Speed reducer with internal-tooth flexible gear

A technology of reducer and flexible spline, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc. It can solve the problems of increasing the cost of deformation bearings, the teeth cannot be completely meshed, and the use conditions are limited, so as to improve the meshing The effect of strength, low machining accuracy, and good output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

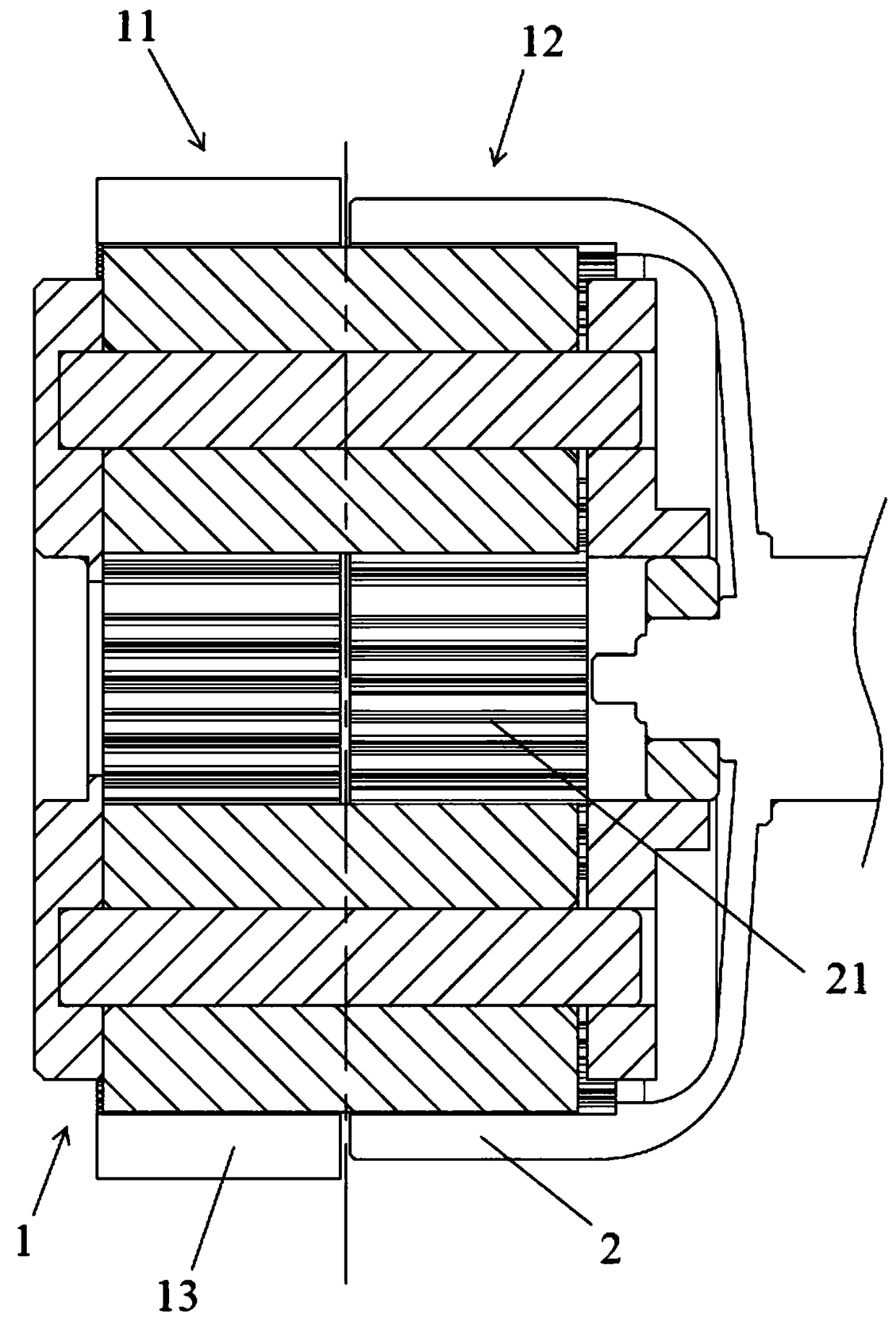

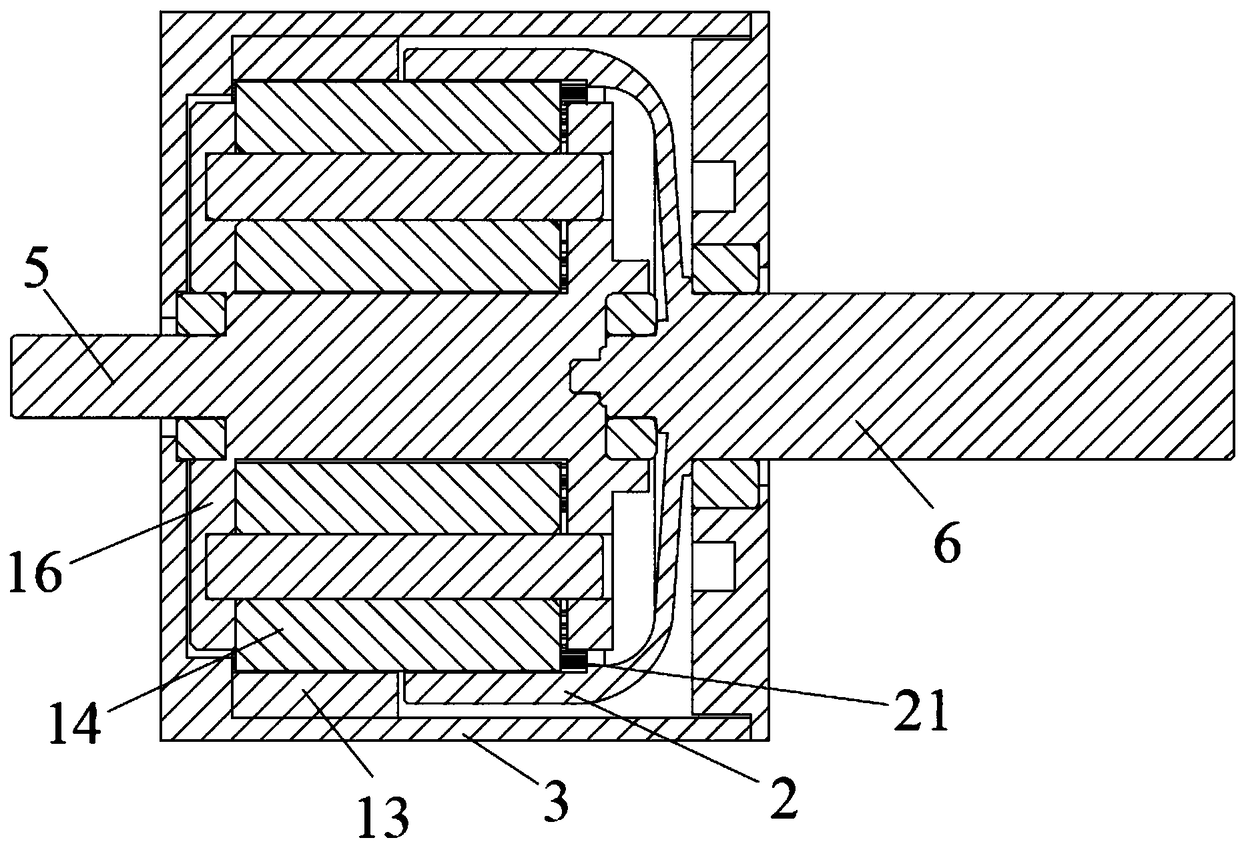

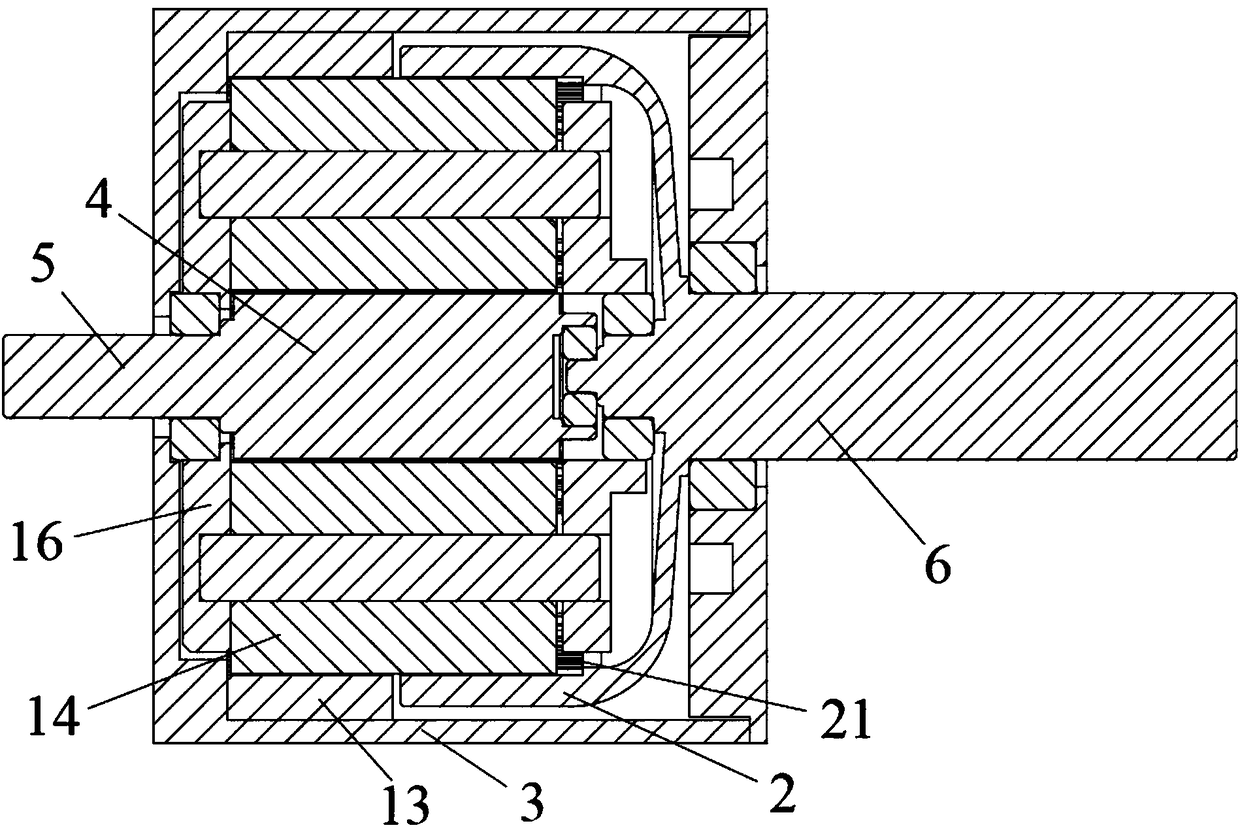

[0044] refer to figure 1 As shown, an embodiment of the internal tooth flexible gear reducer of the present invention has a planetary gear set 1 and a flexible gear 2, and the planetary gear set is provided with a first meshing part 11 and a second meshing part 12, and the first meshing part and the The inner ring gear 13 of the planetary gear set is connected, and the planetary gear set meshes and rotates in the inner ring gear; the internal tooth part 21 is arranged on the inner wall of the flex spline, and the inner gear part is connected with the second meshing part, and the flex spline is on the outer circumference of the planet gear set Mesh rotation; at this time, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com