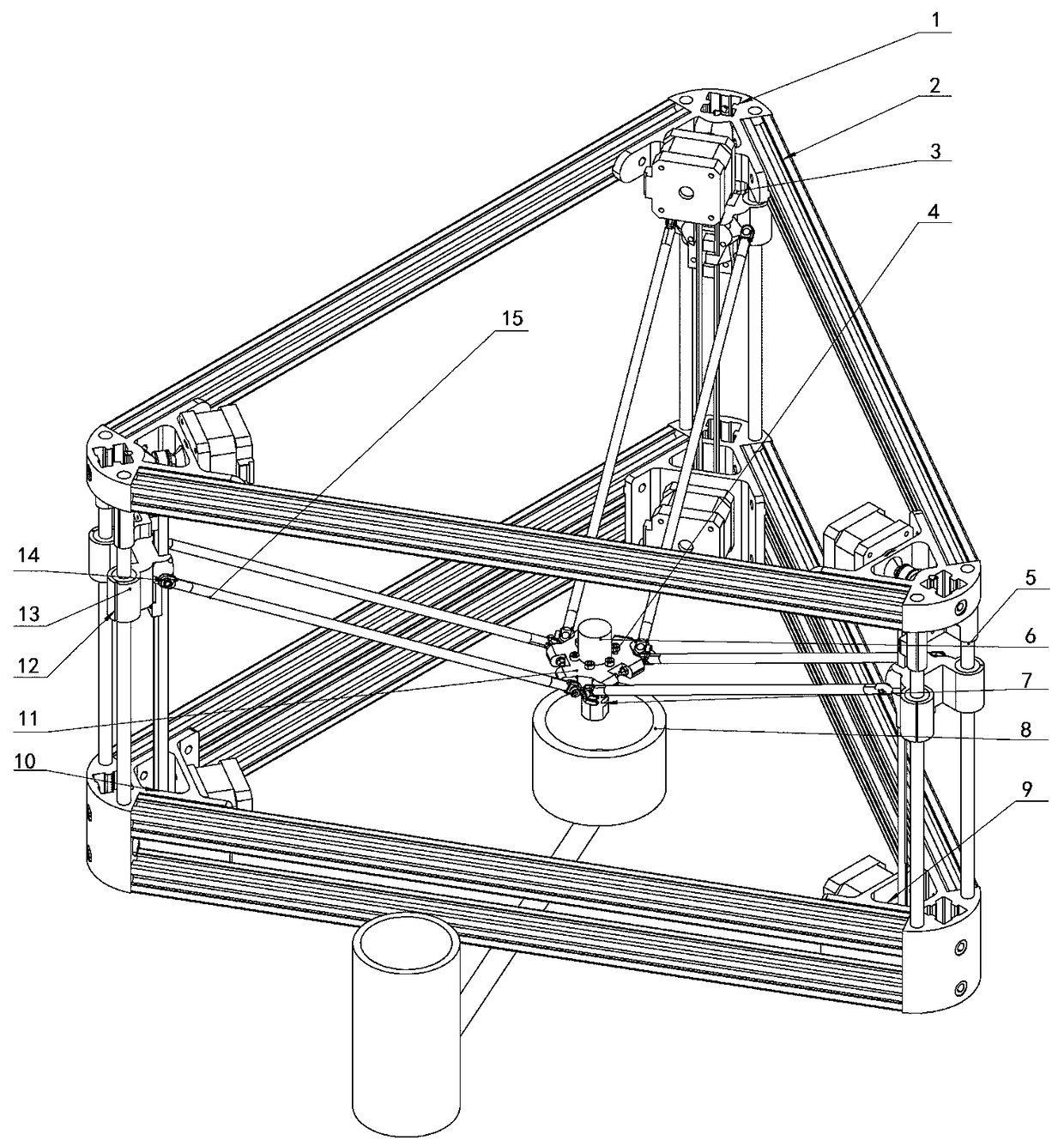

[0015] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a three-dimensional lifting forming device of the present invention includes two sets of triangular support frames, one set of two sets of triangular support frames is on the top, and one set is on the bottom. An equilateral triangle, each profile 2 has a connecting corner part 1 between each profile 2 and another adjacent profile 2, and there are three profiles 2 and three connecting corner parts 1 on a set of triangular support frames, and the two sets of triangular support frames are up and down Overlap settings.

[0017] The connecting angle part 1 is provided with a belt pulley and a motor 9, and the motor 9 drives the pulley to rotate. A polished rod 5 is arranged between the corresponding two connecting angle parts 1 in the two groups of triangular support frames. The polished rod 5 is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com