drug combination preparation

一种片剂、药学的技术,应用在制备该片剂领域,能够解决固有溶解度差、降低药物功效、低水溶性等问题,达到良好稳定性和溶解性、治疗或预防高血压、良好成片性和生产效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1: the preparation of bilayer tablet

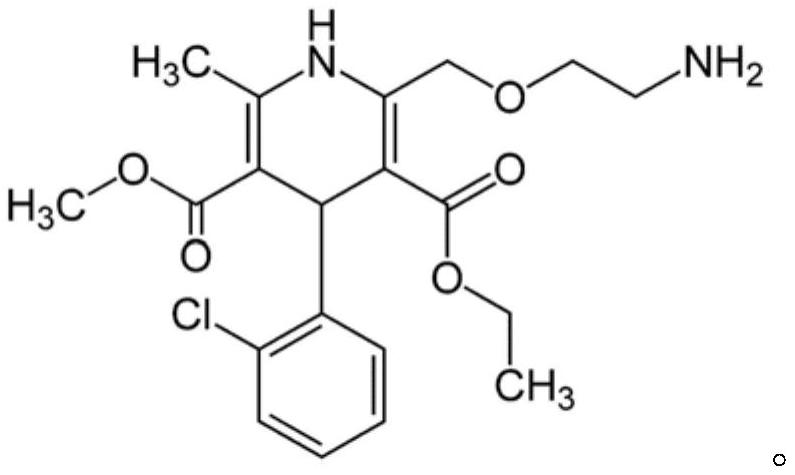

[0062] 6 g of hydroxypropylcellulose and 3 g of polyethylene glycol 15-hydroxystearate were dissolved in purified water and ethanol to prepare a binding solution (1). 16 g of candesartan cilexetil, 65 g of microcrystalline cellulose, and 10 g of pregelatinized starch were uniformly mixed in a high-speed mixer to prepare a mixture (1). The binding solution (1) is added to the mixture (1), granulated and then dried. Sieved granules (1) were obtained by sieving with a 20-mesh sieve in a semi-dry state and with a 30-mesh sieve in a dry state.

[0063] 79 g of silicified microcrystalline cellulose were added to the sieved granules (1 ) and mixed in a double cone mixer. Then, 1 g of magnesium stearate was added to obtain a lubricated mixture (1).

[0064] 5 g of hydroxypropylcellulose was dissolved in purified water and ethanol to prepare a binding solution (2). 13.87 g of amlodipine besylate, 71.13 g of microcrystalline c...

Embodiment 2

[0068] Embodiment 2: the preparation of bilayer tablet

[0069] 6 g of hydroxypropylcellulose and 3 g of polyethylene glycol 15-hydroxystearate were dissolved in purified water and ethanol to prepare a binding solution (1). 16 g of candesartan cilexetil, 65 g of microcrystalline cellulose, and 10 g of pregelatinized starch were uniformly mixed in a high-speed mixer to prepare a mixture (1). The binding solution (1) is added to the mixture (1), granulated and then dried. Sieved granules (1) were obtained by sieving with a 20-mesh sieve in a semi-dry state and with a 30-mesh sieve in a dry state.

[0070] 79 g of silicified microcrystalline cellulose were added to the sieved granules (1 ) and mixed in a double cone mixer. Then, 1 g of magnesium stearate was added to obtain a lubricated mixture (1).

[0071] 2.5 g of hydroxypropylcellulose was dissolved in purified water and ethanol to prepare a binding solution (2). 6.935 g of amlodipine besylate, 35.565 g of microcrystallin...

Embodiment 3

[0075] Embodiment 3: the preparation of bilayer tablet

[0076] 3 g of hydroxypropylcellulose and 1.5 g of polyethylene glycol 15-hydroxystearate were dissolved in purified water and ethanol to prepare a binding solution (1). 8 g of candesartan cilexetil, 32.5 g of microcrystalline cellulose, and 5 g of pregelatinized starch were uniformly mixed in a high-speed mixer to prepare mixture (1). The binding solution (1) is added to the mixture (1), granulated and then dried. Sieved granules (1) were obtained by sieving with a 20-mesh sieve in a semi-dry state and with a 30-mesh sieve in a dry state.

[0077] 39.5 g of silicified microcrystalline cellulose were added to the sieved granules (1 ) and mixed in a double cone mixer. Then, 0.5 g of magnesium stearate was added to obtain a lubricated mixture (1).

[0078] 2.5 g of hydroxypropylcellulose was dissolved in purified water and ethanol to prepare a binding solution (2). 6.935 g of amlodipine besylate, 35.565 g of microcrysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com