A Differential Measurement Method of Viscous Dissipation in Microscale Polymer Melt Extrusion

A viscous dissipation, melt extrusion technology, applied in the field of polymer rheology testing, can solve the problems of viscous dissipation heat loss, low accuracy of measurement methods, etc., to reduce heat loss, low thermal conductivity, and improve measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific implementation mode 1: In this implementation mode, a microscale polymer melt extrusion viscosity dissipation differential measurement method is specifically carried out according to the following steps:

[0018] 1. Install the micro-scale polymer melt extrusion viscous dissipation measurement device at the opening of the rheometer;

[0019] 2. Put the polymer particles into the rheometer cylinder 1, use the temperature control system of the rheometer to plasticize to keep the temperature of the polymer melt constant, and set the shear rate; the polymerization in the rheometer cylinder 1 The molten material flows out from the capillary die 4 and directly contacts the measuring part of the miniature temperature sensor 7;

[0020] 3. The heat generated by viscous dissipation when the polymer melt in the capillary die 4 flows in a steady state is transferred to the capillary die 4, and the temperature of the capillary die 4 rises, and the extruded polymer melt is ...

specific Embodiment approach 2

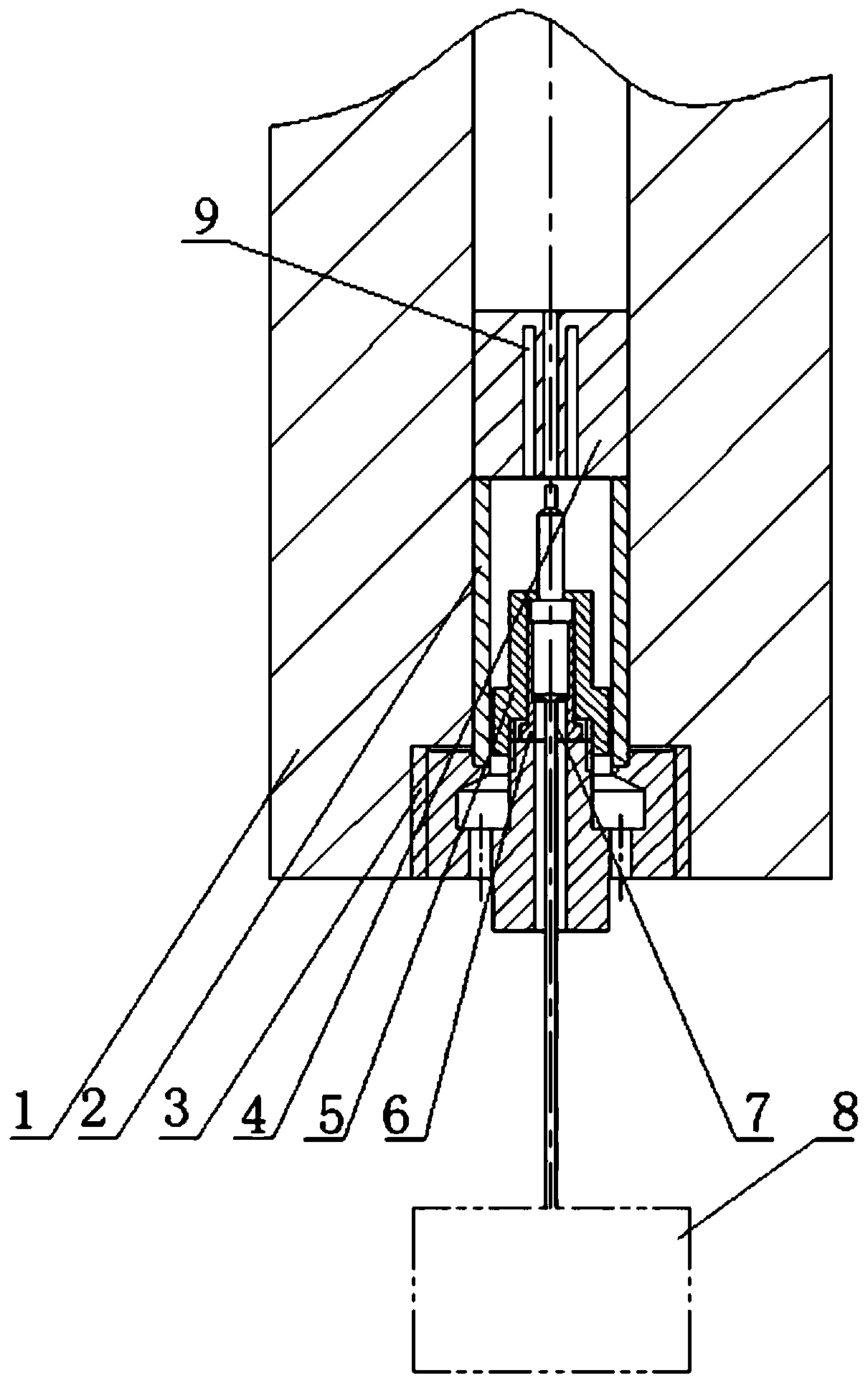

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the micro-scale polymer melt extrusion viscosity dissipation measurement device includes a rheometer barrel 1, a sleeve 2, and a die support 3 , capillary die 4, fixed sleeve 5, sleeve support 6, miniature temperature sensor 7 and data acquisition system 8; Wherein rheometer barrel 1 outlet adopts threaded connection die support 3, in the rheometer barrel 1, the sleeve 2 is pressed on the die support 3, the capillary die 4 is set at the entrance of the rheometer barrel 1 and pressed on the sleeve 2, and the side of the capillary die 4 with the ring groove 9 facing downward ; One end of the sleeve support 6 withstands the miniature temperature sensor 7, and the other end sits on the die support 3; one end of the fixed sleeve 5 has a round hole, and the other end is processed with an internal thread, and the measurement part of the miniature temperature sensor 7 passe...

specific Embodiment approach 3

[0025] In the third embodiment: the difference between this embodiment and the first or second embodiment is that the detection part of the miniature temperature sensor 7 is a circular plane. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com