Photo-thermal conversion polyurethane energy storage thin film material and preparing method and thin film thereof

A technology of light-to-heat conversion and thin-film materials, which can be used in heat exchange materials, chemical instruments and methods, etc., and can solve problems such as deformation and leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

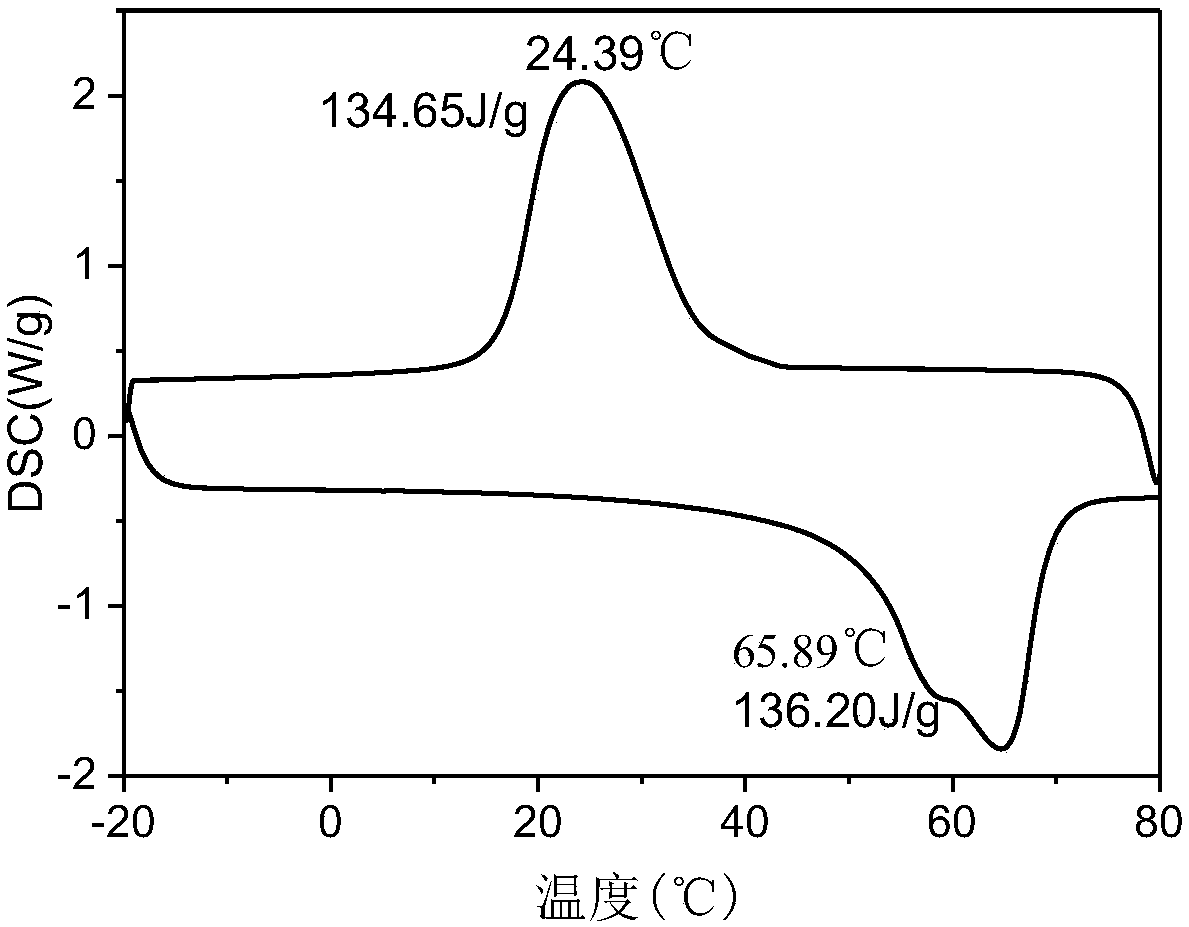

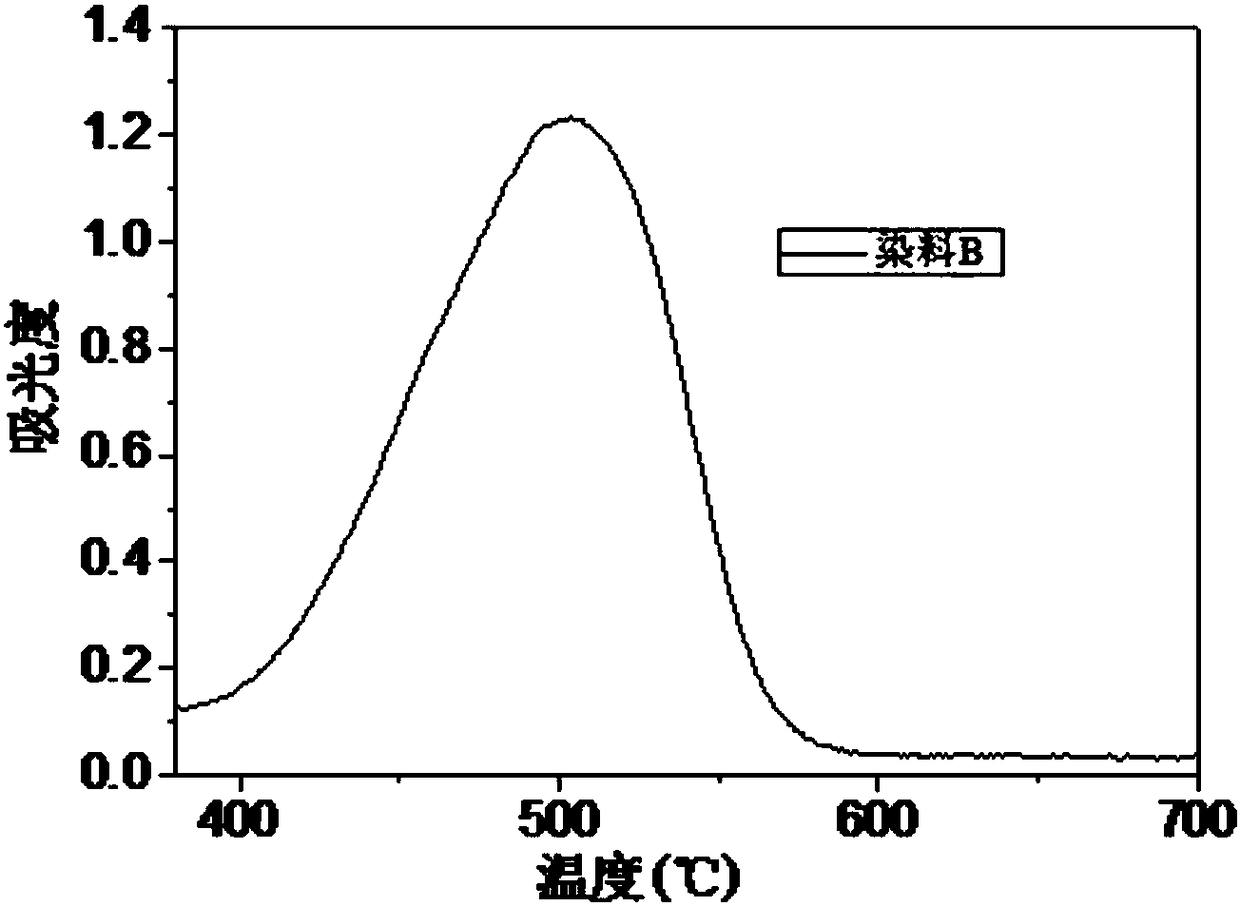

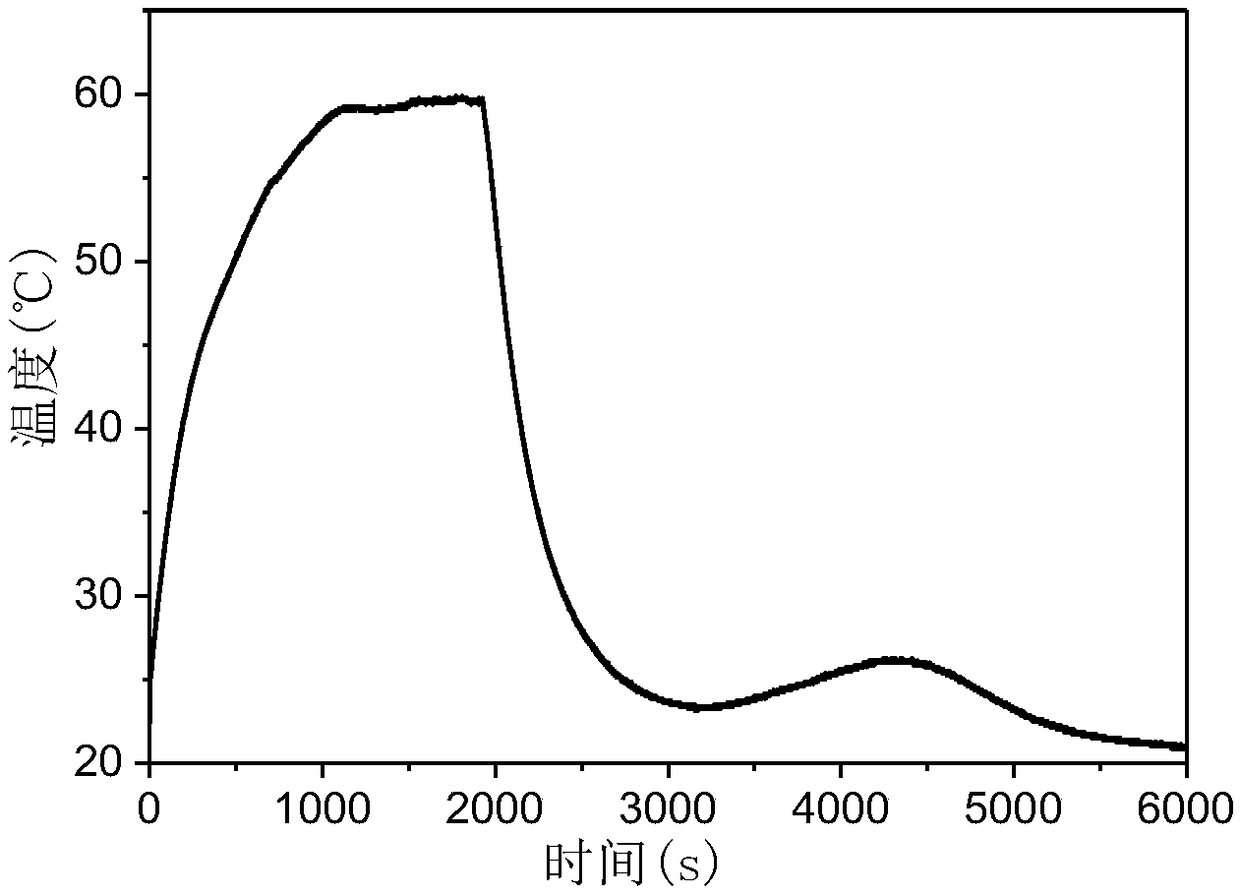

[0065] Add 10g of polyethylene glycol 2000, 10g of polyester diol PBA2000 and 40mL of N,N-dimethylformamide (DMF) into a four-neck flask, blow in nitrogen, heat to 40-50°C to dissolve, then lower the temperature To 35°C, 5.5 g of 4,4'-diphenylmethane diisocyanate (MDI) dissolved in 40 mL of N,N-dimethylformamide (DMF) was added thereto, and the reaction was kept for 1 to 2 hours. Then add 0.13g of dye B dissolved in 20mL N,N-dimethylformamide (DMF) to the reaction system, where R=H in dye B (see Table 1 for the structure), raise the temperature to 65°C, and react 1~ 2h. Finally, 1.2 g of 1,4-butanediol was added to the system. After the addition, the temperature was raised to 85° C., and the reaction was continued for 2 to 3 hours to obtain a polyurethane solution. Take 10mL of the solution and put it into a 15cm×10cm×1cm polytetrahydrofuran mold, and dry it in a drying oven at 60°C to obtain the light-to-heat conversion polyurethane energy storage film.

Embodiment 2

[0067] The other contents of this embodiment are the same as in Example 1, except that the consumption of polyethylene glycol 6000 is 9.6g, the consumption of PBA2000 is 16.8g, the consumption of dye B is 0.16g, and R=H in dye B (see Table 1).

Embodiment 3

[0069] The other content of this embodiment is the same as that of Example 1, except that the consumption of polyethylene glycol 8000 is 13.6g, the consumption of PBA2000 is 16.6g, the consumption of dye B is 0.16g, and R=H in dye B (for structure see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap