Detachable multi-angle steel jacking pipe deviation rectifying device

A deviation rectifying device, a technology of steel pipe jacking, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problems of rising jacking force, economic loss, head-up, etc., and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

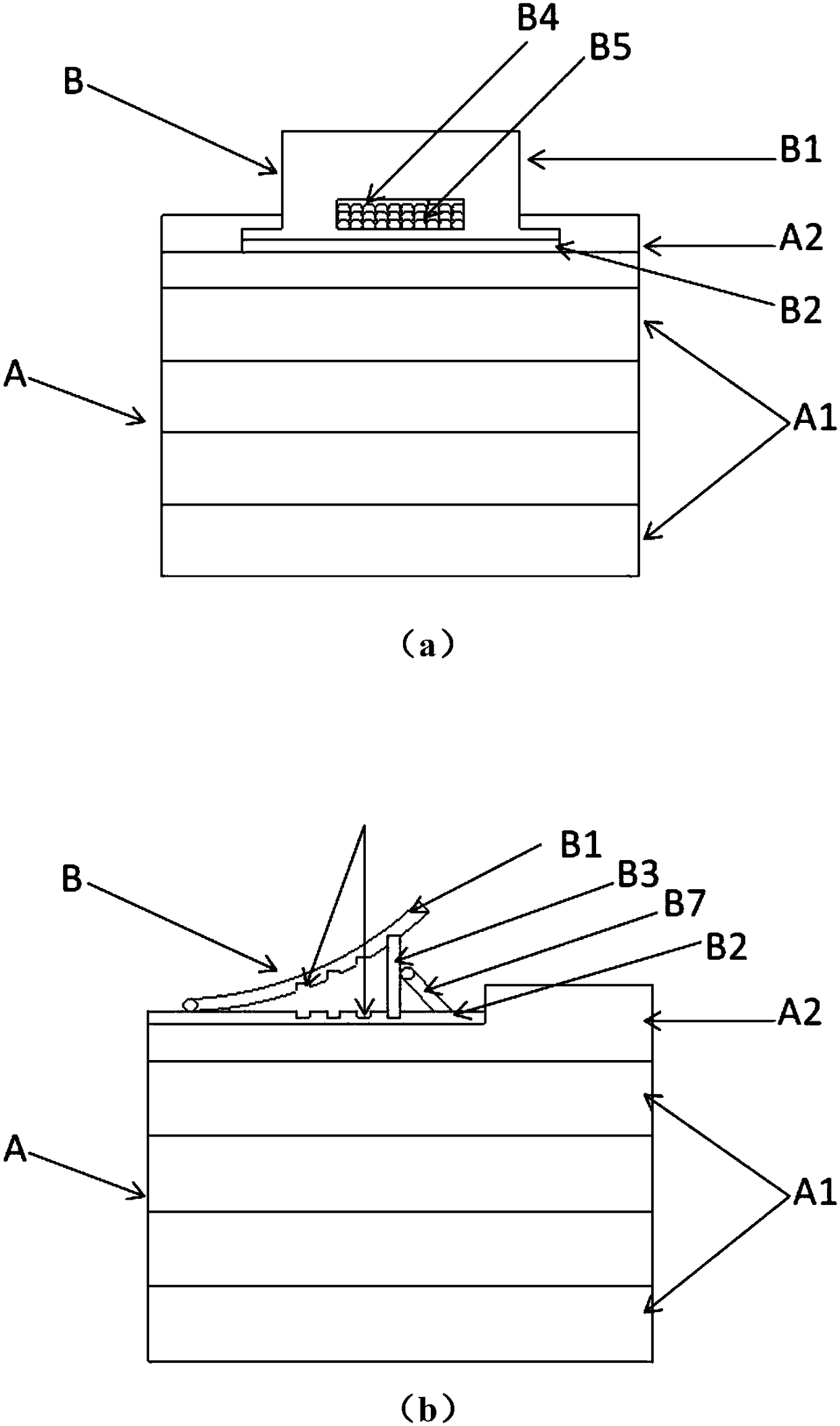

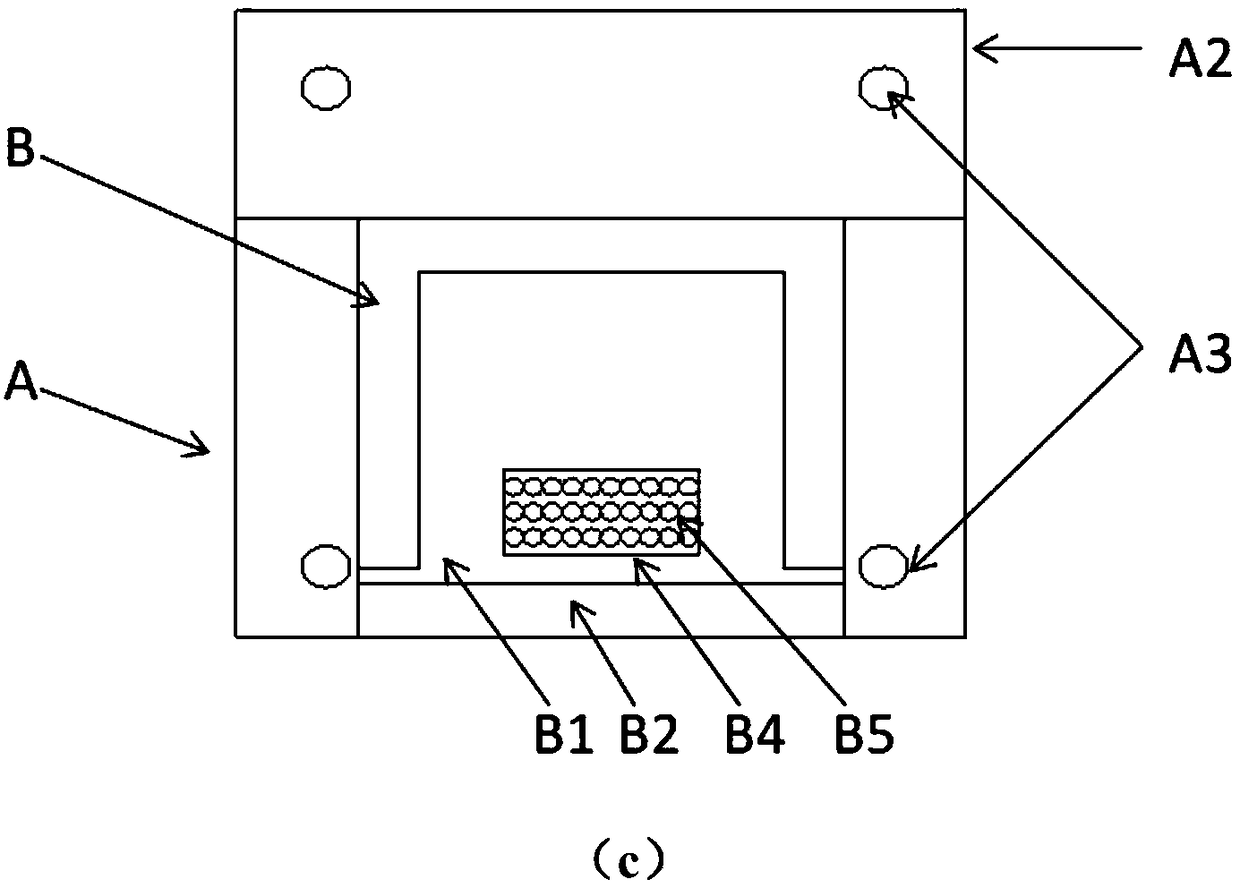

[0039] Such as figure 1 As shown, a detachable multi-angle steel pipe jacking device is installed below the steel pipe C slotted along the axis direction, including a concrete base A and an arc-shaped steel plate tripod B, wherein: the upper surface of the concrete base is The stepped, curved steel plate tripod B is installed on the upper surface of the concrete base A, and placed on the lower side of the stepped upper surface of the concrete base A, and the curved steel plate is fixed by using the height difference of the upper surface of the concrete base A tripod.

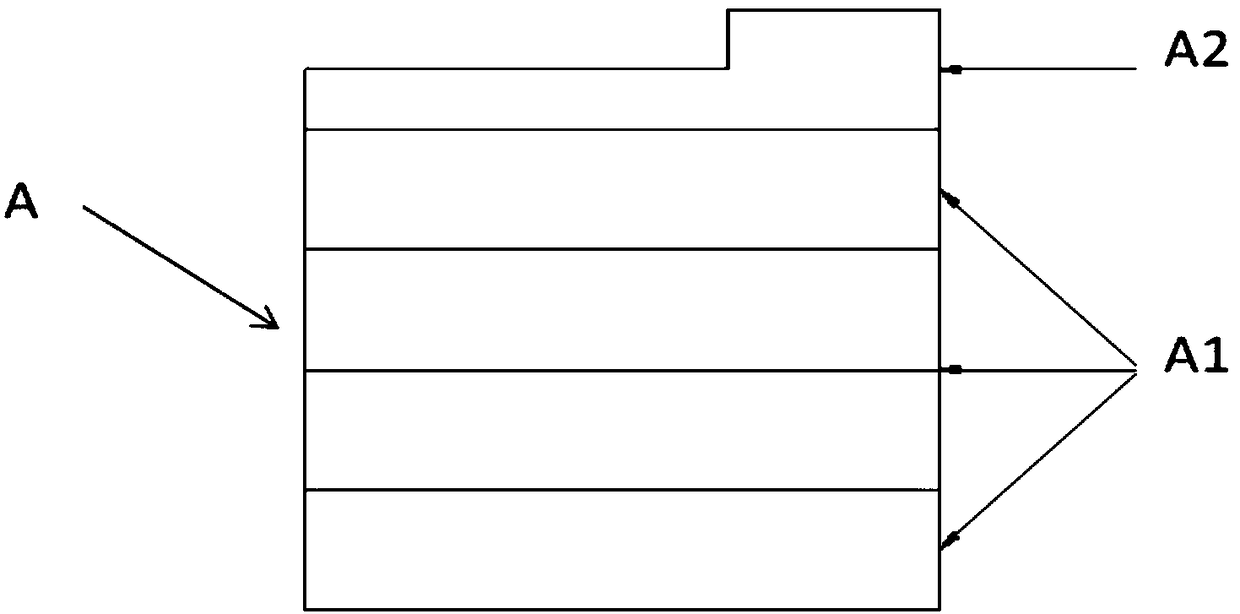

[0040] Such as figure 2 As shown, the concrete base A is composed of concrete slabs, including a plane first concrete slab A1 and a stepped second concrete slab A2; image 3 As shown, the first concrete slab A1 and the stepped second concrete slab A2 are provided with a reserved hole A3, the second concrete slab A2 is placed on the top of the first concrete slab A3, and the rigid plug is inserted into the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com